Patents

Literature

151results about How to "Improve metallurgical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

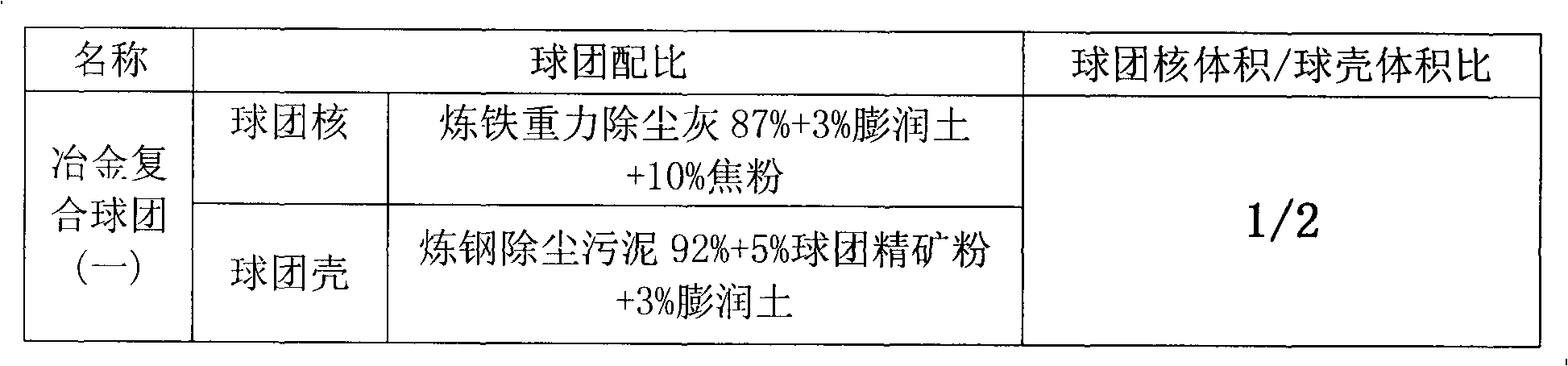

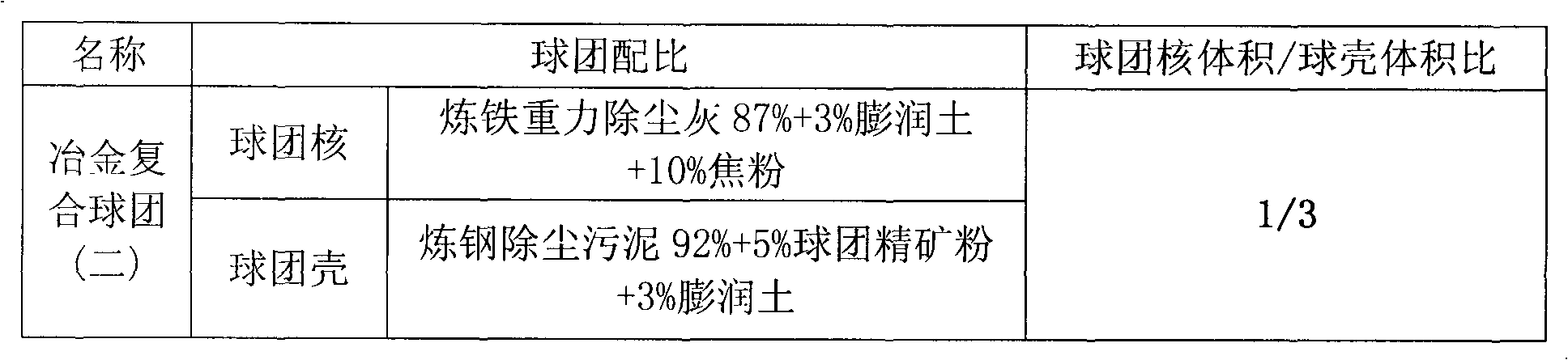

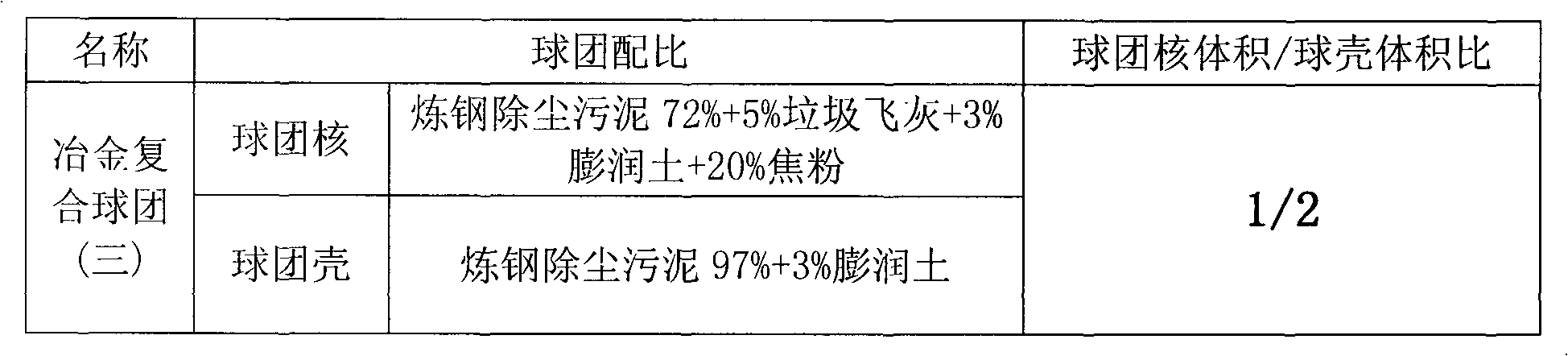

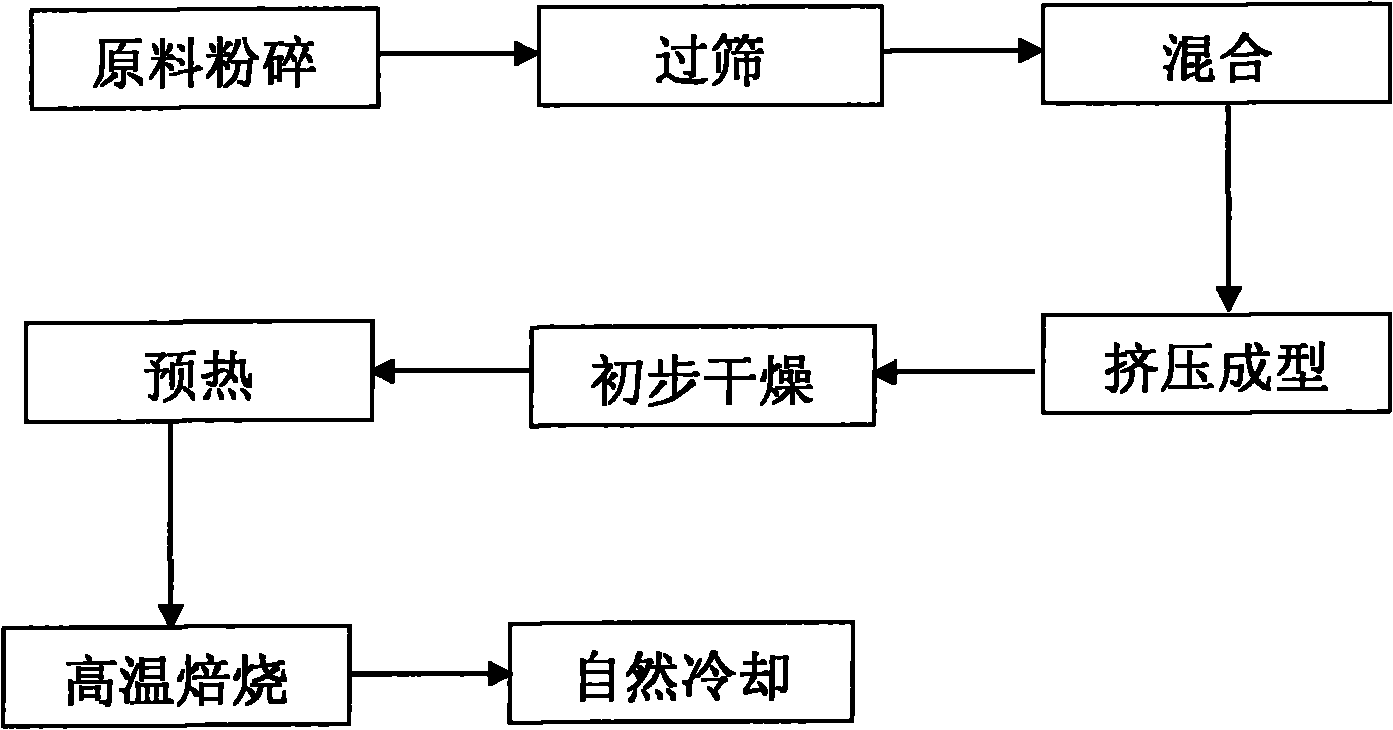

Metallurgical composite pelletizing prepared through twice pelletizing method, as well as preparation method and application thereof

ActiveCN101613800AImprove iron gradeIncrease valueBlast furnace detailsManufacturing convertersSocial benefitsAdhesive

The invention provides a metallurgical composite pelletizing prepared through a twice pelletizing method, as well as a preparation method and an application thereof. The pelletizing is provided with a pelletizing shell formed by a central pelletizing core and a pellet material coating the outside of the pelletizing core. The internal pelletizing core of the formed pelletizing is in a reducing atmosphere, the outside of the formed pelletizing is in an oxidizing atmosphere, and the metallurgical composite pelletizing undergoing twice pelletizing satisfies the metallurgical requirements. The pelletizing core takes an iron-containing material and reducing coal dust or coke powder as raw materials in which adhesive and waste fly dust are added, and is obtained by means of disk pelletization or pressure pelletization. The pelletizing shell takes the iron-containing material and the pelletizing core as raw materials in which the adhesive is added, and is obtained by means of disk pelletization and taking the pelletizing core as the center of the sphere. Various metallurgical performance indexes of the composite pelletizing are highly better than normal pellets. The composite pelletizing not only realizes the harmlessness and the recycling of the waste fly ash, but also can greatly improve the technical and economic indexes of iron making blast furnaces. In addition, the composite pelletizing not only achieves such social benefits as energy conservation, emission reduction, environment protection and environment pollution treatment, but also can create considerable economic benefits.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Purpose of heavy metal sludge, acid pellet and preparation method and purpose thereof

ActiveCN101805827AEnsure the quality of the furnaceImproving the Blast Furnace Charge StructureBlast furnace detailsHeavy metalsSludge

The invention discloses a purpose of heavy metal sludge, an acid pellet and a preparation method and a purpose thereof. The invention takes stainless steel cold-rolling heavy metal sludge as a raw material for preparing the acid pellet of the sludge. The acid pellet of the sludge is mainly prepared by the following raw materials by weight percent: 5-50 percent of stainless steel cold-rolling heavy metal sludge, 30-70 percent of iron ore concentrate, 2-8 percent of composite binding agent, 4-15 percent of carbon powder and 10-30 percent of water. The preparation method of the acid pellet of the sludge comprises the main steps of pretreatment of raw materials, mixing of raw materials, pelletizing and roasting. The acid pellet of the sludge is used as a raw material of a blast furnace. The invention solves the problems that the prior art can not effectively treat and comprehensively utilize the stainless steel cold-rolling heavy metal sludge.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing TiAl alloy plate by argon atomization in powder metallurgy

ActiveCN102513537AThe overall thickness is thinImprove mechanical propertiesMetal rolling arrangementsMechanical propertyImpurity

The invention relates to a method for preparing a TiAl alloy plate by argon atomization in powder metallurgy. The method comprises the following steps of: reducing the content of inclusions in TiAl alloy powders by purity smelting in a cold-wall crucible and high-purity argon atomization; performing hot isostatic pressure compaction on the high-purity prealloy powder which is atomized by pure argon under such conditions that the temperature is 1100 to 1300 DEG C, the pressure is 140 to 200 MPa and the compaction time is 2 to 4 hours; removing coatings of the alloy blank after hot isostatic pressure compaction and then performing surface treatment and coating; heating alloy and rolling at a high temperature; and removing coatings to obtain a powder TiAl alloy plate. The plate has the advantages of uniform deformation, good surface quality, fine and uniform texture, low oxide and impurity contents, small thickness, good overall mechanical property and high quality and reliability. The method solves the key problems in development and application of TiAl alloy powder-metallurgy plates, and provides a technical support for innovation and progress of civil industry and aerospace industry.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Mold powder for continuous casting of high aluminium-titanium-rare earth steel

The invention discloses a mold powder for continuous casting of high aluminium-titanium-rare earth steel, which comprises the following compositions in percentage by weight: 20 to 40 percent of CaO, 30 to 50 percent of SiO2, 3 to 8 percent of F, 5 to 9 percent of Na2O, 0 to 5 percent of Li, 0.5 to 5 percent of C, less than 8 percent of Al2O3, less than 5 percent of MgO and the balance of inevitable impurities; and the alkalinity range of CaO / SiO2 is R+ / -0.05, wherein R is alkalinity and is equal to between 0.917 and 0.333M; and M is the sum of mass percent of Al, Ti and rare earth elements in molten steel. The mold powder improves the performance, can meet the requirement of the continuous casting of steel types such as Al, Ti, rare earth and the like, fully guarantees the thickness, lubrication and consumption of a melt cinder layer, avoids causing surface defects of casting blanks such as cinder inclusion, cracks and the like or causing steel leakage due to too big withdrawal resistance, and effectively guarantees smooth continuous casting process and the surface quality of the casting blanks so as to produce high-quality casting blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

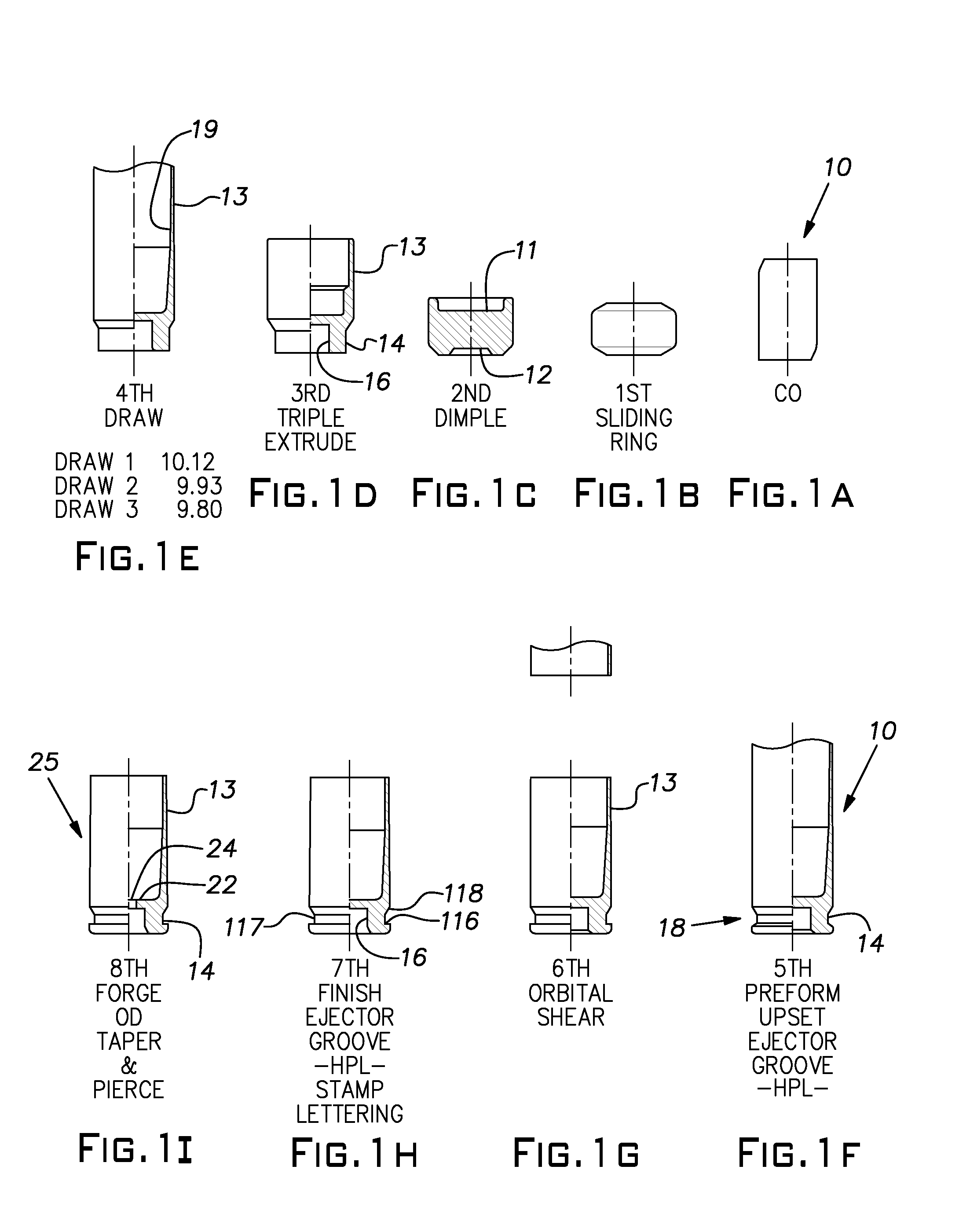

Precision forged cartridge case

ActiveUS20140083319A1Improve propertyLess prone to failureShaping toolsForging hammersEngineeringNet shape

