Patents

Literature

95results about How to "Adjust particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silicon dioxide-coated magnetic microspheres

InactiveCN101783217AThe operation process is simpleHigh magnetic contentSilicaFerroso-ferric oxidesTetraethyl orthosilicateReaction timing

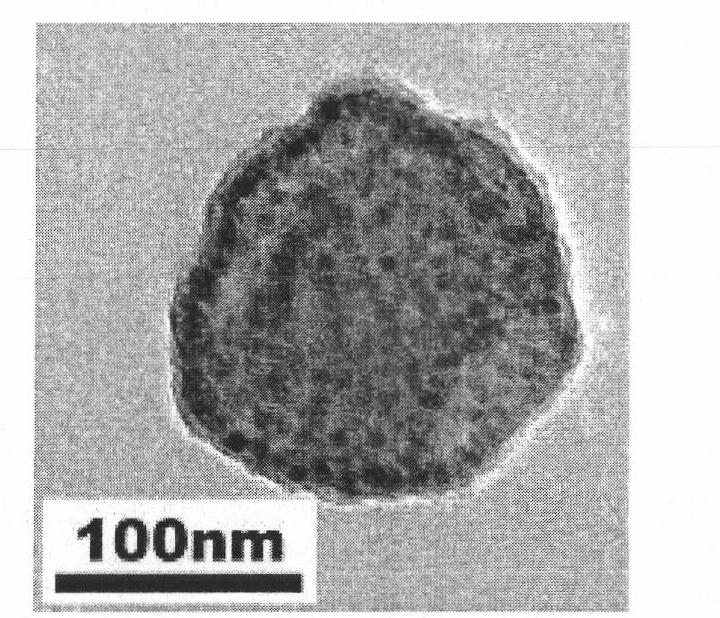

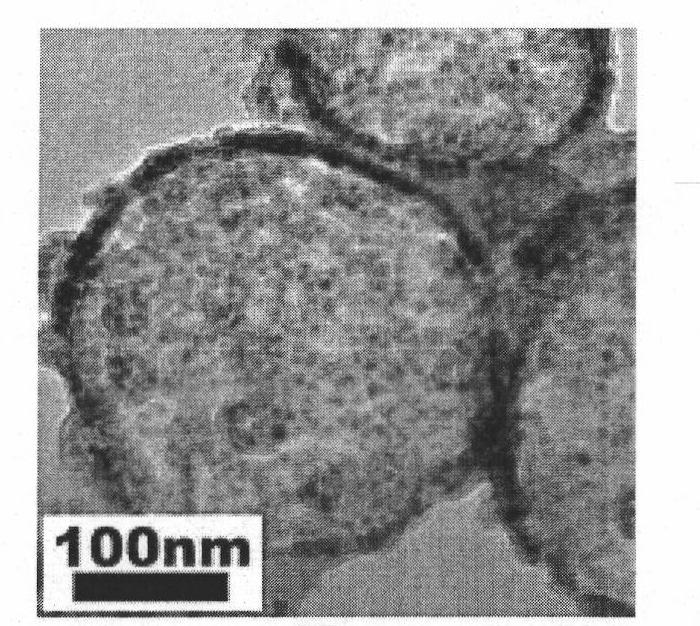

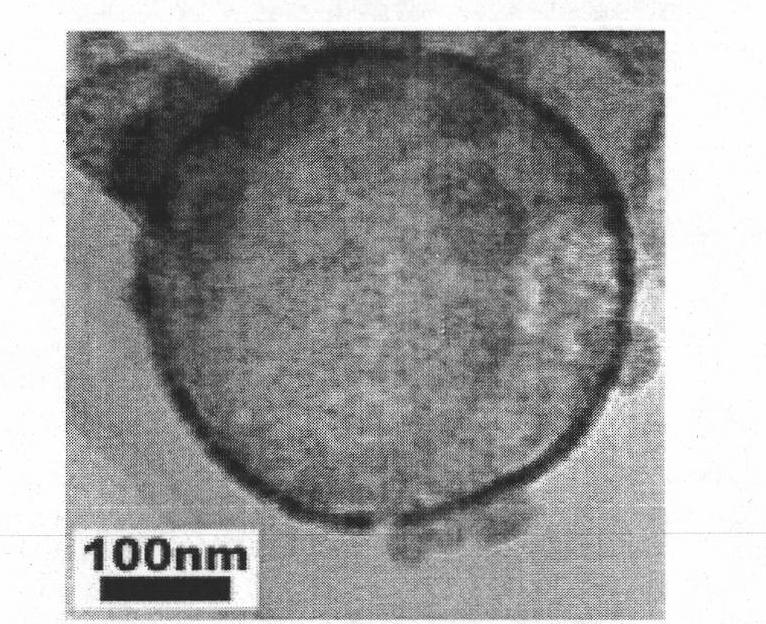

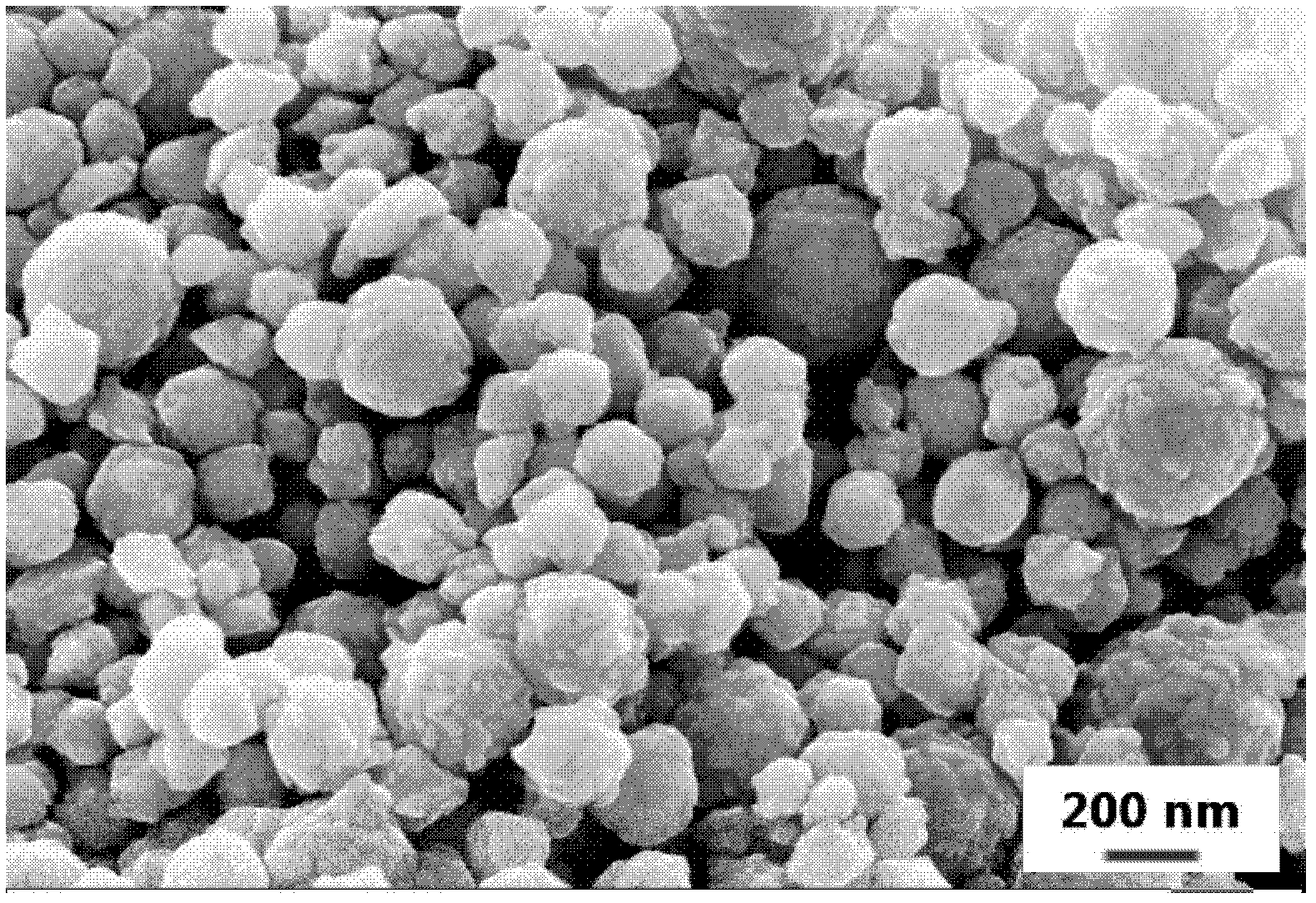

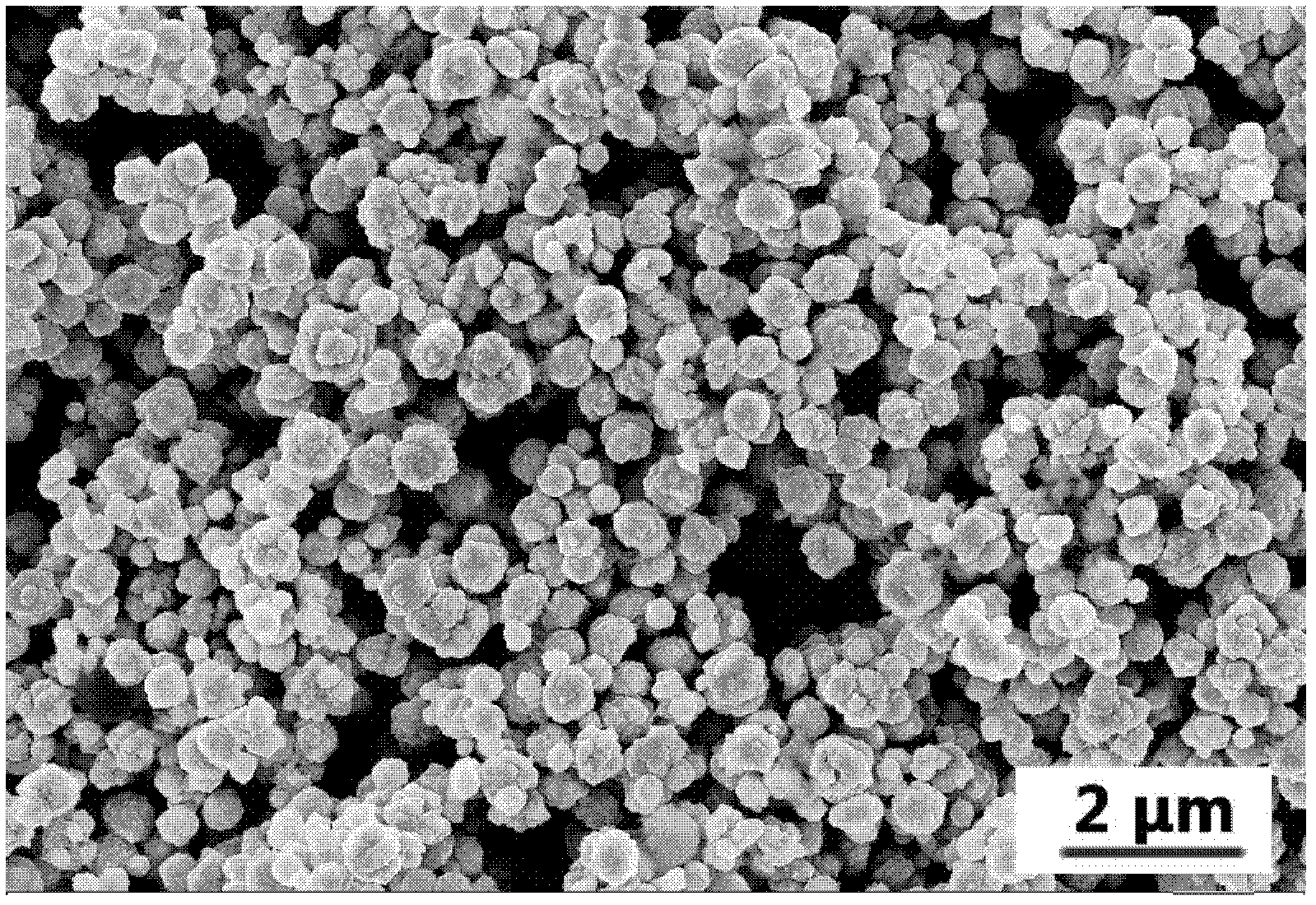

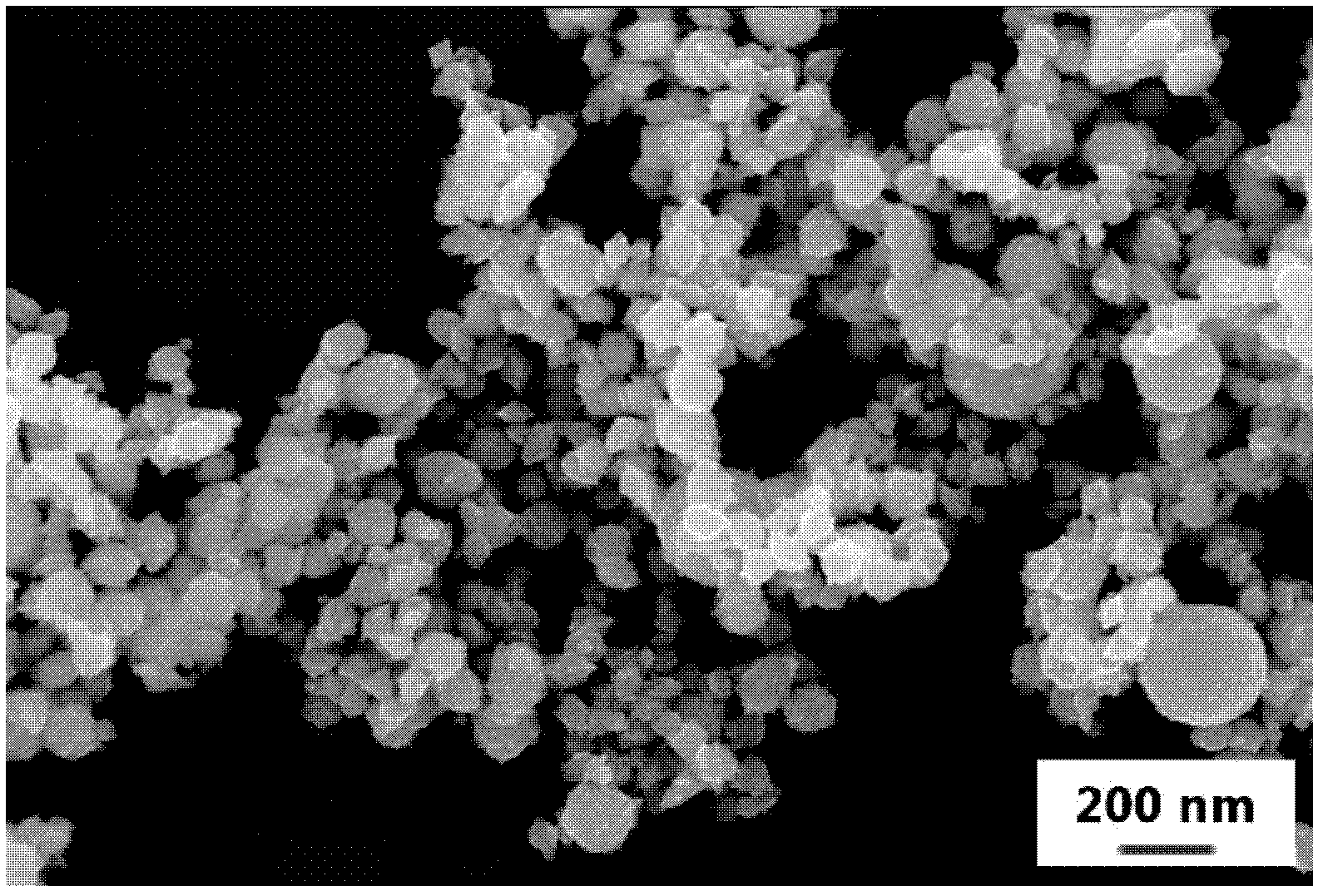

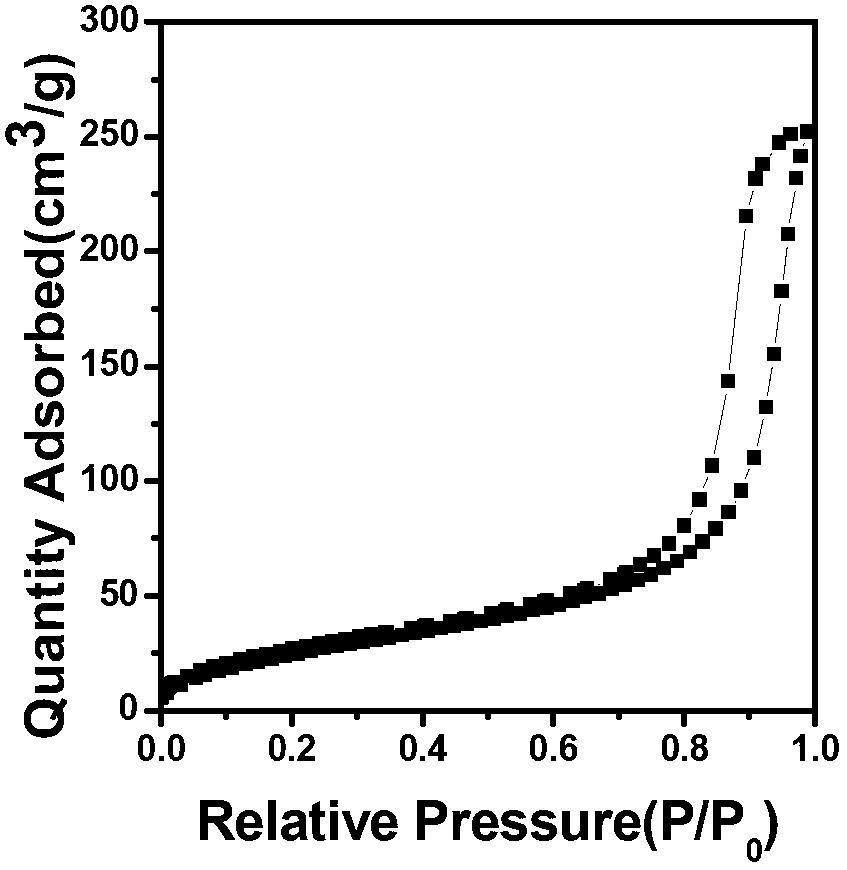

The invention discloses a method for preparing silicon dioxide-coated magnetic microspheres, which belongs to the technical field of nano-magnetic materials. In the method, the characteristic that nanoparticles are easily arranged on a two-phase solution interface is utilized to form oil-in-water emulsion or microemulsion which is stabilized by oil-soluble magnetic nanoparticles and the hydrolysis of tetraethyl orthosilicate is further produced on the surfaces of droplets, so that a silicon dioxide-coated layer is formed. The method has the advantages of no need of using any surfactant, simple reaction operation process and short reaction time; particle diameters of the coated magnetic microspheres are 50 to 400nm; and the magnetic content of the microspheres can be simply controlled at the same time when the particle diameters of the magnetic microspheres are controlled.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Process for preparing intermediate-phase carbon microspheres

An intermediate-phase carbon microspheres (0.1-100 microns) is prepared through preparing raw material composed of basic material material and catalyst, polymerizing reaction, separating the resultant and drying. The said basic raw material is aromatic heavy oil and / or asphalt. The said catalyst is chosen from the oxides of Fe, Ni and Co. Its advantages are high output rate (20-70% and controllable granularity.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Magnetic lignin nano drug carrier

InactiveCN107693506ASmall sizeAdjust particle sizeCosmetic preparationsToilet preparationsWater dispersibleHalf-life

The invention discloses a preparation method and pharmaceutical composition of a plurality of magnetic lignin nanoparticles. Nano micelles are prepared by selecting lignins (such as alkaline lignin, milled wood lignin, Kraft lignin and mixtures thereof). One lignin and liposoluble drugs are dissolved in an organic solvent respectively, and then an aqueous solution of magnetic nanoparticles is slowly dropwise added for self-assembly to form nanoparticles. The pharmaceutical composition contains the lignin nanoparticles, the magnetic nanoparticles and drugs insoluble in water. The magnetic lignin nanoparticles can be used as a drug carrier, can improve the water dispersibility of poorly soluble drugs, reduces toxicity and prolongs the cyclic half-life in organisms.

