Patents

Literature

60results about How to "Improve sinter quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

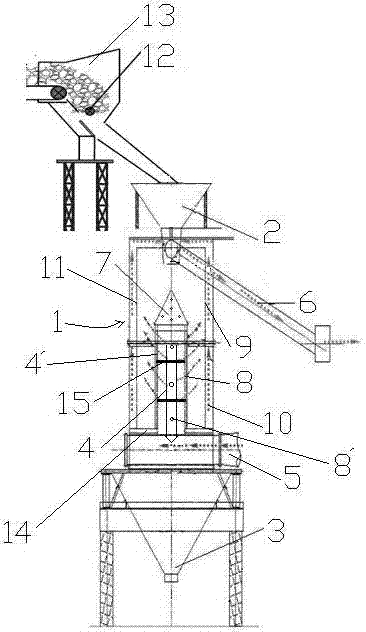

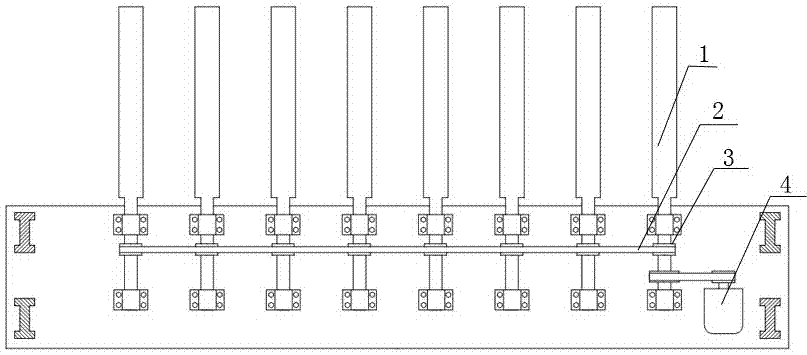

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

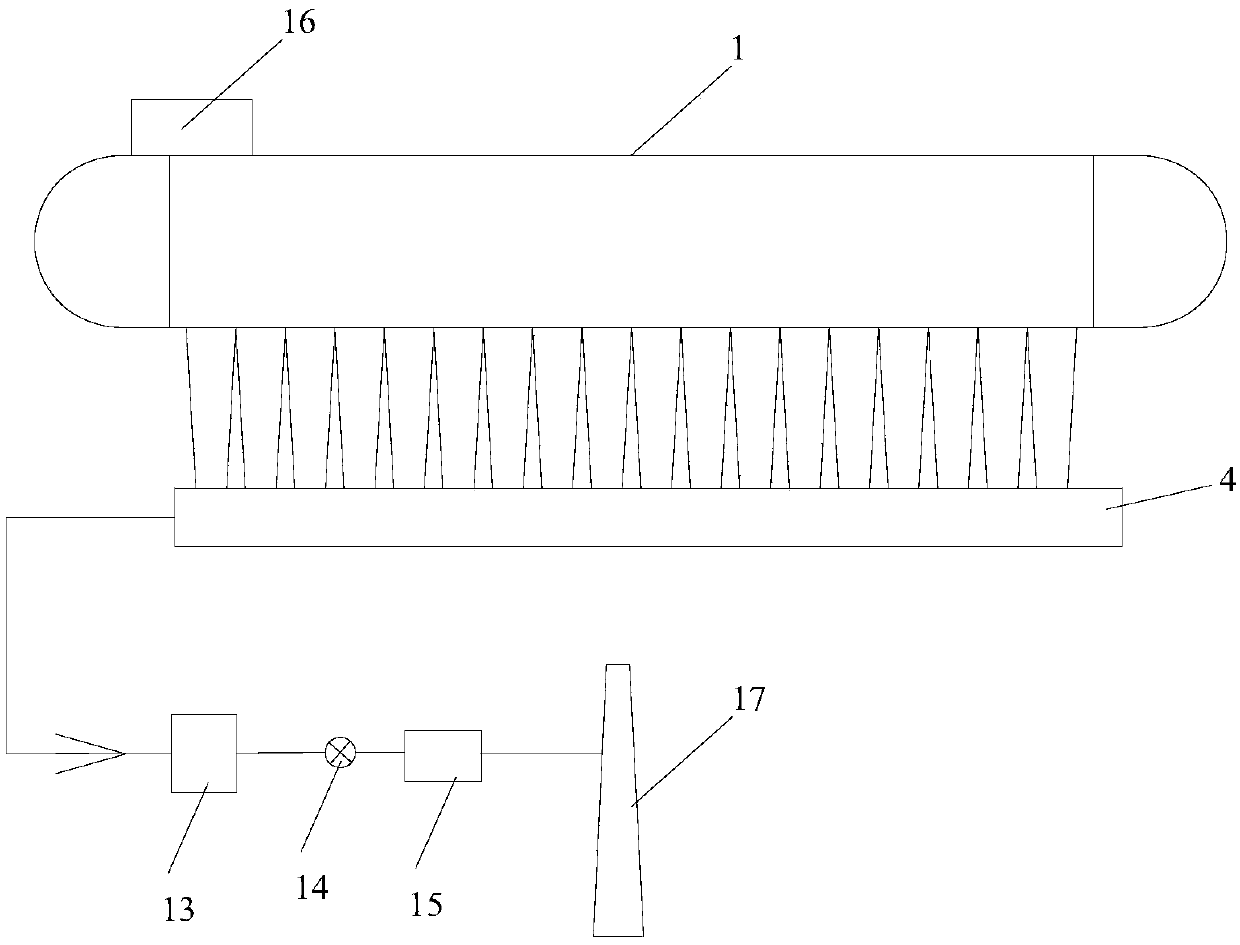

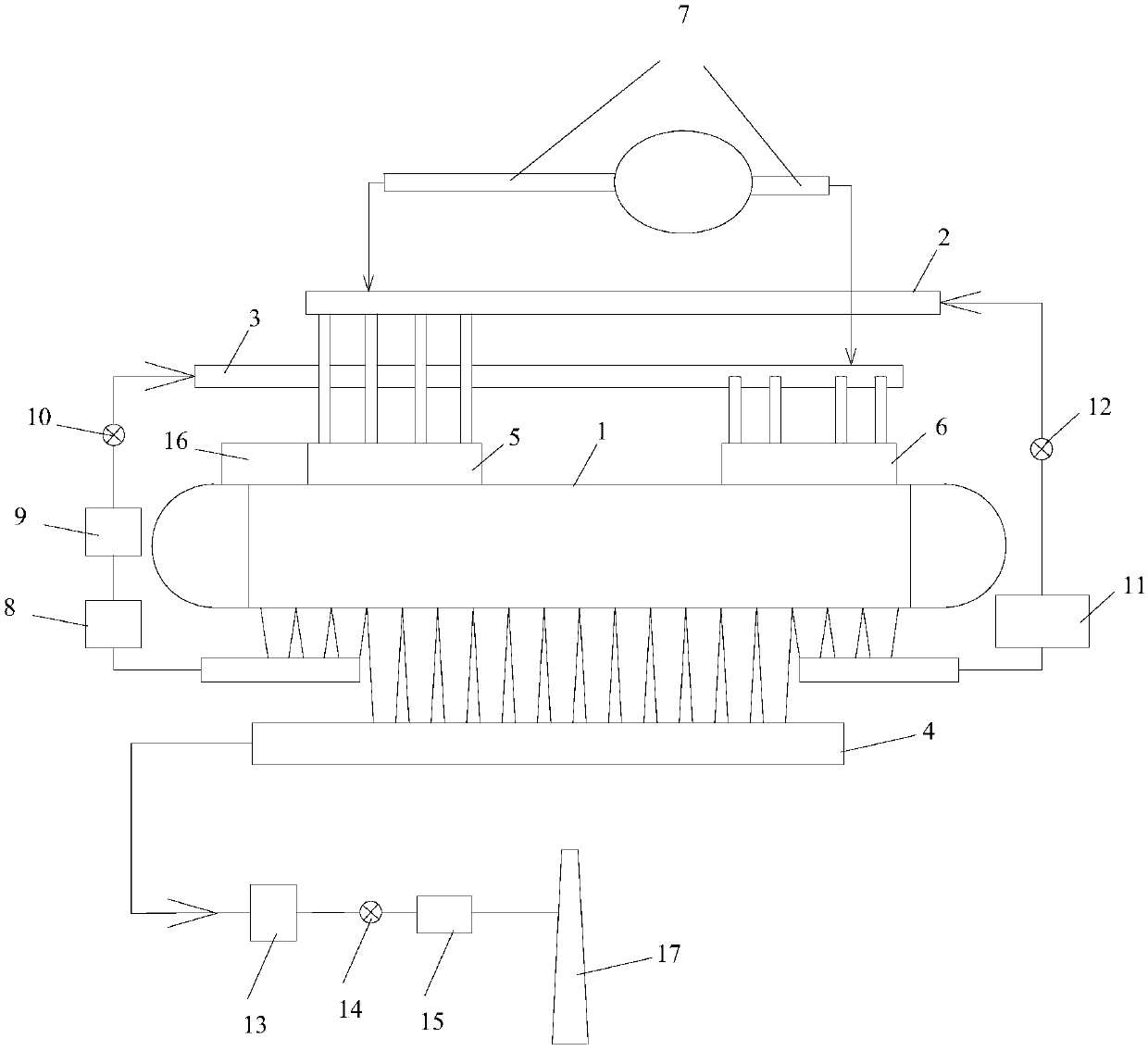

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

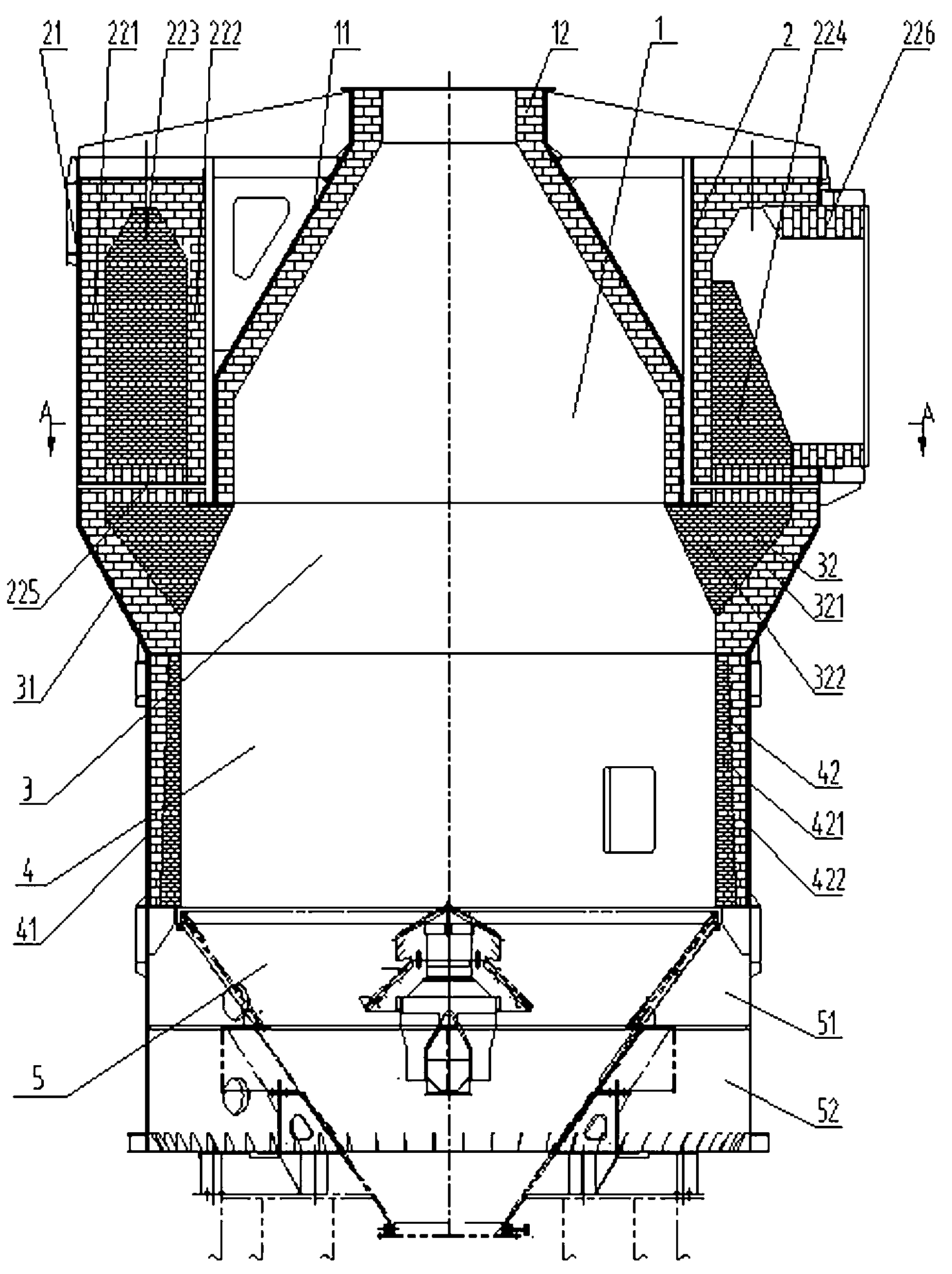

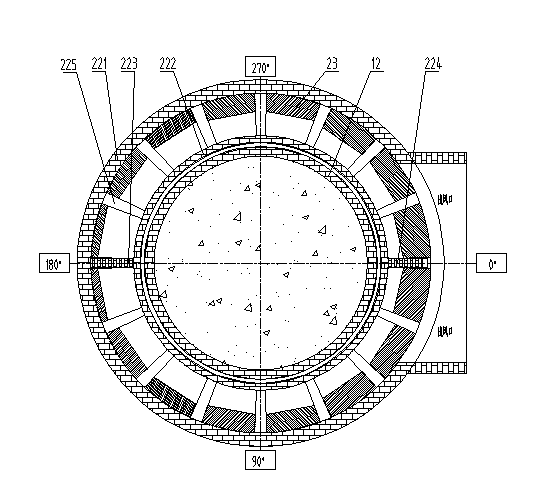

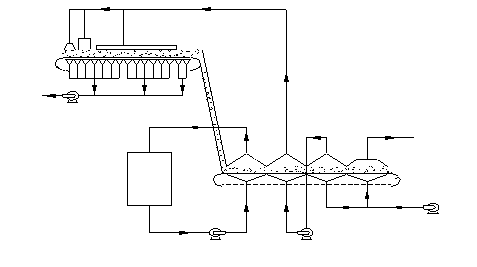

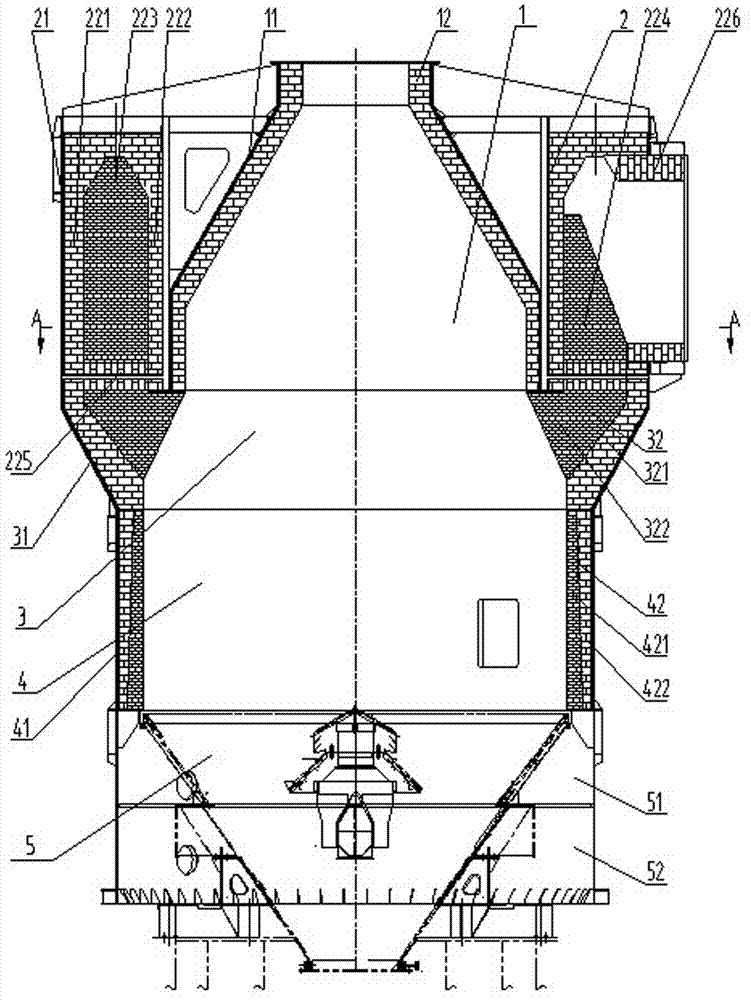

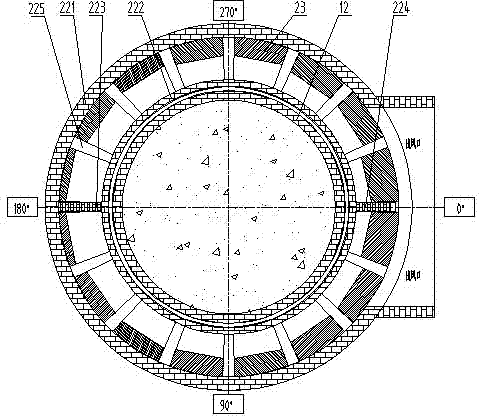

Sintered ore cooling furnace

ActiveCN103234361AAvoid volatilitySimple structureIncreasing energy efficiencyHandling discharged materialCounter flowMaterial distribution

The invention discloses a sintered ore cooling furnace device. The device is composed of a pre-storage area, an annular air flue area, a chute area, a cooling area and an air chamber. High-temperature sintered ores are continuously and evenly distributed into a cooling furnace for cooling through a charging port above the pre-storage area by a material distribution device, high-temperature sintered ores are subjected to counter-flow heat exchange with low-temperature air blown from the bottom of the furnace in the cooling area of the cooling furnace, sintered ores are cooled to below 180 DEG C, low-temperature ores are discharged by a discharging device, the low-temperature air is heated to about 600 DEG C through counter-flow heat exchange and enters a waste heat recycling system through an air outlet, and hot air and hot sintered ores are effectively sealed inside the cooling furnace in the whole process. By the aid of the device, on the premise that the quality of sintered ores is guaranteed or improved and the return fine rate is reduced, the efficiency of recycling of waste heat of sintered ores is improved to the maximum extent.