Owner:THE NAT MASCH CO

Furnace protecting acid pellet and production technology thereof

InactiveCN1557976AHigh compressive strengthImprove metallurgical performanceBlast furnace detailsAdhesiveTitanium

The furnace protecting oxide pellet is produced through grinding and mixing V-Ti concentrate and coarse concentrated titanium ore into material containing iron in 52-55 wt% and titania 17-20 wt%, mixing with bentonite as adhesive, stoving at 400-500 deg.c, making raw oxide pellet in a disc pellet making machine, roasting at 1200-1250 deg.c under over oxygen concentration 4-8 % for 15-30 min, cooling in the furnace, and sieving to obtain the furnace protecting oxide pellet with iron content of 50-53 wt%, titania content of 15-18.5 wt%, ferrous content lower than 1.5 wt%, and compression strength of 1500-2800 N each. The furnace protecting oxide pellet has excellent performance, and good furnace protecting effect.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING

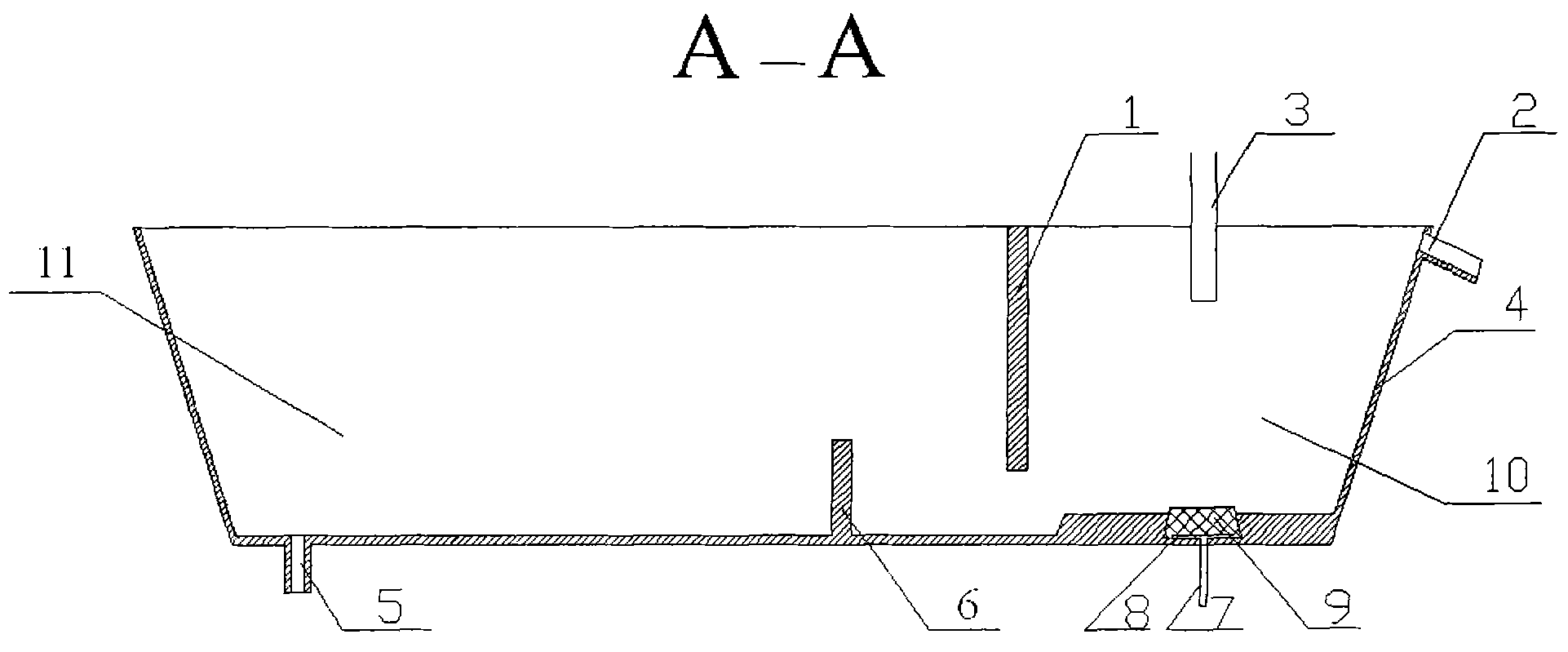

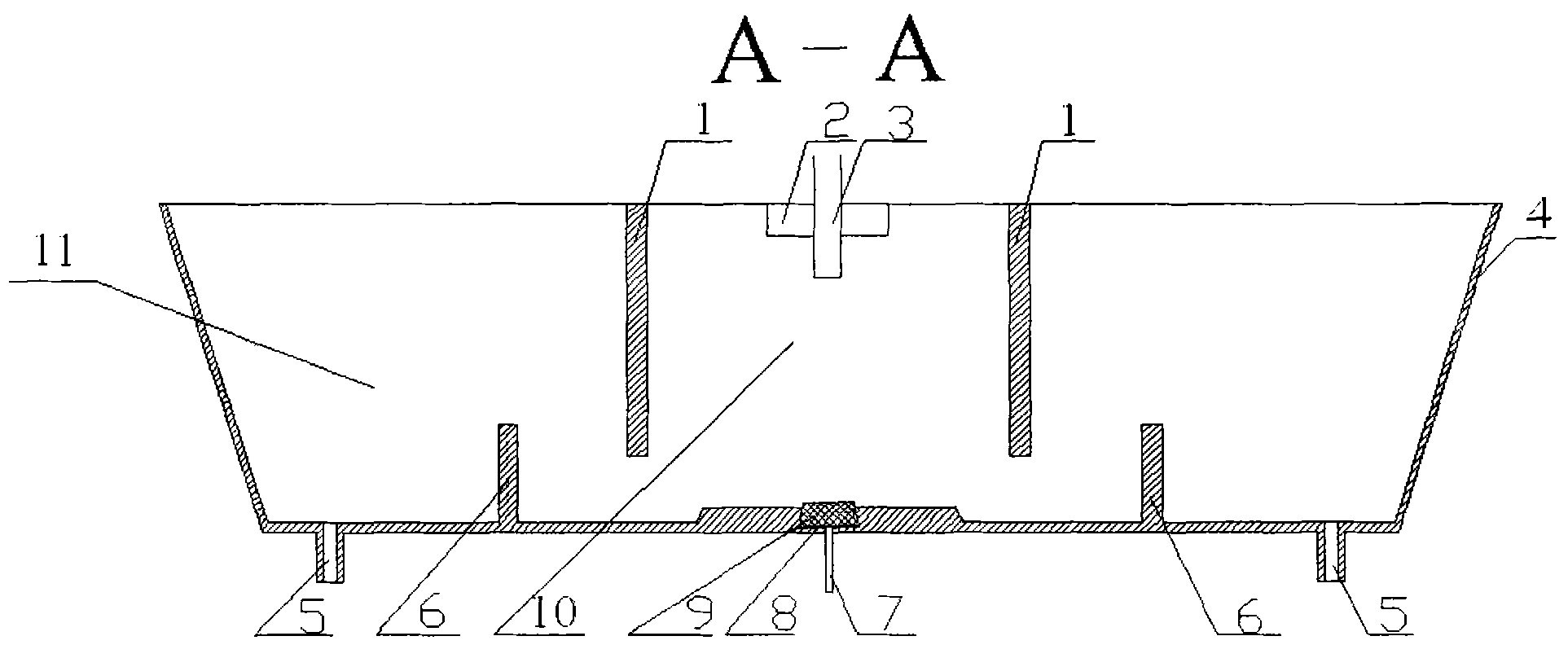

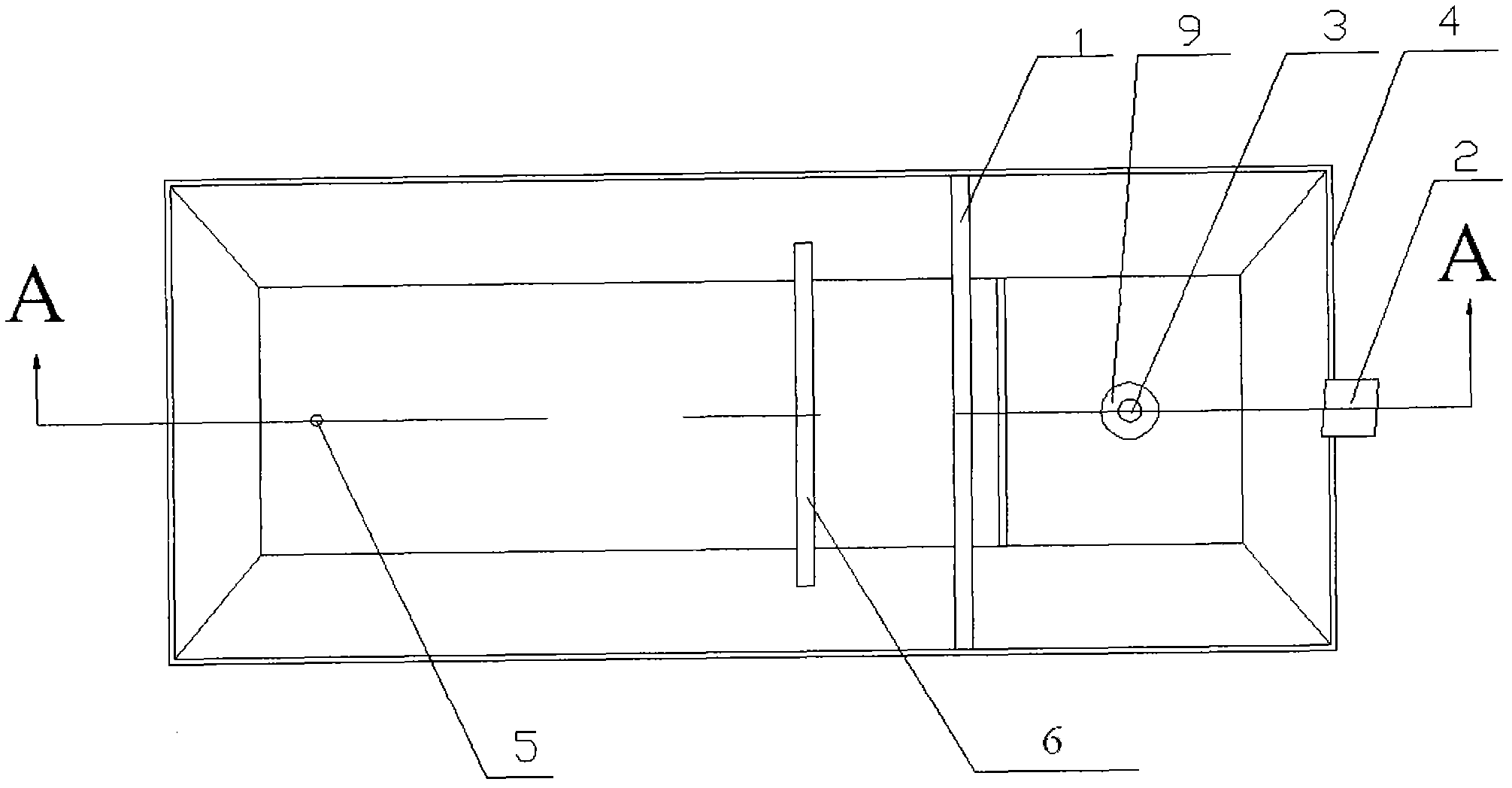

Continuous casting tundish for improving cleanliness of molten steel

The invention discloses a continuous casting tundish for improving cleanliness of molten steel and belongs to the field of ferrous metallurgy technology. The continuous casting tundish comprises a tundish, porous bricks, an overflow groove, a slag blocking wall and a dam. The continuous casting tundish for improving cleanliness of molten steel provided by the invention makes full use of the double effects of argon foam stirring and cleaning, is safe, practical, simple and convenient, can obviously improve the separation effect of impurities and gases in the molten steel and improve the cleanliness of the molten steel and the quality of billet steel and the like.