Owner:TIANJIN UNIV OF SCI & TECH

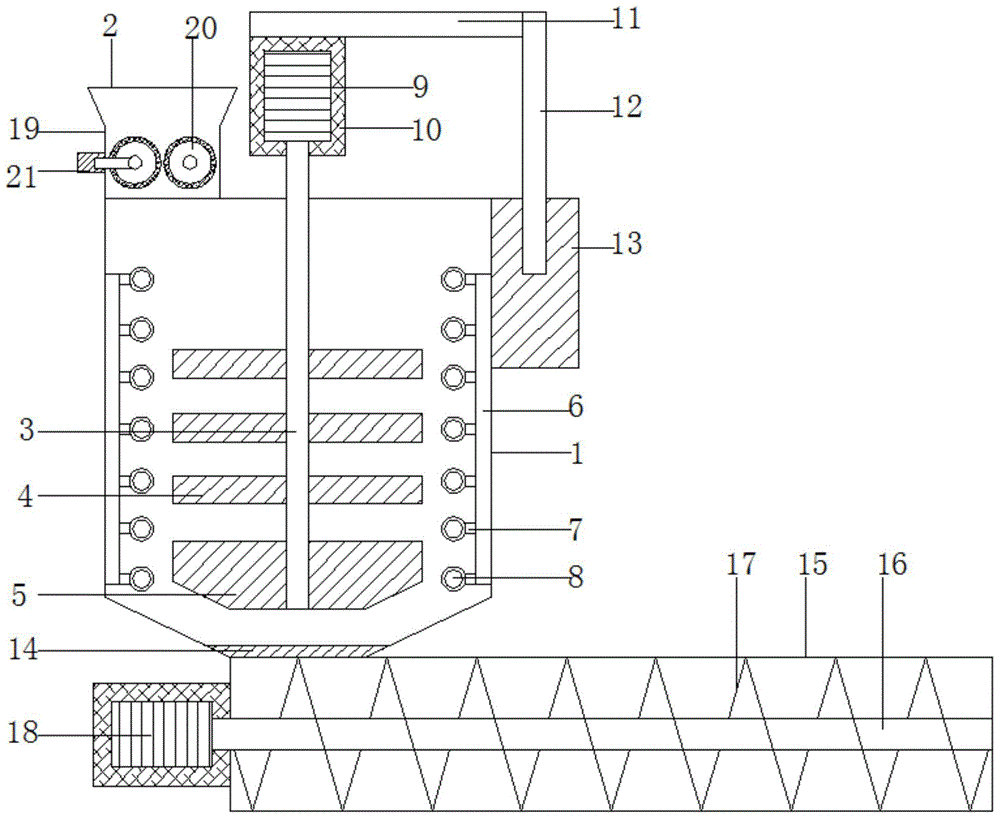

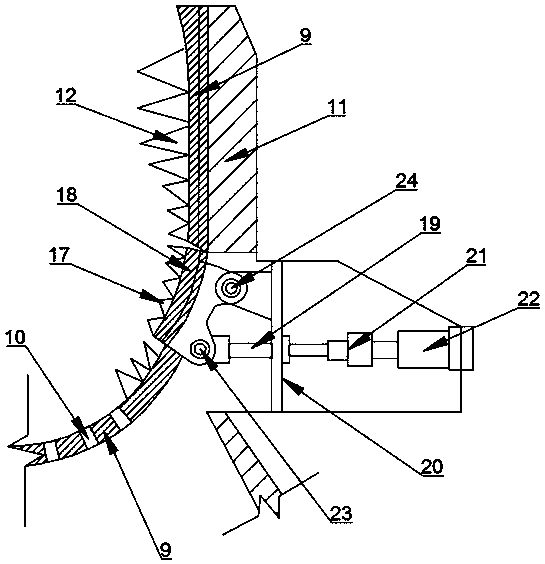

Efficient concrete stirrer with crushing device

InactiveCN104960092AQuality improvementQuality assuranceDischarging apparatusMixing operation control apparatusHydraulic cylinderEngineering

The invention discloses an efficient concrete stirrer with a crushing device. The efficient concrete stirrer comprises a stirring barrel, a spiral conveying barrel and a crushing cavity. A feeding hopper is arranged at the left end of the upper side of the stirring barrel. The lower side of the feeding hopper is connected with the crushing cavity. Two crushing rollers are arranged inside the crushing cavity side by side. A crushing gap is arranged between the two crushing rollers. According to the efficient concrete stirrer with the crushing device, concrete is stirred in the horizontal direction and the vertical direction at the same time through stirring blades, a stirring plate and stirring wheels. A hydraulic cylinder is utilized for driving a stirring mechanism to move up and down to perform stirring, the stirring effect and the working efficiency of the stirrer are greatly improved, and the quality of the concrete is guaranteed; automatic discharging is achieved through a bolt conveying mechanism, concrete continues to be stirred in the discharging process, and the working efficiency of the stirrer is improved; in addition, the noise of the stirrer is low in the working process, concrete raw materials can be sufficiently crushed, and the size of crushed particles can be controlled.

Owner:苏晓玲

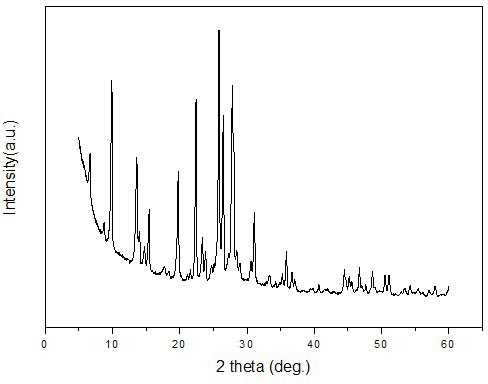

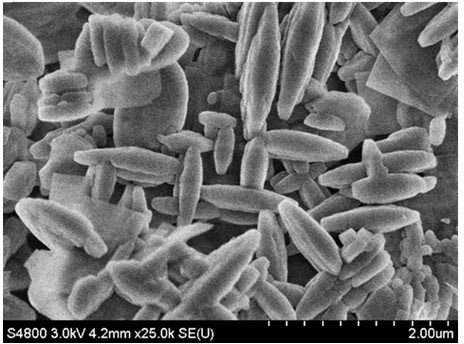

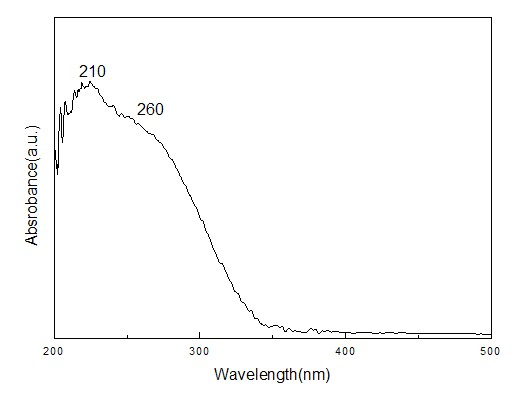

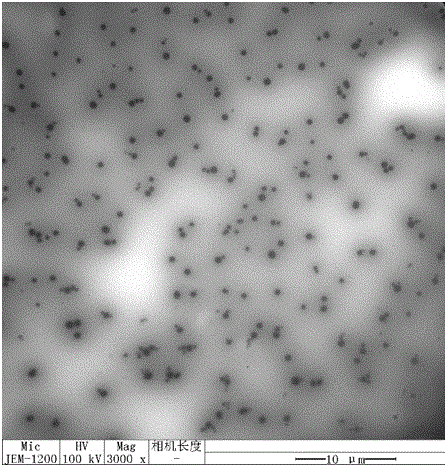

Preparation method of titanium-containing nano-mordenite molecular sieve

InactiveCN102674389AHigh titanium contentEasy to synthesizeNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsMordenite

The invention discloses a synthesis method of a titanium-containing nano-mordenite molecular sieve, comprising the following steps of: firstly, dissolving an aluminum source in sodium hydroxide solution, adding a silicon source, stirring by strong magnetic force at room temperature for evenly dispersing, mixing the evenly-dispersed silicon source and aluminum source solution to prepare glue at room temperature, adding the mordenite molecular sieve serving as a seed crystal, quickly adding Ti-containing micromolecule organic amine solution into the mixed solution, stirring by strong magnetic force at room temperature for evenly dispersing, transferring into a reaction crystallization kettle, carrying out crystallization reaction at 150-170DEG C for 0.5-3d, and carrying out conventional leaching, washing and drying operations to obtain a solid product. The synthesis method has the characteristic that the titanium atom is led into a micropore skeleton in the manner of quadridentate and high dispersion by using hydro-thermal synthesis, the micromolecule organic amine serving as the chelant of impurity metal titanium atom, and the one-step method is used, so that the obtained titanium-containing nano-mordenite molecular sieve is high in crystallinity and purity, controllable in particle size and shape and low in cost, and causes little environment pollution, thereby being convenient for the large-scale industrial production.

Owner:EAST CHINA NORMAL UNIV

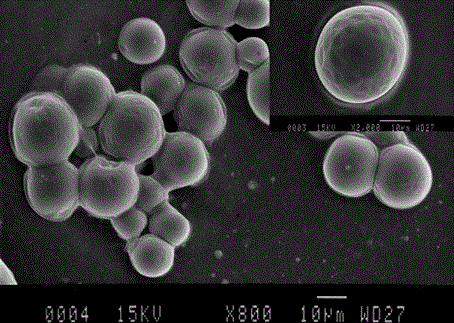

Chemical method for preparing cobalt nickel nanoscale alloy powder

A chemical method for preparing cobalt nickel nanoscale alloy powder uses hydrazine hydrate as reductants to prepare the cobalt nickel nanoscale alloy powder by a liquid phase reducing method. The method is characterized in that the particle size of the product can be adjusted by means of changing the process factors such as metal salt concentration, the adding quantity of the reductants, addition of surfactants and the like, and the stoichiometric ratio of Co / Ni of the product is controlled by the aid of the stoichiometric ratio of Co / Ni of initial salt, so that components of the CoNi nanoscale alloy powder are controlled. The prepared powder is spherical, the particle size of the prepared powder ranges from 50 nanometers to 700 nanometers, and the prepared powder is evenly distributed and is cobalt nickel mixed alloy powder. The method not only is simple in process and low in raw material cost, but also realizes economical macroscopic preparation, and facilitates practical use of the cobalt nickel nanoscale alloy powder.

Owner:UNIV OF SCI & TECH BEIJING

Oil-absorbing resin and preparation method

ActiveCN103333286AImprove hydrophobicityImprove adsorption capacityOther chemical processesPolymer scienceDistilled water

The invention relates to an oil-absorbing resin and a preparation method thereof. The oil-absorbing resin comprises an oil phase: 5-15 parts of glycol dimethacrylate, 15-30 parts of isobornyl methacrylate, 20-40 parts of p-diphenyl sulfone methacrylate, 10-15 parts of triethylene glycol methacrylate, 10-20 parts of divinylbenzene, 20-30 parts of styrene, 50-200 parts of porogen, 0.5-2 parts of AIBN; and a water phase: 500-1000 parts of distilled water, 5-15 parts of PVA, and 20-50 parts of NaCl. According to the preparation method provided by the invention, the isobornyl methacrylate and the p-diphenyl sulfone methacrylate are used as main synthesis materials, and meanwhile, the non-polar crosslinking agents divinylbenzene and glycol dimethacrylate are used as crosslinking agents, and the styrene with higher hydrophobicity is used as a comonomer to synthetically prepare the oil-absorbing resin which can effectively absorb oil.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

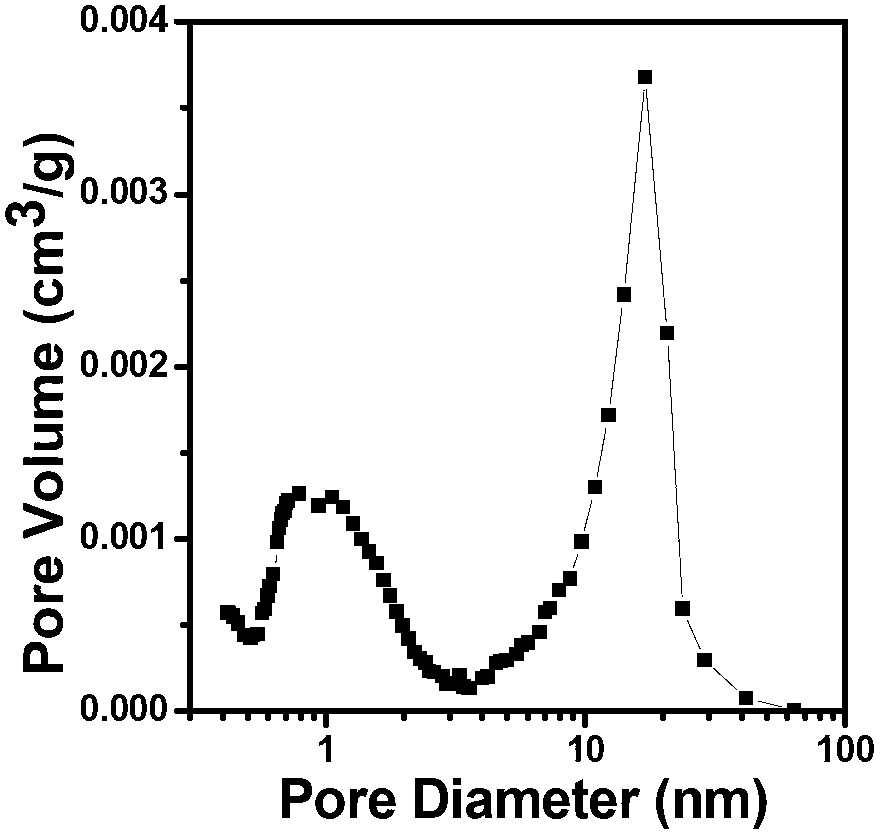

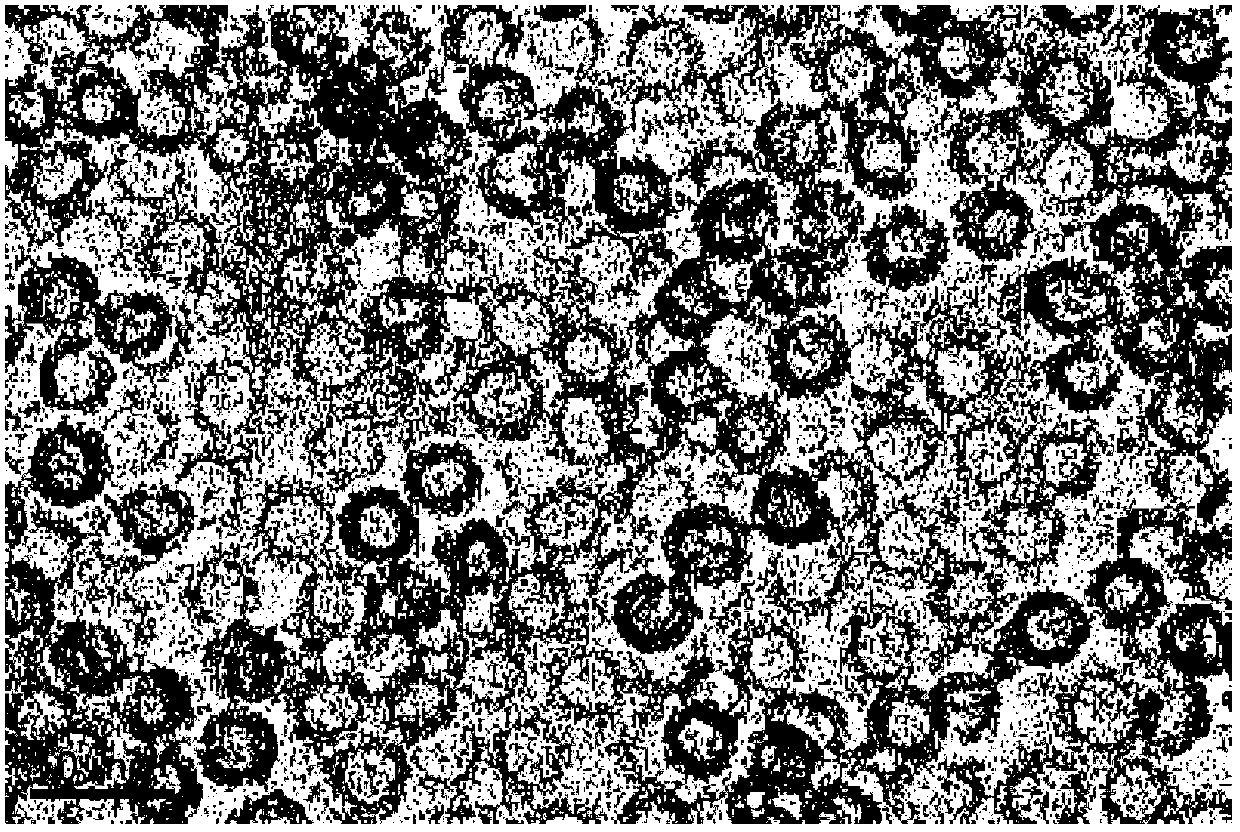

Material for hollow nano organosilicon sphere and preparation method of material

InactiveCN102806071ASmall sizeEvenly dispersedOther chemical processesAlkali metal oxides/hydroxidesReaction temperatureDrug release

The invention relates to a material for a hollow nano organosilicon sphere and a preparation method of the material, which belong to the technical field of novel mesoporous functional materials. The preparation method comprises the steps of producing, dialyzing and drying the hollow nano organosilicon sphere and removing a surfactant. The reaction condition is mild, the operation is easy and simple, a cosurfactant is not required to be added, and the final material is cheap and easy to obtain. Physicochemical properties of the material for the hollow organosilicon sphere, such as particle diameter, pore diameter, wall thickness and composition, can be modulated by changing the raw material ratio, reaction temperature, acid concentration in a reaction system, reaction time, adding amount of pore-enlarging agents and polymerization inhibitor, and categories and proportion of organosilicon sources. The material has wide application prospects in the fields of oil gas adsorption, catalyst carriers, slow drug release, separation, chromatography, pigments, microreactors and the like.

