Air classification device for steel slag sand production

A steel slag sand and air separation technology, which is applied in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc. problem, to achieve the effect of simple structure, improved air selection efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

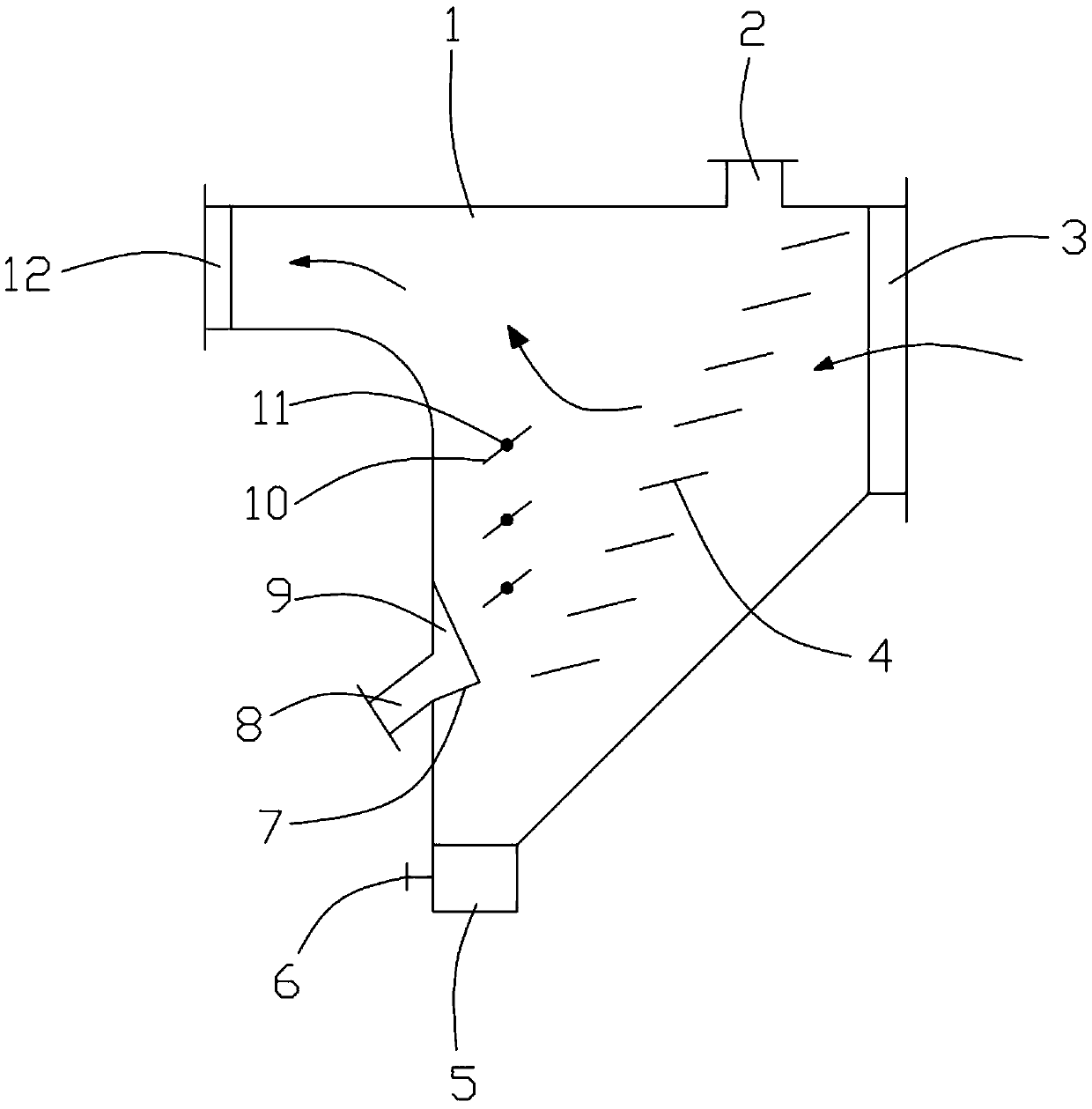

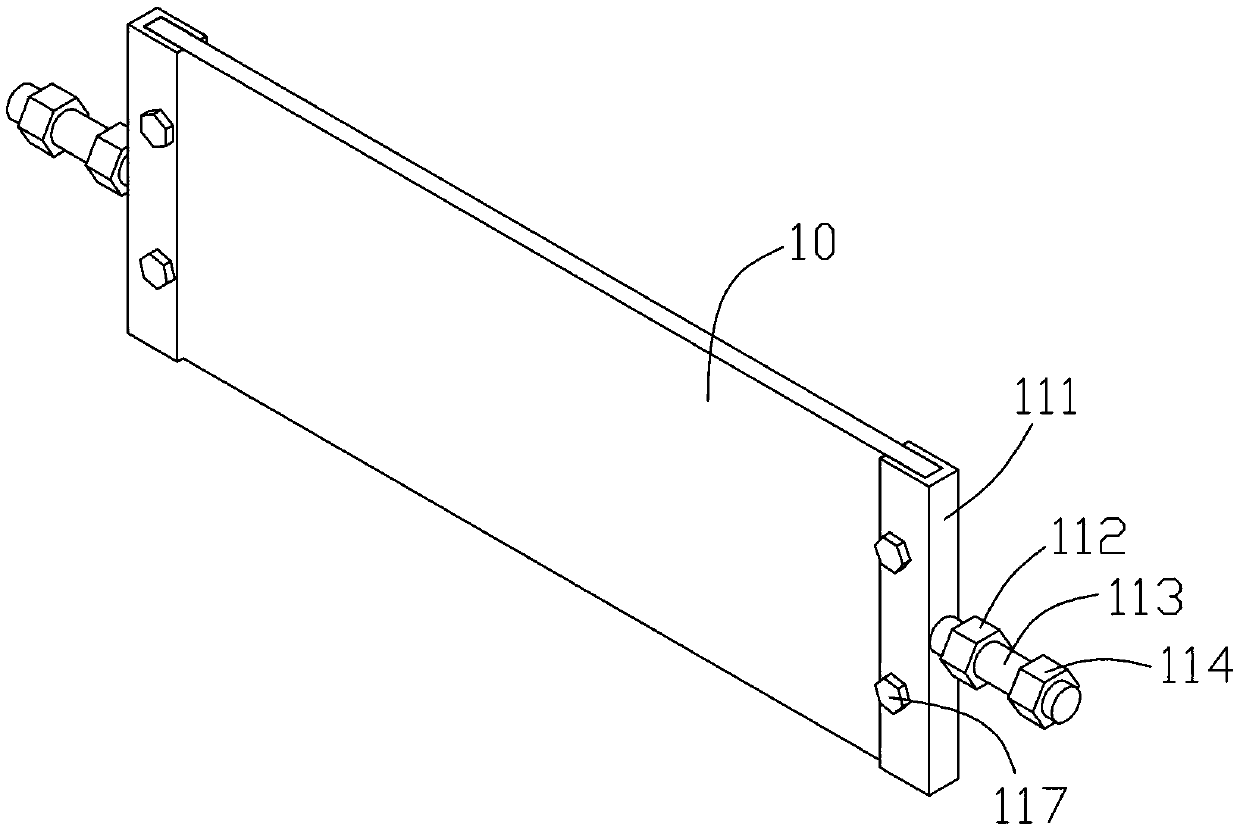

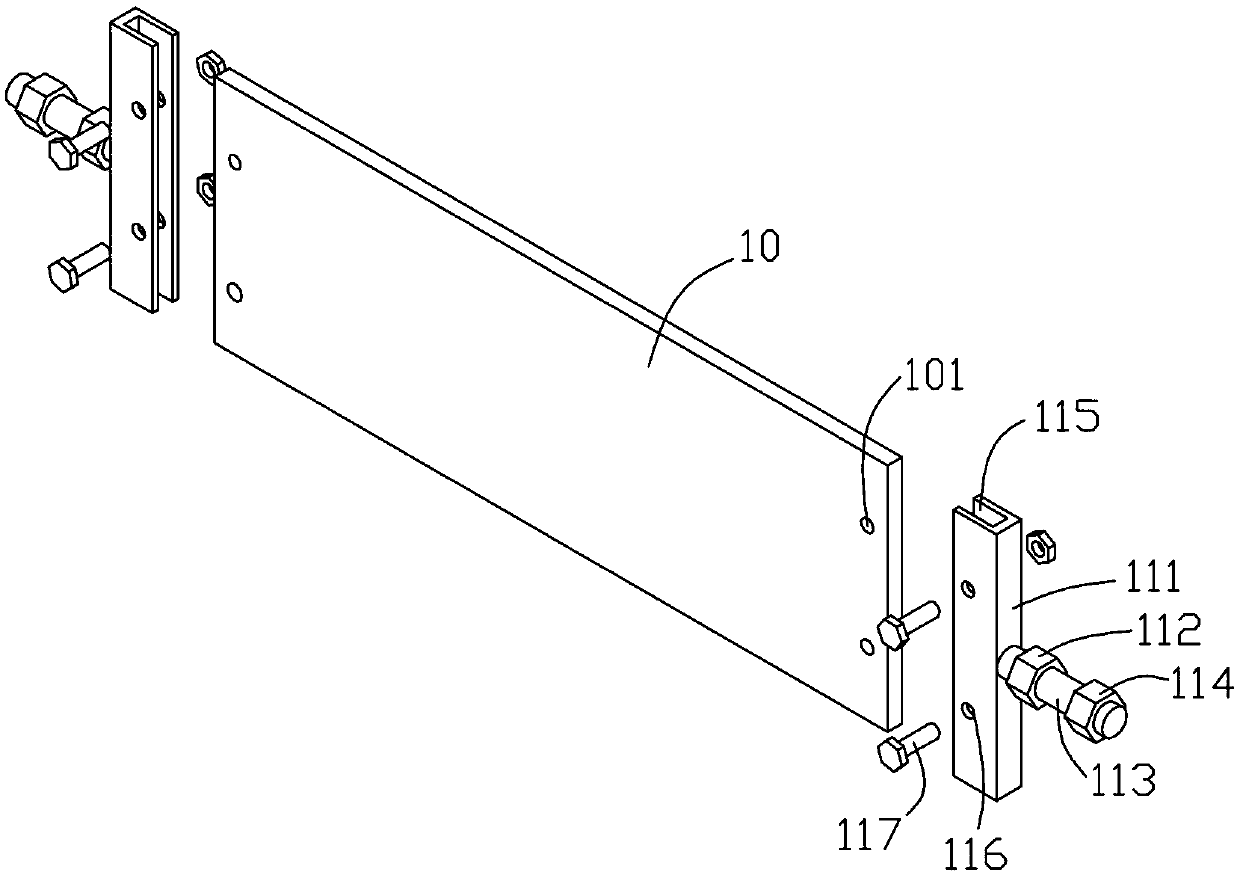

[0034] refer to figure 1 , the winnowing device that is used for steel slag sand production in the present embodiment, comprises V-shaped box body 1 and the first guide plate 10 that is arranged in V-shaped box body 1, the second guide plate 7 and break up plate 4 ; The top of the V-shaped box 1 is provided with a feed inlet 2, and the bottom is provided with a coarse material outlet 5; the upper end of the left side wall of the V-shaped box 1 is provided with an air outlet 12, and the lower end is provided with a middle material outlet 8; The upper end of the right side wall of the box body 1 is provided with an air inlet 3; the breaking plate 4 is distributed below the feed inlet 2 in a step shape, and is used to disperse the steel slag raw material entering from the feed inlet 2, Under the action of the incoming wind, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com