Owner:SHANDONG IRON & STEEL CO LTD

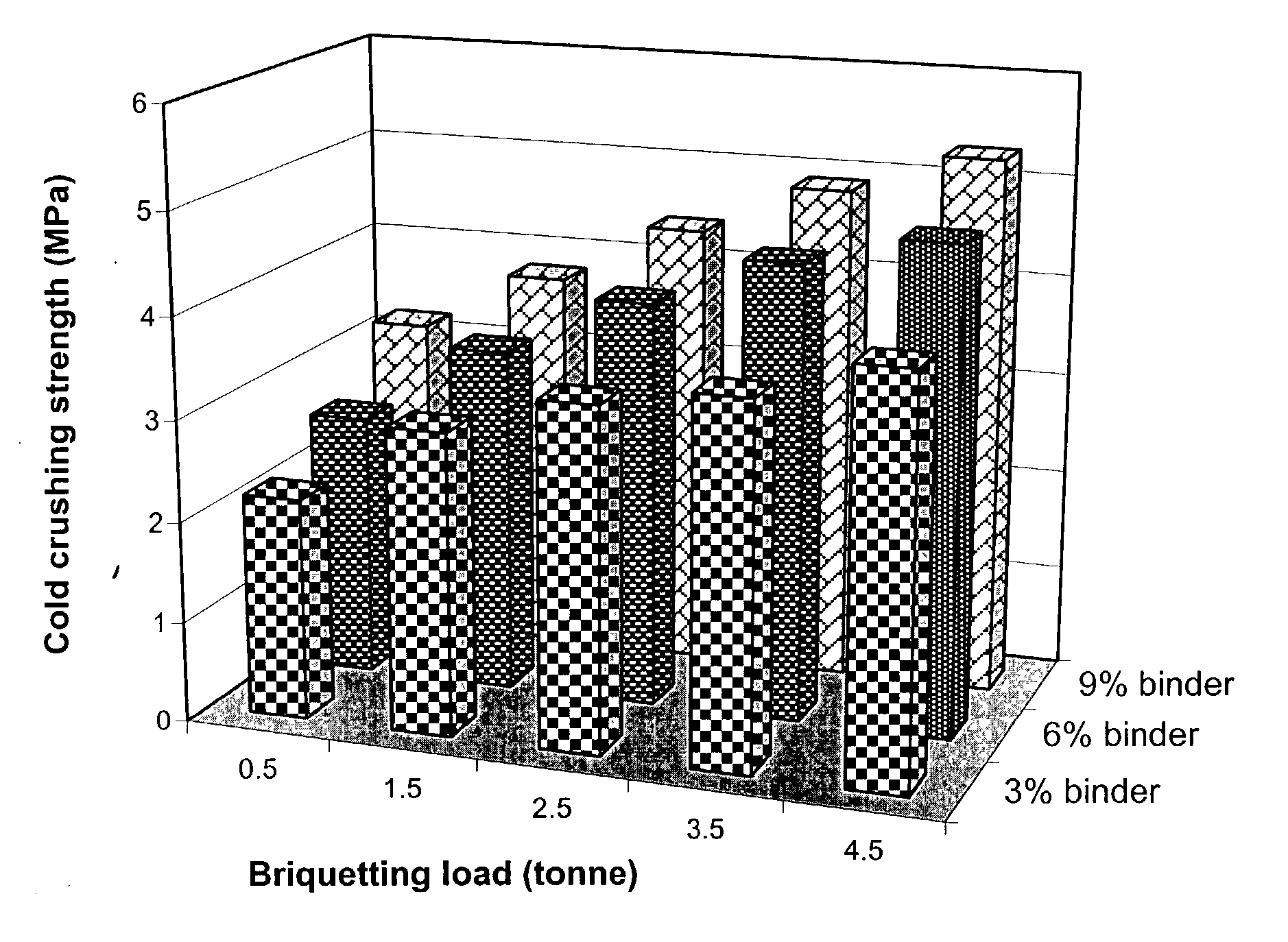

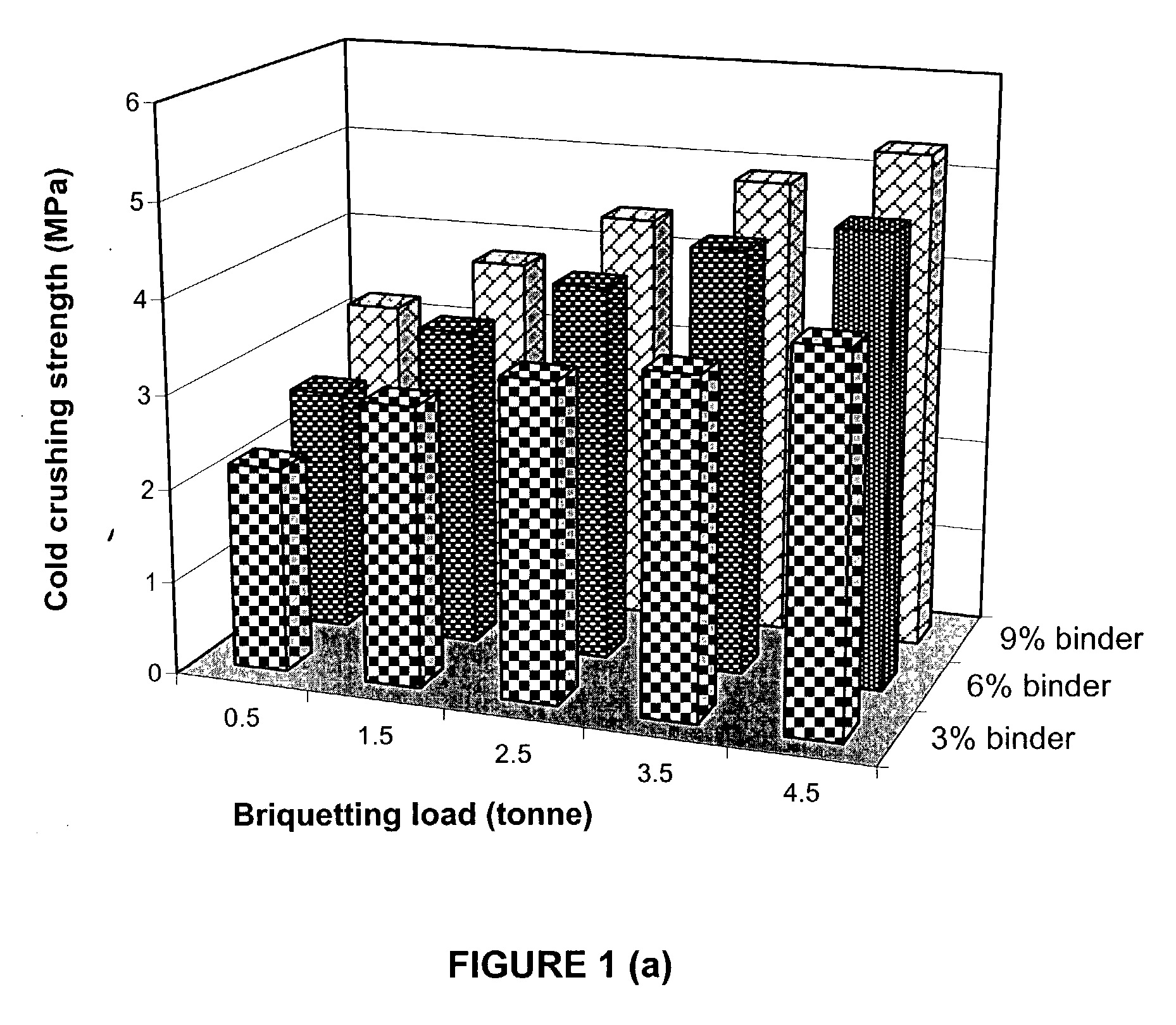

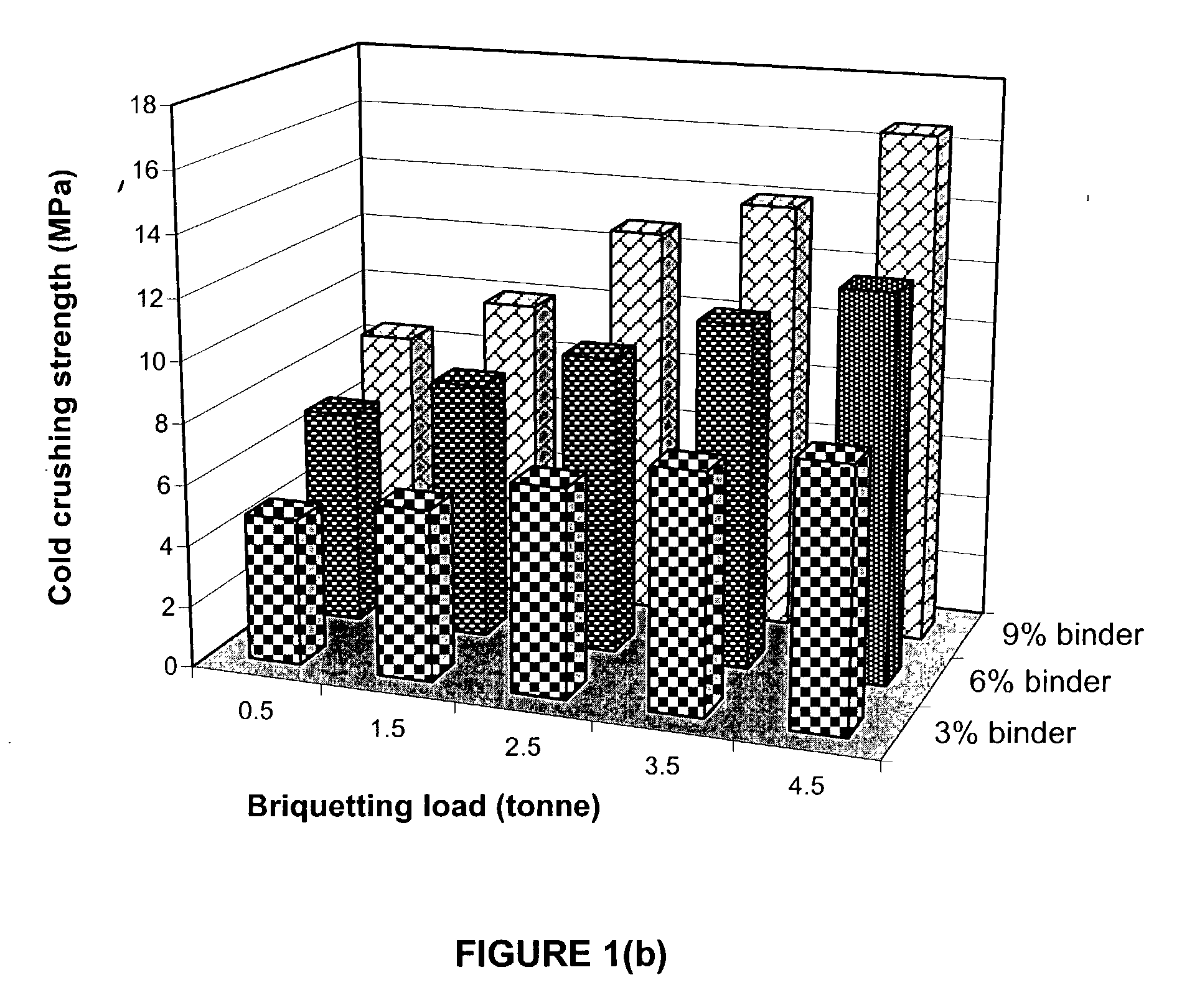

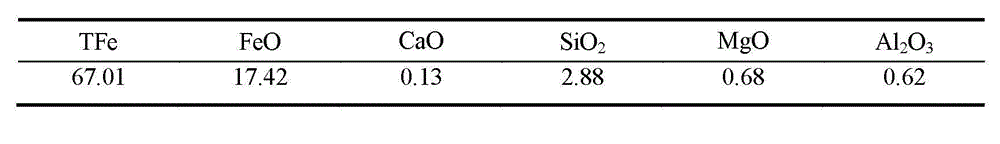

Process for cold briquetting and pelletisation of ferrous or non-ferrous ores or mineral fines by iron bearing hydraulic mineral binder

InactiveUS20040107800A1Eliminate processingEnergy efficiencySolid waste managementProcess efficiency improvementMetallurgyAtmospheric air

The present invention provides a process for cold briquetting and pelletization of ferrous or non-ferrous or mineral fines using iron bearing hydraulic mineral binders for metallurgical applications, said process consisting the steps of: mixing 80-95% by Wt. of a metallurgical / mineral / carbonaceous / oil contaminated dust / fines / sludge with 3-10% by Wt. of an iron bearing hydraulic mineral binder and optionally with 2-6% by Wt. water and 0.05 to 0.20% by Wt. of a surface active agent to form a homogenized dry mix / slurry, pelletizing / compacting the dry mix / slurry to form an agglomerated mass, and curing the agglomerated mass for 3-20 days by exposing the agglomerated mass to atmospheric air for 10-14 hours followed by moisture treatment.

Owner:COUNCIL OF SCI & IND RES

Method for preventing self-fluxed pellets from bonding in roasting

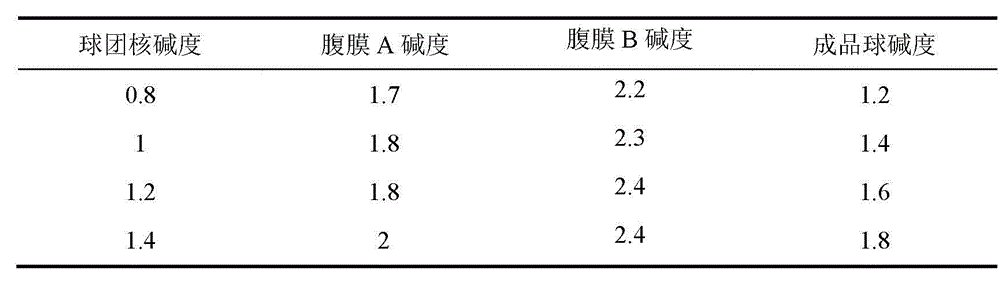

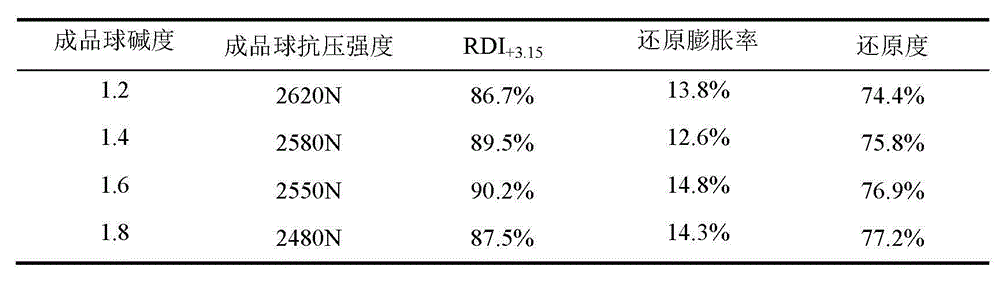

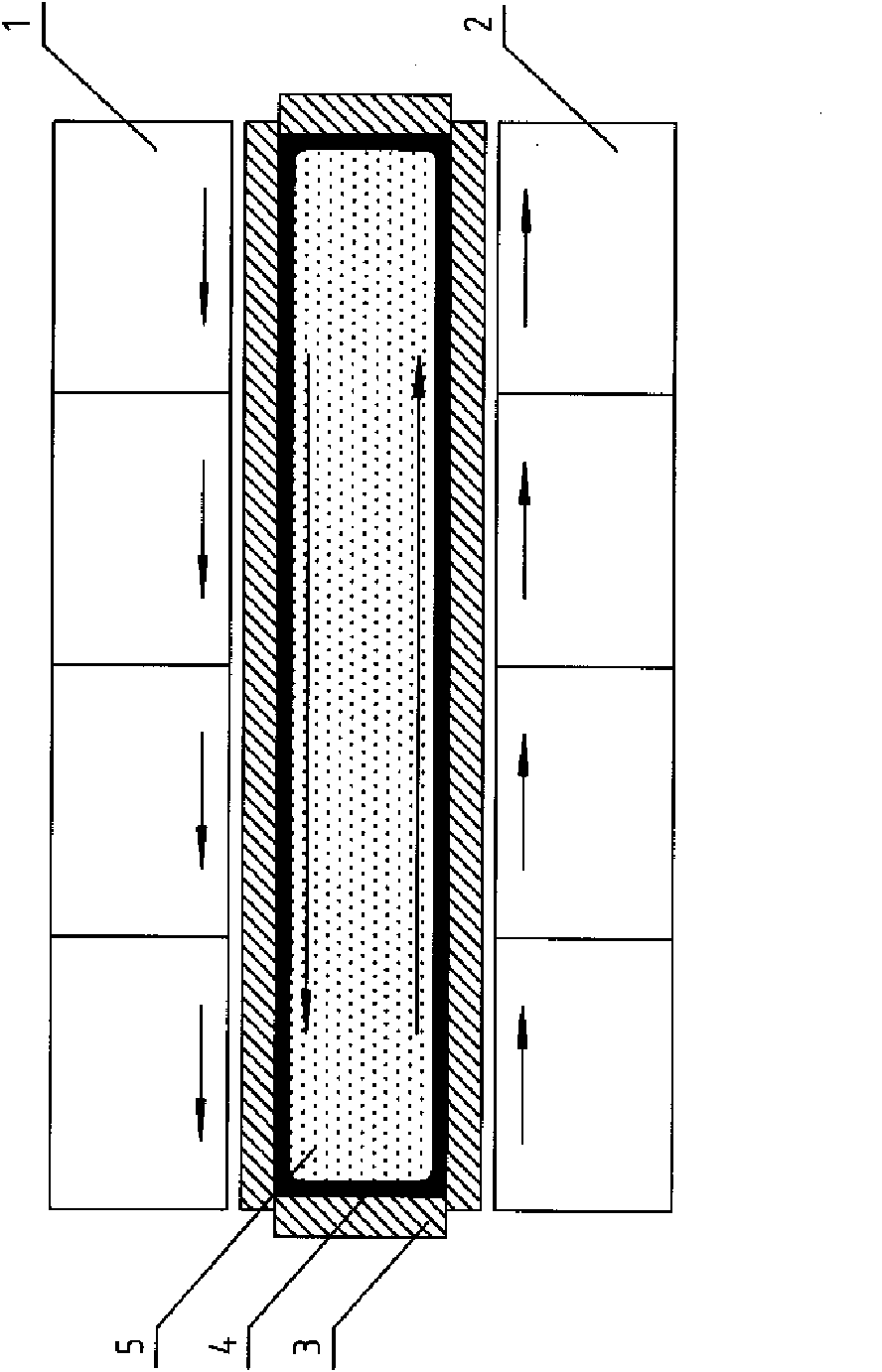

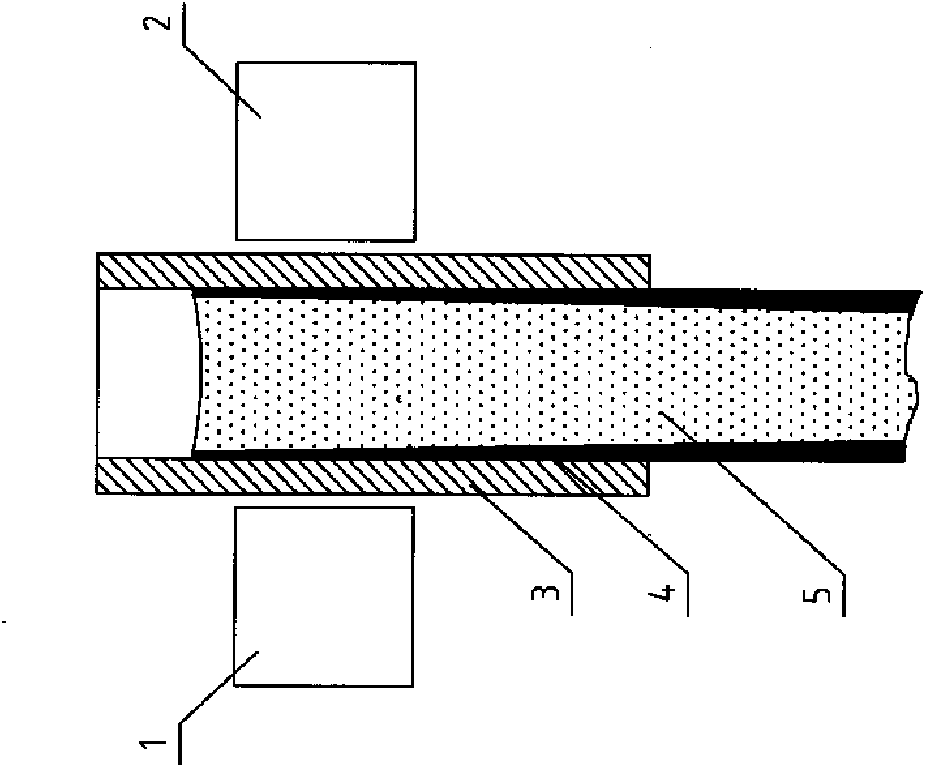

The invention discloses a method for preventing self-fluxed pellets from bonding in roasting. The method comprises technical steps as follows: mixing an iron material, a fusing agent and a bonder to obtain mixture; uniformly mixing dolomite powder and ferroboron flavor powder to obtain a bonding resisting film A; uniformly mixing line powder, ferrum and phosphorus and sodium carboxymethylcellulose to obtain a bonding resisting film B; positioning self-fluxed pellet cores into a balling tray; wrapping watered pellet cores by the bonding resisting film A, then wrapping by the bonding resisting film B; transferring raw balls into a roasting furnace or a rotary kiln; preheating for 20 minutes at 700 to 800 DEG C; preheating for 10 minutes at 900 to 1000 DEG C; and then roasting for 30 minutes at 1150 to 1200 DEG C, so as to obtain finished-product pellets. The method has the advantages and effects that the self-fluxed pellets are hardly bonded during a roasting process; alkalinity is distributed as gradient, so that a metallurgical performance of the self-fluxed pellets can be favorably improved, a feeding ratio of the self-fluxed pellets can be increased, and therefore, a charging material structure of a blast furnace can be further optimized.

