Optimization method of sintering proportioning structure

An optimization method and technology for sintering mixture, applied in the field of sintering ingredients, can solve the problems affecting the quality and yield of sintered ore, insufficient flow range, difficulty in actual production, etc., to promote sustainable development, reduce solid fuel consumption, and improve sintering The effect of mineral quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

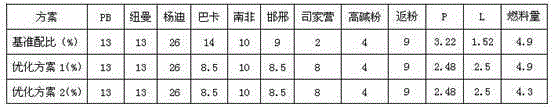

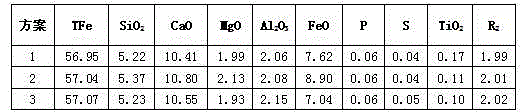

Examples

Embodiment Construction

[0036] The present invention conducts experimental research on the particle size composition changes before and after granulation of the sintered mixed material, and after statistical analysis of a large amount of data, it is found that during the granulation process, iron ore powder particles always exist in three states, that is, nucleation particles , Intermediate particles and adhesion powder are defined by particle size. Nucleation particles are particles with a particle size in the range of 0.63 mm to 10 mm, which are called nuclear ores. The role of the ball core, the ore powder with a particle size of less than 0.2mm is called adhesion powder, which adheres to the nuclear ore after granulation and no longer exists alone, while the particles with a particle size in the range of 0.2mm to 0.63mm are called intermediate particles , that is, it is not easy to nucleate, and it is not easy to be adhered, which has an adverse effect on the air permeability of the material layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com