Method for synthesizing polyphosphoric acid by taking wet-process purified phosphoric acid and phosphoric acid anhydride as raw materials

A wet purification and polyphosphoric acid technology, applied in the field of phosphorus chemical industry, can solve the problems of high requirements on material and sealing performance, difficult to clean, affecting the start-up of polyphosphoric acid production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

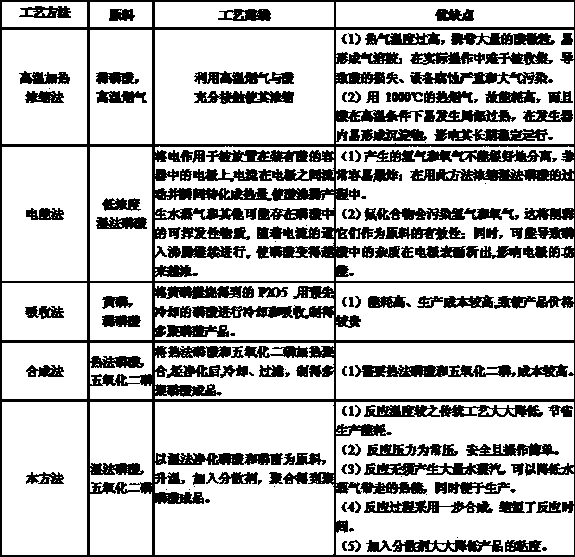

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Put 150g of phosphorus pentoxide in a three-necked flask at one time, slowly add 100g of wet-process purified phosphoric acid with a mass fraction of 76%, and keep stirring to dissolve the phosphorus pentoxide powder as much as possible, and then fix the three-necked flask on the oil bath Here, set the temperature of the collector-type constant temperature heating magnetic stirrer at 150°C, and the speed at 225 rpm to fully mix the materials. After the temperature rises to the set temperature, add the viscosity reducer tall oil with a mass concentration of 0.01%, and keep the temperature constant After 4 hours of polymerization reaction, the phosphorus pentoxide powder was completely dissolved to obtain a colorless and fluid transparent polyphosphoric acid with a mass concentration of phosphoric acid of 116%.

Embodiment 2

[0018] Put 150g of phosphorus pentoxide in a three-necked flask at one time, slowly add 85g of wet-process purified phosphoric acid with a mass fraction of 74%, and keep stirring to dissolve the phosphorus pentoxide powder as much as possible, and then fix the three-necked flask on the oil bath Here, set the temperature of the collector type constant temperature heating magnetic stirrer to 100°C, and the speed to 225 rpm to fully mix the materials. After the temperature rises to the set temperature, add the viscosity reducer tributyl phosphate with a mass concentration of 0.02%. After constant temperature polymerization for 5 hours, the phosphorus pentoxide powder was completely dissolved to obtain a colorless and fluid transparent polyphosphoric acid with a mass concentration of phosphoric acid of 116%.

Embodiment 3

[0020] Put 150g of phosphorus pentoxide in a three-necked flask at one time, slowly add 60g of phosphoric acid with a mass fraction of 78% wet method, and keep stirring to dissolve the phosphorus pentoxide powder as much as possible, and then fix the three-necked flask in an oil bath , set the temperature of the collector type constant temperature heating magnetic stirrer to 140 ° C, and the speed to 225 rpm to fully mix the materials. After the temperature is raised to the set temperature, add 0.03% viscosity reducer tannin to perform constant temperature polymerization. After 6 hours, the phosphorus pentoxide powder was completely dissolved to obtain a colorless and fluid transparent polyphosphoric acid with a mass concentration of phosphoric acid of 115%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com