Owner:CHANGZHOU UNIV

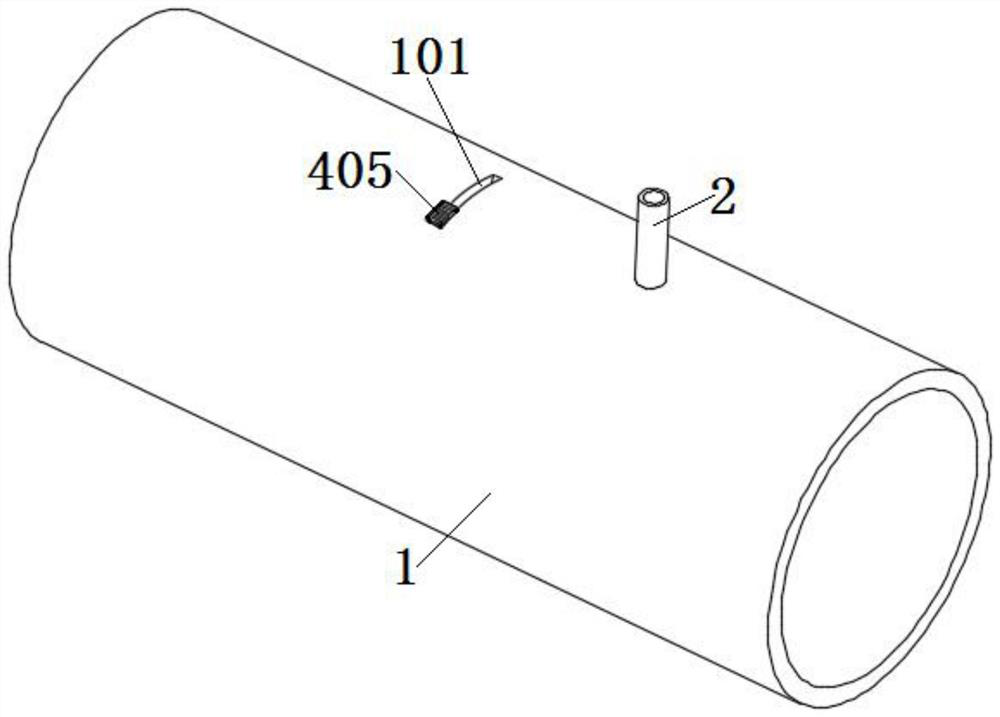

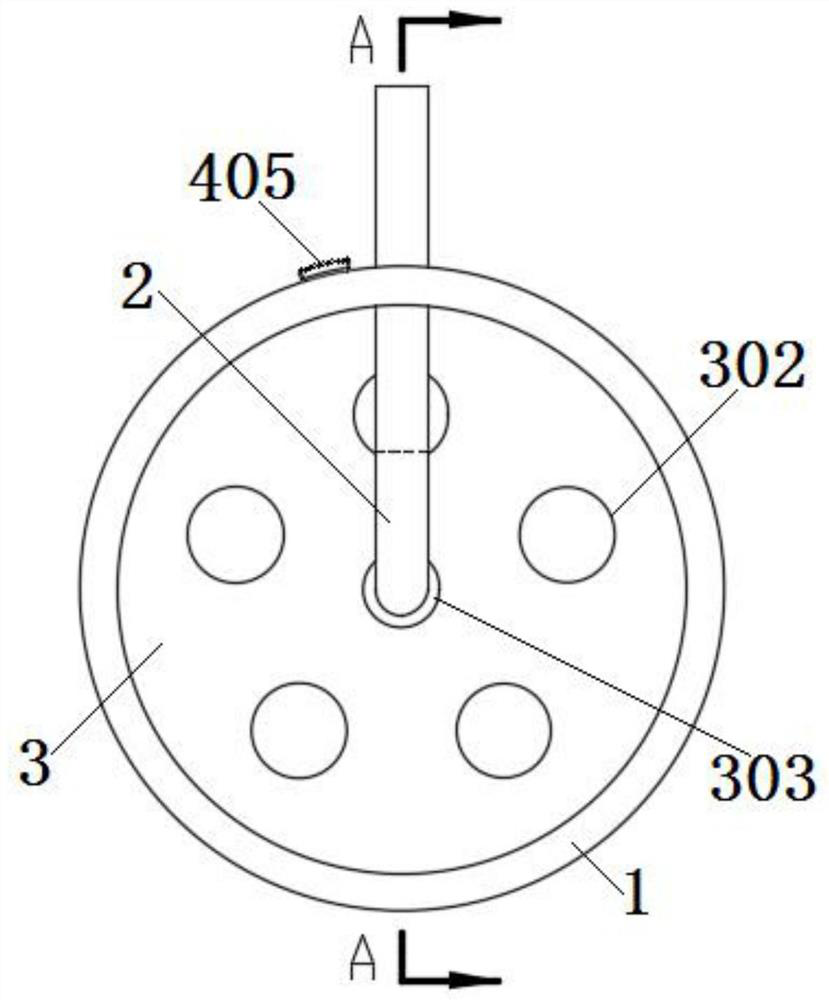

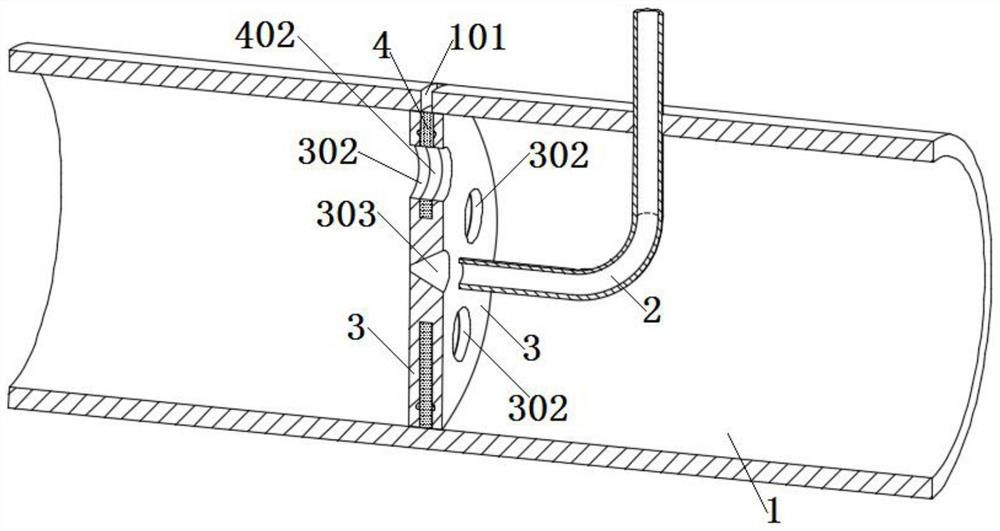

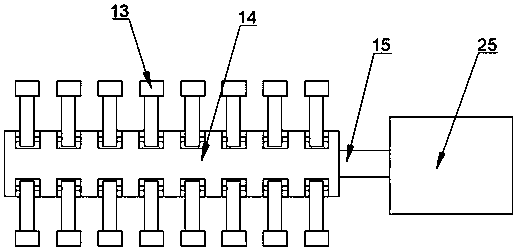

Atomization dosing device integrated in breathing machine pipeline

PendingCN111956931ARealization of atomizationCompact structureRespiratorsMedical atomisersEngineeringApparatus instruments

The invention discloses an atomization dosing device integrated in a breathing machine pipeline, and relates to the technical field of medical instruments. The device comprises a mixed gas supply pipeand a medicine supply pipe; fixing plates are fixed in the mixed gas supply pipe side by side; an adjusting notch is formed in the side wall of the mixed gas supply pipe; an adjusting plate is rotationally connected between the two fixing plates through a connecting column; vent holes are circumferentially arrayed in the side surfaces of the two fixed plates; the connecting column is provided with an atomization hole, and the two ends of the atomization hole penetrate through the fixing plates.; the medicine supply pipe corresponds to the atomization hole in position; adjusting holes corresponding to the vent holes are formed in the side surface of the adjusting plate; and shifting rods in clearance fit with the adjusting notches are fixed to the peripheral side face of the adjusting plate. The adjusting plate is rotated to adjust the gas amount, so that the particle size of atomized liquid drops is adjusted, and the purpose that the particle size of the atomized liquid drops is uniform and controllable is achieved.

Owner:合肥中科力一科技有限公司

Multistage ultrasonic atomizing spraying device

PendingCN110052340AImprove atomization effectReduce liquid viscosity coefficientLiquid spraying apparatusSpray nozzleEngineering

The invention provides a multistage ultrasonic atomizing spraying device. The multistage ultrasonic atomizing spraying device comprises a gas inlet, a plurality of resonating tube structures, a hemispherical focusing structure, a gas-liquid mixing room, a liquid inlet, a guider and a spray nozzle device, wherein the hemispherical focusing structure is arranged in the gas-liquid mixing room. Afterpassing through the resonating tube structures, gas generates ultrasonic waves, and obtains supersonic speed, so that primary atomizing is accomplished in the gas-liquid mixing room. Through the hemispherical focusing structure, secondary atomizing is accomplished. Atomized liquid and gas are mixed to accomplish tertiary atomizing through the guider and the spray nozzle device. The multistage ultrasonic atomizing spraying device is simple in structure, is reasonable in design, adopts a multistage ultrasonic atomizing technology, is good in atomizing effect, and can obtain smaller fog drops with more uniform atomizing particle diameters.

Owner:JIANGSU UNIV

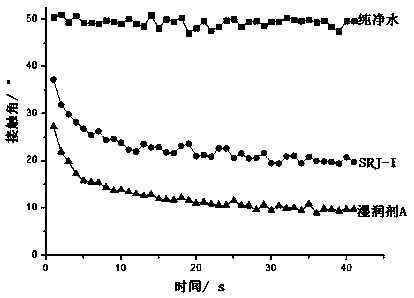

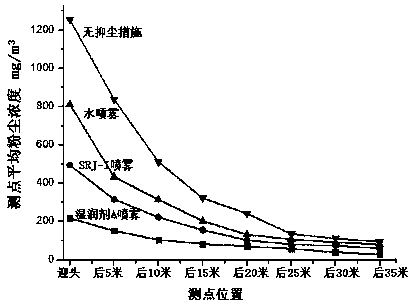

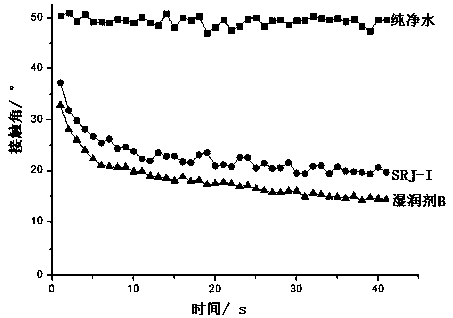

Polynary ionic wetting agent for inhibiting mine dust and preparation method thereof

InactiveCN108059948AImprove performanceImprove wettabilityOther chemical processesTransportation and packagingInorganic saltsChemical reaction

The invention discloses a polynary ionic wetting agent for inhibiting mine dust and a preparation method thereof, which are applied to the inhibition of a lot of dust produced during the production ofa mining working face of a mine. A variety of anionic, cationic, nonionic and neutral ionic surfactants are first isotropically combined and compounded, then anisotropically cross-compounded, added with water, put into a chemical reaction kettle and agitated under 120 DEG C for 2 hours while pressure is kept at 0.8MPa; inorganic salt is added to improve the ionized characteristic of the mixture,and agitation is carried out for 1 hour; adhesive is added to improve the capturing capability of mixture droplets, curing and reinforcing agent is added to increase the suspension period of the droplets in the air, and agitation is carried out for 2 hours; imidazole ionic liquid is added as an additive, agitation is carried out for 1 hour, the mixture is depressurized, cooled and taken out of thekettle, and thereby the polynary ionic wetting agent is formed. The wetting agent can greatly improve wetting capability and capturing capability on respirable dust and prolong the suspension life ofdroplets; the mine dust suppression cost is low, skin cannot be injured, machine corrosion is little, and the polynary ionic wetting agent has good applicability and environment-friendliness.

Owner:CHINA UNIV OF MINING & TECH

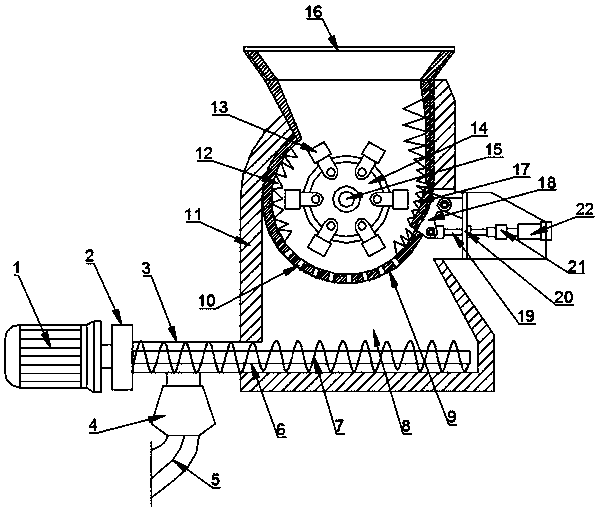

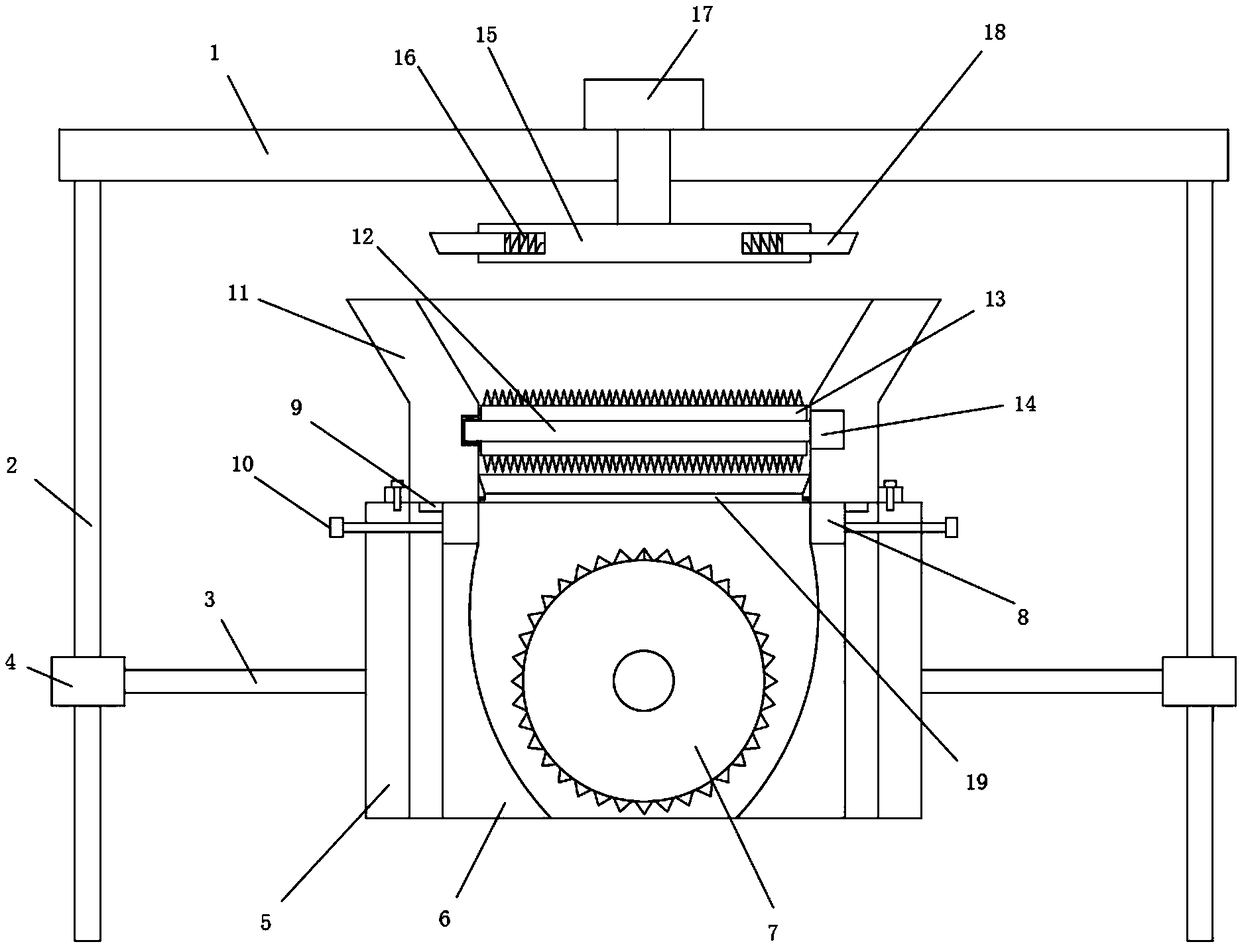

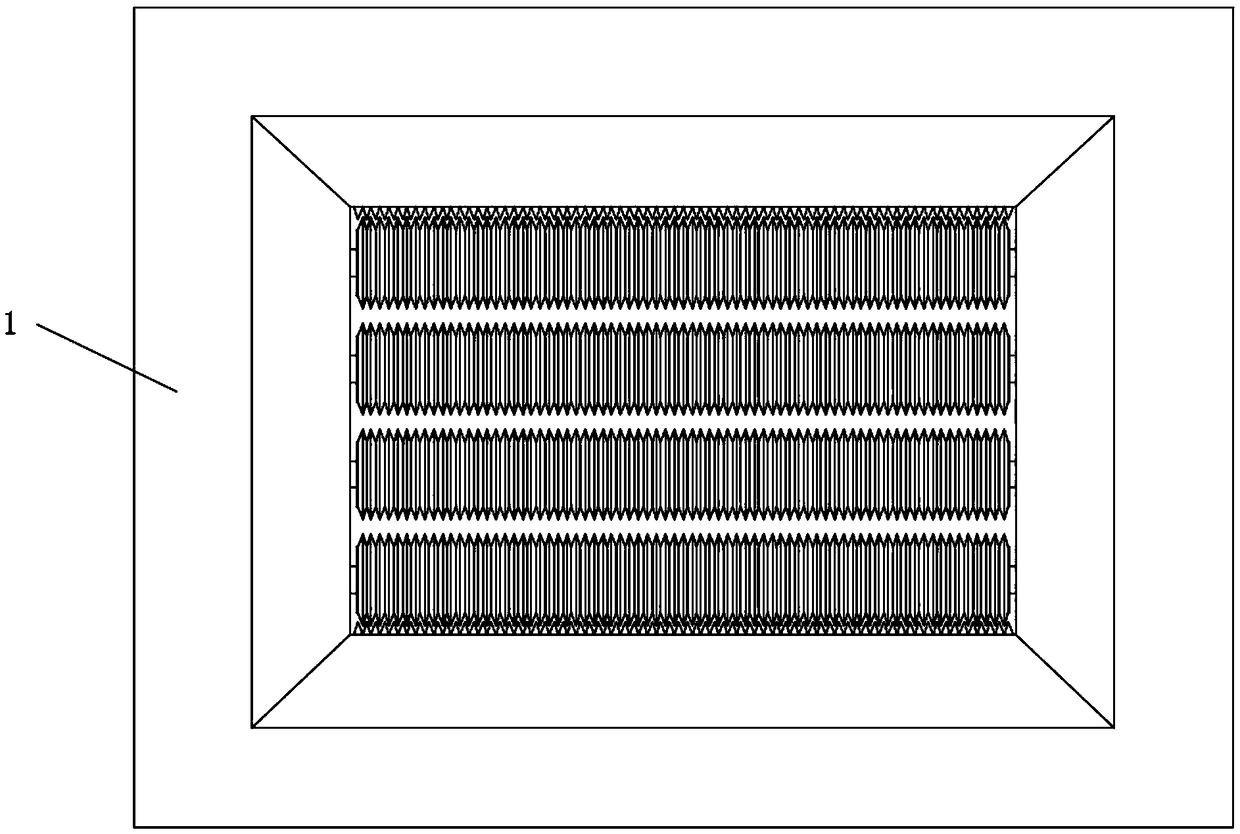

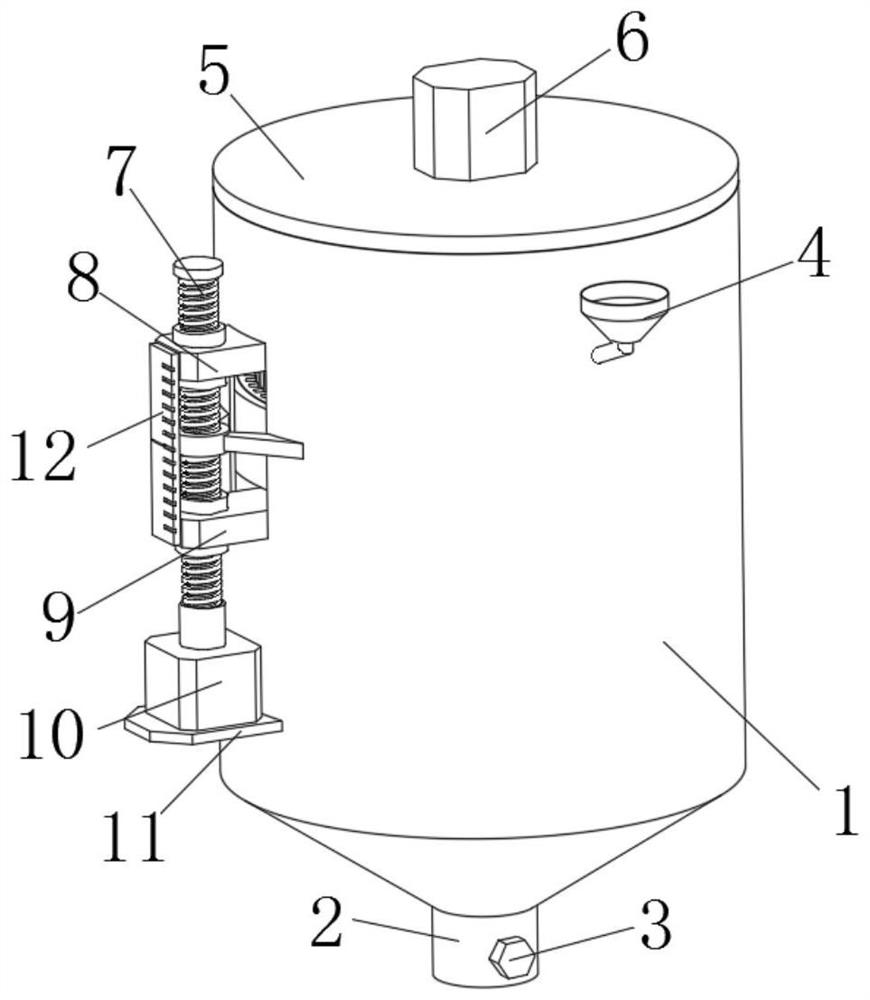

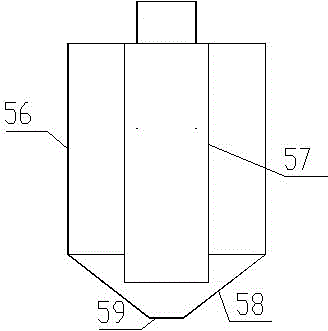

Crusher capable of conveniently adjusting crushing size

InactiveCN108311221AAdjust the clearanceAdjust particle sizeGrain treatmentsArchitectural engineeringCrushed stone