Owner:中信重工工程技术有限责任公司

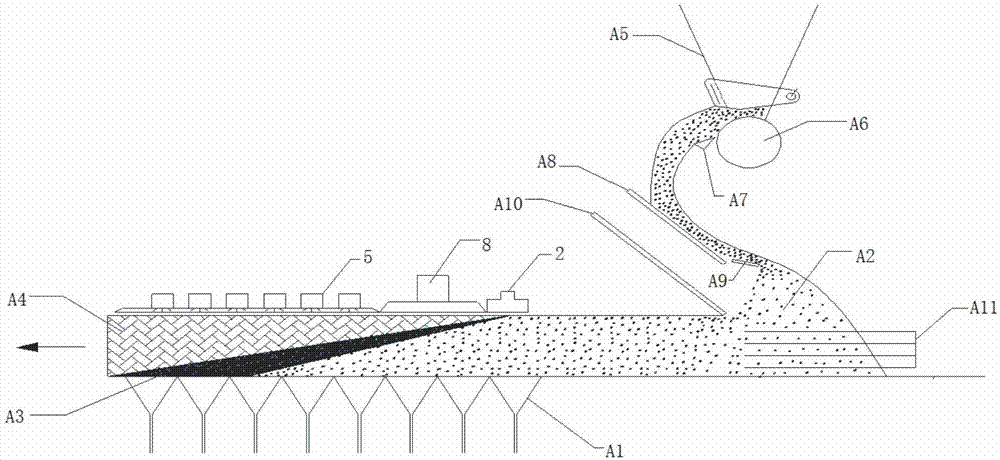

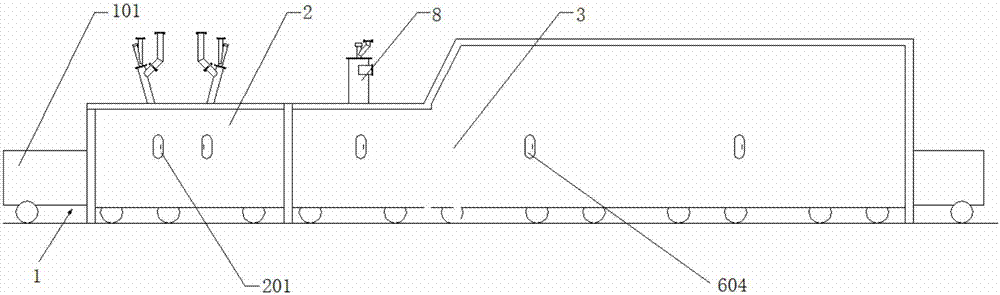

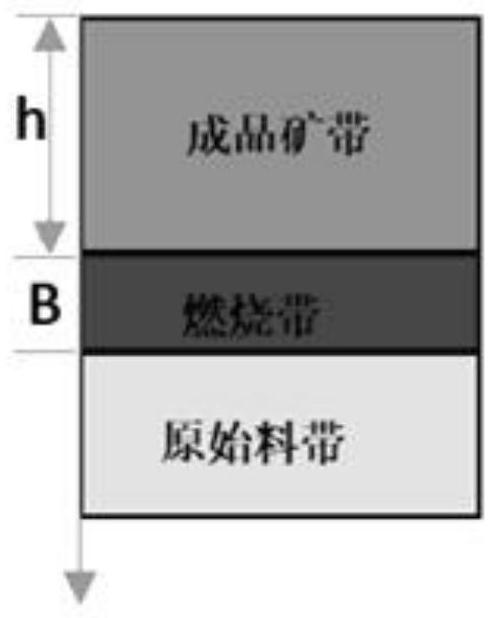

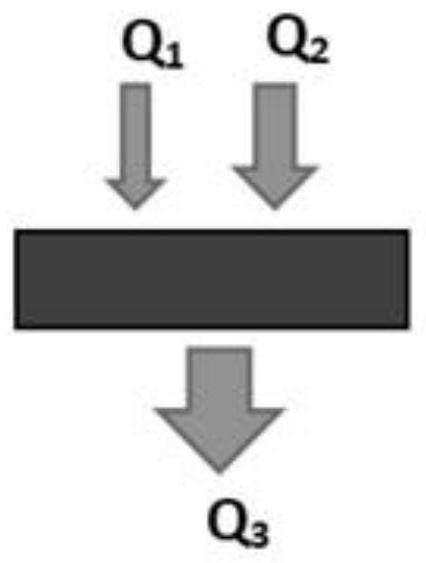

Soaking sintering process based on combustible gas blowing

The invention discloses a soaking sintering process based on combustible gas blowing. The soaking sintering process comprises the following steps: (1) batching; (2) charging; (3) igniting; (4) sintering; (5) performing heat preservation and heat supplementation: when agglomerate is formed on the surface layer of a sintering mix materiel after ignition, blowing a sintering flue gas or ring cooling machine hot gas to the surface of the sintering mix materiel by arranging a heat preservation and heat supplementation device on the sintering mix materiel; (6) performing soaking sintering based on combustible gas blowing: blowing a combustible gas to the part above the surface layer of the sintering mix materiel to enable the combustible gas to be combusted in the combustion layer of the sintering bed; and (7) completing sintering, and discharging. The invention provides a gas feeding method and device for uniform sintering, and aims to solve the problems of reducing the solid fuel consumption on the premise of improving the sintered ore quality and further reducing the carbon dioxide emission of the blast furnace.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