Owner:ANGANG STEEL CO LTD

Pellet ore binder prepared by taking sludge generated in sewage treatment as raw material

InactiveCN102409169AAdhesiveHarmlessSludge treatmentProcess efficiency improvementActivated sludgeMineral Sources

The invention relates to a pellet ore binder prepared by taking sludge generated in sewage treatment as a raw material. The binder comprises sludge in a preliminary sedimentation tank, sludge in a coagulation sedimentation basin or residual activated sludge, wherein the sludge in the preliminary sedimentation tank, sludge in the coagulation sedimentation basin or residual activated sludge are powdery sludge obtained by drying, crushing and treating. The invention also relates to an application and a usage method of the pellet ore binder prepared by sludge. The pellet ore binder prepared by sludge generated in sewage treatment is capable of raising the grade and the metallurgy performance of a furnace ore, reducing the iron-making cost, reducing the resource consumption and energy consumption, minimizing the pollutant discharge capacity and raising the capability of national steel material and product in the competition of international markets. The sludge generated in sewage treatment which is difficult to be treated can be obtained resource utilization with high efficiency, so that the mineral product resource such as bentonite and the like can be saved.

Owner:BEIJING JUNZHIQING SCI & TECH

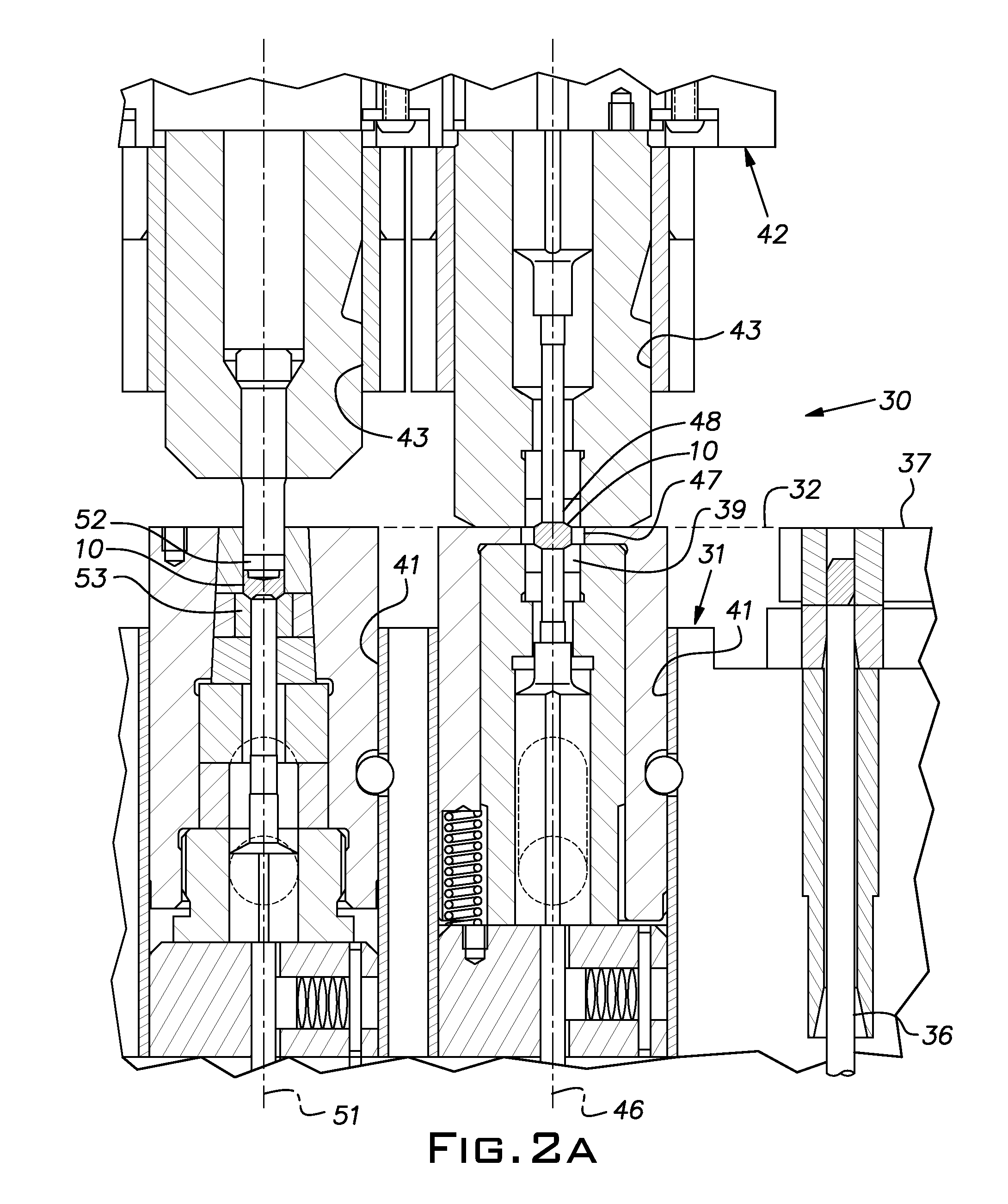

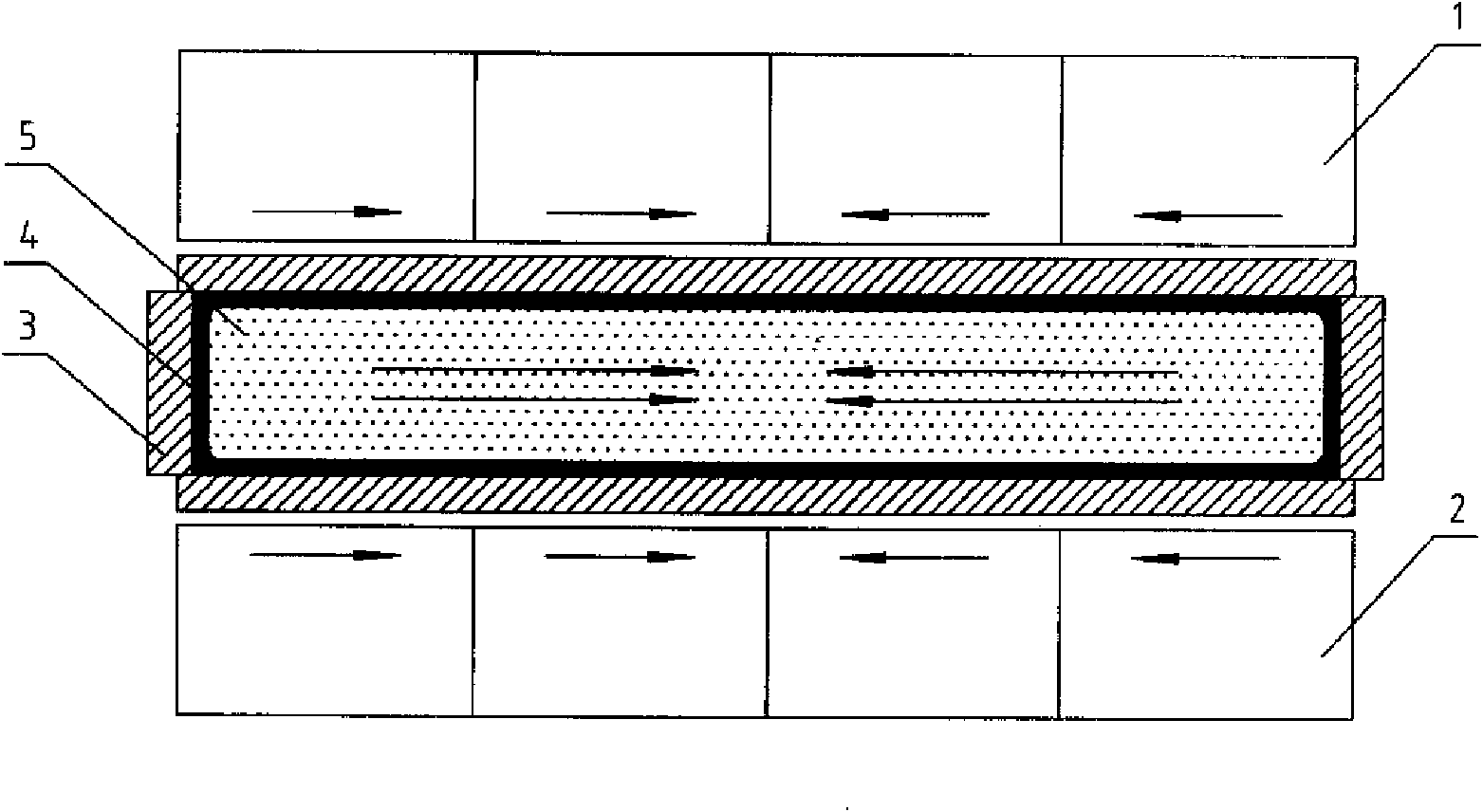

Electromagnetic stirring and flow control device technology for multi-mode bar plate continuous casting crystallizer

InactiveCN101549393AImprove metallurgical performanceAdded stirring functionElectromagnetic shieldingMolten steel

The invention relates to an electromagnetic stirring and flow control device technology for multi-mode bar plate continuous casting crystallizer, which includes respectively setting the inner arc induction apparatus and outer arc induction apparatus which are from electromagnetic stirring induction apparatus at two sides of the crystallizer copper plate, and molten steel passing through the induction apparatus and crystallizer copper plate. The inner arc induction apparatus and outer arc outer arc induction apparatus respectively set at least four magnetic field zone, and the magnetic field size and field direction of each magnetic field zone can be adjusted independently, and by changing the setup of magnetic field, single rotation stirring schema, electro-magnetism slowdown schema, electro-magnetism speedup schema, two zones rotation stirring schema and four zones rotation stirring schema can be combined into. The invention tentatively manufactures one set of multi-mode bar plate continuous casting crystallizer electromagnetic stirring and flow control device by employing slotless and magnetic shading technology, which well accounts for the difficulty of installation, greatly diminishes the alteration cost caused by increasing electromagnetic stirring, and also greatly increases the metallurgy effect of bar plate crystallizer electromagnetic stirring.

Owner:HUNAN ZHONGKE ELECTRIC

High-reducibility pellet and preparation method thereof

The invention relates to a preparation method of a high-reducibility pellet. In the method, hematite concentrate, dehydrated molten iron-smelting sludge, a magnesium-containing additive and a binding agent are mixed according to a mass percentage of 88-95%:1-8%:2.5-5.5%:0.7-1.5%. When the raw materials are uniformly mixed, moisture of the mixed raw materials is controlled to be 4-9%. A wet-grinding process is carried out for 2-9 min, and then a finished product of the high-reducibility pellet is obtained successively through a pelletizing process, a drying process, a pre-heating process and a roasting process after the wet-grinding process finished. The high-reducibility pellet is not less than 60% in TFe, is 1.0-3.0% in MgO content and is 0.8-1.4 in a ratio of CaO to SiO2. By means of the method, not only are problems, such as high temperature during pre-heating and roasting process, a long time and a low strength of the finished product of the high-reducibility pellet and the like, during preparation of an oxidizing pellet by the hematite concentrate are solved effectively, but also the pellet is significantly enhanced in reducing performance, thereby achieving energy conservation and emission reduction during iron smelting.

Owner:BAOSHAN IRON & STEEL CO LTD

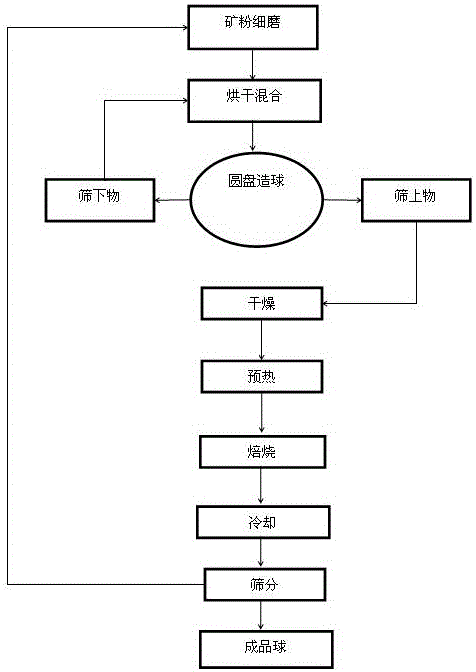

Preparation method of high-vanadium high-chromium type vanadium titanium magnetite pellets

The invention provides a preparation method of high-vanadium high-chromium type vanadium titanium magnetite pellets and belongs to the technical field of blast-furnace smelting in a comprehensive utilization method of high-vanadium high-chromium type vanadium titanium magnetite. The preparation method comprises the steps that wet-grinding is performed on the imported high-vanadium high-chromium type vanadium titanium magnetite, compounding is performed according to a pellet raw material ratio, raw materials are dried and mixed, bottom water is added for material mixing, the materials are braised, pelletizing is performed, fresh pellets are screened, the pellets with the size being 8-16 mm are obtained, then drying and pre-oxidation, shaft furnace roasting and cooling are performed, and the high-vanadium high-chromium type vanadium titanium magnetite pellets are obtained. By means of the method, the problems that the pellet magnetite is prone to superfusion, therefore agglomeration or nodulation is caused, and the yield and quality of the finished pellets are influenced are solved, the quality of the fresh pellets is truly and effectively improved, and the yield and quality of the pellet magnetite are guaranteed.

Owner:NORTHEASTERN UNIV

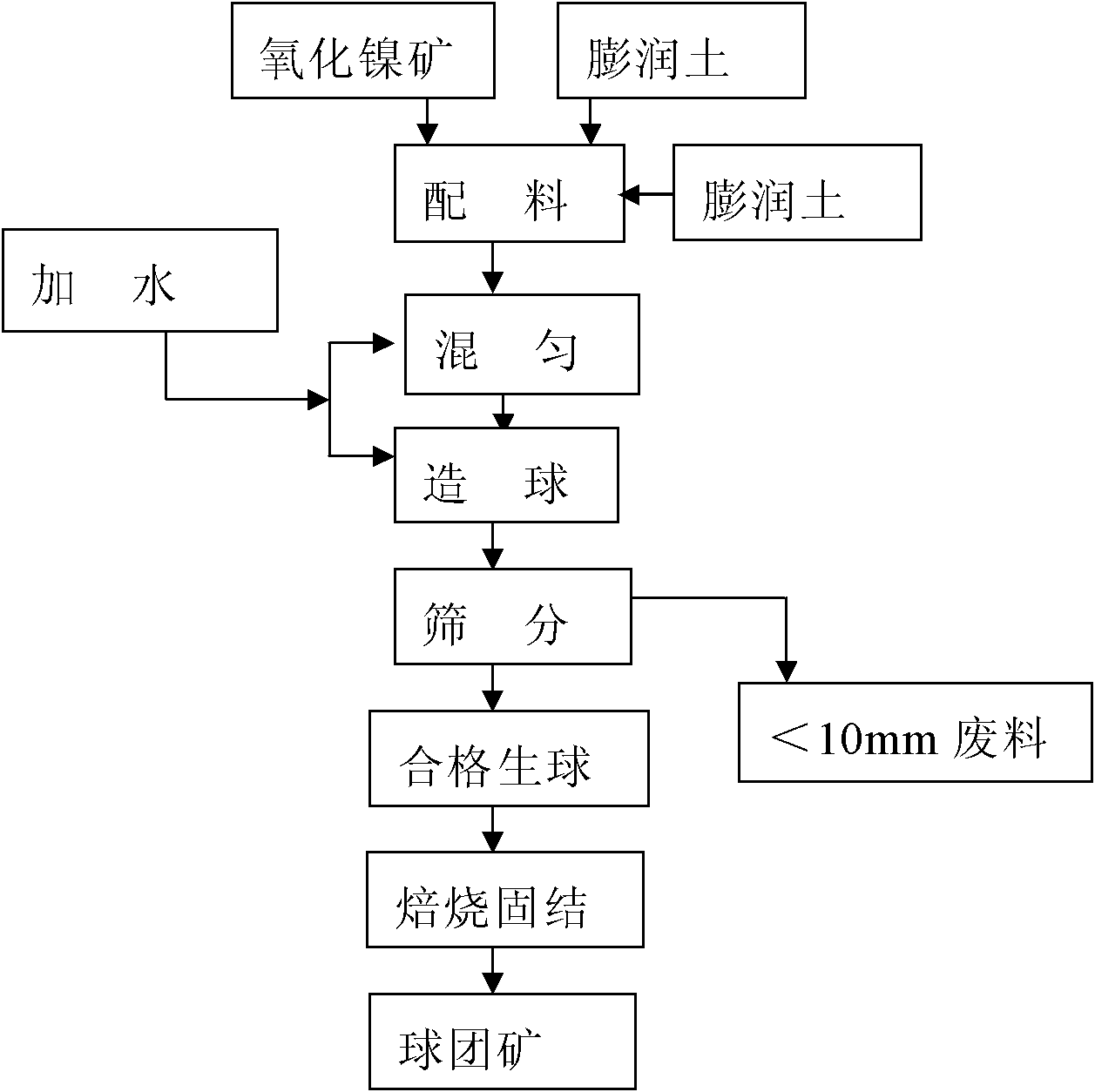

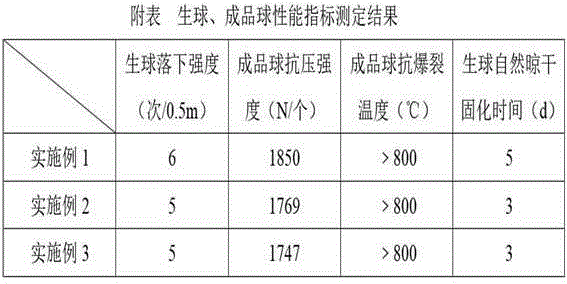

Method for producing pellets from laterite-nickel ore

The invention belongs to production techniques of ferronickel, and particularly relates to a method for producing pellets from laterite-nickel ore, which comprises the following steps: proportioning: evenly mixing 1-4 wt% of bentonite, 1-8 wt% of quicklime and the balance of nickel oxide; pelletizing: adding water to the uniform mixture until the water content reaches 10-15%, and pelletizing by using a pelletizer; screening to remove raw materials of which the particle sizes are smaller than 10mm, thereby obtaining qualified raw pellets; and roasting to solidify, and cooling to obtain the nickel pellets. In the invention, the pellets are made into alkaline ore with a certain alkalinity, and the amount of coke is reduced in the blast-furnace smelting, thereby improving the physical properties of the blast-furnace smelted ferronickel; and in the ferronickel smelting process, the coke ratio is low, the yield is high, and the content of nickel in the smelted ferronickel is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing mixed iron powder cold-pressing pellets

