Rapeseed screening equipment for agricultural production and processing

A screening equipment and technology for rapeseed, which are applied in the direction of sieving, separating solids from solids by air flow, and solids separation, etc., can solve the problems of low screening accuracy, low work efficiency, mixed with rapeseed, etc., so as to improve the air separation Efficiency and precision, high work efficiency, the effect of reduced debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

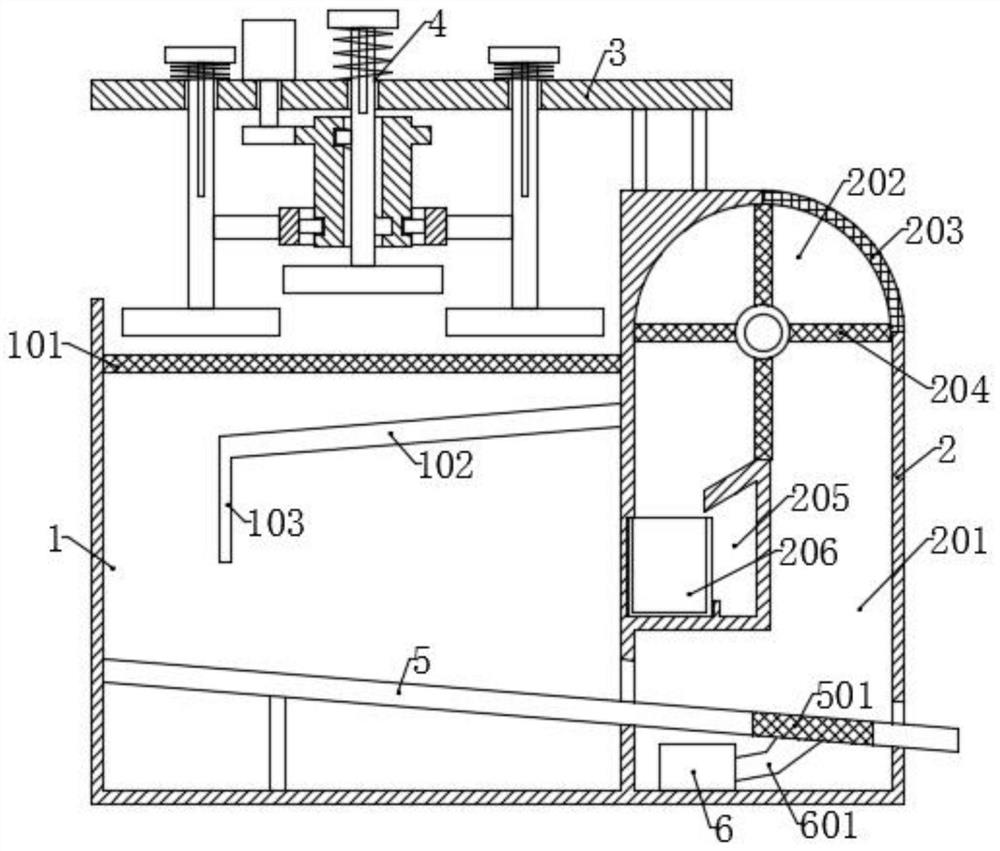

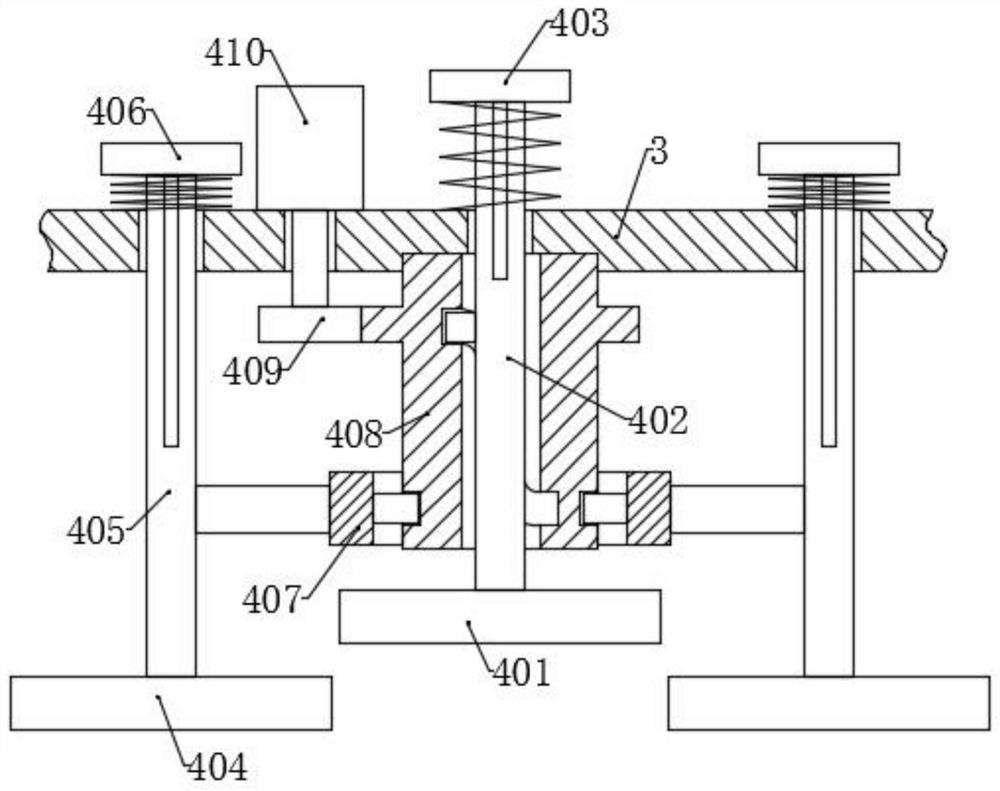

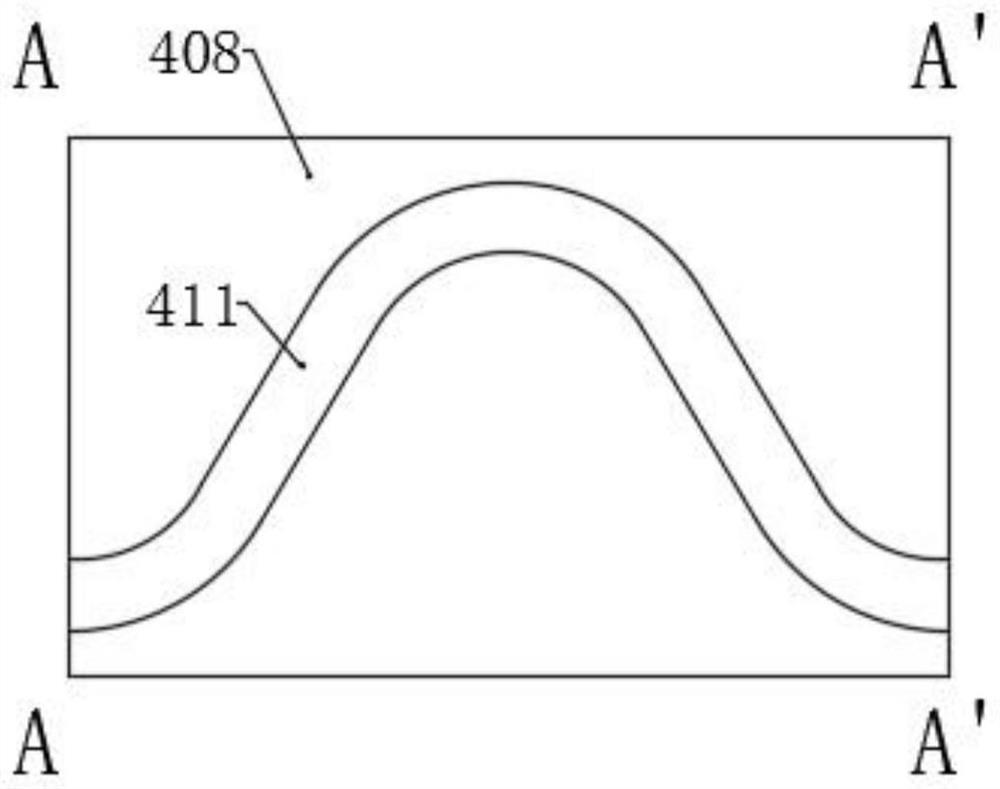

[0036] Please refer to the accompanying drawings, the present invention provides a technical solution: a rapeseed screening equipment for agricultural production and processing, including a separation box 1 and a screening box 2 fixed on the right side of the separation box 1, characterized in that the separation box 1 The upper part of the upper part is fixed with a detachment net 101, the bottom of the detachment net 101 is fixed with an inclined material guide plate 102, and the bottom is fixed with an inclined blanking plate 5, the height of the left end of the described material guide plate 102 is lower than the right end, and the left end is fixed with a vertical Straight baffle plate 103, the height of the left end of the blanking plate 5 is higher than the right end, and the right end passes through the side walls of the separation box 1 and the screening box 2 and stretches out, and the right side wall of the separation box 1 and the screening box 2 The position corres...

Embodiment 2