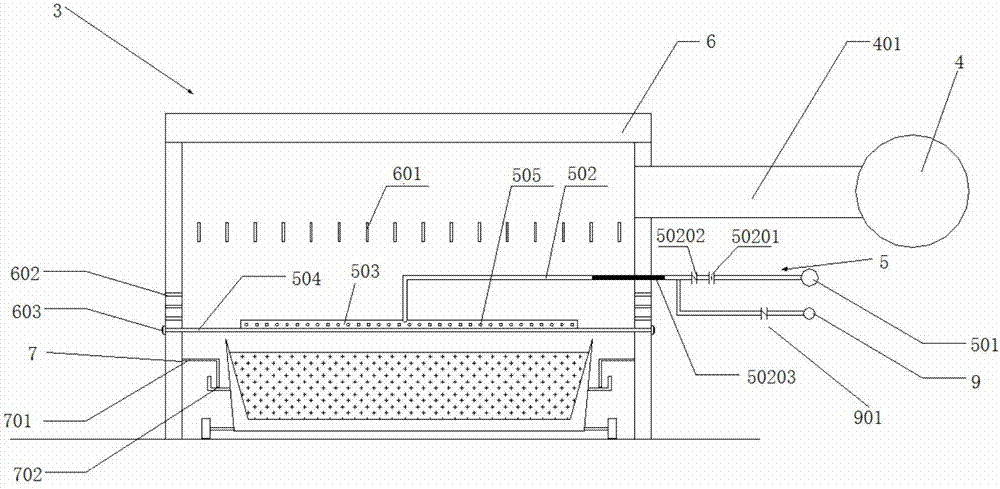

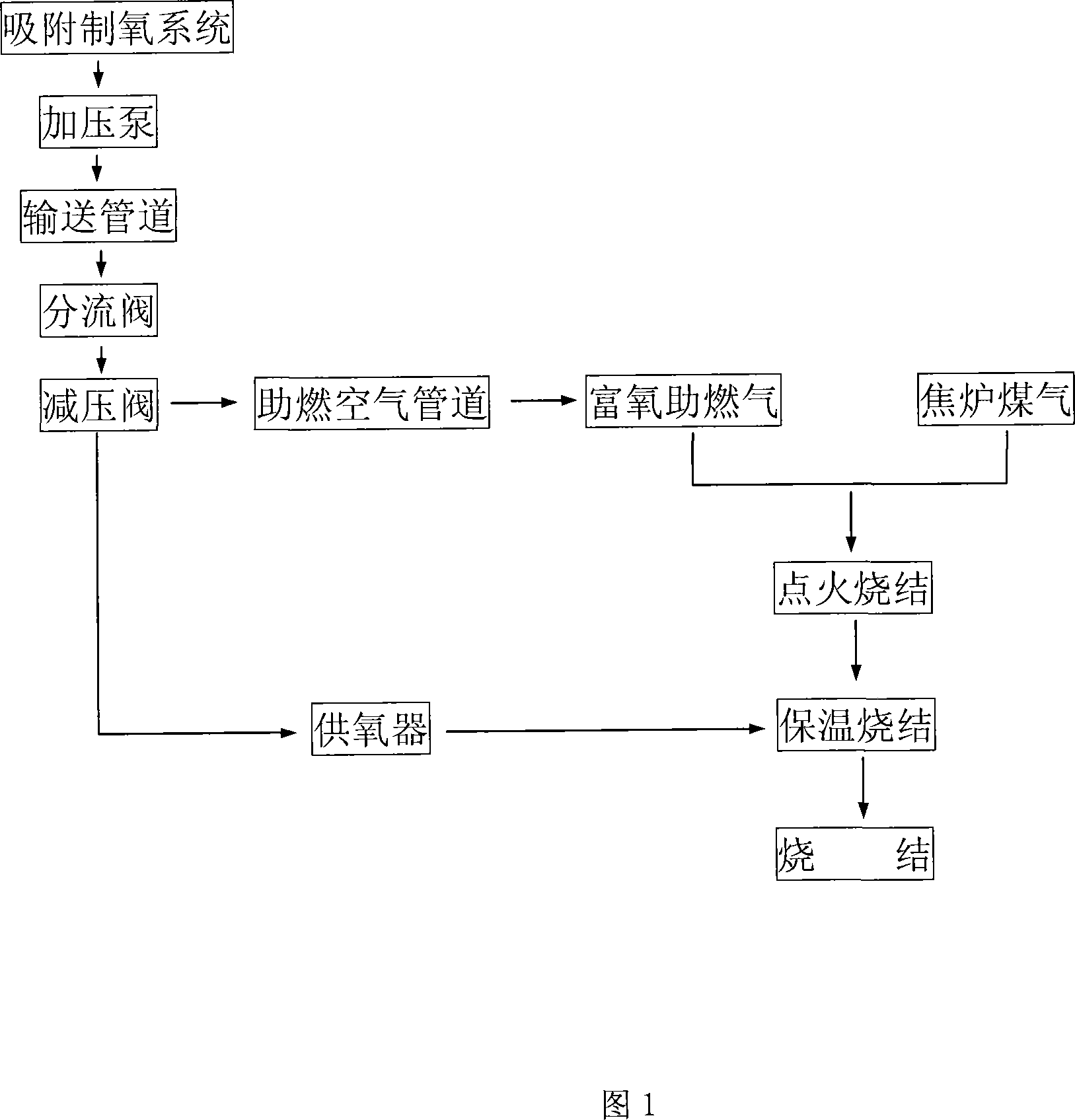

Oxygen-enriched sintering technique

The present invention relates to a rich oxygen sintering technology, which comprises ignition rich oxygen and heat preservation rich oxygen, namely, the rich oxygen sintering is used in both the ignition section and the heat preservation section of a continuous strand sinter machine. The rich oxygen sintering technology has the technical proposal that: first, ignition rich oxygen: oxygen with 93 percent purity produced with an adsorption oxygen producing system is delivered to a combustion-supporting pipeline after passing through a pressurization pump, a transfer pipeline, a flow dividing valve, and a pressure reduction valve, the oxygen and the combustion-supporting air in the combustion-supporting pipeline are mixed, to form the required combustion-supporting air with rich oxygen, and the oxygen content in the combustion-supporting air with rich oxygen is 22 to 25 percent; then ignition is performed after the combustion-supporting air with rich oxygen and coke oven gas is mixed with 2.7: 1 to 4.2:1 proportion of the combustion-supporting air with rich oxygen and the coke oven gas; second, heat preservation rich oxygen: oxygen with 93 percent purity produced with an adsorption oxygen producing system is delivered to an oxygen supply apparatus after passing through a pressurization pump, a transfer pipeline, a flow dividing valve, and a pressure reduction valve, the oxygen supply apparatus adds oxygen to the sintering heat preservation section through the periphery of a heat preservation cover, to lead the oxygen content in the heat preservation atmosphere after being filled with oxygen to achieve 22 to 30 percent, and the rich oxygen is supplied to the sintering material layer through forceful air draught.