The invention discloses a method for preparing mixed iron powder cold-pressing pellets, belonging to the technical field of metallurgical pellet smelting. The method comprises the following steps: applying a formulated composite binder to compression moulding of mixed iron powder, wherein the proportion of the mixed iron powder is that iron ore powder: scale powder is 70:30; the material proportion in the process of compression moulding is that mixed iron powder: composite binder: water is 100:3.5-3.6:6-8. The method adopts a cold-pressing pelletizing process to prepare the iron power pellets meeting the use requirements, and all the performance indexes of the strength and the cracking temperature of green pellet and the compression strength of finished pellet of the pellets meet the quality requirements of the pellets. The technical problem of iron powder cold-pressing moulding puzzling iron and steel enterprises for a long term is solved. The method can fully utilize the current iron-containing waste in the iron and steel enterprises, solves the residue problem of the iron-containing waste, and achieves the purposes of reasonably utilizing resources and reducing environmental pollution. The method can be suitable for industrial production and has good economic, social and environmental benefits.

Owner:LANZHOU UNIVERSITY

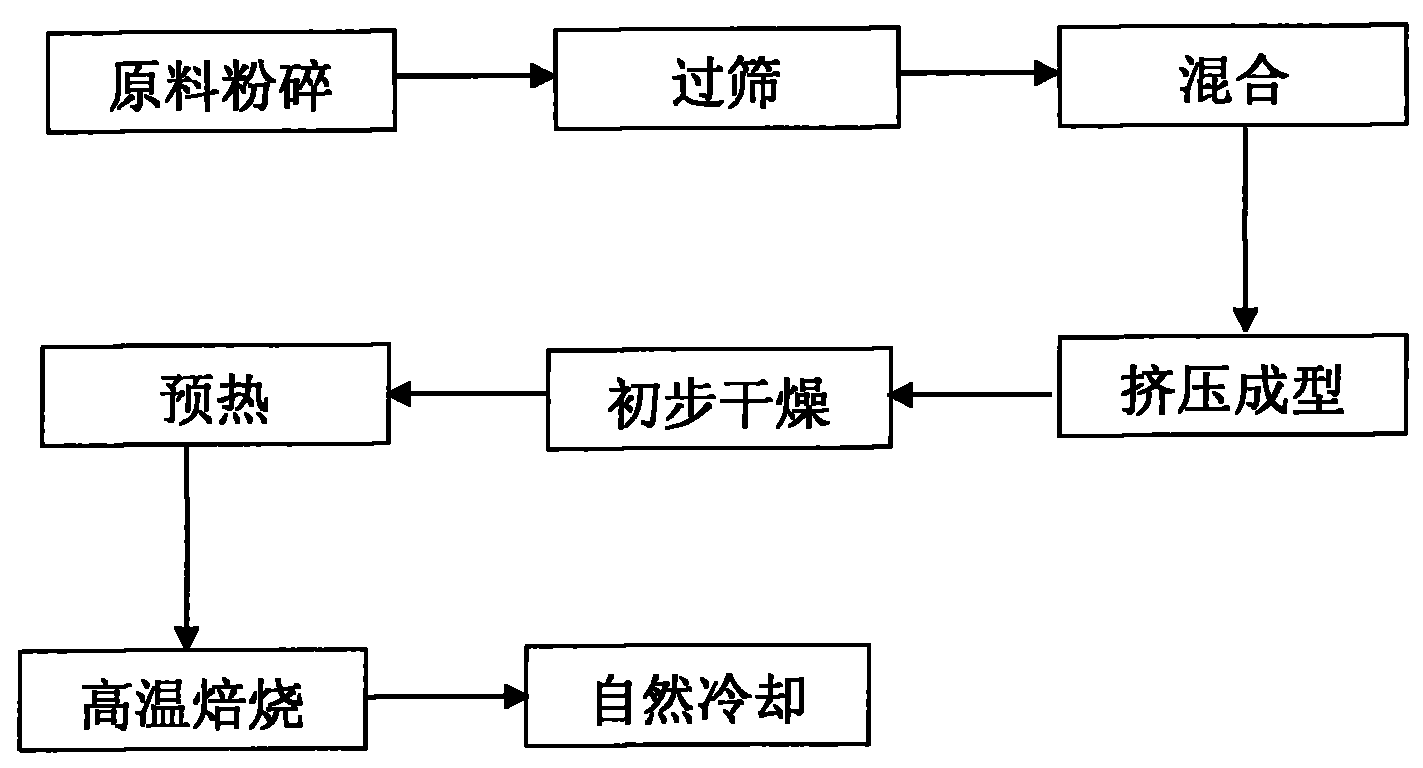

Preparation method of low-silicon high-magnesium iron ore pellets

InactiveCN106119524AReduce expansion and pulverization damageIncrease productivityHigh magnesiumAdhesive

The invention relates to a method for preparing low-silicon high-magnesium iron ore pellets, which belongs to the field of metallurgy technology. The specific method is to pulverize and finely grind iron concentrate to obtain iron concentrate powder, which requires a fineness of -200 mesh ≥ 65%; Concentrate powder and binder are made into a mixture, which is subjected to high-pressure roller milling, drying, and then mixed by a powerful mixer; the mixture is pelletized by adding water to a disc pelletizer, and passed through a vibrating screen to obtain a particle size of 9‑ 15mm qualified green pellets; transported to the grate machine for drying and preheating, and then into the rotary kiln for roasting, after roasting, the high-temperature pellets are cooled and cooled, and the explosive powdered pellets are screened to obtain qualified low-silicon and high-magnesium pellets. The invention uses low-silicon and high-magnesium iron concentrate powder without adding magnesium-containing materials, and only uses ordinary binders to produce ternary alkalinity ≥ 1.5, containing MgO ≥ 3.30%, and containing SiO 2 ≤3.5% pellets.

Owner:HEBEI IRON AND STEEL

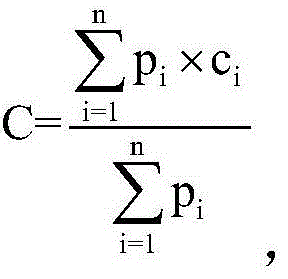

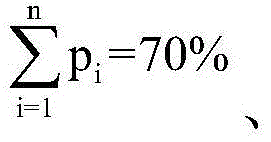

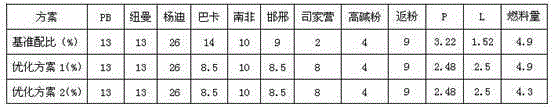

Burdening optimization method for sintering

InactiveCN103911507AImproved metallurgical propertiesCost efficientUltimate tensile strengthMaterials science

The invention discloses a burdening optimization method for sintering. Through adjustment of the using amount of each sintering raw material, sintered ore with high quality can be produced, wherein the yield, the dropping strength, the tumbler strength, the abrasion resistance index, the reducibility, the low-temperature reduction disintegration property, and the like of the sintered ore meet requirements of sintering and iron making production.

Owner:CHONGQING UNIV +1

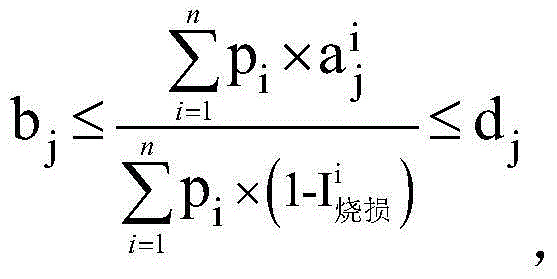

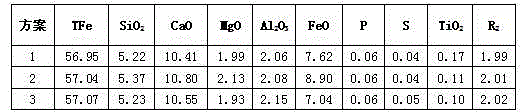

Titanium concentrate and vanadium-iron concentrate bulk concentrate acidic oxidized pellet and preparing method thereof

ActiveCN108359792AGood metallurgical performanceDoes not affect titanium dioxide contentTitaniumRoasting

The invention discloses a titanium concentrate and vanadium-iron concentrate bulk concentrate acidic oxidized pellet and a preparing method thereof, and belongs to the field of metallurgy. The preparing method of the titanium concentrate and vanadium-iron concentrate bulk concentrate acidic oxidized pellet comprises following steps of uniform mixing of titanium concentrate, vanadium-iron concentrate and an organic binding agent, pelletizing, drying, oxidizing roasting, cooling, and obtaining the titanium concentrate and vanadium-iron concentrate bulk concentrate acidic oxidized pellet. The micro-size fraction titanium concentrate and the micro-size fraction vanadium-iron concentrate are used at the same time, the organic binding agent is arranged and used for pelletizing, under the high-temperature oxidizing atmosphere, roasting is carried out to prepare the acidic oxidized pellet, through control over the material proportion, pelletizing,, drying and roasting, the desulfurization degree reaches 95% or above, the pressure resisting strength of the titanium concentrate and vanadium-iron concentrate bulk concentrate acidic oxidized pellet is 1800N / pellet, and the S is smaller than 0.015%, and the application prospect is quite considerable.

Owner:PANZHIHUA UNIV

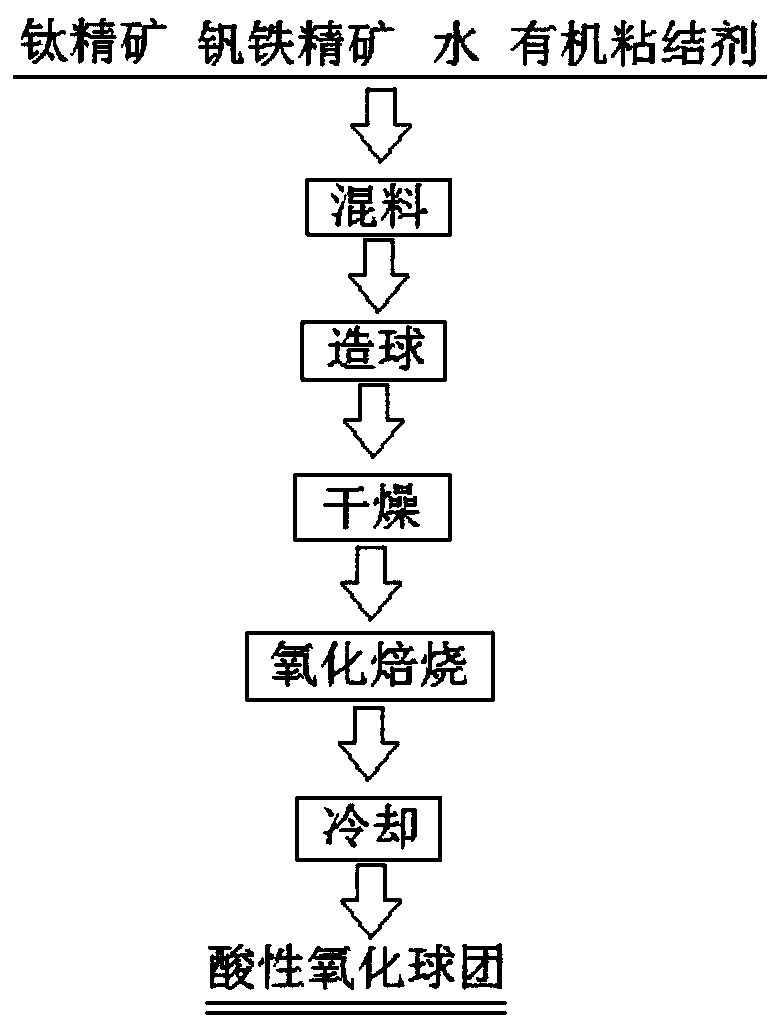

Oxidized pellet production process and system using chain grate-rotary kiln system

ActiveCN110894573AReduce wind temperatureIncrease wind temperatureRotary drum furnacesThermodynamicsProcess engineering

The invention discloses an oxidized pellet production process using a chain grate-rotary kiln system, which comprises the following steps: (1) green pellets are dried, preheated and oxidized through achain grate, then materials passing through the chain grate are conveyed to the rotary kiln to be roasted and then conveyed to an annular cooler to be cooled, and pellet ore is obtained; 2) hot air exhausted from the first circular cooling section is conveyed to the rotary kiln, the hot air exhausted from the rotary kiln is conveyed to a second preheating section, and the hot air exhausted from the second preheating section is conveyed to an air draft drying section in an air draft manner; 3) hot air exhausted from the second annular cooling section is conveyed to the first preheating sectionin an air blowing manner; and 4) the hot air exhausted from the third annular cooling section is conveyed to an air blast drying section in an air blast manner. According to the scheme, hot air is blown into the first preheating section, so that the air pressure in the first preheating section is greater than that of the second preheating section, and gas in the first preheating section does notneed to be denitrified; and meanwhile, a stable hot air area is formed in the first preheating section, and the preheating effect of upper-layer and lower-layer pellets is guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