The invention discloses a crusher capable of conveniently adjusting the crushing size. The crusher comprises a discharge pipe, a crushing cylinder, a crusher shell, fixed hammers, rotary hammers, a feed hopper, movable hammers and a movable block, wherein the crushing cylinder is arranged in the crusher shell, the multiple fixed hammers are welded to the inner wall of the crushing cylinder, the multiple rotary hammers are connected to the side wall of a crushing roller through pin shafts, the lower part of the outer side of the movable block is connected to a movable hinge base, the movable hinge base is fixed to the end part of a connecting rod, and the connecting rod penetrates through a through groove in a baffle plate and is connected to a telescopic rod of an electric cylinder througha connector. The crusher has the advantages that the rotary hammers and the fixed hammers are used for crushing stone which falls between the rotary hammers and the fixed hammers, the crushing effectis good, the movable block is driven to rotate inwards or outwards around a fixed hinging base through the telescopic rod of the electric cylinder, so that gaps between the movable hammers and the rotary hammers can be adjusted, the particle size of the crushed stone can be further adjusted, and the crusher is convenient and fast to use.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

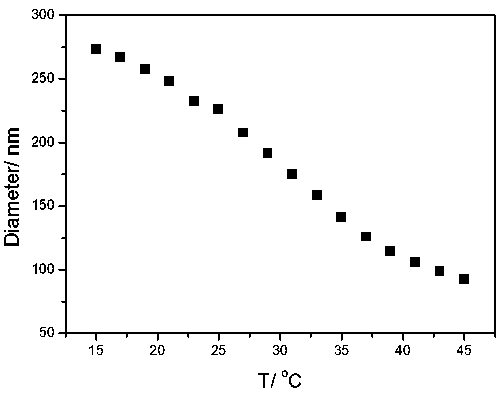

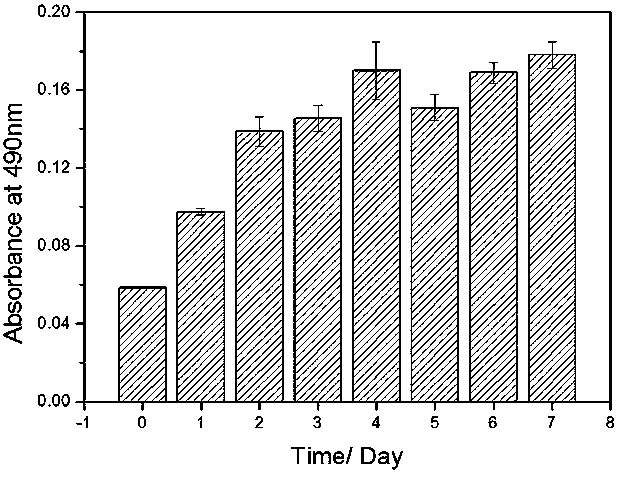

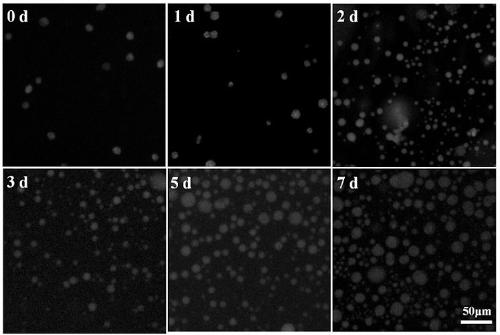

PEG type thermosensitive hydrogel three-dimensional cell scaffold as well as preparation method and application thereof

InactiveCN109054049AEasy to prepareMild conditionsPharmaceutical delivery mechanismCell culture supports/coatingChemistrySide chain

The invention relates to a PEG type thermosensitive hydrogel three-dimensional cell scaffold and as well as a preparation method and application thereof. The preparation method of the three-dimensional cell scaffold comprises the steps of mixing acrylate water-soluble macromolecular polymerizable monomer containing a PEG side chain, an initiator, a surfactant, a cross-linking agent and / or comonomer, reacting and obtaining PEG type thermosensitive nano gel; mixing the PEG type thermosensitive nano gel with cells uniformly at room temperature, and forming the PEG type thermosensitive hydrogel three-dimensional cell scaffold by thermally inducing in-situ embedded cells. The preparation method is easy to conduct, is featured by mild conditions, and damages cells slightly. Compared with a traditional PNIPAM type thermosensitive hydrogel scaffold, the PEG type thermosensitive hydrogel scaffold has high biocompatibility, is degradable, is adjustable in nature, prolongs syneresis slightly along with time, and can keep cells growing and proliferating for long time, thereby being an ideal tissue engineering material, and being used in fields like in vitro culture of cells, tissue repair andtumor treatment.

Owner:NANHUA UNIV

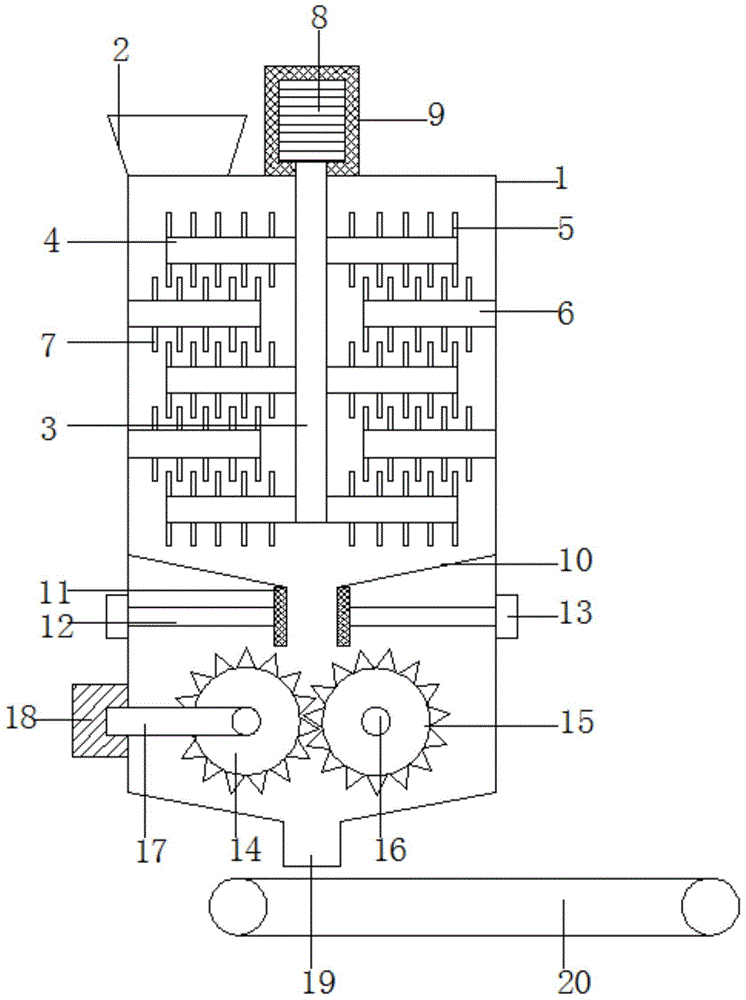

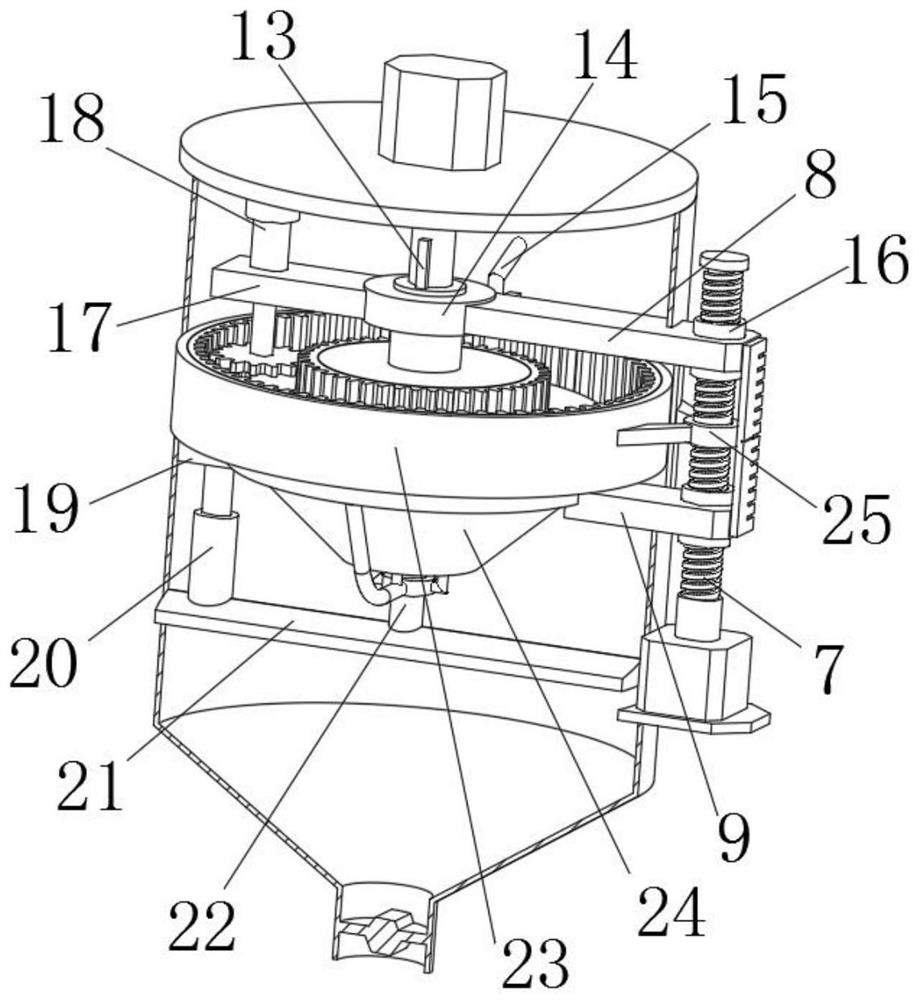

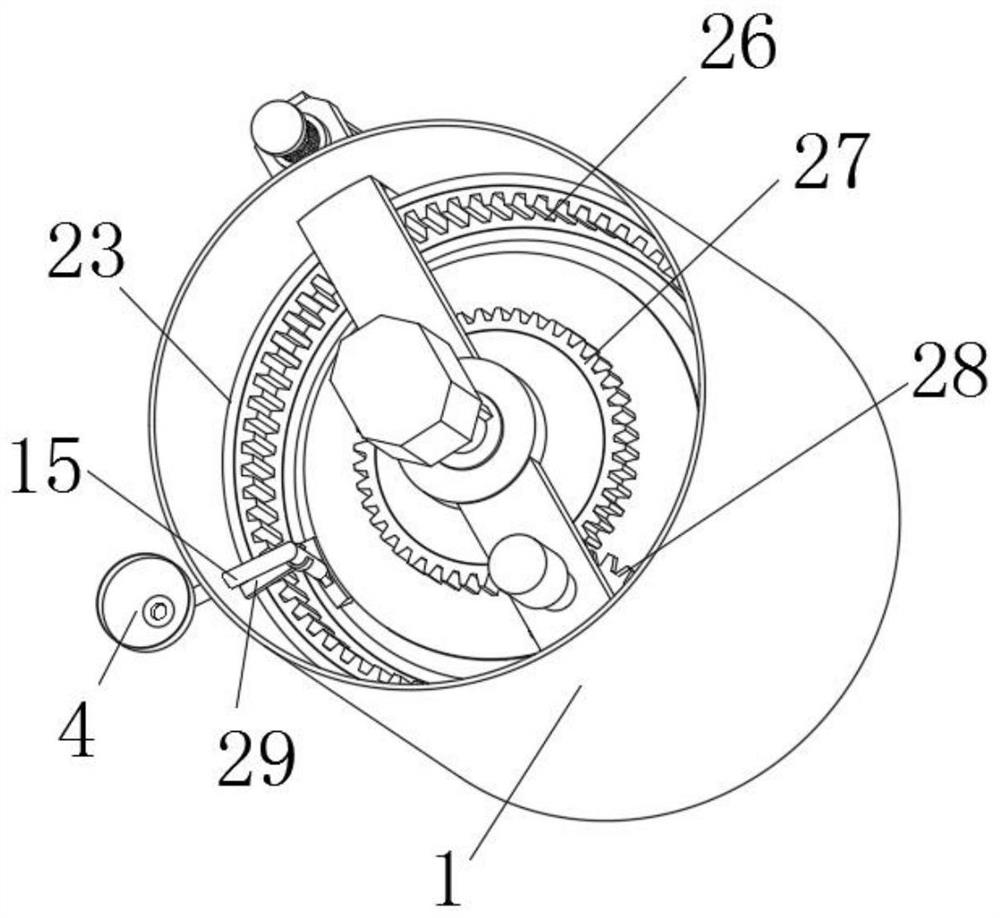

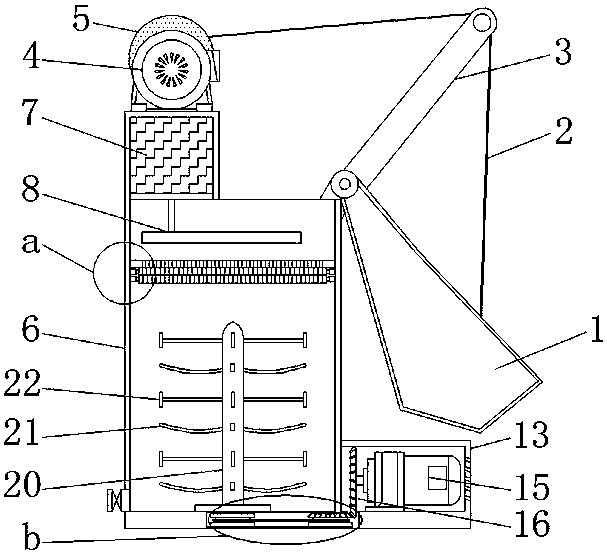

Deironing pulverizer for producing ceramics

The invention discloses a deironing pulverizer for producing ceramics. The deironing pulverizer comprises a pulverizer body, an electromagnet and a hydraulic cylinder, wherein a feeding funnel is disposed at the left end of the upper side of the pulverizer body, a rotary shaft is vertically disposed at the axis of the pulverizer body, rotary pulverizing rods are disposed on the outer wall of the rotary shaft in a left-right symmetry manner, five pairs of rotary beating short rods are disposed on the outer wall of each rotary pulverizing rod in an up-down symmetry manner, and fixed pulverizing rods are disposed on the inner wall of the pulverizer body in a left-right symmetry manner. The deironing pulverizer has the advantages that the rotary pulverizing rods, the rotary beating short rods, the fixed pulverizing rods and fixed beating short rods jointly beat and pulverize materials, high beating force and high pulverizing strength are achieved, pulverizer work efficiency is increased, secondary pulverizing of the materials is performed by a meshed gear set, material pulverizing effect is guaranteed, the particle size of the materials pulverized by the gears can be adjusted, high practicality is achieved, iron and magnetic substances in the materials can be removed, and finished product quality is guaranteed.