Owner:LAIWU IRON & STEEL GRP

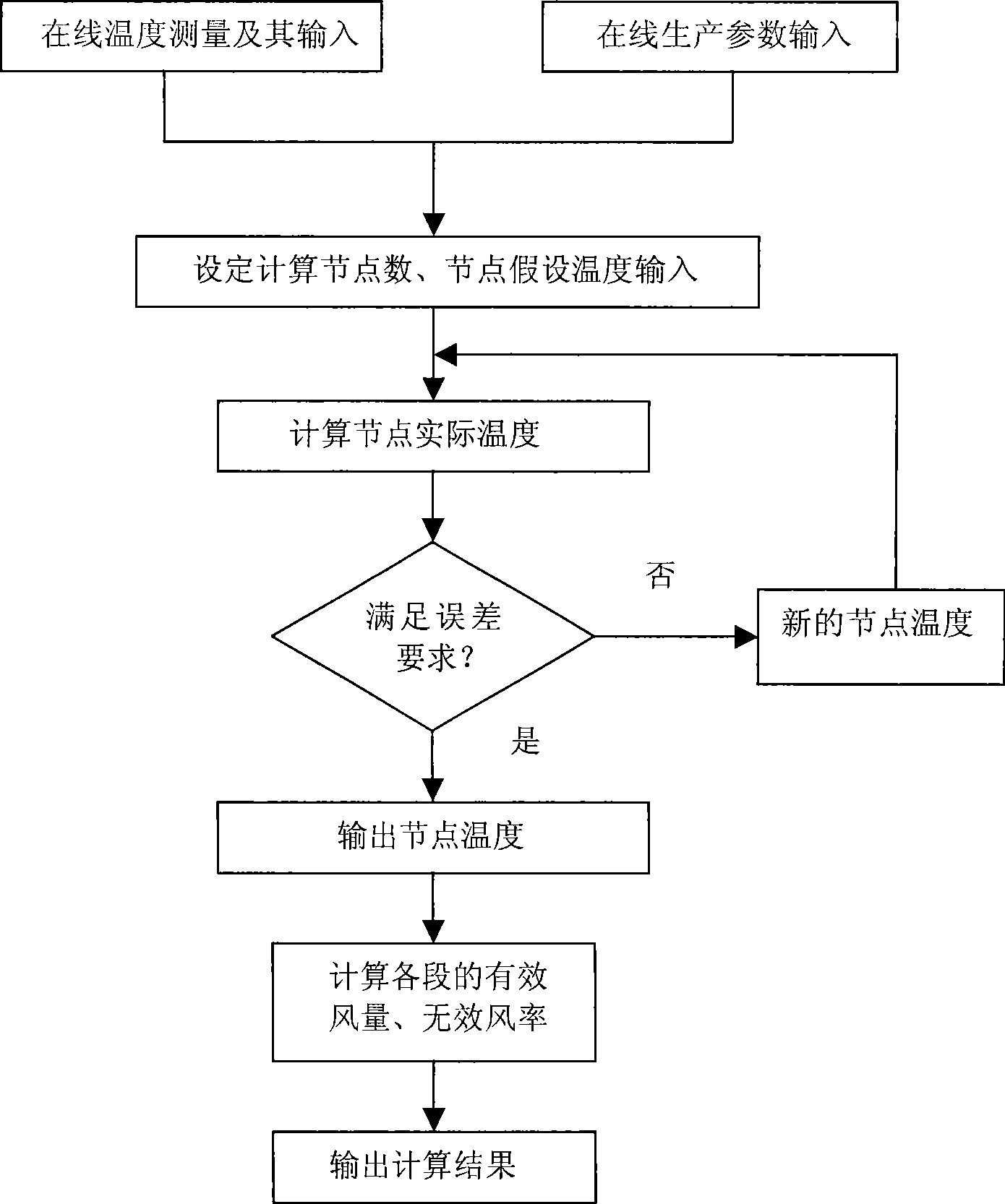

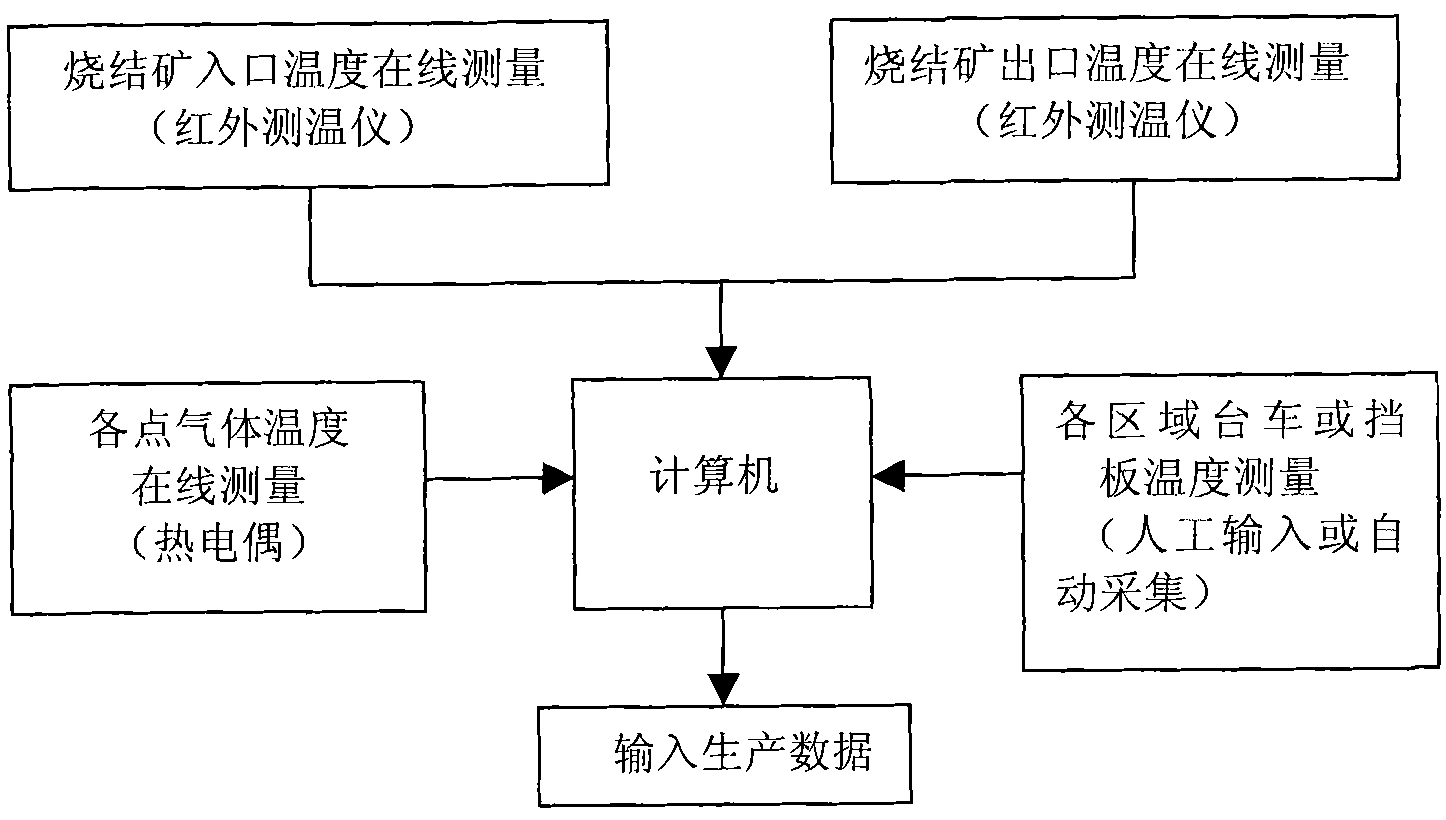

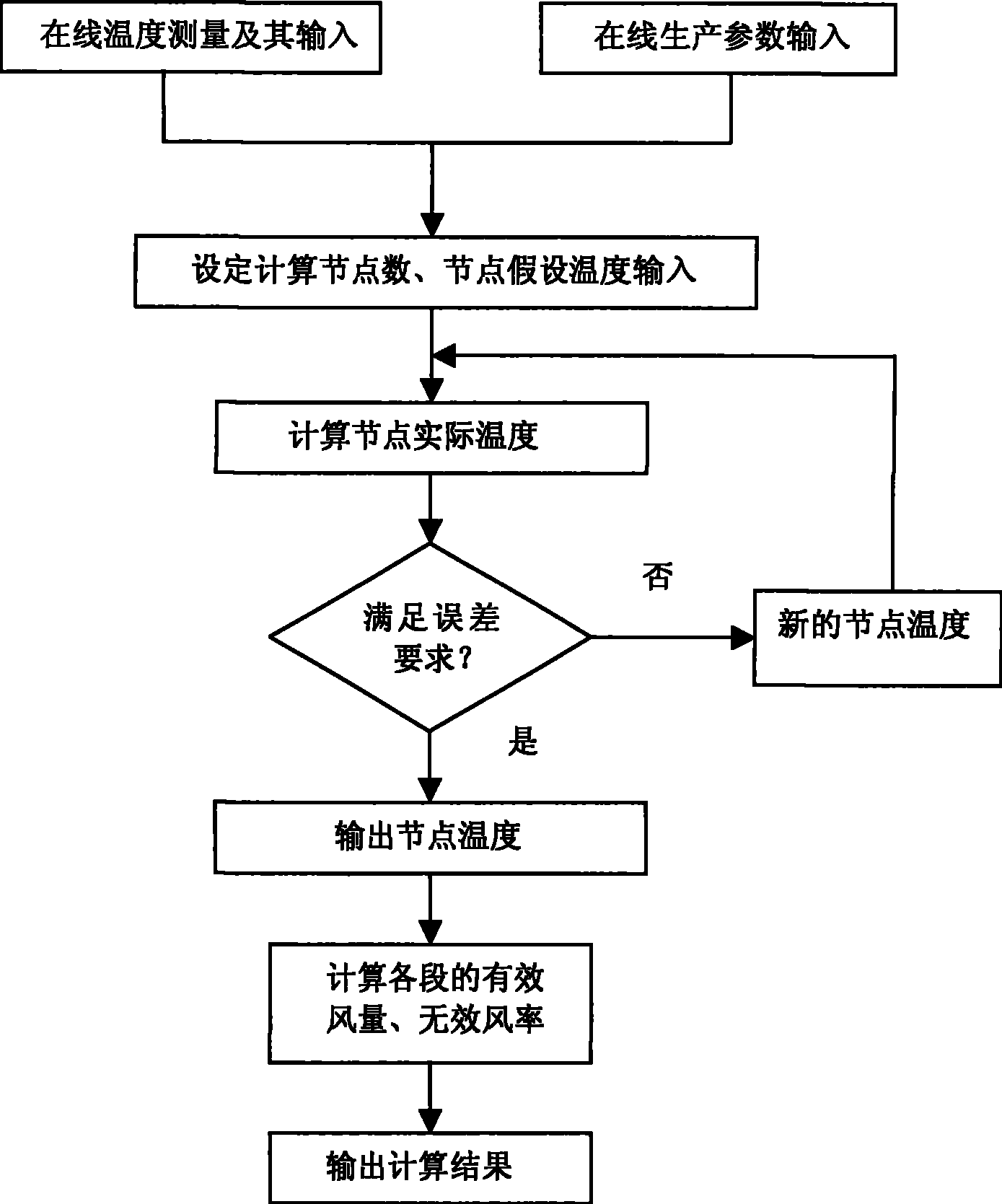

Sintered ring cold machine air leakage rate on-line diagnostic method

InactiveCN101290253AReduce power consumptionImprove sinter qualityMuffle furnacesRetort furnacesCalculated resultLeakage rate

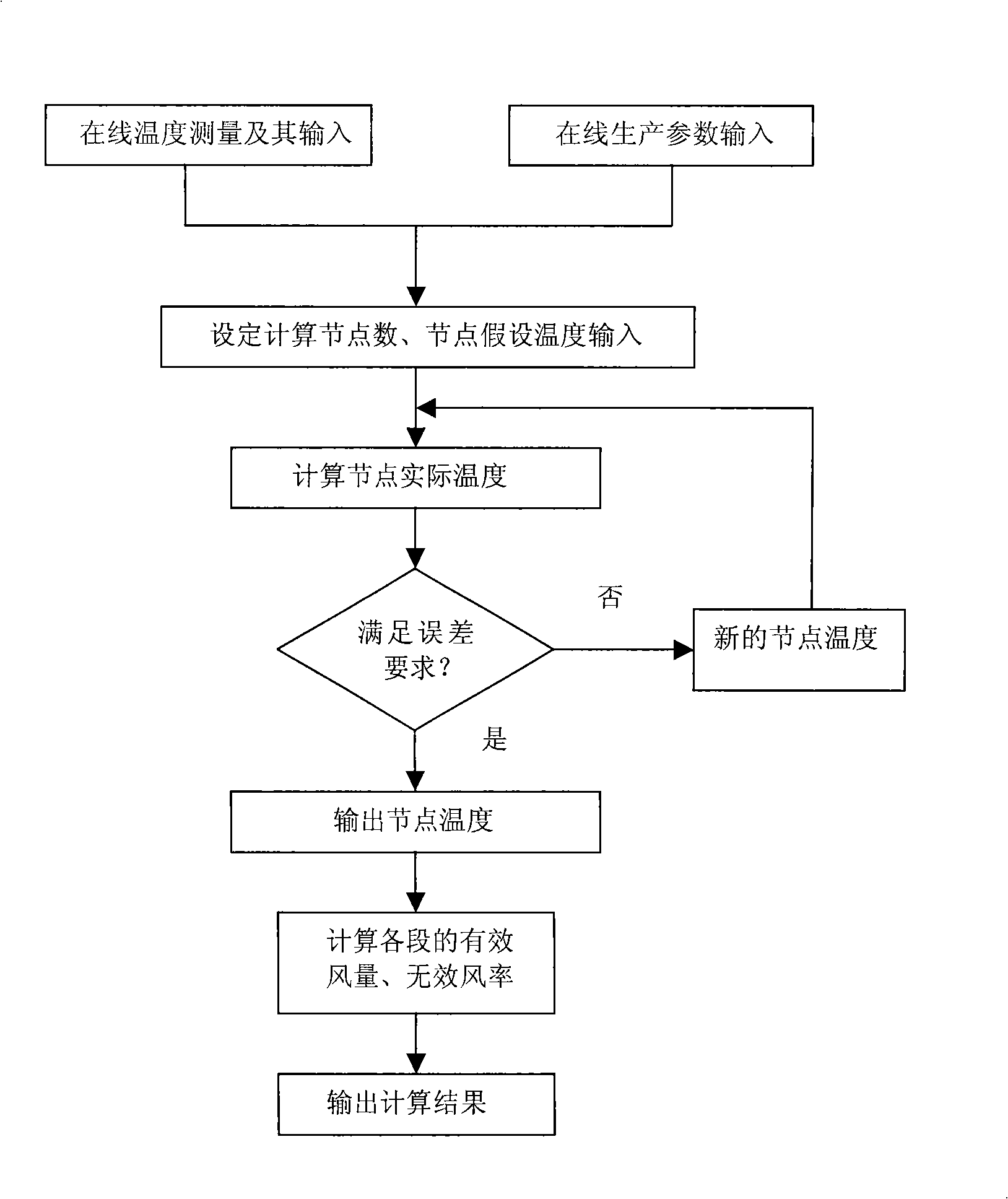

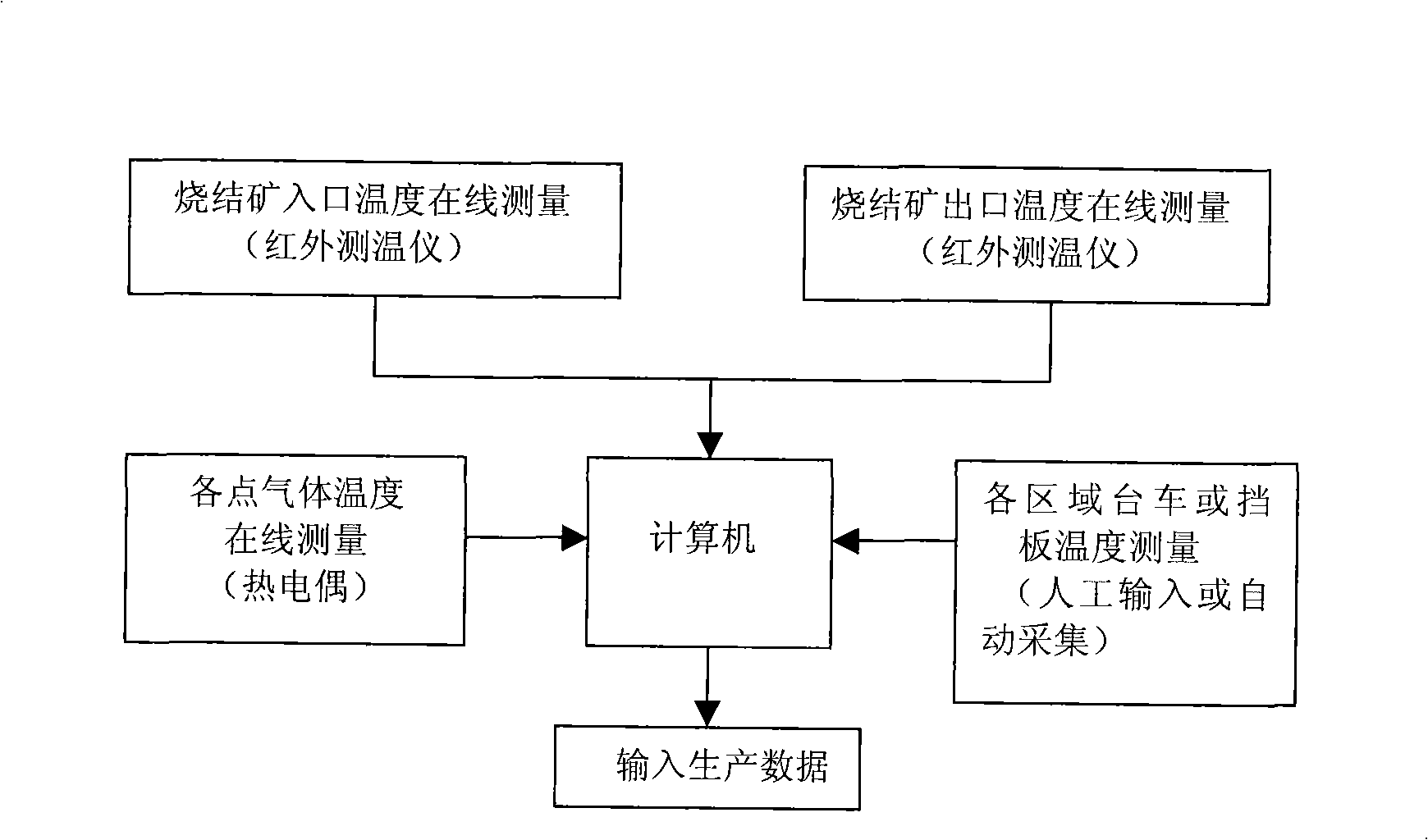

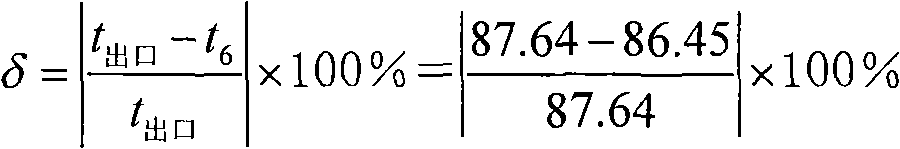

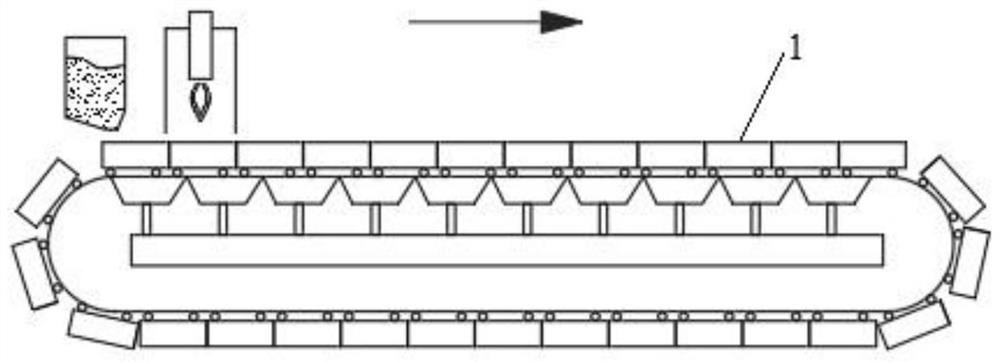

The invention relates to cooling control equipment for metallurgy in sintered ore preparation, in particular to a method for diagnosing the air leakage rate of a sintered ring cooling machine. The method for on-line diagnosing the air leakage rate of the sintered ring cooling machine comprises the following steps that: the sintered ring cooling machine is divided into a plurality of sections; beginning from a sintered ore inlet of each section, a hypothetic temperature of a node in an outlet of each section after the sintered ore is cooled is set; according to a thermal equilibrium method, the sintered ore temperature of each node is calculated step by step till the sintered ore temperature in the outlet is calculated out; the calculated result is compared with the actual measuring result; if the trial temperature error and the trial heat loss error of the sintered ore in the outlet are in a preset range, the calculation is terminated and the sintered ore temperature of each node can be obtained; if the errors are beyond the preset range, the node temperature is reset and the calculation is carried out again; according to the sintered ore temperature in each node, the ineffective air rate, that is the air leakage rate of each section, is further calculated; and the sum of the air leakage rate of the sections is the total air leakage rate. The method for diagnosing the air leakage rate of the sintered ring cooling machine provides foundation for controlling harmful air leakage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Soaking sintering method based on layered composite heat supply