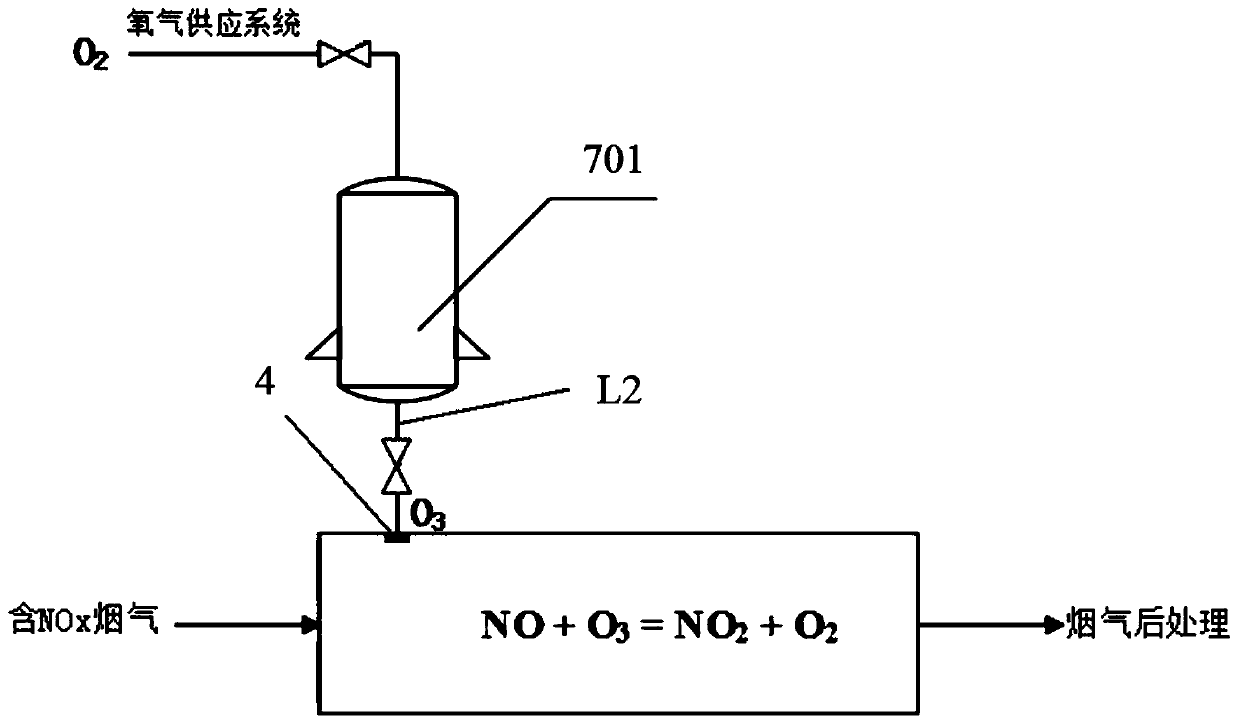

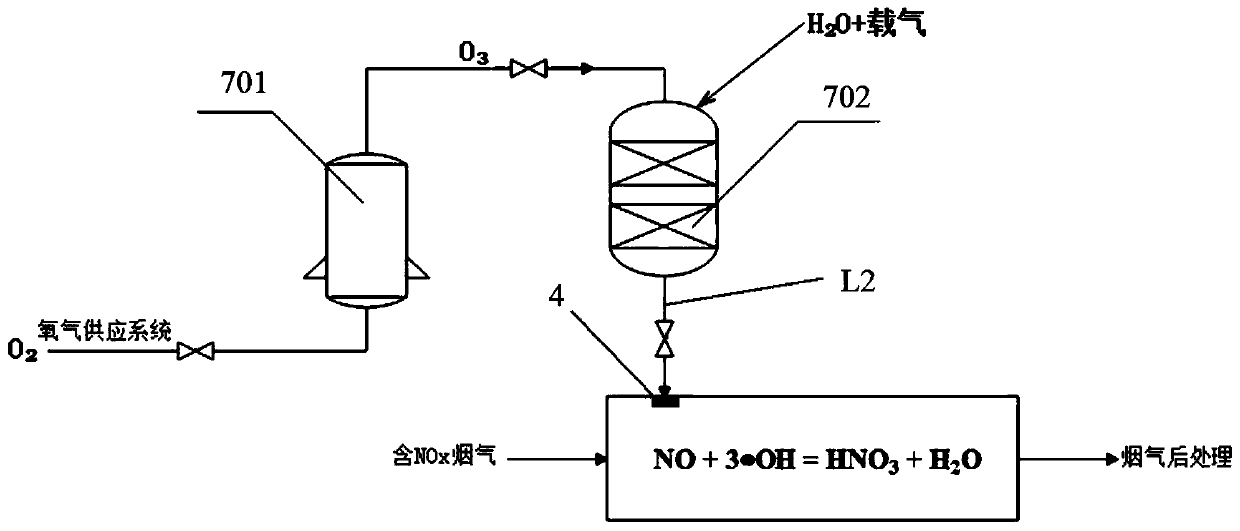

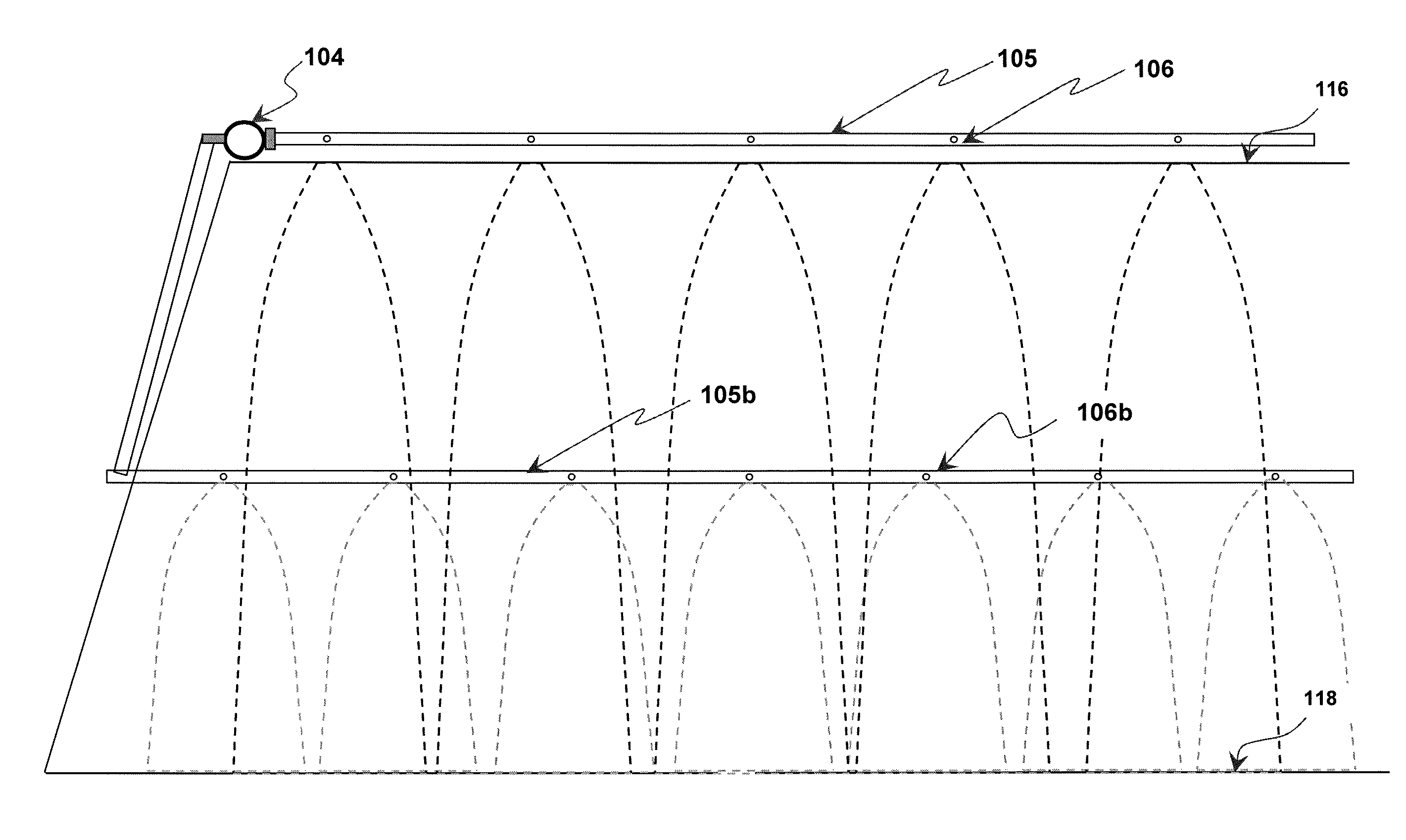

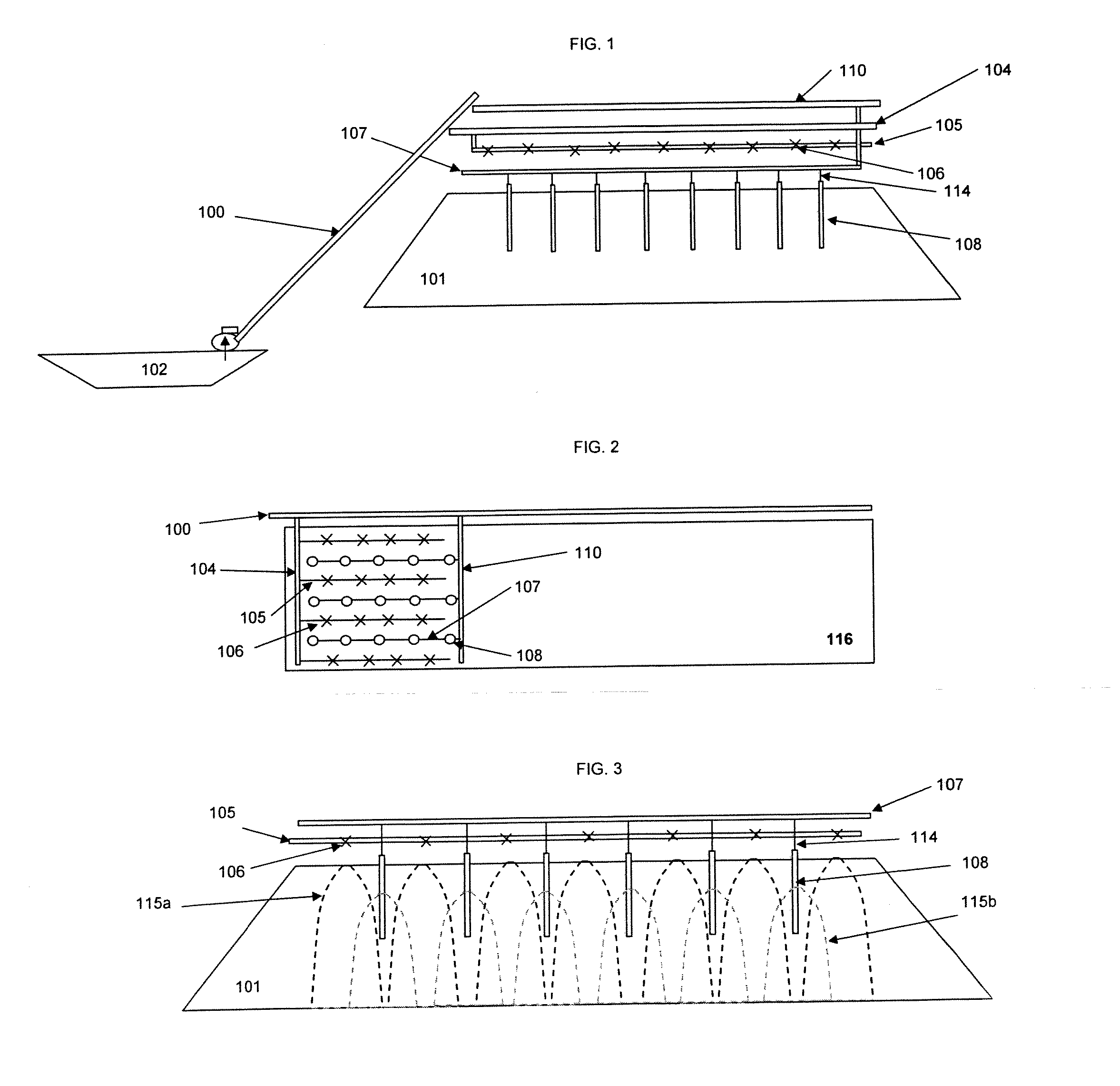

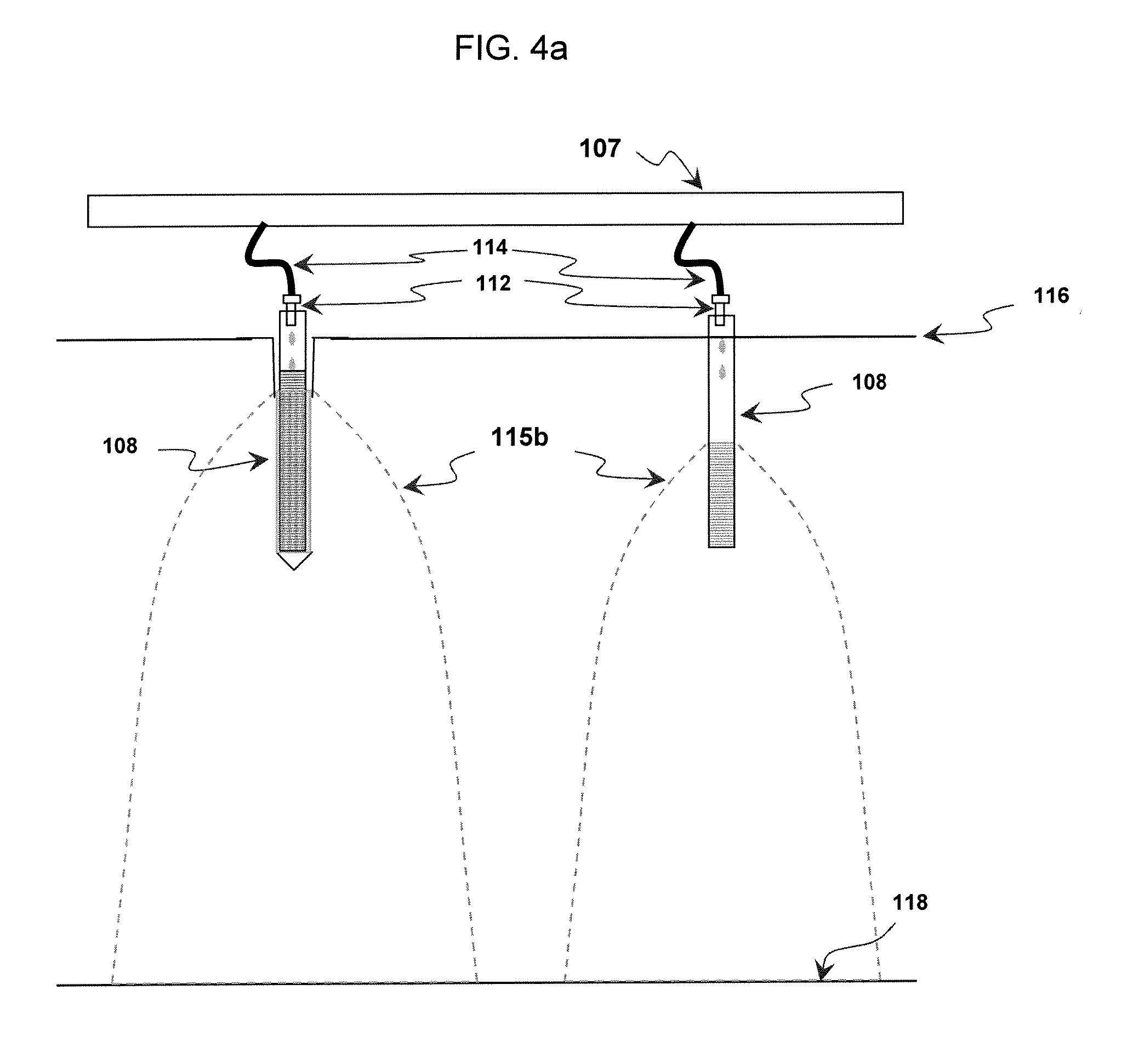

Hybrid Irrigation System

ActiveUS20090230207A1Improve solution deliveryReduce penetrationSolvent extractionWatering devicesPositive pressureEngineering

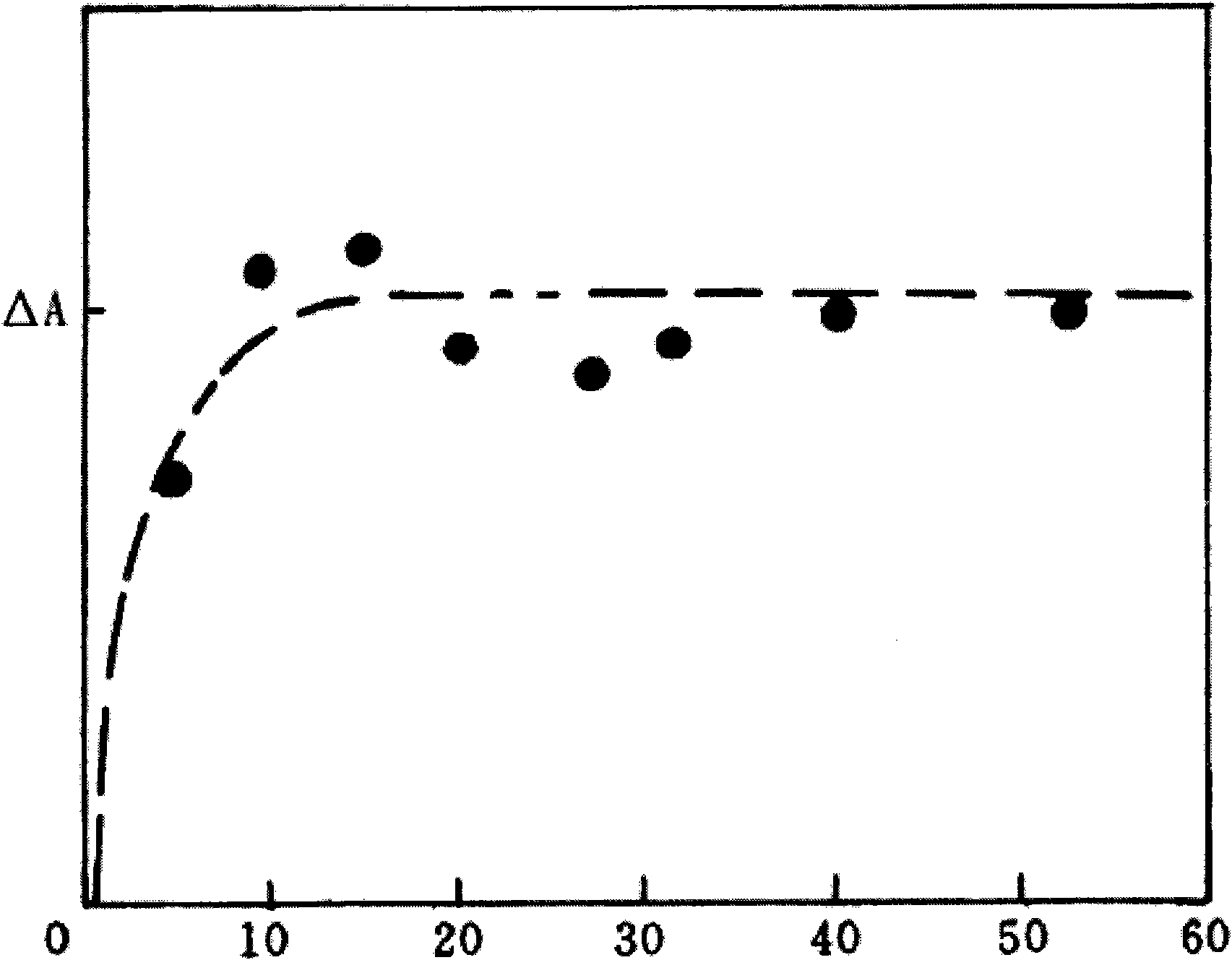

An improved method and system is described for applying a leach solution to ore in the process of heap leaching. The Hybrid Irrigation System (HIS) relies on both surface solution delivery techniques as well as sub-surface solution application to improve the solution uniformity and metallurgical performance of a leaching process. The methods and systems allow for controlled application of leach solution with a hydraulic head applied that can be adjusted or varied depending on the conditions of the ore from negative, atmospheric or positive pressure, while distributing leaching solution in a uniform manner independent of surface variability with respect to elevation and infiltration capacity of the ore surface. The systems and methods have particular application to low permeability ores like high clay content copper, silver, uranium, and gold ores and nickel / cobalt laterite, but can be used in any heap leach application where control must be maintained with respect to surface ponding, stability and accessibility, and uniform reagent distribution, resulting in improved leaching performance.