Owner:顾马飞

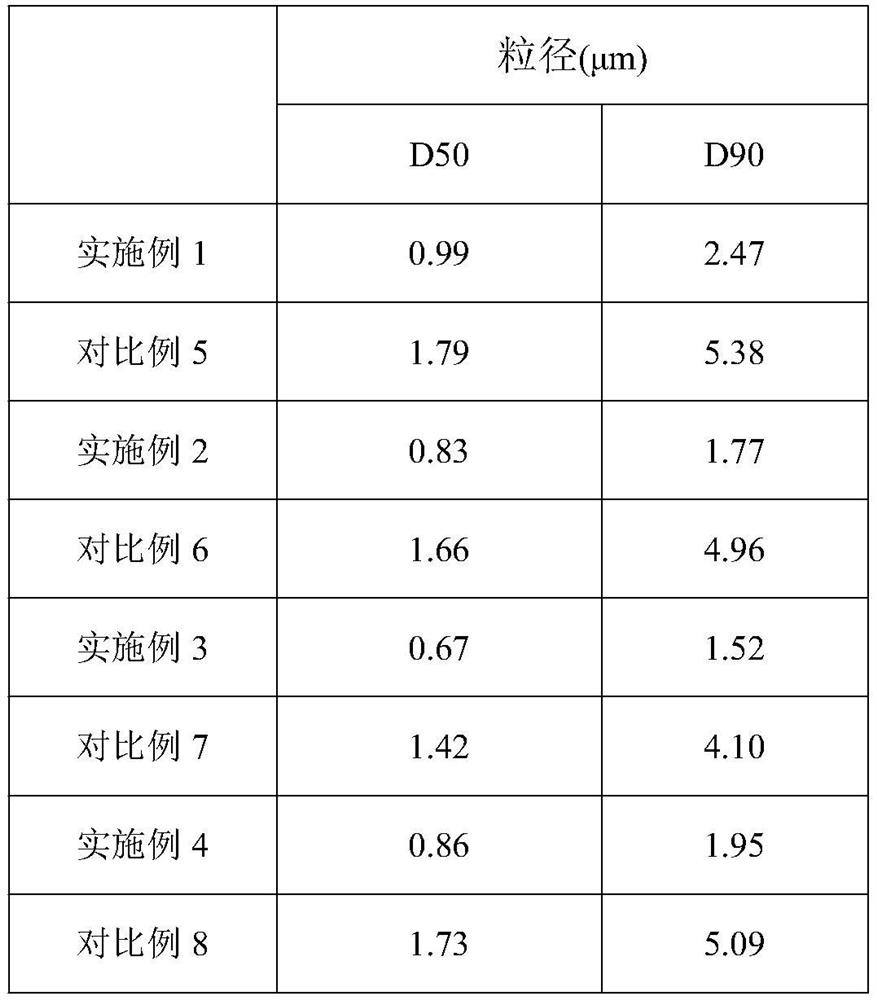

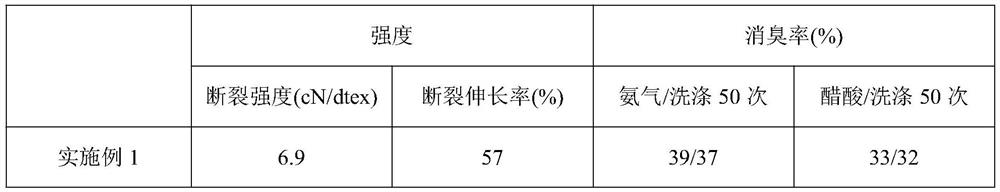

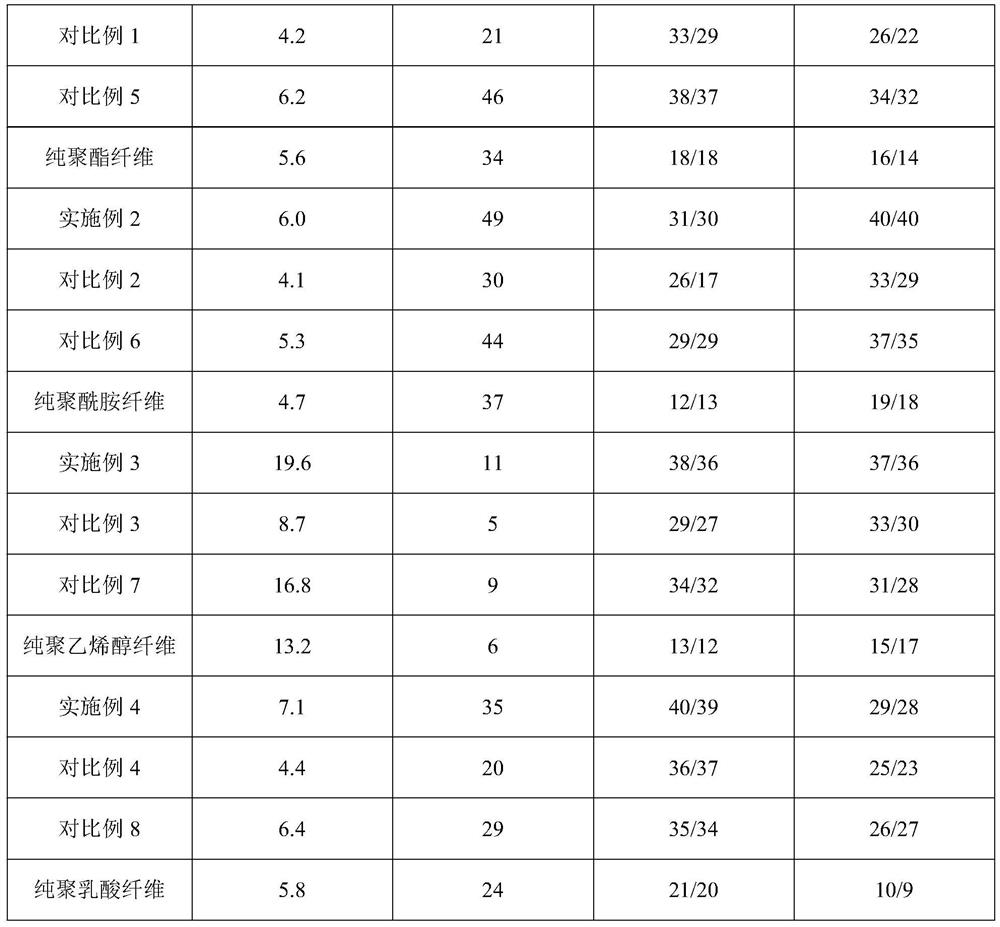

Compound deodorizing, antibacterial and antiviral multifunctional fiber and preparation method thereof

ActiveCN113652766AImprove mixing dispersibilityGood compatibilityBiocideDisinfectantsAnti bacterialAntibacterial agent

The invention belongs to the technical field of functional fiber materials, and discloses compound deodorizing, antibacterial and antiviral multifunctional fiber and a preparation method thereof. PVA and an organosilicon quaternary ammonium salt antibacterial agent are added into a traditional Chinese medicine antiviral extracting solution to obtain a mixed solution, then a catalyst and a sodium silicate or silicate ester compound are added for a condensation reaction, PVA-SiO2 interpenetrating network particles coating a traditional Chinese medicine antiviral component and the organosilicon quaternary ammonium salt antibacterial agent are obtained, and the obtained functional particles and a fiber matrix are subjected to mixed spinning, so that the product is obtained. The PVA is used as a coating agent of the traditional Chinese medicine antiviral component and the organosilicon quaternary ammonium salt antibacterial agent, so that mixing and dispersion of the traditional Chinese medicine antiviral component and the organosilicon quaternary ammonium salt antibacterial agent in the fiber matrix are promoted; and further an interpenetrating network enhanced structure is formed with SiO2. The long-lasting deodorizing, antibacterial and antiviral effects can be achieved and the fiber strength can be enhanced by introducing the multifunctional fiber into the fiber matrix.

Owner:芯安健康科技广东有限公司

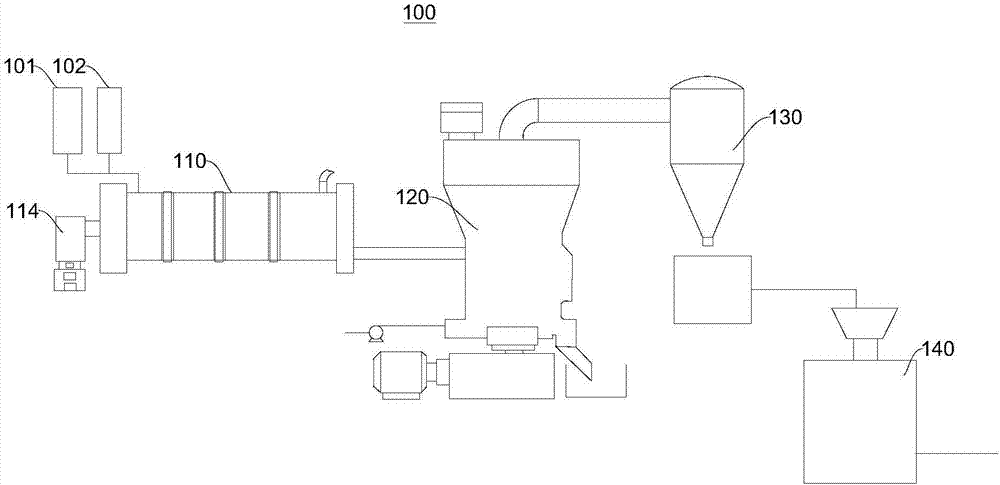

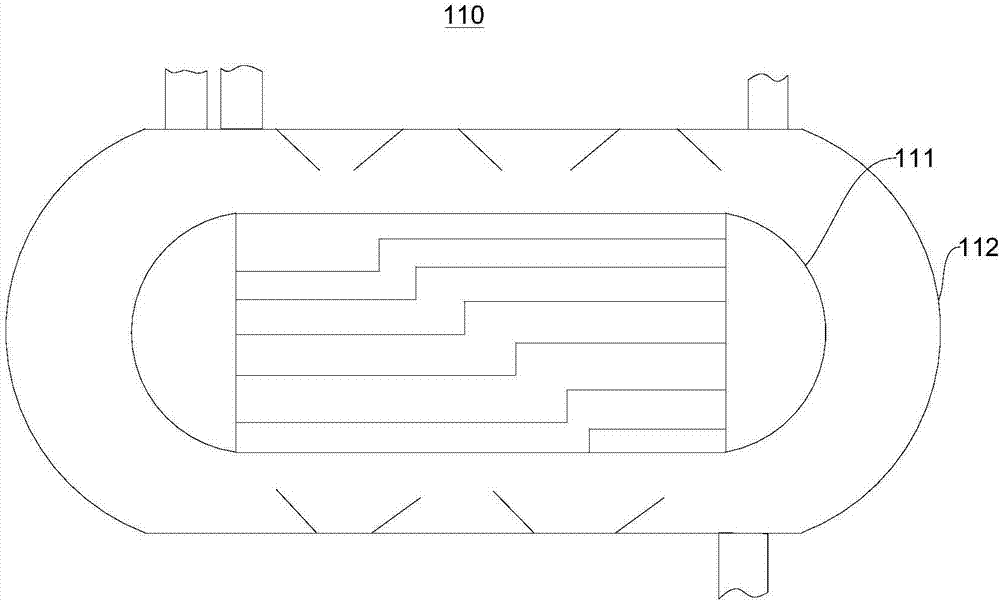

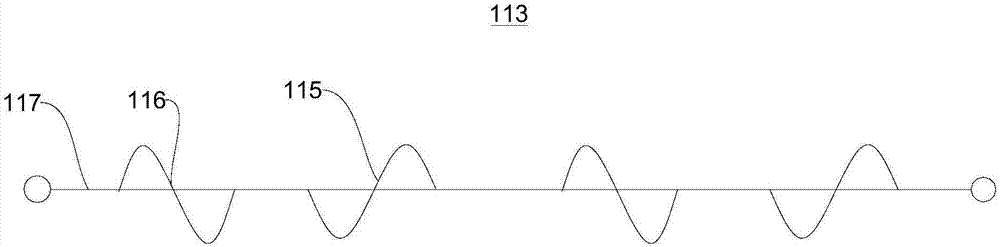

Admixture production system and admixture production process

InactiveCN107139340AIncrease productivityImprove qualityMixing operation control apparatusPretreatment controlWater contentBuilding material

The invention relates to the field of building materials, in particular to an admixture production system and an admixture production process. The admixture production system comprises a drying mechanism, a grinding mechanism and a sorting mechanism all of which are sequentially connected. An outlet of the grinding mechanism communicates with the sorting mechanism and is provided with a bin gate, and the bin gate is in sliding connection with a shell of the grinding device so that the size of the outlet can be adjusted. A material overturning device of the drying mechanism is provided with a forward paddle and a reverse paddle, agminated materials are constantly scattered through the cooperative use of the forward paddle and the reverse paddle, the internal materials are constantly overturned to the surface, the materials can make more sufficient contact with hot air flow, and the water content of the dried materials is reduced. The production efficiency of the whole system is higher, meanwhile, the quality of the finally obtained admixture is improved, and the quality of the admixture is more stable.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP

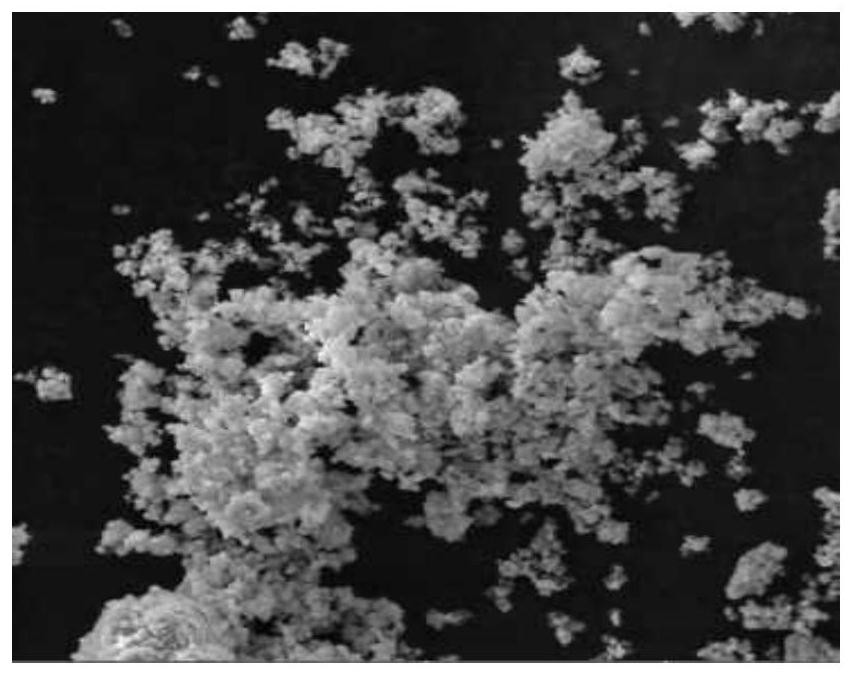

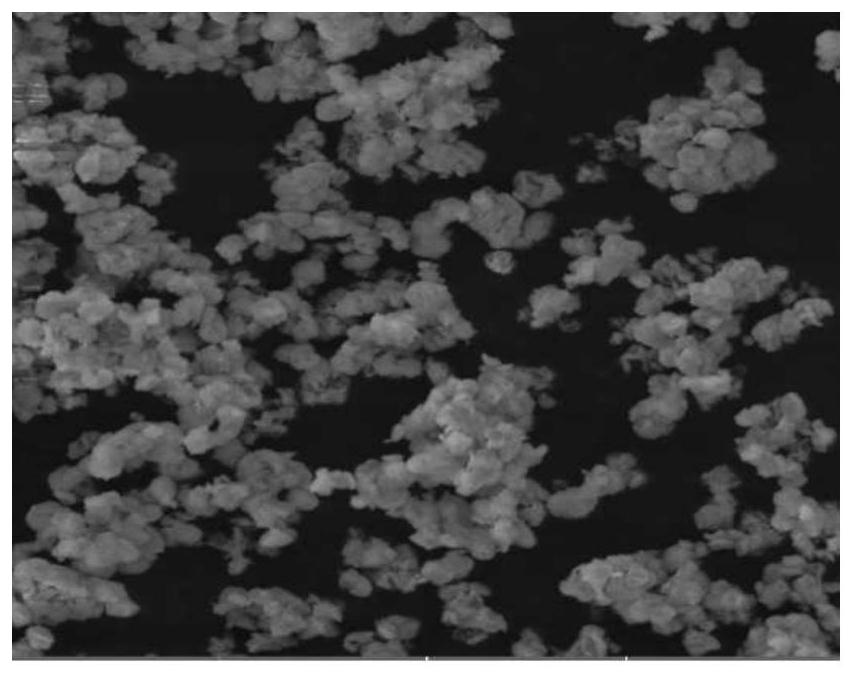

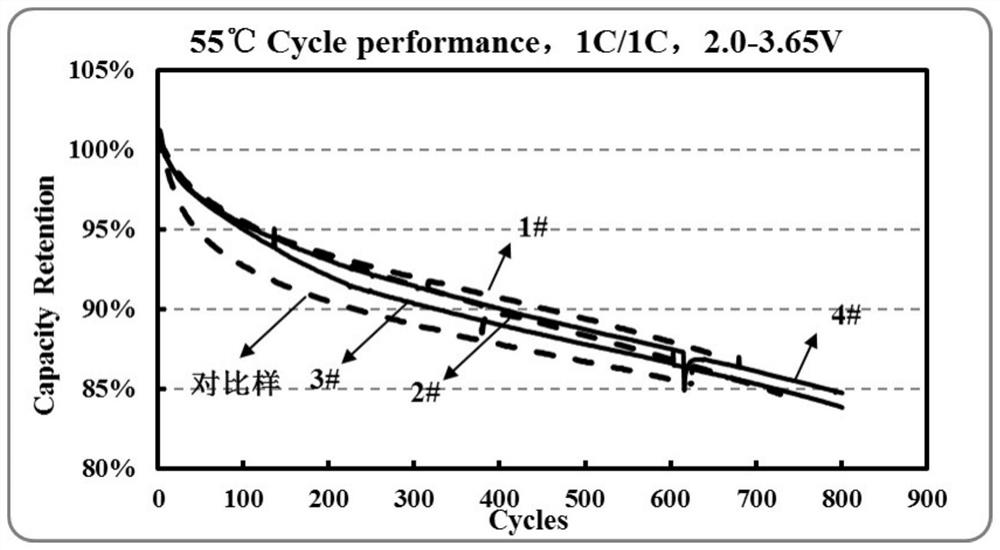

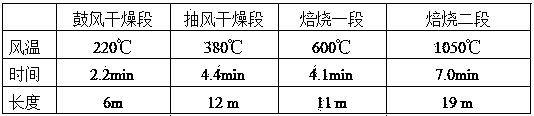

Preparation method of three-dimensional ordered spherical lithium iron phosphate material

InactiveCN112390240AReduce pollutionStrong periodicity of the pore structureCell electrodesSecondary cellsLithium iron phosphateMicrosphere

The invention discloses a preparation method of a three-dimensional ordered spherical lithium iron phosphate material. The preparation method comprises the following steps: preparing polystyrene colloidal crystals by a soap-free emulsion polymerization method, preparing lithium iron phosphate precursor sol, and dropwisely adding the lithium iron phosphate precursor sol into the polystyrene colloidal crystal, after the lithium iron phosphate precursor sol wets the whole polystyrene colloidal crystal, drying the polystyrene colloidal crystal under air flow overnight, and then sintering and naturally cooling the polystyrene colloidal crystal to obtain the three-dimensional ordered spherical lithium iron phosphate material. The sphere diameter of the polystyrene colloidal crystal is adjusted by controlling the polymerization reaction time of a soap-free emulsion polymerization method, the ionic strength of a system and the concentration of an ionic copolymer. According to the prepared three-dimensional ordered spherical lithium iron phosphate material, the integrity and uniformity of a spherical structure can be reserved to the maximum extent, meanwhile, the particle size of lithium iron phosphate can be adjusted according to the sphere diameter of polystyrene microspheres, and the prepared lithium iron phosphate material has the characteristics of large specific surface area, highporosity and the like of a common spherical material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

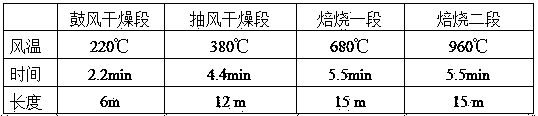

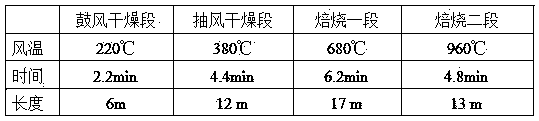

Method for improving quality of magnetite powder pellets

The invention relates to a method for improving the quality of magnetite powder pellets. The method comprises a prehating calcination process in which the lengths of a first calculation section and a second calcination section of a chain grate are transformed, the conventional first calcination section is lengthened, and the conventional second calcination section is shortened; calcination temperature parameters are adjusted; specifically, temperature of the first calcination section is increased and temperature of the second calcination section is reduced; and meanwhile, the particle size of the pellets is correspondingly adjusted to 7-14mm from conventional 9-16mm. The method has the advantages that the temperature of the second calcination section is reduced, the strength of pellet finished products is aslo improved, and meanwhile, the metallurgical performance of the pellet finished products is aslo improved; and by adjusting the particle sizes of the pellets, the problem that the layer-by-layer uniform oxidation of the pellets is affected as the outer layers of the magnetite powder pellets are easy to rapidly solidify is solved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Controllable emulsifying preparation method of PLGA micro-nano carriers of different scales

InactiveCN105943498ASimple processAdjust particle sizePharmaceutical non-active ingredientsEmulsion deliveryCelluloseActive agent

The invention relates to a controllable emulsifying preparation method of PLGA micro-nano carriers of different scales. According to the preparation method, PLGA is dissolved in ethyl acetate to serve as an oil phase, polysorbate and sorbitan fatty acid ester form a mixed nonionic surfactant, a solution containing stabilizer hydroxyethyl cellulose serves as a water phase, O / W PLGA micro / nano emulsion with a stable structure and a uniform particle size can be obtained by controlling the quality or volume of the system, adjusting the component ratio of the water phase, the oil phase and the surfactant and changing uniform mixing manner, and the PLGA micro / nano carriers are obtained by carrying out reduced-pressure rotary distillation at room temperature to remove ethyl acetate, washing with deionized water, separating and drying. The particle sizes of the PLGA micro / nano carriers can be adjusted under single scale by adjusting the hydrophilic / hydrophobic equilibrium value of the mixed nonionic surfactant. The prepared PLGA micro / nano carriers can meet the requirement of different administration manners and loading substances for the particle size of the carrier.