The invention relates to a soaking sintering method based on layered composite heat supply. The soaking sintering method based on layered composite heat supply comprises the following steps that 1), proportioning is carried out on an iron-containing raw material, a flux, a solid fuel and water, and the proportioned sintering mixture is distributed onto a sintering machine trolley; 2) the sintering mixture distributed to the sintering machine trolley is ignited, and the fact of sintering the surface-layer sintering mixture in the sintering machine trolley is started; 3) high-temperature gas is injected to the material surface of the sintering mixture after ignition, and the high-temperature gas supplies heat to the middle-upper layer sintering mixture; (4) after heat preservation and heat supply, combustible gas is injected to the material surface of the sintering mixture, and the combustible gas is combusted in the material layer to supply heat to the middle-layer sintering mixture; and (5) after gas injection, steam is injected to the material surface of the sintering mixture, and the steam accumulates heat to supply heat to the lower-layer sintering mixture. By adopting the method, the problems of insufficient heat of an upper material layer and excessive heat of a lower material layer in traditional sintering can be effectively solved, and green soaking low-carbon sintering is realized.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method for smelting vanadium-titanium magnetite by blast furnace

InactiveCN101638698ALittle impact on performanceIncrease contentBlast furnace detailsBlast furnace smeltingFerrous metallurgy

The invention belongs to the technical field of ferrous metallurgy, in particular to a method for smelting a vanadium-titanium magnetite by a blast furnace, which aims to provide a method for smeltinga vanadium-titanium magnetite by a blast furnace with lower cost. The method comprises the following step: adding the following raw materials into a blast furnace for smelting in percentage by weight: agglomerate being more than or equal to 60 percent and less than or equal to 70 percent, mixing pellet being more than or equal to 0 percent and less than or equal to 30 percent, full vanadium-titanium pellet being more than 0 percent and less than or equal to 30 percent and lump ore being more than or equal to 3 percent and more than or equal to 7 percent, wherein the percentage composition ofthe full vanadium-titanium pellet is not 0, and the summation of the mixing pellet and the full vanadium-titanium pellet is 30 percent. TiO2 which is a final slag component of the blast furnace smelting method is 21-23 percent by weight, and the final slag component has no influence on the stable operation of the blast furnace within a proper range of the normal smelting of the blast furnace at present. The method reduces the content of the TiO2 in the agglomerate, increases the content of the TiO2 in the pellets, improves the proportion of schreyerite in the smelting raw materials in the blast furnace and lowers the smelting cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Compound sintering method for powdery iron-containing waste mini-pellets

InactiveCN101736147ASolve Feiyang's impact on the environmentRelief ConcentrationProcess efficiency improvementCoke ovenWaste material

The invention discloses a compound sintering method for powdery iron-containing waste mini-pellets, which aims to reduce the environmental pollution of raising dust of powdery iron-containing waste materials and avoid the influence on the sintering quality. The method comprises the steps of: arranging two rows of atomizers in a drum mixer; mixing synthetical powder uniformly through the drum mixer, and performing intensified granulation on the synthetical powder to obtain pellets with the diameters of between 3 and 8mm under the action of a rotary force of the drum mixer; mixing the synthetical powder pellets and coke powder in percentage by weight: 96.5 percent of the synthetical powder pellets and 3.5 percent of the coke powder; distributing the mixture on a belt-type sintering machine after the mixing, adopting a double-sloping girdle ignition furnace, using coke oven gas for ignition at the temperature of 1,050 DEG C, using an exhaust fan at a rate of 4,500m3 / min for air draft, and consolidating to form mini-pellet ore with the diameter of between 3 and 8mm under the condition of the suction negative pressure of 8,500Pa and the sintering temperature of 1,200 DEG C; and adding the mini-pellet ore taken as an iron material into a sintering mixture for secondary sintering consolidation to obtain compound sintered ore.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for improving liquidity of high titanium slag in blast furnace smelting vanadium titano-magnetite

ActiveCN103276126AQuality improvementImprove liquidityBlast furnace detailsMagnetiteBlast furnace smelting

The invention relates to a method for improving liquidity of high titanium slag in blast furnace smelting vanadium titano-magnetite. The method comprises the following steps: preparing boron iron concentrate into vanadium titanium sintered ore, adding the sintered ore into a blast furnace together with other furnace burdens; injecting solid boric acid and pulverized coal into the furnace, so that the contents of the sintered ore and B2O3 entering the slag in a blowing mode account for 0.8-1.3 weight percent of the total slag amount. According to the method, the quality of the high titanium vanadium titano-magnetite is improved, the liquidity of high titanium slag is effectively improved, and the slag and iron are favorably separated; and moreover, the method is simple in process and favorable for industrial application since the coal burning process, the coal blowing process and equipment do not need to be improved.

Owner:UNIV OF SCI & TECH BEIJING

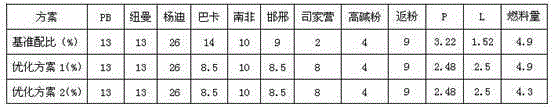

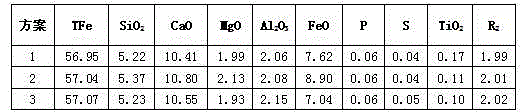

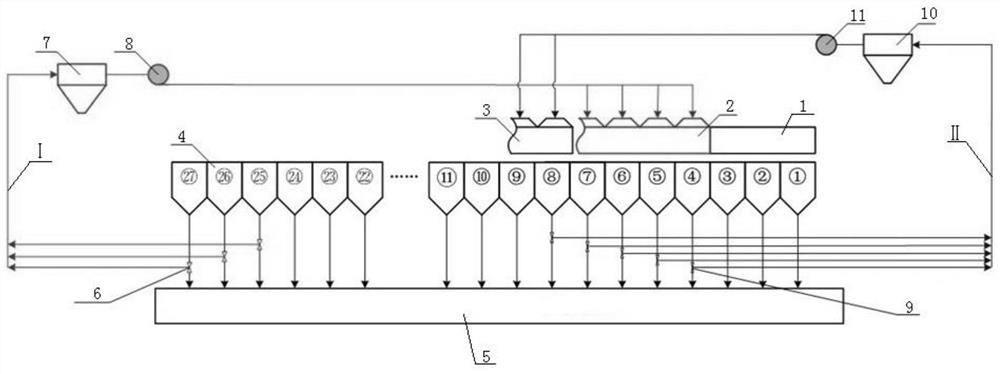

Optimization method of sintering proportioning structure

The invention relates to an optimization method of a sintering proportioning structure, belongs to the technical field of sintering proportioning, and solves the problem that a sintering process and the quality improvement of sintering ores cannot be realized in an existing sintering proportioning mode. The optimization method is characterized by prior to determination of the dosages of iron mine powder, fusing agents and fuels in a sintering mixture, comprising the following steps: 1, drying the iron mine powder for sintering into dry basis iron mine powder; 2, uniformly mixing and splitting each dry basis iron mine powder and testing P nucleus which is the weight percent of Nuclear ore with grain size of 0.63-10mm in the dry basis iron mine powder, and P powder which is the weight percent of adhesive powder with the grain size less than 0.2mm in the dry basis iron mine powder respectively; 3, testing L powder which is the liquid phase fluidity index of the adhesive powder with the grain size less than 0.2mm in the dry iron mine powder; 4, repeatedly carrying out the steps from 1 to 3, and testing the nucleus ratio, the powder ratio and the liquid phase fluidity indexes of the second iron mine powder, the third iron mine powder,... and the ith iron mine powder; and 5, determining the proportion of the iron mine powder in the mixture according to a restriction condition. According to the optimization method, the adverse effect on the sintering process and the quality of the sintering ores caused by superfusion of the ores or the insufficiency of liquid phase quantity can be avoided, and the method is reasonable in carbon proportioning, easy to operate, high in practicability and can adapt to a diversified raw material structure.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Composite sintering catalyst

ActiveCN102660349AImprove heat utilizationImprove breathabilitySolid fuelsCarboxymethyl starchSodium Bentonite

The invention relates to composite sintering catalyst which is made of, by weight percent, 3-12% of carboxymethyl starch, 20-60% of borax, 10-35% of dextrin, 5-10% of slaked lime, 10-30% of calcium bentonite and 5-15% of lignin. By the aid of the composite sintering catalyst, on the basis of not changing sintering components and sintering technology, the sintering process can be greatly improved,thermal utilization rate of fuels can be increased, consumption of the fuels is greatly reduced by 5-10%, reactivity of the fuels is enhanced, permeability of beds of material is improved, the speed of vertical sintering is increased, utilization coefficient of sintering is increased, the quality of sinters or refectories is improved, yield is increased by 3%-5%, and sintering cost is reduced.

Owner:通化耐博新材料股份有限公司

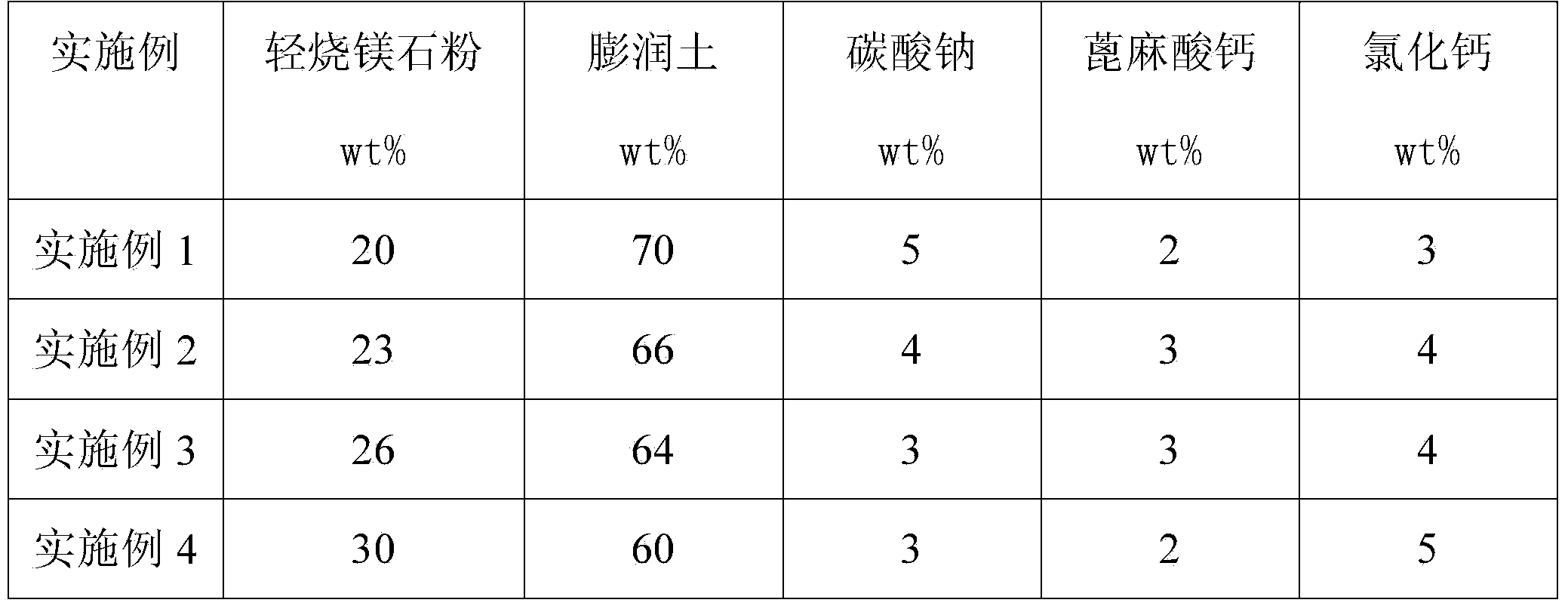

Magnesium composite bentonite for pelletizing

The invention provides magnesium composite bentonite for pelletizing. The bentonite comprises the following components in percentage by weight: 20-30% of light-burned magnesite powder, 60-70% of bentonite, 3-5% of sodium carbonate, 2-3% of calcium ricinoleate and 3-5% of calcium chloride; the magnesium composite bentonite comprises the following main chemical components in percentage by weight: 25-30% of MgO, 45-55% of SiO2, and less than 15% of water. By adopting the magnesium composite bentonite disclosed by the invention, the MgO content of a pellet ore can be increased to 1.5%, the mechanical strength of the pellet ore can be increased by 1.5-2%, the initial softening temperature of the pellet ore can be increased by 150-200 DEG C, the MgO content of a sintering ore can be reduced relatively, the quality of the sintering ore can be improved, and the consumption of a sintering fuel can be reduced.