[0044] On the basis of Embodiment 1, an auxiliary fan 208 is provided on the right side of the bottom of the collection chamber 205, and an auxiliary air duct 209 is provided on the auxiliary fan 208, and one end of the auxiliary air duct 209 is located in the air inlet channel 201, and Inclining to the upper right, the right side wall of the air inlet channel 201 is also provided with an auxiliary fan 208 and an auxiliary air duct 209, which are symmetrical to the auxiliary fan 208 and the auxiliary air duct 209 on the left.

[0045] The working principle of this embodiment is basically the same as that of Embodiment 1, the difference is that when the debris in the rapeseed enters the air inlet channel 201, the auxiliary fan 208 and the auxiliary air duct 209 on both sides will make the debris Continue to move upwards, so that the debris can enter the collection chamber 205 smoothly.

Embodiment 3

[0047] On the basis of Embodiment 2, a cam chamber 105 is provided on the right side of the baffle plate 103, and a camshaft 702 is rotatably connected to the cam chamber 105, and a third motor is connected to one end of the camshaft 702, and the detachment box 1 is provided with a spring groove 104 on the left side wall, and a vibration spring 701 is arranged in the spring groove 104. The right end of the vibration spring 701 is connected with the first sieve plate 7, and the right end of the first sieve plate 7 passes through the baffle plate 103 and extend into the cam cavity 105, and the extending end is fixed with a fixed plate 704, and the fixed plate 704 is correspondingly connected with the camshaft 702.

[0048] After the rapeseed is detached from the stalk, it falls on the material guide plate 102 through the detachment net 101. When the rapeseed moves to the left end along the material guide plate 102, it falls on the first sieve plate 7, and the third motor drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com