Method for improving quality of magnetite powder pellets

A technology for magnetite powder and pellets is applied in the field of improving the quality of magnetite powder pellets. performance, increased strength, reduced temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

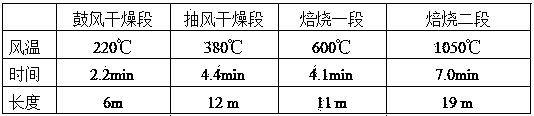

[0033] Example 1: Baseline Example (Prior Art)

[0034] This benchmark example is a conventional grate machine-rotary kiln production process, and the roasting section of the grate machine is longer, while the second roasting section is shorter.

[0035] The specific steps of the pellets prepared by this process are as follows:

[0036] (1) Ingredients:

[0037] Ingredients by weight percentage are:

[0038] Iron Concentrate Powder 98%

[0039] Bentonite 2.0%

[0040] Among them, the iron ore concentrate powder is magnetite powder from Dai County, Shanxi Province, with a particle size of less than 0.044mm (325 mesh) accounting for 96.3%, TFe accounting for 65.3%, and FeO accounting for 27.4%.

[0041] (2) Mixing and pelletizing

[0042] The above ingredients are mixed by a mixer, and then added to the disc pelletizer to replenish water, pelletized to produce pellets, and pellets with a moisture content of 9.0%-9.6% (by weight percentage) are obtained. The pellet particl...

Embodiment 2

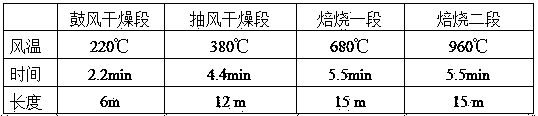

[0050] This embodiment is an example of adjusting the length of the grate roasting stage 1 and roasting stage 2 to produce pellets, wherein the particle size of the pellets is also adjusted.

[0051] (1) Renovate and adjust the length of the first roasting section and the second roasting section of the grate

[0052] By modifying the partition wall inside the grate hood, the partition wall between the first stage of roasting and the second stage of roasting is moved to the direction of the second stage of roasting, and the original first stage of roasting is adjusted from 11 m to 15 m, while the second stage of roasting is adjusted from 19 m Adjusted to 15m;

[0053] (2) Adjust the temperature of the first and second stages of roasting

[0054] Adjust the roasting temperature parameters of the grate machine, increase the temperature of the first stage of roasting from 600°C to 680°C, and reduce the temperature of the second stage of roasting from 1050°C to 960°C.

[0055] (3...

Embodiment 3

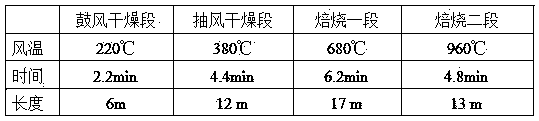

[0080] This embodiment is on the basis of Embodiment 2, and further improves the temperature of the first stage and the second stage of roasting.

[0081] (1) Renovate and adjust the length of the first and second stages of grate roasting

[0082] By modifying the partition wall inside the grate hood, the partition wall between the first stage of roasting and the second stage of roasting is moved to the direction of the second stage of roasting, and the original first stage of roasting is adjusted from 11 m to 17 m, while the second stage of roasting is adjusted from 19 m 13m;

[0083] (2) Adjust the temperature of the first and second stages of grate roasting

[0084] Adjust the roasting temperature parameters, increase the temperature of the first stage of roasting to 700°C, and increase the temperature of the second stage of roasting to 980°C.

[0085] (3) Ball making

[0086] The types and proportions of iron ore powder and bentonite used for pelletizing are the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com