Owner:王志

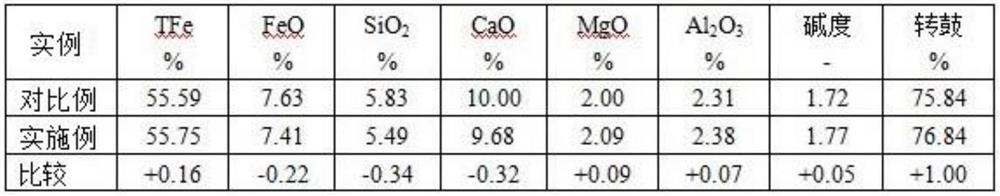

Vanadium-titanium concentrate powder thick material layer sintering technology

The invention discloses a vanadium-titanium concentrate powder thick material layer sintering technology. The vanadium-titanium concentrate powder thick material layer sintering technology comprises the following steps that sintering raw materials are mixed to be uniform, and the sintering raw materials comprise, by weight, 50-60 parts of vanadium-titanium concentrate powder, 5-8 parts of iron oreconcentrate powder, 10-20 parts of a fluxing agent and 3-5 parts of fuel; the sintering raw materials are crushed; the powder is infiltrated with water and then prepared into pellets; the pellets aredistributed on sintering equipment, and the distributing thickness is 720-740 mm; the pellets are sintered into pellet ore; and the pellet ore is cooled. By changing the component proportion of the sintering raw materials and adding the fluxing agent to improve the air flow fluidity, therefore, the large sintering material distributing thickness is achieved, and the sintered ore quality is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

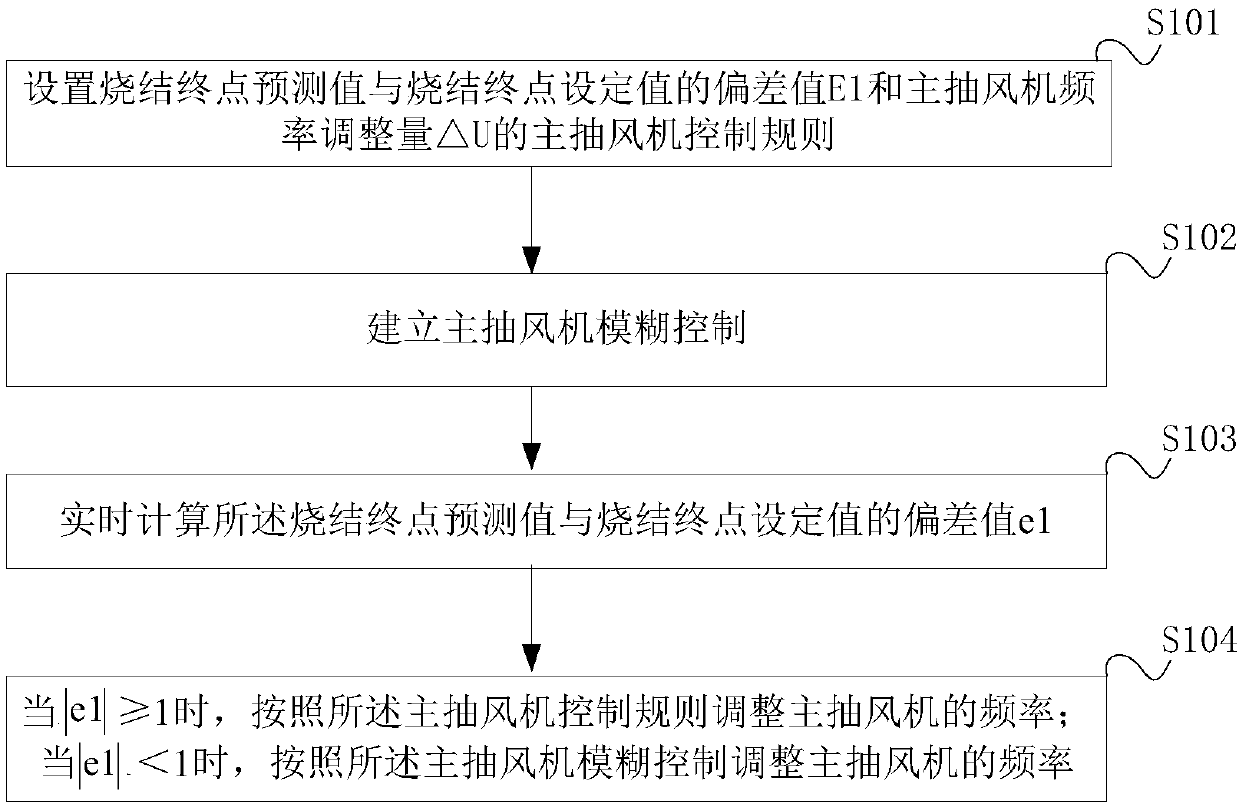

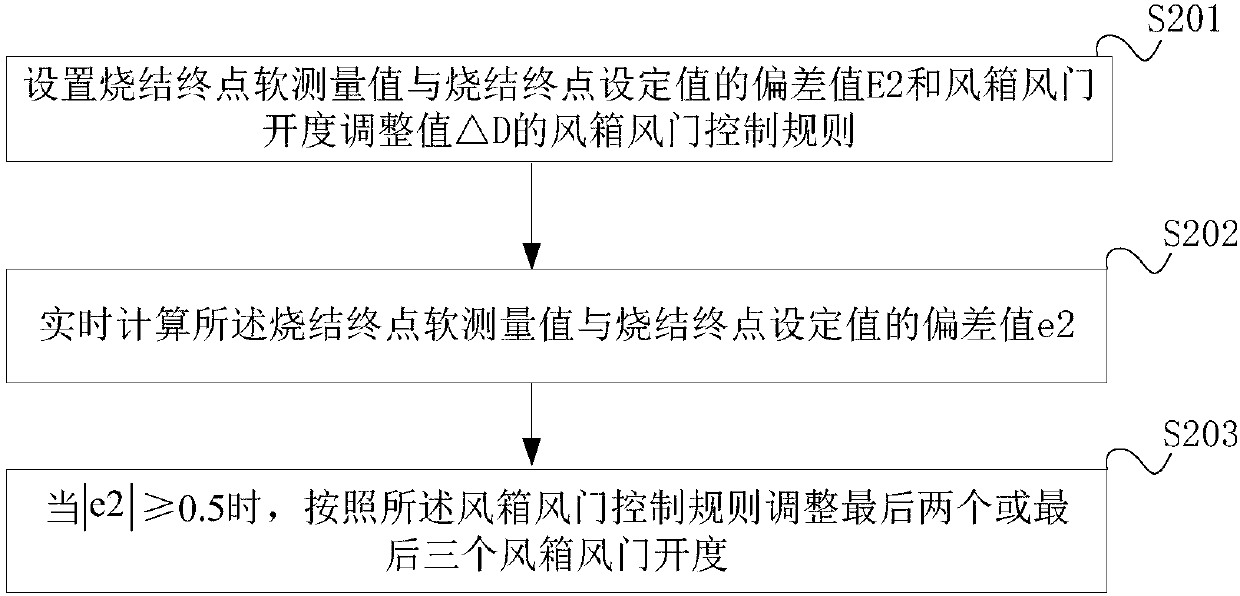

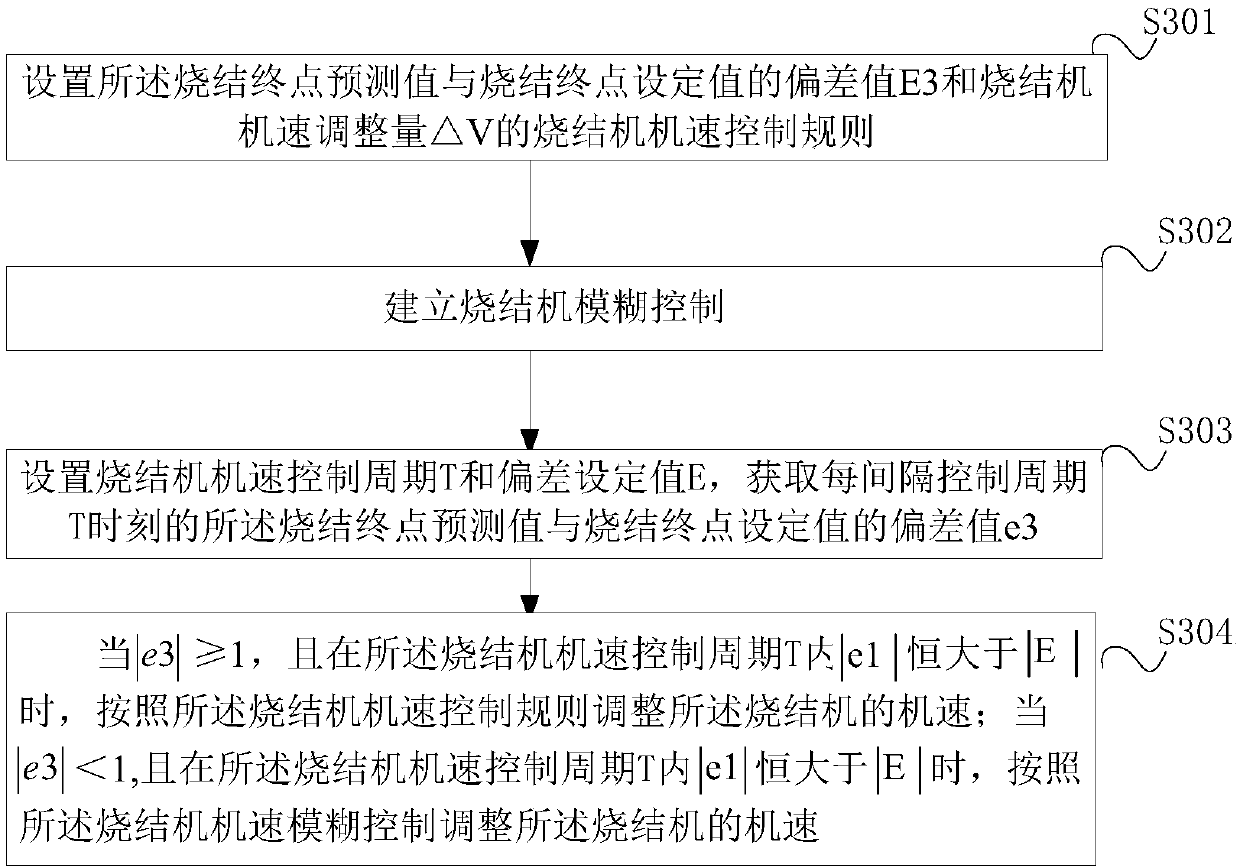

S intering end point position control method and system

ActiveCN107941010ARealize coordinated controlStable sintering production processFurnace typesControl devices for furnacesFuzzy control systemPosition control

The invention provides a sintering end point position control method and system. The method comprises the steps of setting a deviation value E1 of the sintering end point prediction value and the sintering end point set value and a main exhaust fan frequency control rule of the main exhaust fan frequency adjustment amount delta U, and establishing a main exhaust fan frequency fuzzy control; setting a deviation value E2 of the sintering end point soft measurement value and the sintering end point set value and an air box air door control rule of the air box air door opening degree adjusting value delta D; and setting the deviation value E3 of the sintering end point prediction value and the sintering end point set value and a sintering machine machine speed control rule of the sintering machine machine speed adjustment amount delta V, establishing a sintering machine machine speed fuzzy control, and according to the deviation values e1 and e2 monitored in real time, an overall coordination control of the sintering process state is realized through the operations that the controls on the main exhaust fan frequency and the air box air door opening degree serve as a main control, and the control on the sintering machine machine speed serves as an auxiliary control. According to the sintering end point position control method and system, the sintering end position can be facilitatedto be stably controlled to be close to a set value, the sintering production process is stabilized, and sintering production efficiency is improved.

Owner:SHANXIN SOFTWARE CO LTD

Thick material layer sintering production method

The invention discloses a thick material layer sintering production method. According to the method, an upper layer sintering mixture and a lower-layer sintering mixed material of a sintering machinecan be sintered at the same time through twice material spreading and twice ignition, so that the thickness of a sintered material layer is improved, the yield of sintered ore is improved, and sintering indexes are improved; after primary material spreading and before secondary ignition, special carbon pellets are placed, so that heat supply and mineralization time of an upper material layer can be increased, the quality of upper-layer sintered ore is improved, and the sintered ore return amount is reduced; and the hypoxia problem of a lower sintered material layer is solved, the lower sintered material layer is fully mineralized, and the quality of lower-layer sintered ore is improved.