Owner:G&S PARTNERS +1

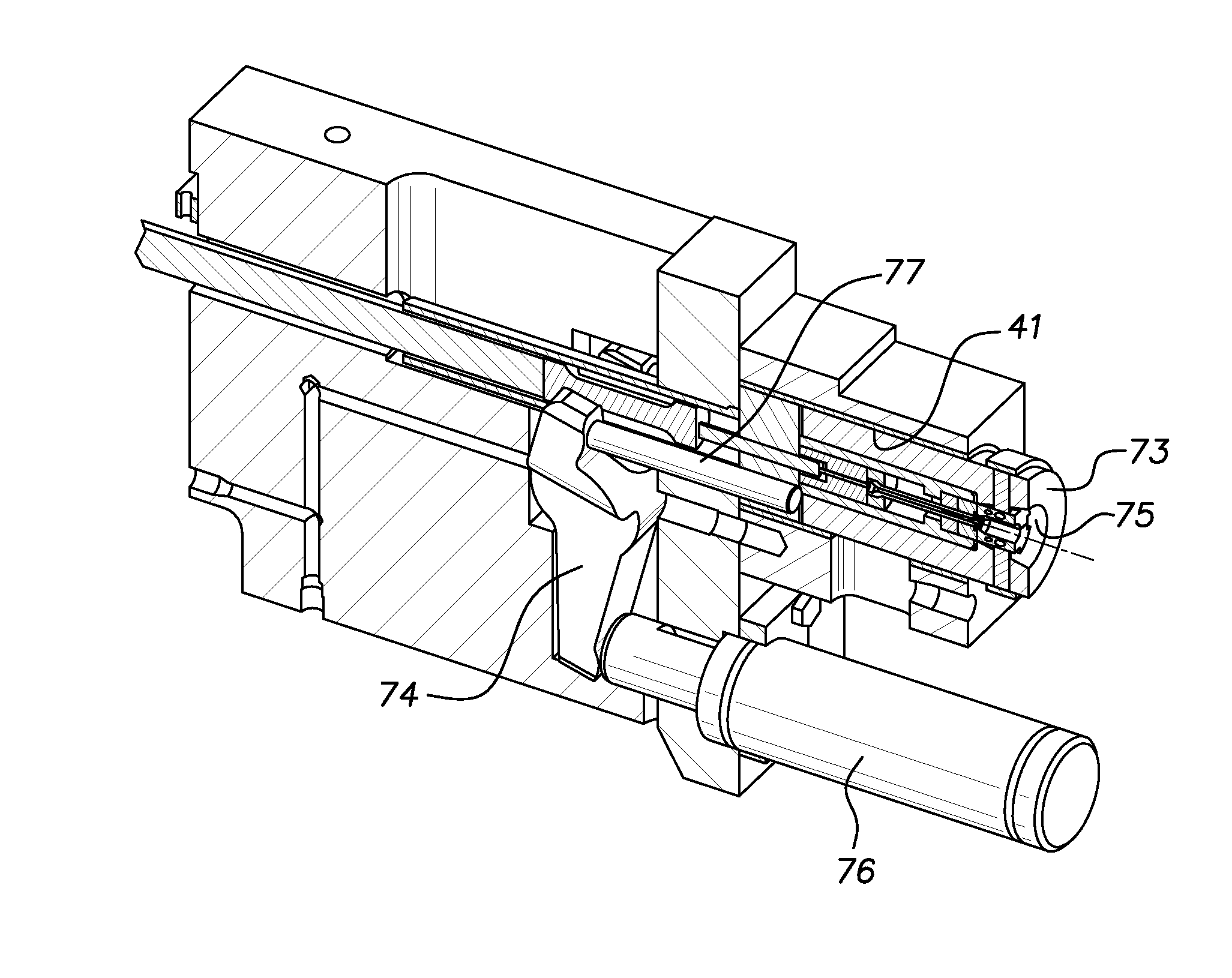

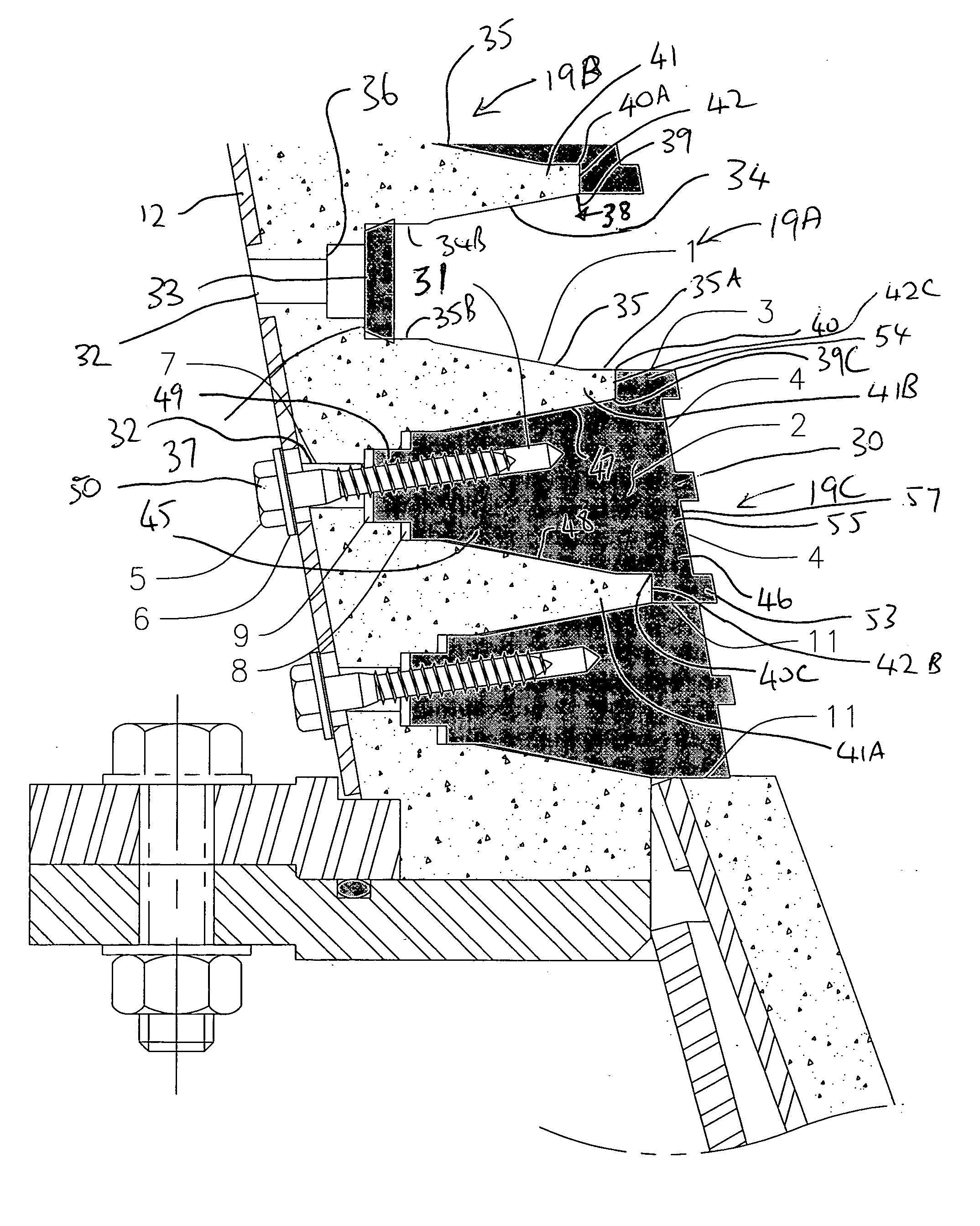

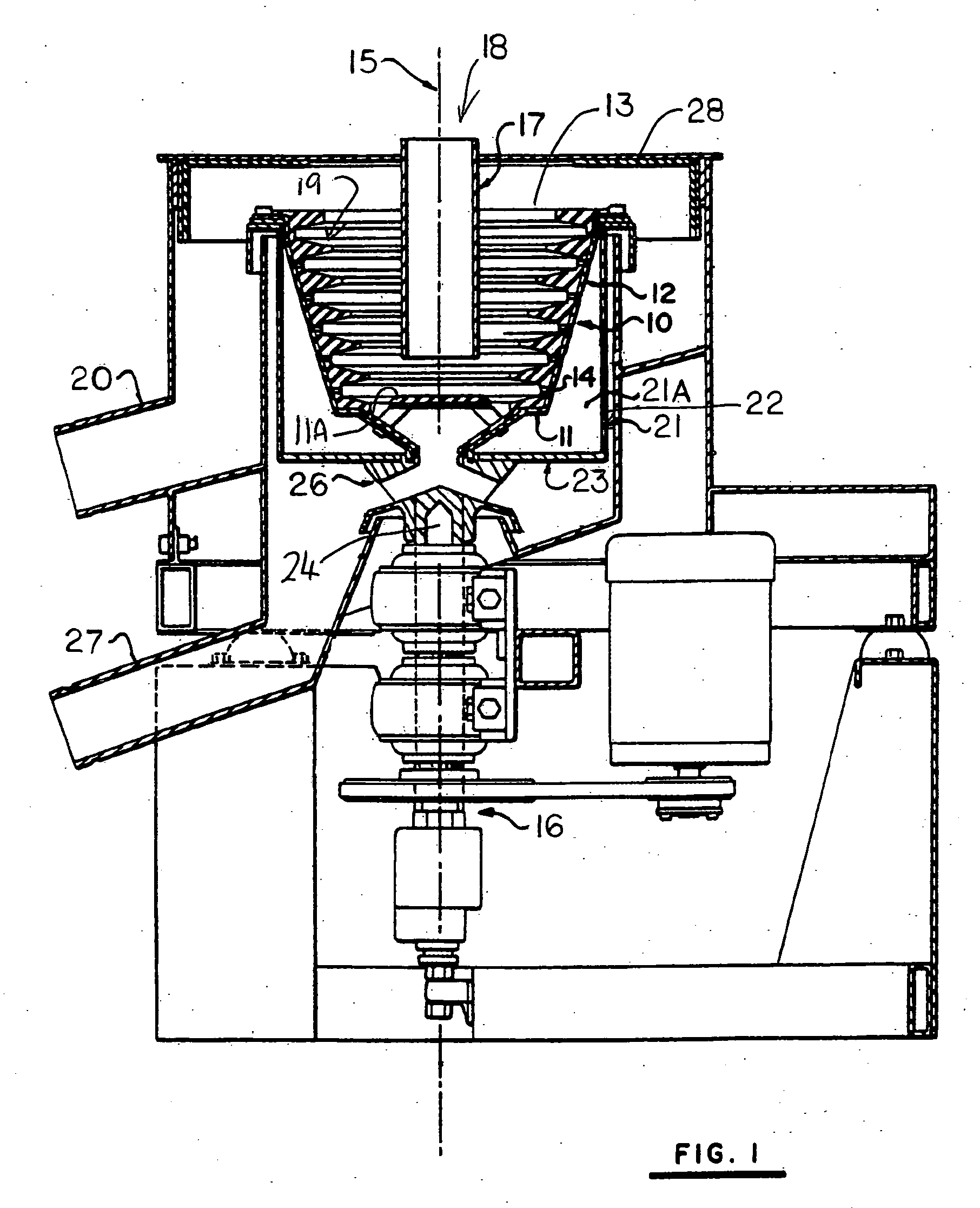

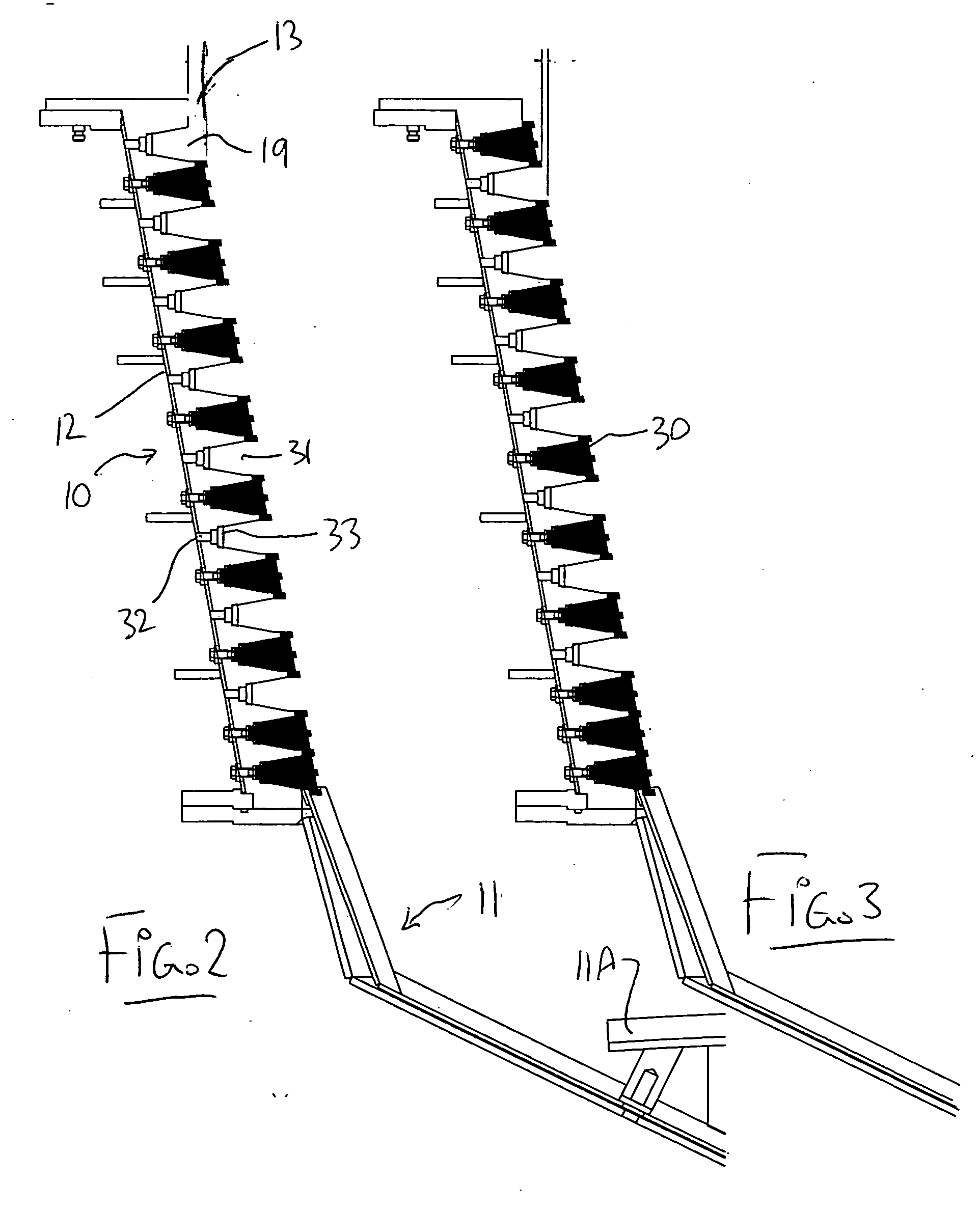

Centrifugal separator with fluid injection openings formed in a separate strip insert

ActiveUS20060135338A1Reduce turbulenceImprove metallurgical performanceRotary centrifugesSlurryMechanical engineering

A centrifuge concentrator bowl includes a plurality of fluidized recesses at axially spaced positions along the peripheral wall. Each recess is defined by two side walls which has water injection holes for fluidizing materials collecting in the recess. Some of the recesses are at least partly defined by a removable insert member arranged to be attached to a suitable mounting on the wall of the bowl. Each insert member includes a face portion defining a surface facing toward the axis of the bowl for engaging the slurry and preventing wear. The face portion may include a side portion on one side or both sides located radially inwardly of a rib on a respective side of the recess and at least partly covering the rib so as to prevent the slurry from contacting the rib and causing wear to the rib.