Owner:OCEAN UNIV OF CHINA

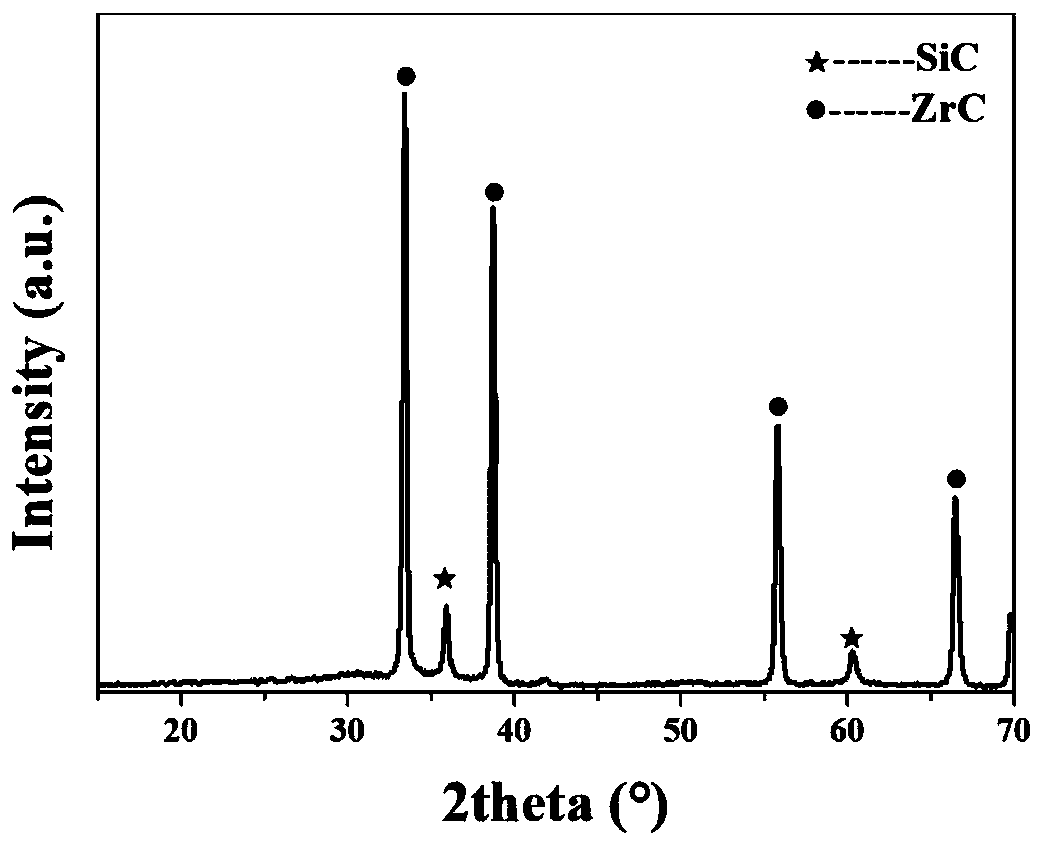

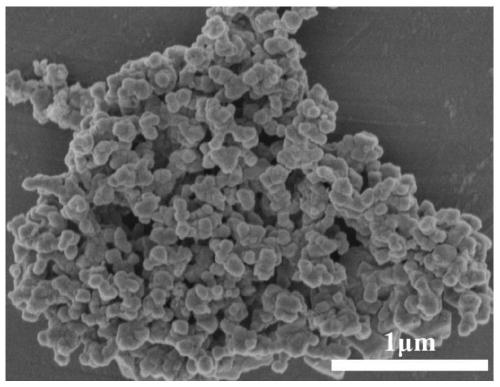

Precursor-conversion-method preparation process of self-dispersion superfine ZrC-SiC ceramic composite powder

The invention discloses a precursor-conversion-method preparation process of self-dispersion superfine ZrC-SiC ceramic composite powder. Zirconium oxychloride octahydrate and tetraethoxysilane are used as a zirconium source and a silicon source; glucose is adopted as a carbon source and a carbonization product dispersing agent in a pyrolysis process, hydrogen peroxide is adopted as a hydrolysis accelerant and absolute ethyl alcohol and deionized water are adopted as composite solvents, and the process comprises respectively preparing a zirconium precursor solution, a tetraethoxysilane solutionand a glucose solution and uniformly mixing the solutions to obtain a silicon-zirconium precursor solution; and drying the silicon-zirconium precursor solution, and carrying out heat treatment at 1450-1600 DEG C for 1-2 hours under argon atmosphere protection to obtain the ZrC-SiC ceramic powder with favorable dispersity, a narrow particle size distribution range and an average particle size of less than 100 nm. The raw materials are safe and non-toxic, the cost is low, the process is simple, the reaction process is easy to control, the synthesis temperature is low, and the prepared ceramic powder is fine and uniform in particle size, good in dispersity and suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Waste concrete on-site reproduction machine for road deck and operation method of waste concrete on-site reproduction machine

ActiveCN108435750AChange and adjust working statusWork status adjustmentSolid waste managementSolid waste disposalCollection systemTurning frames

A waste concrete on-site reproduction machine for a road deck comprises a frame, wherein a power headstock is arranged at the front end part of the frame; a plurality of wheels are arranged at the bottom of the frame; a primary crushing device, a secondary crushing device, a cement mortar removal device, a fine vibration screen, an aggregate collection system and a stirring device are sequentiallyarranged on the frame from front to back; a material output opening of the primary crushing device is connected with a material input opening of the secondary crushing device through a first belt conveyor; and a material output opening of the secondary crushing device is connected with a material input opening of the cement mortar removal device through a second belt conveyor. To sum up, the waste concrete on-site reproduction machine is high in mechanical degree and working efficiency, and achieves on-site reproduction of concrete roads with respect to conventional severely-destroyed cementconcrete pavements, particularly rural concrete pavements which have narrow construction spaces and are inconvenient in material transport, thus realizing on-site recycling of waste concrete, increasing income and reducing expenditure.

Owner:ZHENGZHOU UNIV

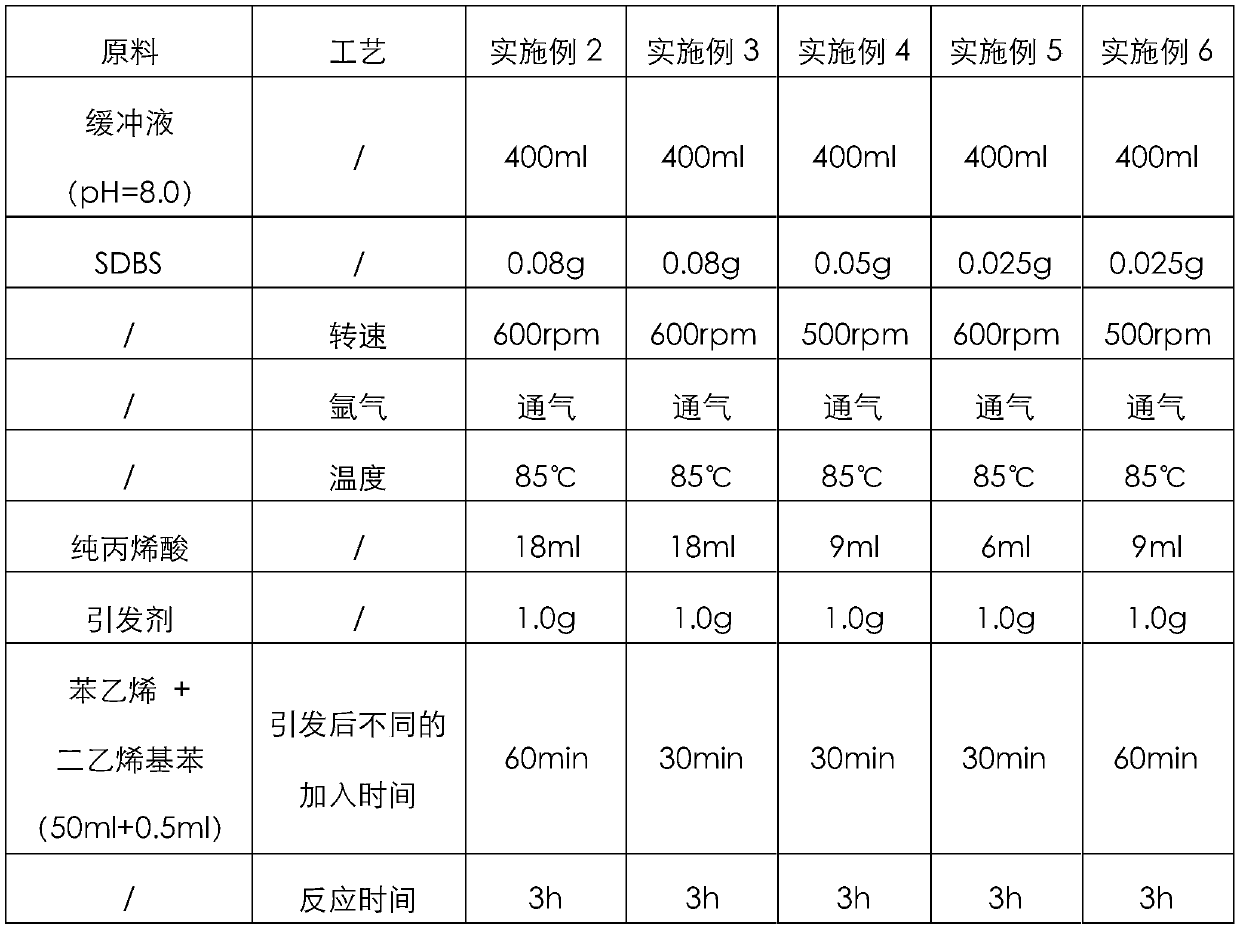

Preparation process for non-cleaning carboxyl polystyrene microspheres

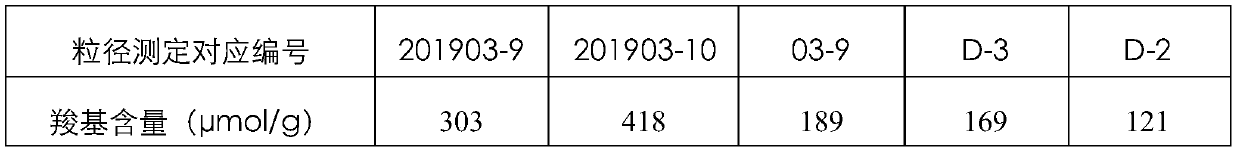

ActiveCN110790853AParticle size controllableAdjustable surface carboxyl contentMicroballoon preparationBulk chemical productionPolymer scienceFunctional monomer

The invention discloses a preparation process for non-cleaning carboxyl polystyrene microspheres. The process comprises the following steps: (1) pouring a functional monomer solution into an outer aqueous-phase solution at one time, wherein the functional monomer is one or more selected from acrylic acid, methacrylic acid and ethyl acrylate, performing stirring, and adding an initiator to initiatea polymerization reaction; and (2) when the initiated polymerization is performed for 5 min to 2 h, adding a mixture of styrene and divinylbenzene at one time, performing a reaction for a period of time, performing cooling, and performing filtration to obtain the carboxyl polystyrene microspheres. The particle size and carboxyl content of the carboxyl polystyrene microspheres prepared by the process are controllable, the reaction time is shortened, and no or only a small amount of time is required for post-treatment.

Owner:SICHUAN XINCHENG BIOLOGICAL CO LTD

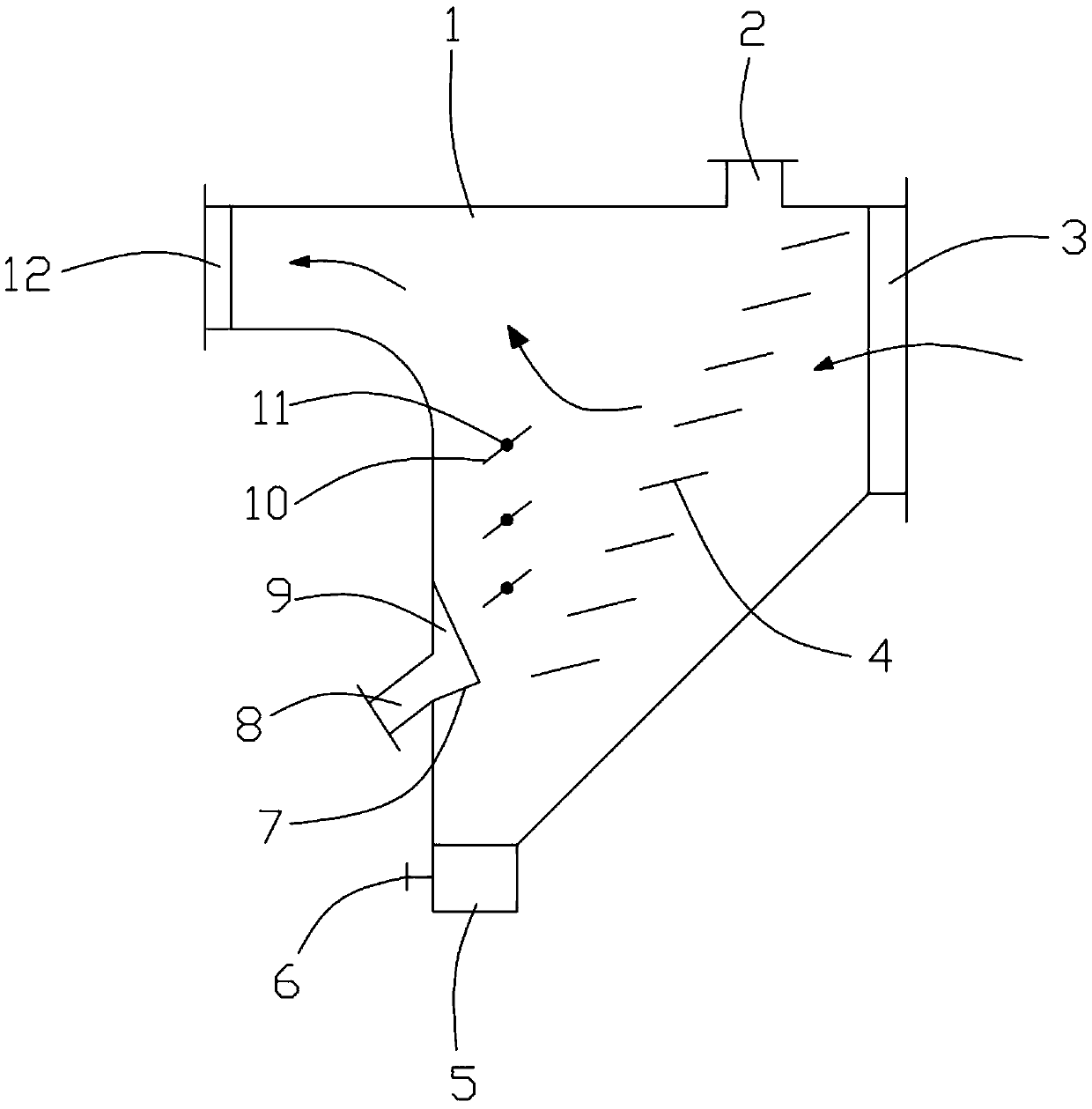

Air classification device for steel slag sand production

PendingCN109675804AImprove winnowing efficiencySimple structureGas current separationSlagEngineering

The invention provides air classification device for steel slag sand production. The air classification device comprises a V-shaped box body, a first flow guide plate, a second flow guide plate and ascattering plate, wherein the first flow guide plate, the second flow guide plate and the scattering plate are arranged in the V-shaped box body. A feeding hole is formed in the top of the V-shaped box body, and a coarse material outlet is formed in the bottom of the V-shaped box body. An air outlet is formed in the upper end of the left side wall of the V-shaped box body, and a steel slag sand outlet is formed in the lower end of the left side wall of the V-shaped box body. An air inlet is formed in the upper end of the right side wall of the V-shaped box body. The scattering plate is distributed below the feeding hole in a stepped mode, and is used for scattering steel slag raw materials entering from the feeding hole and guiding the scattered steel slag raw materials to the left side ofthe scattering plate under the action of air entering from the air inlet. The first flow guide plate is arranged on the left side of the scattering plate and used for guiding steel slag sand in the steel slag raw materials into the second flow guide plate. The included angle between the first flow guide plate and the horizontal plane is adjustable. The second flow guide plate is arranged at the steel slag sand outlet and is used for guiding the steel slag sand out of the steel slag sand outlet. The particle sizes of the steel slag sand can be adjusted by changing the included angle between the first flow guide plate and the horizontal plane. The structure is simple.

Owner:湘潭玉峰新材料科技有限公司

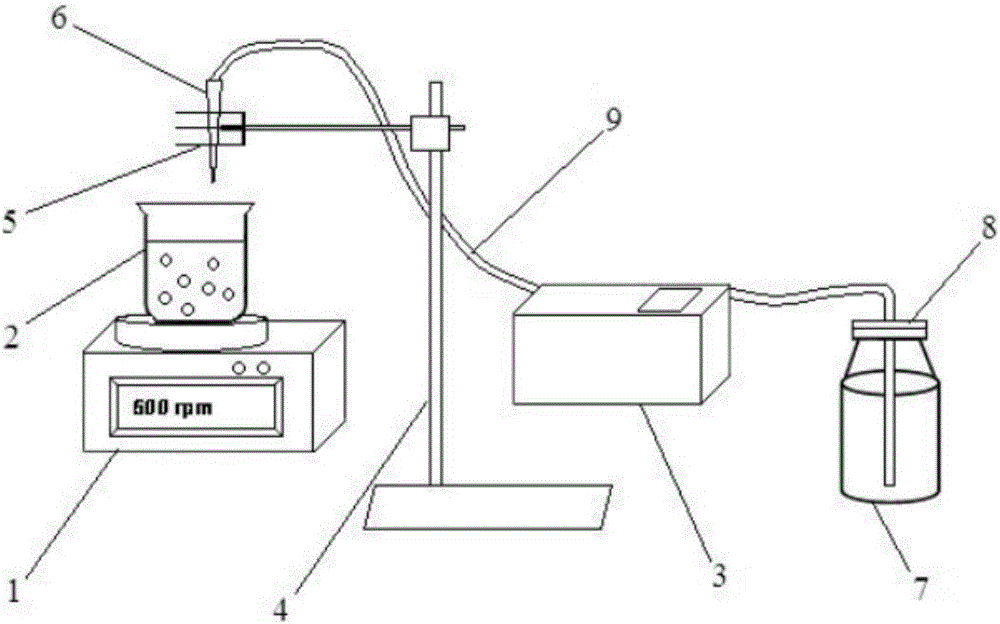

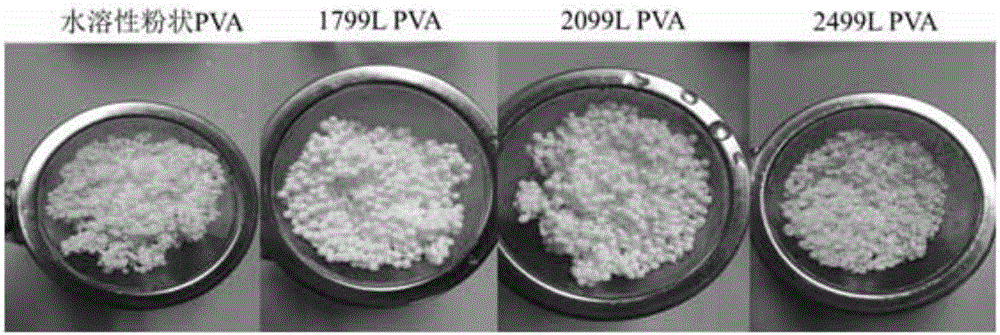

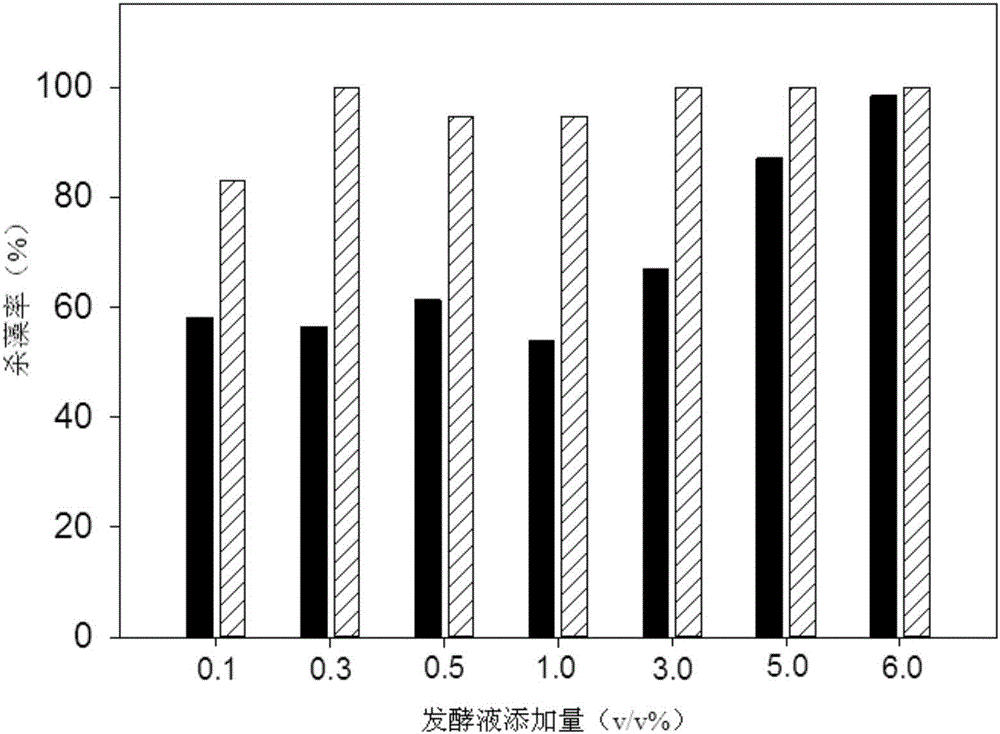

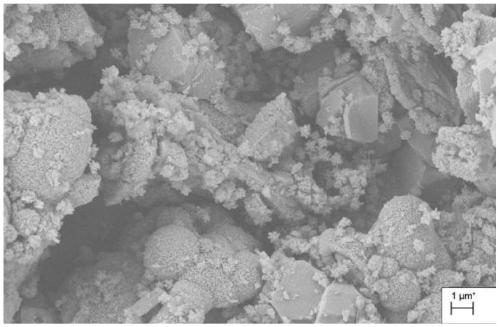

Laboratory bacterium immobilization method

InactiveCN106834264AOvercome artificialityAdjustable sizeMicroorganism based processesOn/in organic carrierContinuous fermentationParticle stability