Owner:ANGANG STEEL CO LTD

Limonite sintering treatment method

The invention discloses a limonite sintering treatment method which comprises the following steps: baking limonite, adding a sintering mixture, and sintering, wherein combustion blast furnace gas is used for baking the limonite, the baking temperature is 410-460 DEG C, and the baking time is 6-10 minutes. The limonite power is mainly composed of the following components in percentage by weight: 37.7-43.66% of TFe, 18.3-23.6% of SiO2, 0.1-0.5% of CaO, 0.3-0.6% of MgO, 4.3-5.6% of Al2O3 and 10.7-12.8% of Ig. Compared with the prior art, the method disclosed by the invention can eliminate the blowout phenomenon of coarse-grain limonite in the sintering process, enhances the strength and yield of the sintered ores, reduces the limonite crystalline water content and fuel consumption, is beneficial to sintering, can improve the metallurgical properties of the sintered ores, enhances the technical economical indexes of blast-furnace smelting, and greatly enhances the resistance to tumbling, yield and metallurgical properties of the sintered ores.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

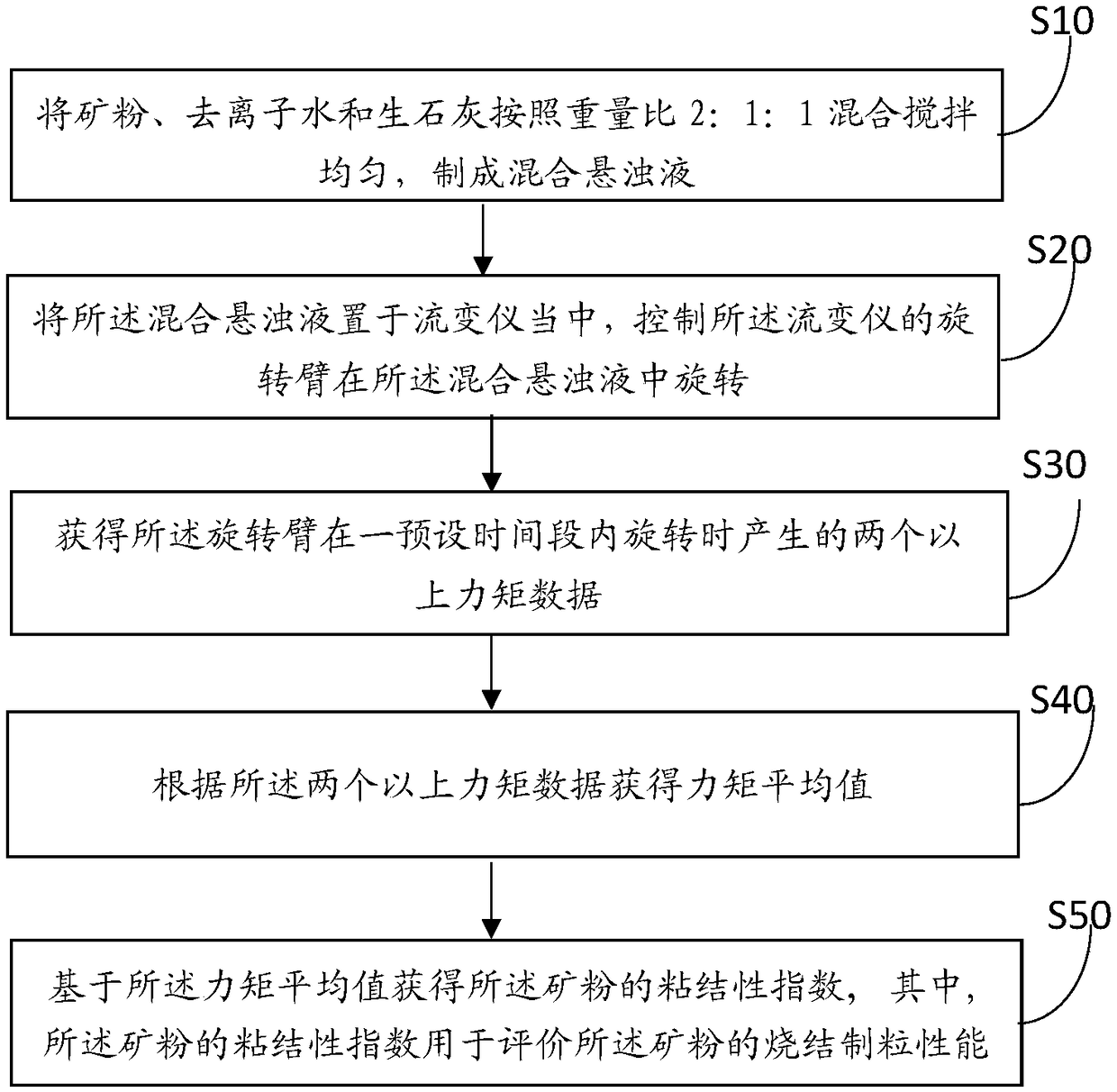

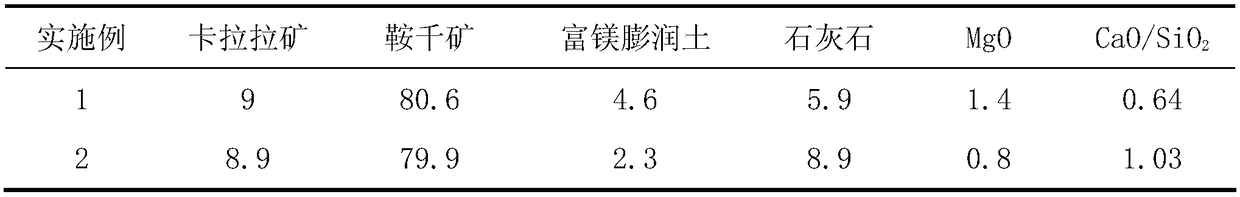

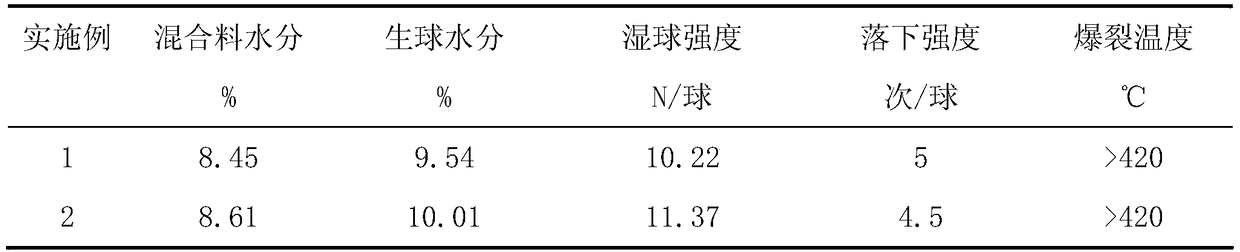

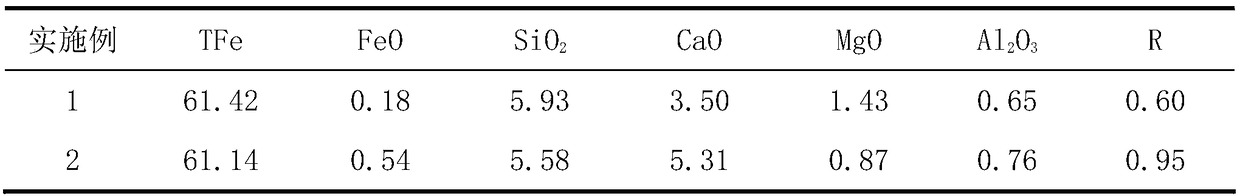

Method for detecting cohesiveness index of iron ore powder

InactiveCN109283096AAccurate evaluation of sintering granulation performanceGuaranteed breathabilityFlow propertiesIron powderMaterials science

The invention discloses a method for detecting the cohesiveness index of iron ore powder. The method comprises the following steps: the ore powder, deionized water and lime are evenly mixed and stirred according to the weight ratio of 2 to 1 to 1 to be made into a mixed suspension; the mixed suspension is placed into a rheometer, and a rotating arm of the rheometer is controlled to rotate in the mixed suspension; two or more torque data generated by the rotating arm during rotation within a preset time period are obtained; a torque mean value is obtained according to the two or more torque data; and the cohesiveness index of the ore powder is obtained based on the torque mean value. The technical problems that effective detection and evaluation methods for the cohesiveness of the ore powder are lacked, the granulation performance of the ore powder cannot be determined, and the permeability of a sinter material layer is affected are solved. The technical effects that the sintering granulation performance of the ore powder is obtained through the cohesiveness index, the permeability of the sinter material layer is guaranteed through the reasonable parameter ratio, and the sinter orequality is improved are achieved.

Owner:SHOUGANG CORPORATION

Magnesium-containing fluxed pellet material preparation method

InactiveCN108396087AReduce consumptionReduce metallurgical performance indicatorsBlast furnace detailsAlkalinityMaterials preparation

The invention provides a magnesium-containing fluxed pellet material preparation method, wherein magnesite is not added during the sintering material preparation, and MgO required by blast furnace slag is provided by pellet; the magnesium-containing fluxed pellet comprises iron ore concentrate and flux, the flux comprises added magnesium-rich bentonite and limestone, the iron content of the iron ore concentrate is more than 67%, the particles with the particle size of 200 mesh is greater than 90%, the MgO content in the magnesium-rich bentonite is more than 40 wt%, the particles with the particle size of 320 mesh is more than 90%, the adding ratio is determined according to the balling performance of the iron ore concentrate and the MgO content required in the pellet; and the CaO content in the limestone is greater than 50 wt%, the particles with the particle size of more than 320 mesh is greater than 90%, and the adding ratio is determined according to the required pellet alkalinity.With the method of the present invention, the sintering fuel consumption can be reduced, the quality of the sintered ore can be improved, the softening temperature of the pellet can be increased, thesoftening temperature range can be narrowed, and the metallurgical performance index can be improved.

Owner:ANGANG STEEL CO LTD

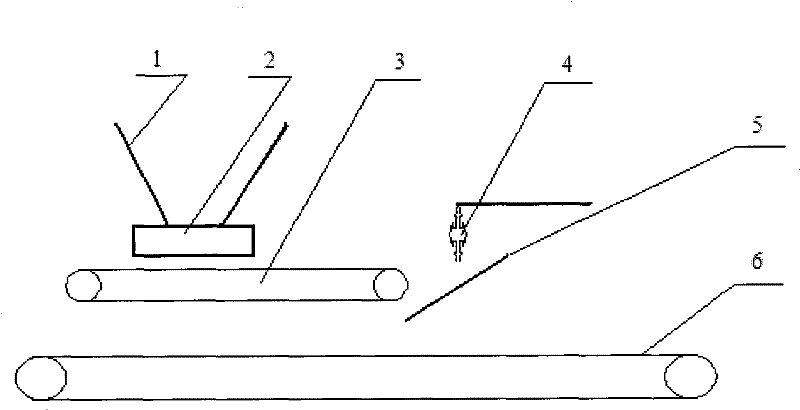

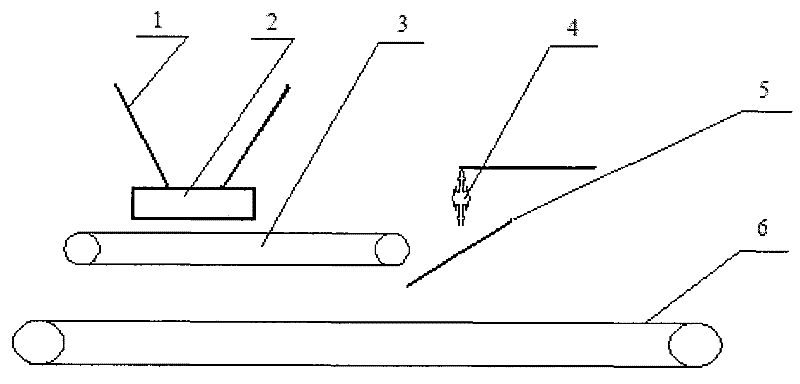

Sintering combustion improver and adding device and adding method thereof

The invention provides a sintering combustion improver and an adding device and adding method thereof. The combustion improver consists of rare earth, potassium permanganate, boric acid, magnesium chloride, ferrous oxide, nitrate, manganese dioxide and quick lime. The adding device consists of an ore tank, a disk feeder, a belt electronic scale, a water-adding nozzle and a material-collecting plate. The adding method comprises the following steps: adjusting the revolution of the disk feeder, controlling the discharging amount of the combustion improver and mixing the combustion improver and the water sprayed by the water-adding nozzle to dissolve in the fuel of a fuel conveyor. The sintering combustion improver has a certain catalytic combustion effect on the gasification combustion reaction of coal power. By adopting the sintering combustion improver, the consolidation strength of the sintered ore is improved, the melting point temperature of the mixed material is reduced, the yield of the sintered ore is increased, the rate of combustion is increased, the burning through point shifts forward and the dosage of solid fuel is reduced so that the fuel consumption can be reduced and the quality of the sintered ore can be improved.