Owner:F L SMIDTH & CO AS

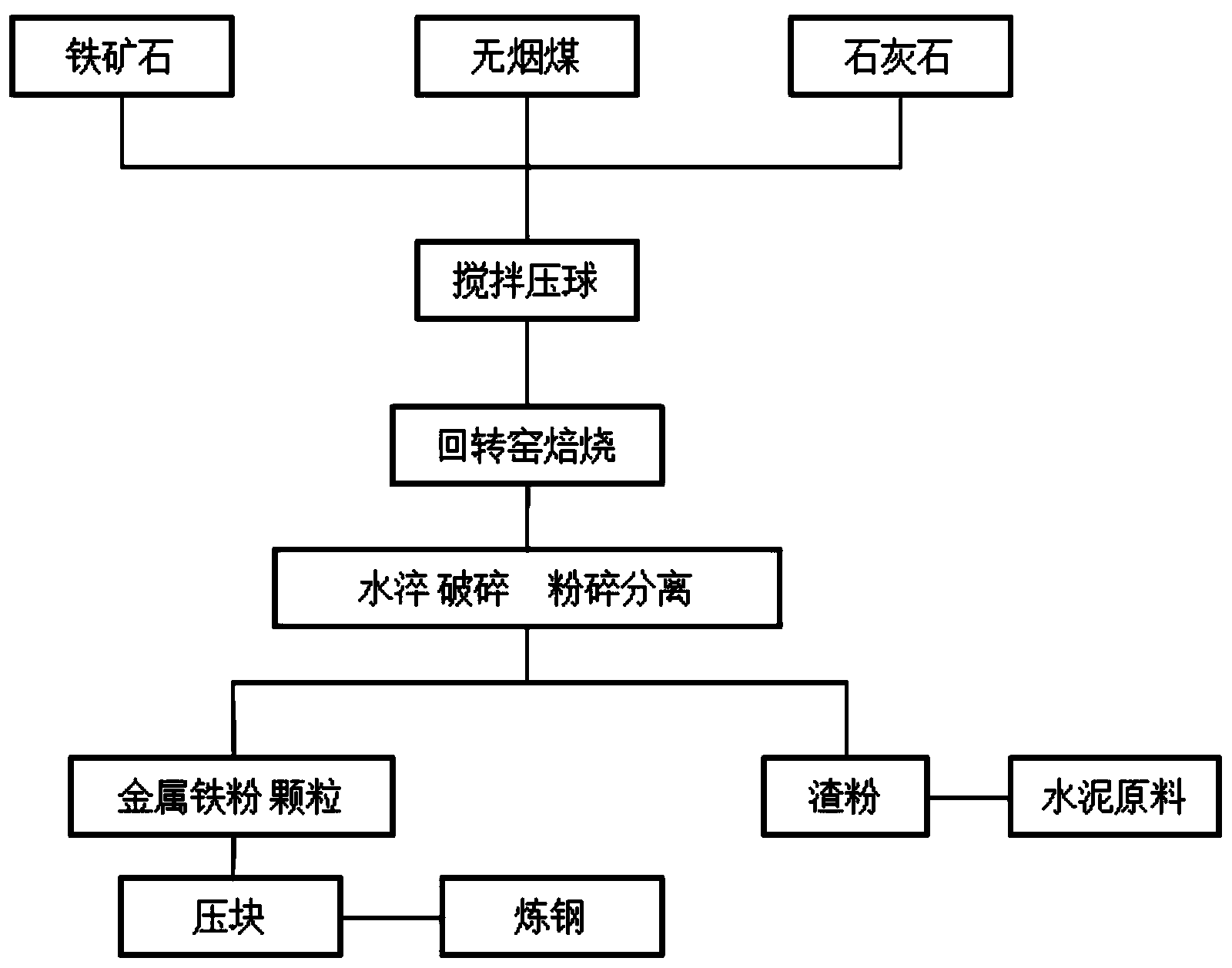

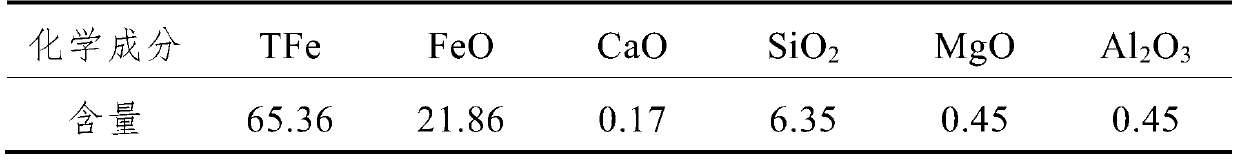

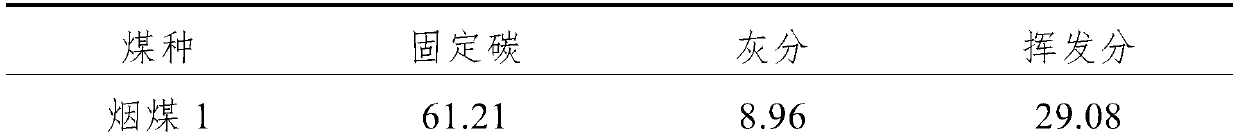

Method for producing metal iron powder by using deep reduction of rotary kiln

InactiveCN104212931AGood metallurgical performanceUniform particle sizeRotary drum furnacesQuenchingPre treatment

The invention discloses a method for producing metal iron powder by using deep reduction of a rotary kiln. The method comprises the following steps: (1) pretreatment: raw iron ore, anthracite and limestone powder are ground to reach a certain fineness by adopting a ball grinder, are then mixed by a double-shaft mixer, and are pressed to form balls by a ball pressing machine; and (2) the deep reduction by the rotary kiln. The deep reduction specifically comprises the following substeps: (1) pellets are dried in a turning plate type drying machine, pass through a preheating section, a reduction section and a deep reduction section in the rotary kiln, and are finally discharged from the kiln for water quenching; and (2) the ore grinding, the screening and the magnetic separation are performed after the water quenching to obtain metal iron powder and iron particles. The method is characterized in that refractory iron ore incapable of being physically separated and enriched is firstly reduced to metal iron and conditions are created to polymerize and grow the metal iron; the separation and the enrichment of iron are realized through grinding and separation of a reduction product; and a new path is provided for the development and the utilization of the refractory iron ore.

Owner:GUANGXI GAOPENG MINING IND SCI & TECH

Method for preparing iron coke

ActiveCN110093467AHigh mechanical strengthImprove yieldBlast furnace detailsSpecial form destructive distillationBriquetteDestructive distillation

Provided is a method for preparing iron coke. Iron coke green balls are subjected to destructive distillation in the mixed atmosphere of CO2 and CO, and the iron coke is prepared. In the mixed atmosphere, the partial pressure of CO2 is 10% or below. The iron coke green balls are briquettes formed by mixing and pressing baring powder coal and iron ore powder. The process is easy to operate, the phenomena that in the iron coke carbonization process, cracks are generated, and the iron coke is eroded by CO2 can be effectively avoided, the mechanical strength of the iron coke is improved, and the yield of the iron coke is increased.

Owner:NORTHEASTERN UNIV

Pellet and production method thereof

The invention belongs to the field of pellets, and particularly relates to a pellet and a production method thereof. The pellet comprises, by weight, 2-4 parts of desulfurized fly ash mixed materialsand 96-98 parts of iron-containing powder, the desulfurized fly ash mixed materials comprise desulfurized fly ash and bentonite, the desulfurized fly ash accounts for 5-30wt% of the total weight of the desulfurized fly ash mixed materials, and the raw materials are palletized and baked to prepare the pellet. According to the pellet, the desulfurized fly ash replaces part of bentonite to serve as production raw materials of the pellet, and the dosage of the bentonite can be reduced when correlative performances of fresh pellets are met, so that taste, strength and metallurgical performances ofthe pellet are improved. The desulfurized fly ash serves as production raw materials of the pellet, so that resource utilization of the industrial solid waste desulfurized ash is achieved, the problemof waste of land resources caused by land occupation due to long-term stacking of the desulfurized ash is solved, the production cost of the pellet is reduced, and the pellet more has more market competitiveness.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD +1

High-chrome vanadium-titanium magnetite blast furnace smelting charging material and blast furnace smelting method

InactiveCN105803141AEasy to reinforceImprove breathabilityBlast furnace detailsBlast furnace smeltingMagnetite

The invention discloses a high-chrome vanadium-titanium magnetite blast furnace smelting charging material. The high-chrome vanadium-titanium magnetite blast furnace smelting charging material comprises, by weight, 75-85% of sintered ore, 13-20% of pellets and 2-5% of common lump ore. The sintered ore is formed by mixing and sintering materials including, by weight, 50-60% of high-chrome vanadium-titanium magnetite, 20-30% of ordinary iron ore and 20% of fuel and fusing agents. The pellets are formed by mixing and roasting materials including, by weight, 97-98% of high-chrome vanadium-titanium magnetite concentrate and 2-3% of bentonite. The common lump ore comprises, by weight, 40-50% of TFe and 15-25% of SiO2 and is free of vanadium and titanium. According to the high-chrome vanadium-titanium magnetite blast furnace smelting charging material, the metallurgical property during smelting is enhanced mainly by improving the high-chrome vanadium-titanium magnetite blast furnace smelting charging material.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for removing impurities by argon blowing by adopting continuous casting tundish air curtain barricade technology

The invention relates to a method for removing impurities by argon blowing by adopting a continuous casting tundish air curtain barricade technology. According to the method, a proper amount of high-alkalinity low-carbon tundish covering agent and the high-alkalinity low-carbon tundish covering agent with carbonized rice husks are added to each furnace on the liquid surface of molten steel in a region right above a strip-shaped air curtain barricade correspondingly according to low-carbon steel and non-low-carbon steel, and therefore the problem that the liquid surface fluctuation of the molten steel caused by argon blowing of the strip-shaped air curtain barricade is large can be solved, and the problem of secondary oxidation and slag entrapment of the molten steel can be more effectively prevented; and in addition, argon bubbles capture the impurities and float upwards to the tundish liquid surface to be adsorbed and more effectively removed by the high-alkalinity low-carbon tundish covering agent, and therefore the metallurgical effect of removing the impurities by argon blowing of the continuous casting tundish strip-shaped air curtain barricade can be improved.

Owner:SHANDONG IRON & STEEL CO LTD

Industrial preparation method of high-fine-powder-rate ore agglomerates

InactiveCN103305688AImprove metallurgical performanceReduce fuel consumptionBlast furnace detailsAlkalinityDolomite

The invention relates to an industrial preparation method of high-fine-powder-rate ore agglomerates. The industrial preparation method is characterized by comprising the following steps of: uniformly mixing a ferrous raw material with bentonite which accounts for 2-6 weight percent of the ferrous raw material to prepare acidic fresh pellets, wherein the particle size of the fresh pellets is 4-10mm; uniformly mixing and granulating raw materials including iron ore concentrates or a mixture of the iron ore concentrates and superfine iron ore concentrates, imported iron ore powder, limestone, light-burned dolomite, quicklime and high-alkalinity sintering mixture of fine coke in a primary mixer and a secondary mixer granulator, and adding the acidic fresh pellets to form an acid-alkali mixture before the materials are put into a distributing belt of a sintering machine, wherein the added amount of the fresh pellets accounts for 20-60 weight percent of the externally distributed high-alkalinity sintering mixture; and distributing the acid-alkali mixture to a trolley of the sintering machine through a swinging belt, a wide belt and a nine-roller distributor, and igniting and roasting to obtain high-quality ore agglomerates. The industrial preparation method has the advantage that the problems of poor air permeability and sintering difficulty during sintering of high-precision powder and in the sintering process of the ferrous raw material containing superfine concentrates are solved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Ultralow carbon welding rod for welding heat resisting steel and stainless steel

InactiveCN1706586ASimple welding processGood metallurgical performanceWelding/cutting media/materialsSoldering mediaChemical compositionPearlite

The present invention belongs to the field of welding material technology, and is welding rod for welding joint of different kinds of steel, especially of heat resistant pearlite steel and stainless steel. The ultralow carbon welding rod of the present invention consists of: C 0.03-0.06 wt%, Si 0.2-0.5 wt%, Mn 0.5-0.8 wt%, Cr 1.5-2.5 wt%, Mo 0.4-0.65 wt% and V 0.10-0.35 wt%, except Fe. Compared with available technology, the present invention has simple and reasonable component design, capacity of effectively preventing the formation of the carbon immigrating layer in fusion area of joint, no martensite structure formed in the joint, excellent welding performance and high normal temperature and high temperature performance of the welded joint.

Owner:SHENYANG POLYTECHNIC UNIV

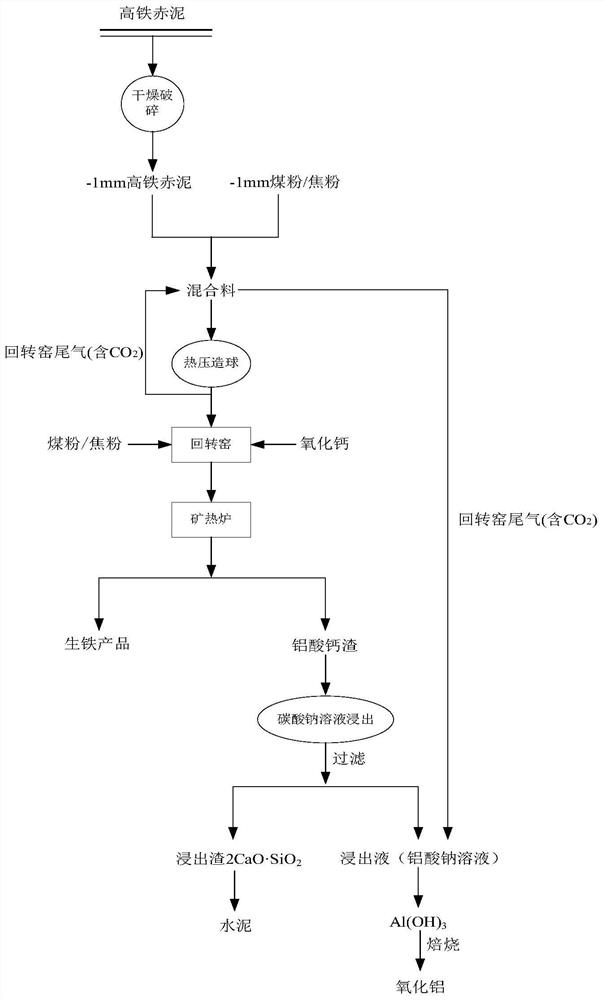

Process for reducing and extracting iron from high-iron red mud

InactiveCN112442565AImprove microstructureClose contactRotary drum furnacesProcess efficiency improvementRed mudCoke

The invention provides a process for reducing and extracting iron from high-iron red mud. The process comprises the following steps: drying the high-iron red mud, crushing the dried high-iron red mudinto particles with the particle size of less than 1 mm, and mixing the particles with a carbon-based reducing agent to prepare high-iron red mud carbon-containing pellets; adding the high-iron red mud carbon-containing pellets, pulverized coal / coke powder and calcium oxide into a rotary kiln to be subjected to reduction roasting, wherein the roasting temperature is controlled to range from 1,050DEG C to 1,250 DEG C, the roasting time is controlled to range from 90 min to 180 min, and obtaining a submerged arc furnace molten material after roasting; and adding the submerged arc furnace moltenmaterial into a submerged arc furnace to be heated, melted and reduced, wherein the melting reduction temperature is controlled to range from 1,350 DEG C to 1,550 DEG C, the time is controlled to range from 30 min to 80 min, and iron oxide in the molten material is completely reduced into metal iron. The process disclosed by the invention solves the problems of high energy consumption, low magnetic separation iron ore concentrate recovery rate, massive existence of iron-aluminum isomorphism and iron-aluminum oxide solid solutions, difficulty in iron-aluminum separation and the like in the existing red mud iron recovery process.

Owner:NORTHEASTERN UNIV

Optimization method of sintering proportioning structure

The invention relates to an optimization method of a sintering proportioning structure, belongs to the technical field of sintering proportioning, and solves the problem that a sintering process and the quality improvement of sintering ores cannot be realized in an existing sintering proportioning mode. The optimization method is characterized by prior to determination of the dosages of iron mine powder, fusing agents and fuels in a sintering mixture, comprising the following steps: 1, drying the iron mine powder for sintering into dry basis iron mine powder; 2, uniformly mixing and splitting each dry basis iron mine powder and testing P nucleus which is the weight percent of Nuclear ore with grain size of 0.63-10mm in the dry basis iron mine powder, and P powder which is the weight percent of adhesive powder with the grain size less than 0.2mm in the dry basis iron mine powder respectively; 3, testing L powder which is the liquid phase fluidity index of the adhesive powder with the grain size less than 0.2mm in the dry iron mine powder; 4, repeatedly carrying out the steps from 1 to 3, and testing the nucleus ratio, the powder ratio and the liquid phase fluidity indexes of the second iron mine powder, the third iron mine powder,... and the ith iron mine powder; and 5, determining the proportion of the iron mine powder in the mixture according to a restriction condition. According to the optimization method, the adverse effect on the sintering process and the quality of the sintering ores caused by superfusion of the ores or the insufficiency of liquid phase quantity can be avoided, and the method is reasonable in carbon proportioning, easy to operate, high in practicability and can adapt to a diversified raw material structure.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com