The invention discloses a laboratory bacterium immobilization method. The method solves the problem that the existing method has a low embedding amount of bacteria, causes poor bacterium immobilized particle stability and utilizes a continuous reaction system difficult to be operated for a long time. The method comprises 1, culturing bacteria to obtain a bacterium liquid, 2, centrifuging the bacterium liquid to obtain immobilized bacteria, 3, dispersing the bacteria through physiological saline, adding a polyvinyl alcohol solution into the dispersion liquid and carrying out mixing to obtain a PVA-bacterium mixed solution, 4, carrying out immobilization through a bacterium immobilization reactor to obtain bacterium immobilized particles, and 5, putting the bacterium immobilized particles into ice water and carrying out standing. The method significantly improves the bacterium embedding amount of the immobilized particles to 15 to 20 g / L, can be well molded, is not broken and does not produce bonding. The immobilized particles have good stability. When the bacterium immobilized particles are used in a continuous fermentation system, the system is stable for at least 2 months. The method is used for bacterium immobilization.

Owner:SHENZHEN UNIV

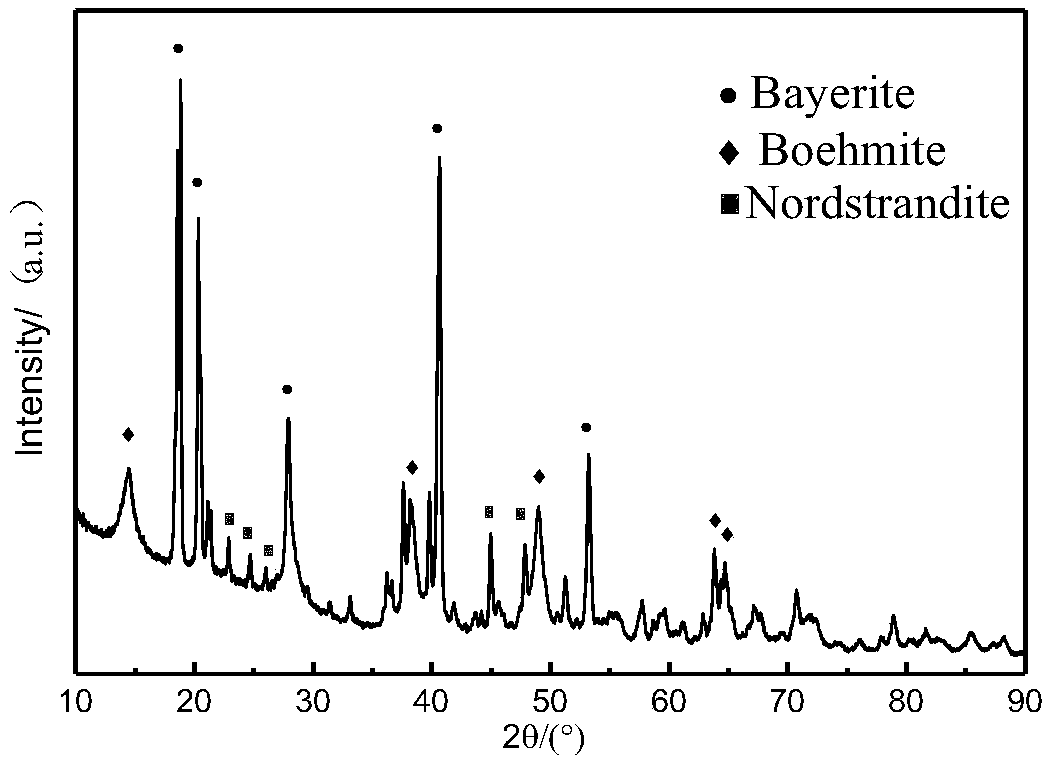

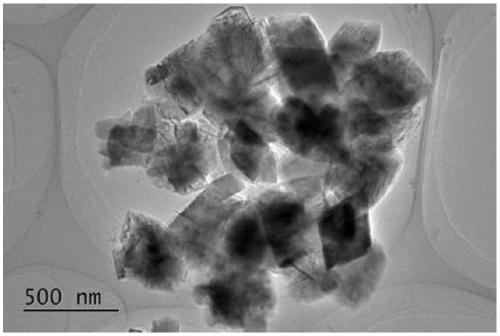

Preparation method of boehmite

PendingCN109336145AReduce hardnessHigh hardnessAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesSolventHydrolysis

The invention provides a preparation method of boehmite, and belongs to the technical field of inorganic powder preparation. According to the preparation method, a solvent heat treatment method is adopted, aluminum hydroxide obtained by the direct hydrolysis of aluminum is used as an aluminum source, boehmite powder with different morphologies can be obtained under different solvents and hydrothermal treatment conditions, and aluminium oxide powder with the corresponding morphologies can be obtained by calcination. The boehmite powder obtained by the invention has the characteristics of special morphology, low specific surface area, small and uniform particle size, good dispersion performance and the like. The boehmite powder prepared with the technology can be applied to the fields of flame retardancy, coating, separation, adsorption and the like. Aluminium oxide obtained with the method can be applied to the fields of abrasives and transparent aluminum oxide ceramics.

Owner:DALIAN JIAOTONG UNIVERSITY

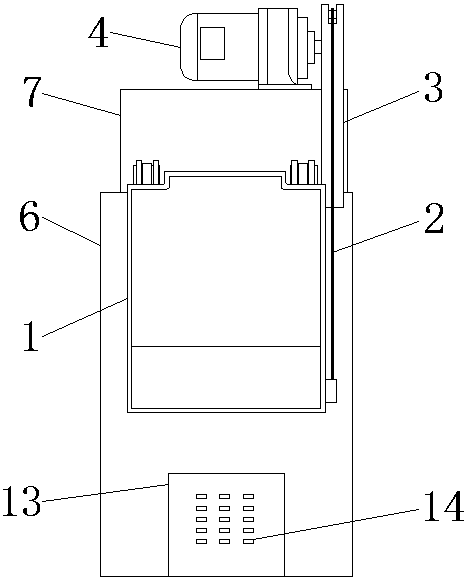

Raw material crushing device for mono-crystal furnace

InactiveCN109289983AAdjust particle sizeImprove practicalityGrain treatmentsEngineeringMechanical engineering

The invention relates to a raw material crushing device for a mono-crystal furnace. The raw material crushing device comprises an upper shell, a lower shell, arc-shaped baffles and a crushing wheel. The upper shell is mounted on the lower shell. The crushing wheel is mounted in the lower shell. The two arc-shaped baffles are arranged on the two sides of the crushing wheel in the lower shell correspondingly. The arc-shaped baffles are movably connected to the bottom of the upper shell through a position adjustment mechanism. The upper end of the upper shell is provided with a feed chute. A pre-crushing mechanism is arranged in the position, below the feed chute, of the interior of the upper shell. The two sides of the lower shell are each connected with a connecting rod. The connecting rodson the two sides are connected to supporting rods on the two sides through connecting seats. The tops of the supporting rods on the two sides are connected with a top seat. A cylinder is connected tothe top seat. The cylinder is connected with a downward pressing plate. The downward pressing plate is movably connected to the interior of the feed chute. The raw material crushing device has the advantages of being simple in structure, easy to manufacture, practicality and high in efficiency.

Owner:XUZHOU HUAAO TEXTILE

Epoxy polyester powder coating production equipment and production process thereof

ActiveCN113321008AAdjustable distanceImprove production nesting effectChemical industryPowdery paintsEpoxyPolyester

The invention discloses epoxy polyester powder coating production equipment and a production process thereof, and relates to the technical field of epoxy polyester powder coating production equipment. The epoxy polyester powder coating production equipment comprises a machine box and a box cover installed on the top of the machine box, the bottom of the machine box is fixedly connected with a discharging pipe, a valve is arranged on the discharging pipe, discharging parts are installed in the machine box, and the discharging parts are connected with the box cover. The epoxy polyester powder coating production equipment is reasonable in structure, by arranging a discharging gap adjusting unit, the distance between the discharging parts is adjusted, the particle size of discharged epoxy polyester powder coating is conveniently adjusted, the production requirements of epoxy polyester powder coating with different requirements are met, and the production cost caused by machining of different equipment is reduced; and by arranging a power transmission unit, reverse simultaneous rotation of the discharging parts is achieved, the discharging effect of production of the epoxy polyester powder coating is improved, the discharging speed of production of the epoxy polyester powder coating is increased, and the practicability is good.

Owner:肇庆市大雄岭新材料有限公司

Efficient circulating fluidized bed grinding equipment and application method thereof

ActiveCN104874457ASolve the problem that it cannot be used for crushing large-diameter mineral hard materialsSimple structureReversed direction vortexGrain treatmentsFluidized bedEngineering

The invention relates to efficient circulating fluidized bed grinding equipment and its application method. According to the invention, a grinding machine is connected in series to a negative-pressure circulating pipe of the circulating fluidized bed grinding equipment. A traditional grinding machine, the circulating fluidized bed grinding equipment and a cyclone dust collector are integrated as a whole. Thus, the technological process of the grinding work is shortened, and a fine powder which accords with requirements can be directly produced. As the fine powder ground by the grinding machine is timely separated from a coarse material, grinding efficiency is raised, and energy consumption of the grinding work is reduced. In comparison with a traditional powder classifier, the cyclone dust collector has a simple structure and is low in equipment cost. In addition, the problem that the circulating fluidized bed grinding equipment cannot be used for pulverizing large pieces of hard mineral materials is solved.

Owner:ZHEJIANG YUNJIE TECH CO LTD

Feeding and stirring device of combination machine

PendingCN108465401AImprove the quality of workParticle size regulationRotary stirring mixersTransportation and packagingMaterial resourcesEngineering

The invention discloses a feeding and stirring device of a combination machine. The device comprises a feeding hopper, a first motor and a case; the outer side of the feeding hopper is connected witha connecting wire; the first motor is arranged at the left side of the upper part of the feeding hopper; a stirring box is arranged below the first motor; the output end of a heating box is provided with a heating rod; a first filter screen, a second filter screen and a third filter screen are sequentially arranged below the heating rod; the case is arranged at the right side of the stirring box;a second motor is arranged inside the case; a connecting disc is connected under a driving disc; the left side of a transmission belt is connected with a driven disc; a stirring rod is arranged abovethe driven disc; and the outer side of the stirring rod is provided with first stirring blades. The feeding and stirring device of the combination machine is convenient for directly material charge, saves manpower and material resources, can control the particle size of materials, can be used to carry out stirring evenly, is beneficial to uniform mixing of the materials, and is beneficial to improving the working quality of the combination machine.

Owner:YANCHENG XIEHE MACHINERY

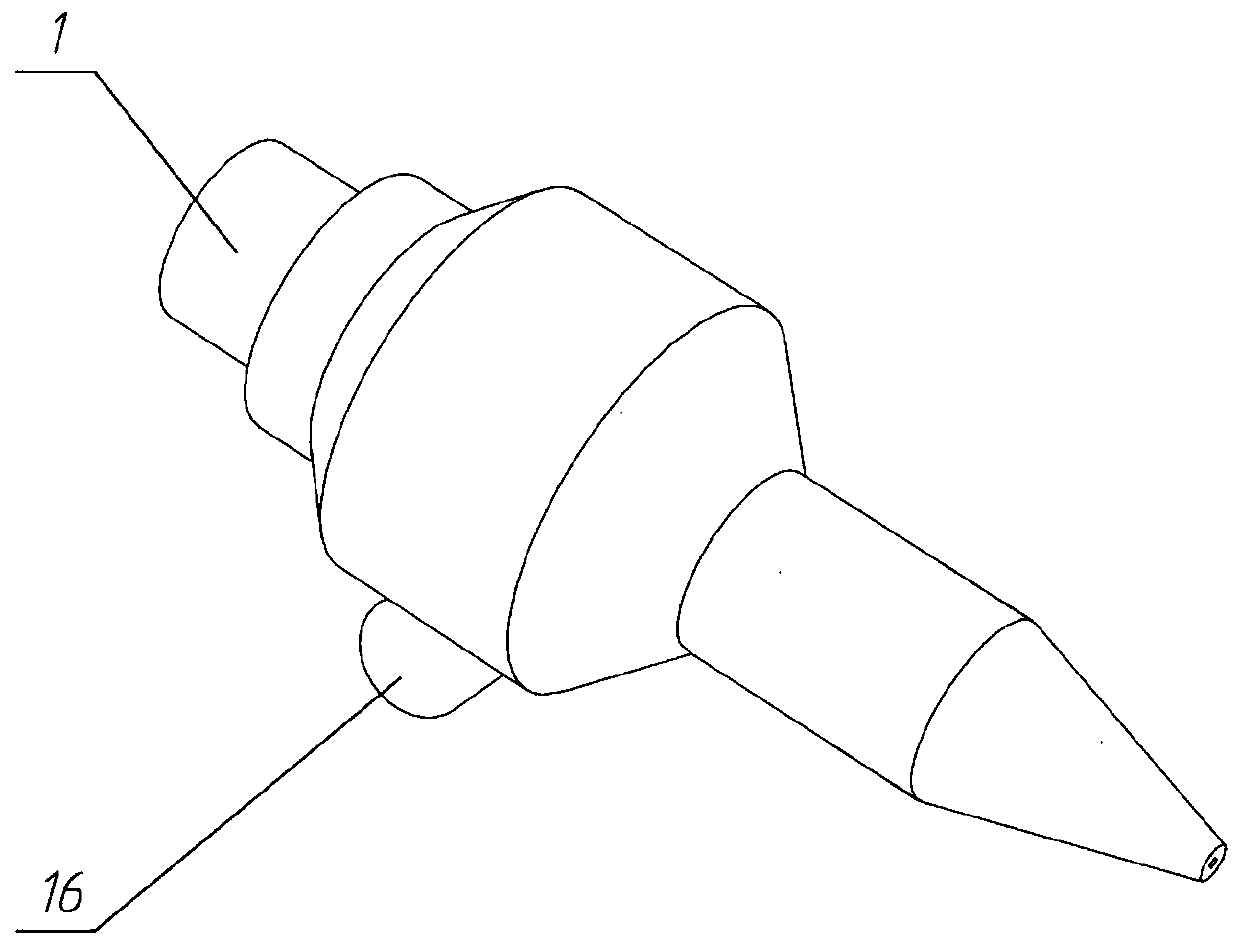

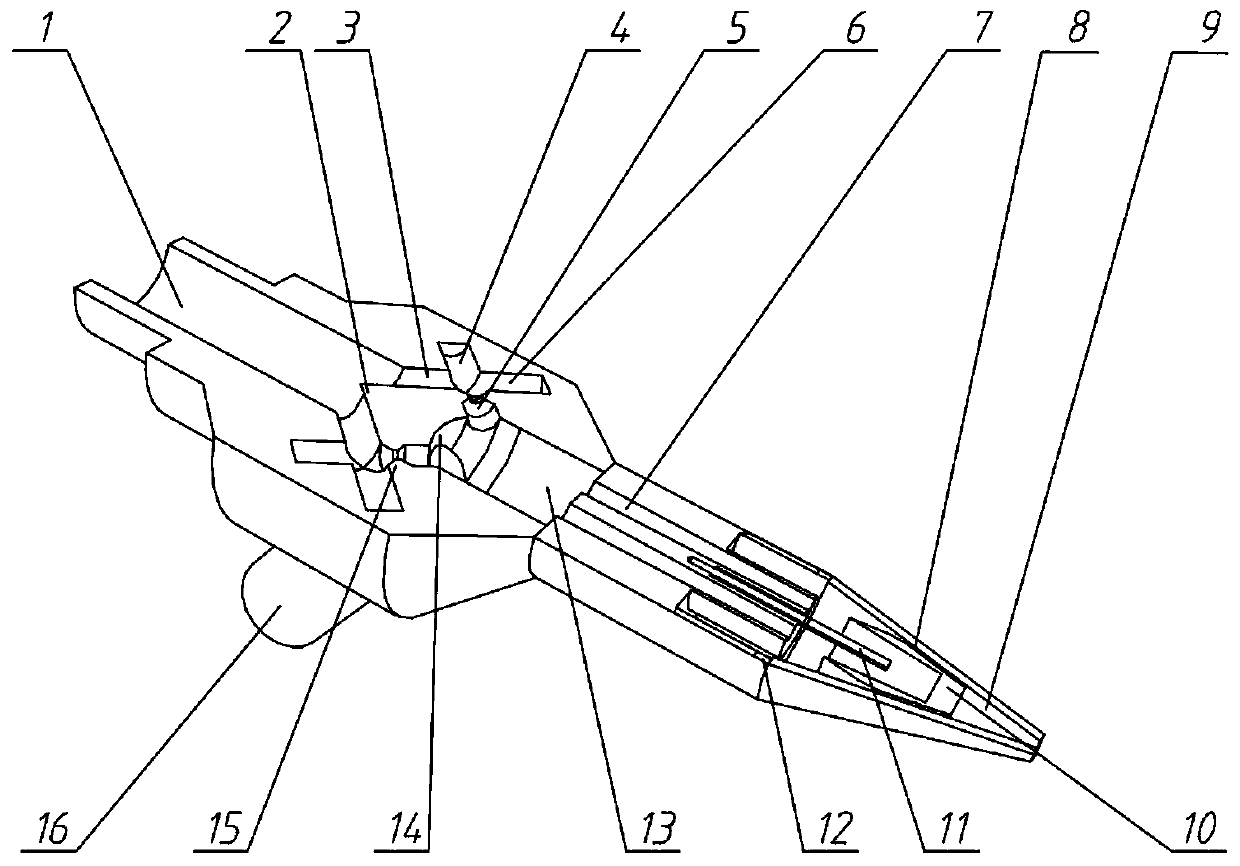

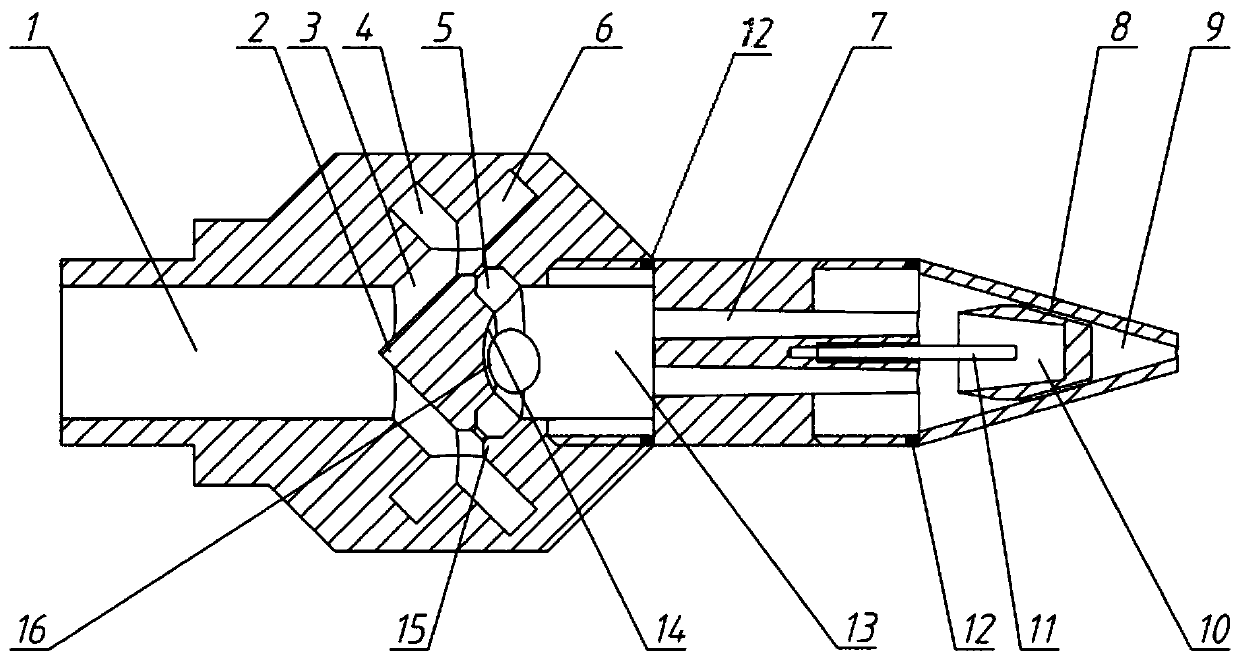

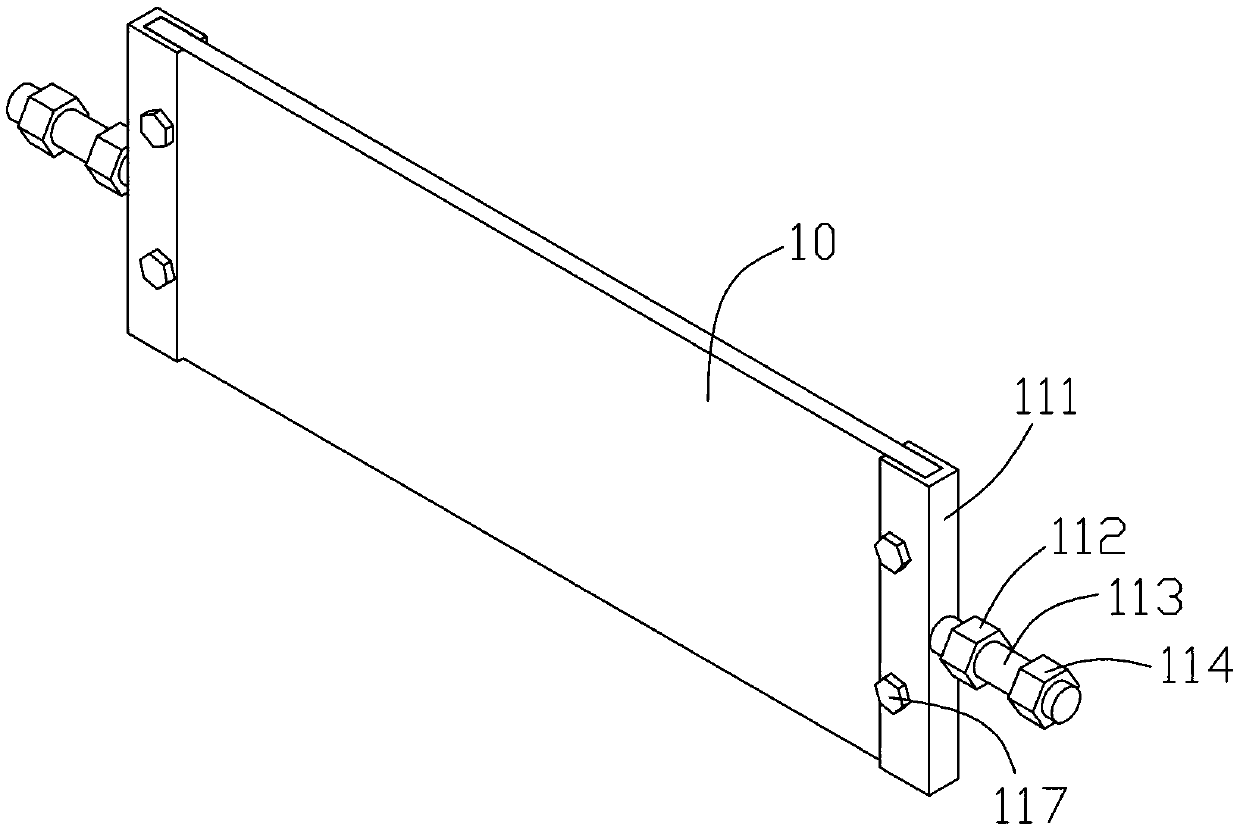

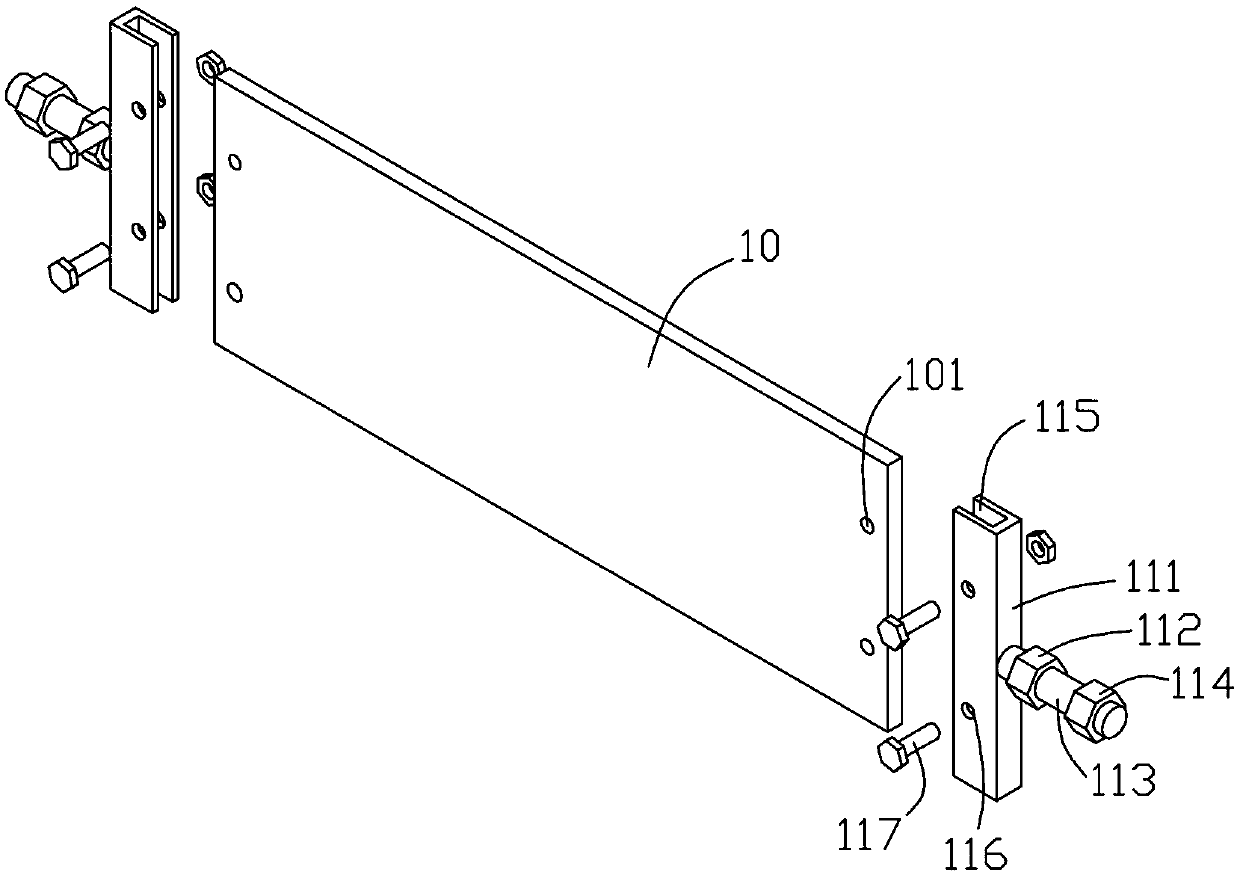

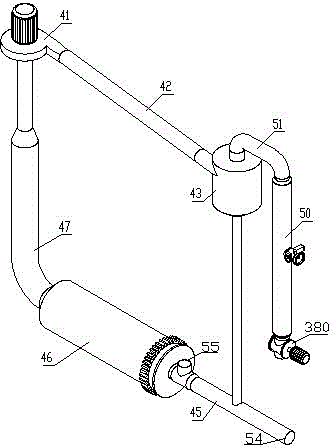

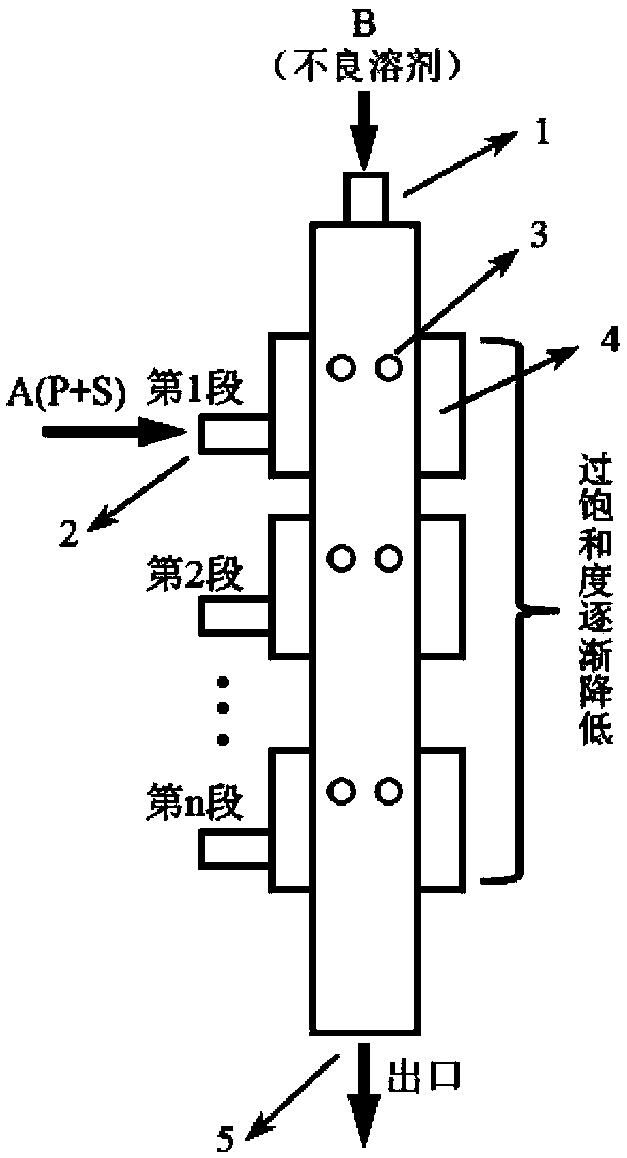

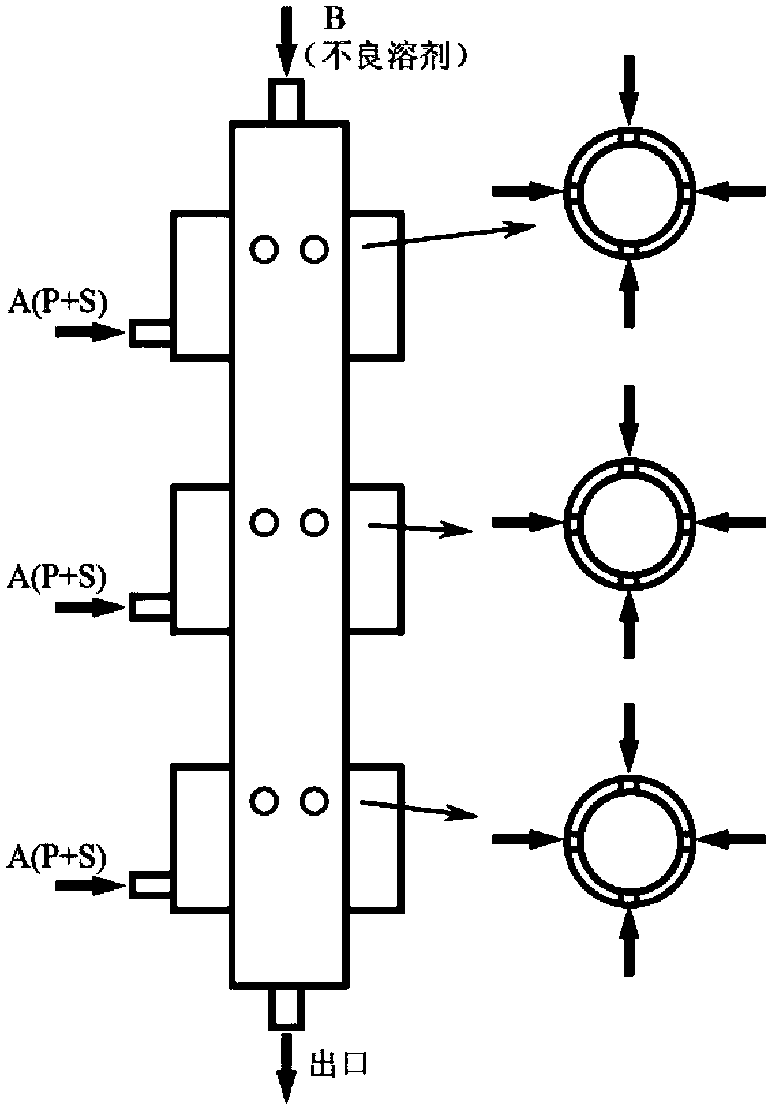

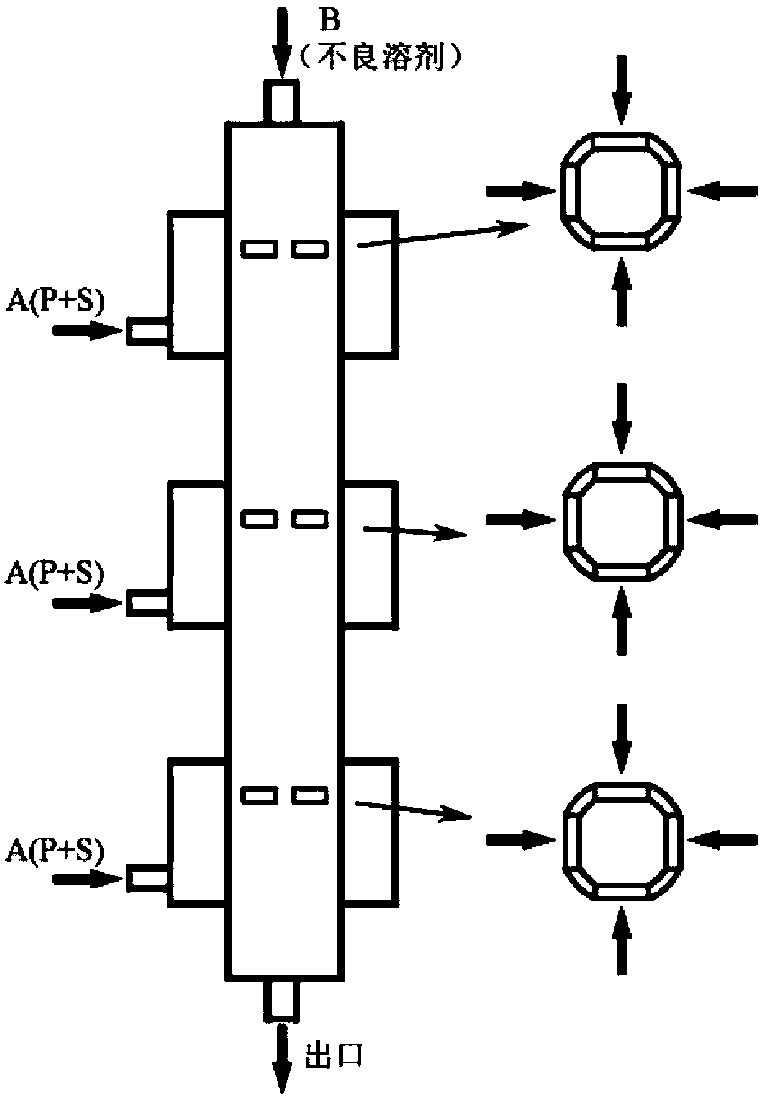

Multi-section feeding type anti-solvent spraying crystallizer and spraying crystallization method thereof

ActiveCN107551599AAdjust particle sizeAdjust its distributionOrganic chemistrySolution crystallizationInorganic saltsAnti solvent

The invention provides a multi-section feeding type anti-solvent spraying crystallizer and a spraying crystallization method thereof. The crystallizer is a tubular crystallizer which is vertically arranged, wherein a main pipe inlet (1) is formed in the upper part of the tubular crystallizer; small holes or slits (2) which are symmetrically distributed are formed in positions with different heights of a main pipe wall from top to bottom; buffering chambers (3) are arranged around the small holes or the slits (2) in the positions with the same height; a side feeding opening (4) is formed in each buffering chamber; a main pipe outlet (5) is formed in the lower part of the tubular crystallizer. According to the multi-section feeding type anti-solvent spraying crystallizer provided by the invention, a solution system A with a certain concentration is prepared by dissolving heterocyclic organic medicine particles, inorganic salt or oxide and particles P of a nitryl energy-containing material into a good solvent S; crude particles P are recrystallized by adopting the tubular crystallizer; the solution system A and a bad solvent are rapidly mixed to continually form a crystal nucleus andthe crystal nucleus grows continually; finally, a suspension solution containing fine particles P is obtained at an outlet of the spraying crystallizer. The particle products obtained by the method have the advantages of controllable grain diameter sizes and distribution, narrow grain diameter distribution and the like.

Owner:SOUTHEAST UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com