Owner:ANGANG STEEL CO LTD

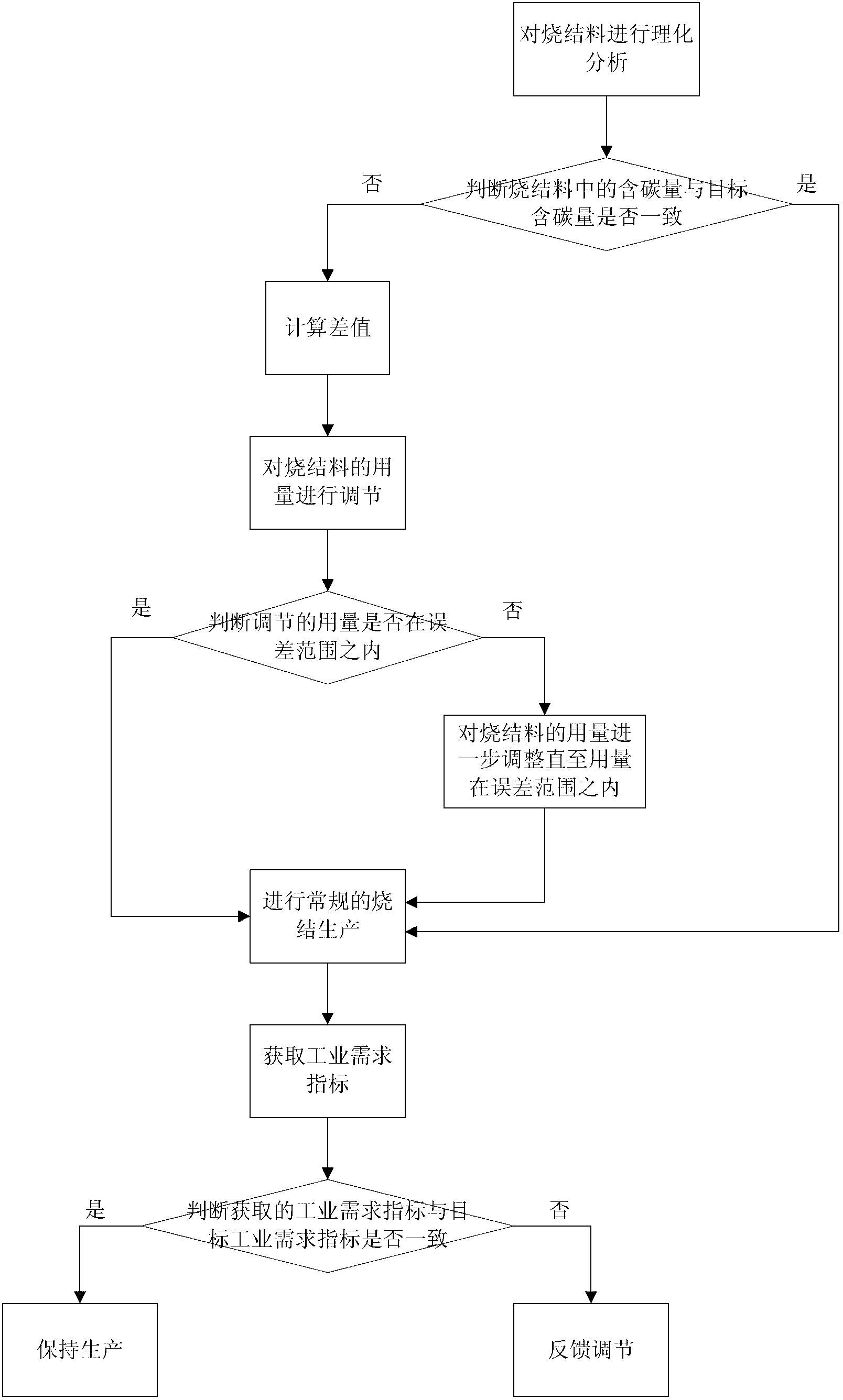

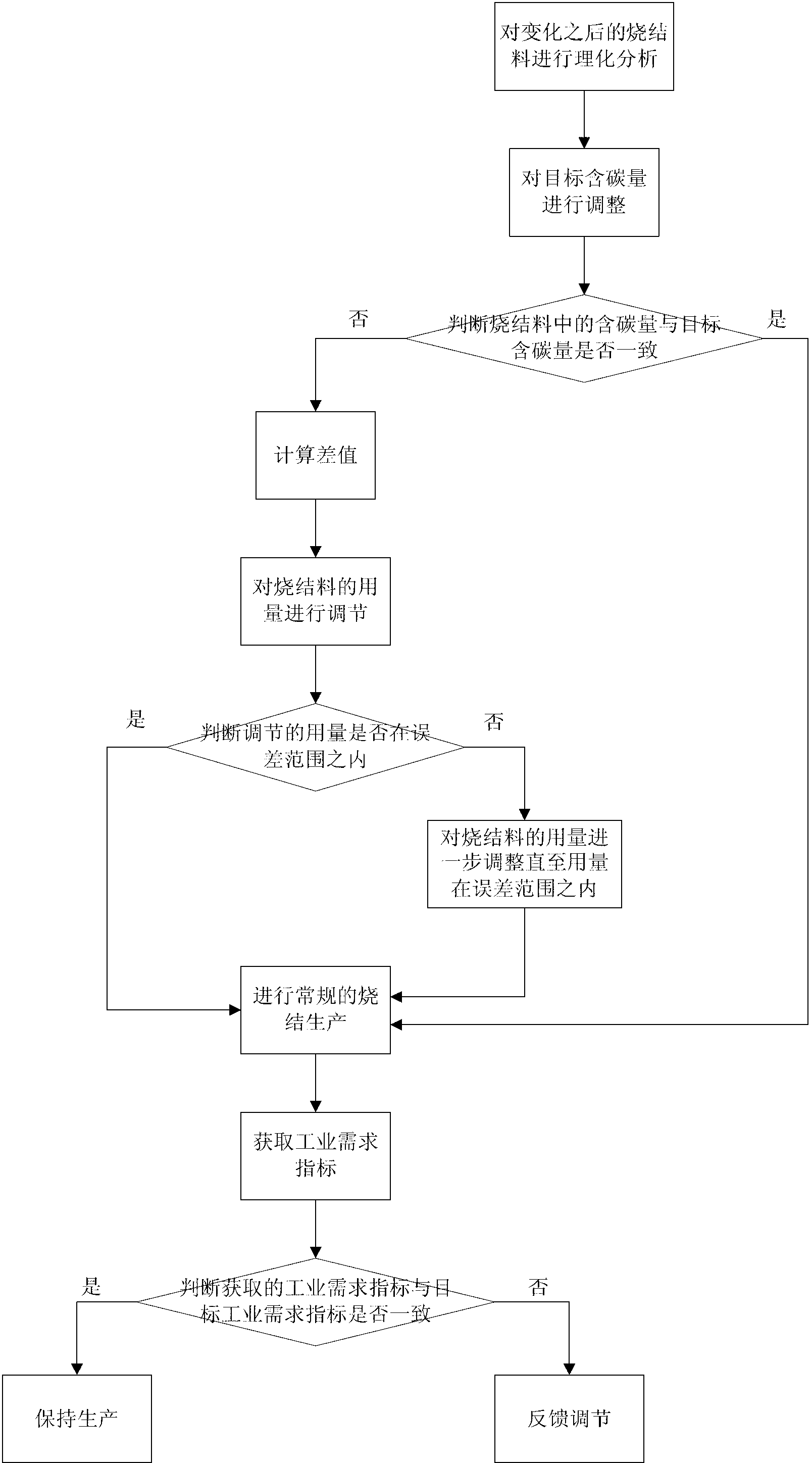

Control method for carbon content of sintered material

ActiveCN103234351ASolving the problem of carbon fluctuationsReduce fuel consumptionFurnace typesUltimate tensile strengthFeedback regulation

The invention relates to the technical field of control methods and discloses a control method for a carbon content of a sintered material. The control method comprises the steps of comparing the carbon content of the sintered material obtained by analysis with a preset target carbon content; if the carbon content of the sintered material does not conform to the target carbon content, adjusting the usage amount of the sintered material until the carbon content of the sintered material conforms to the target carbon content and then performing conventional sintered production; performing feedback regulation on the target carbon content according to industrial demand indexes after the conventional sintered production, and continuing performing comparison regulation on the carbon content of the sintered material according to the target carbon content fed back. According to the control method, stability of the carbon content of the sintered material is guaranteed, the problem of fluctuation of the carbon content of the sintered material is effectively solved, the sintering production process is stable, and the aims of optimizing the sintering process, improving sintering efficiency and quality of sintered ore and reducing solid burn-up and post labor intensity are achieved.

Owner:首钢股份公司迁安钢铁公司

Fluctuation treatment method of sinter bed based on master pumping regulation

The invention relates to a sintering production process of a mixed material and particularly relates to a fluctuation treatment method of a sinter bed based on master pumping regulation. The method provided by the invention completes the sintering process in a qualified manner by monitoring the thickness of a bed on a vehicle to determine the master pumping rotating speed and adjusting the sintering time of a skip car if the bed is thick, so that the sinter quality is improved, the drum strength is improved, the rate of return mine of sintering is reduced, and the circular material amount is reduced. The problem of red ores easy to appear when the bed is thick is avoided, and the service life of a product belt is prolonged.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for improving liquidity of high titanium slag in blast furnace smelting vanadium titano-magnetite

ActiveCN103276126BImprove sinter qualityQuality improvementBlast furnace detailsMagnetiteBlast furnace smelting

The invention relates to a method for improving liquidity of high titanium slag in blast furnace smelting vanadium titano-magnetite. The method comprises the following steps: preparing boron iron concentrate into vanadium titanium sintered ore, adding the sintered ore into a blast furnace together with other furnace burdens; injecting solid boric acid and pulverized coal into the furnace, so that the contents of the sintered ore and B2O3 entering the slag in a blowing mode account for 0.8-1.3 weight percent of the total slag amount. According to the method, the quality of the high titanium vanadium titano-magnetite is improved, the liquidity of high titanium slag is effectively improved, and the slag and iron are favorably separated; and moreover, the method is simple in process and favorable for industrial application since the coal burning process, the coal blowing process and equipment do not need to be improved.

Owner:UNIV OF SCI & TECH BEIJING

A Method for Improving the Air Permeability of All-fine Powder Sintered Material Layer

The invention discloses a method for improving the air permeability of a fully refined powder sintered material layer, relates to the field of steel smelting, in particular to the field of fully refined powder sintered ore. The method comprises the steps that sintering return mines are adopted as granulating balls, are subjected to primary fully refined powder batching mixing, secondary fully refined powder batching mixing, and tertiary fully refined powder batching mixing sequentially, then enter a material loosening device, come out of the material loosening device, and then enter a sintering process. Before being subjected to the primary fully refined powder batching mixing, the sintering return mines are subjected to pre-wetting with atomized water till the water content reaches 4-6%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Sintered ore cooling furnace

ActiveCN103234361BAvoid volatilitySimple structureIncreasing energy efficiencyHandling discharged materialCounter flowMaterial distribution

The invention discloses a sintered ore cooling furnace device. The device is composed of a pre-storage area, an annular air flue area, a chute area, a cooling area and an air chamber. High-temperature sintered ores are continuously and evenly distributed into a cooling furnace for cooling through a charging port above the pre-storage area by a material distribution device, high-temperature sintered ores are subjected to counter-flow heat exchange with low-temperature air blown from the bottom of the furnace in the cooling area of the cooling furnace, sintered ores are cooled to below 180 DEG C, low-temperature ores are discharged by a discharging device, the low-temperature air is heated to about 600 DEG C through counter-flow heat exchange and enters a waste heat recycling system through an air outlet, and hot air and hot sintered ores are effectively sealed inside the cooling furnace in the whole process. By the aid of the device, on the premise that the quality of sintered ores is guaranteed or improved and the return fine rate is reduced, the efficiency of recycling of waste heat of sintered ores is improved to the maximum extent.

Owner:中信重工工程技术有限责任公司

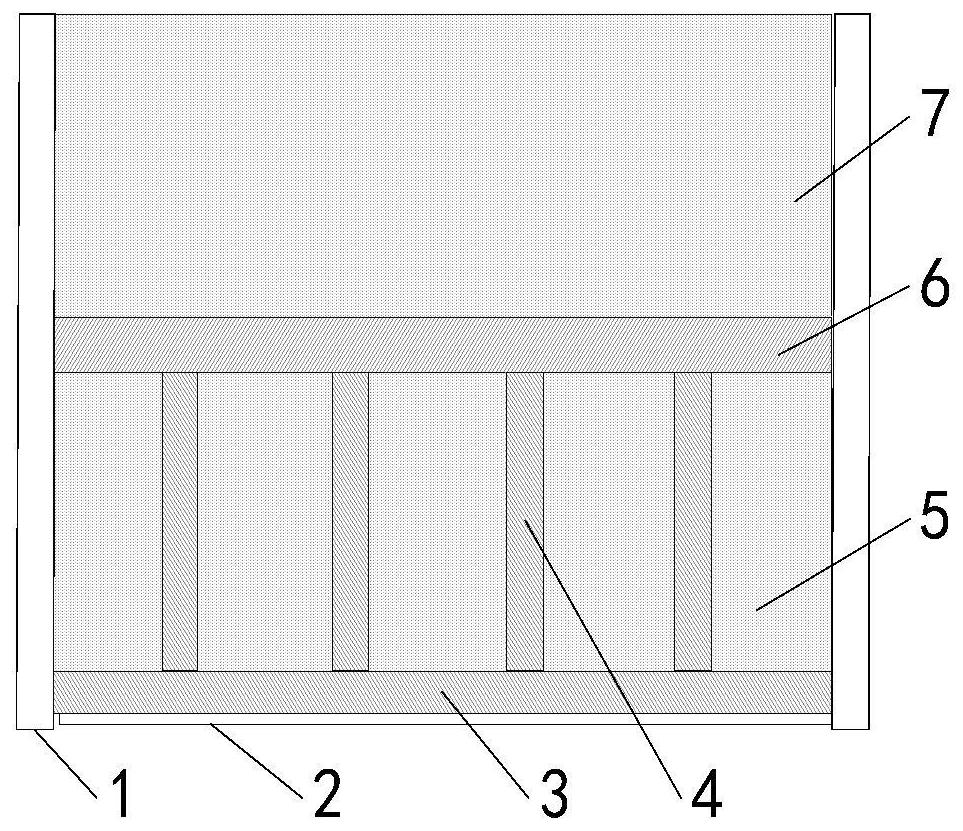

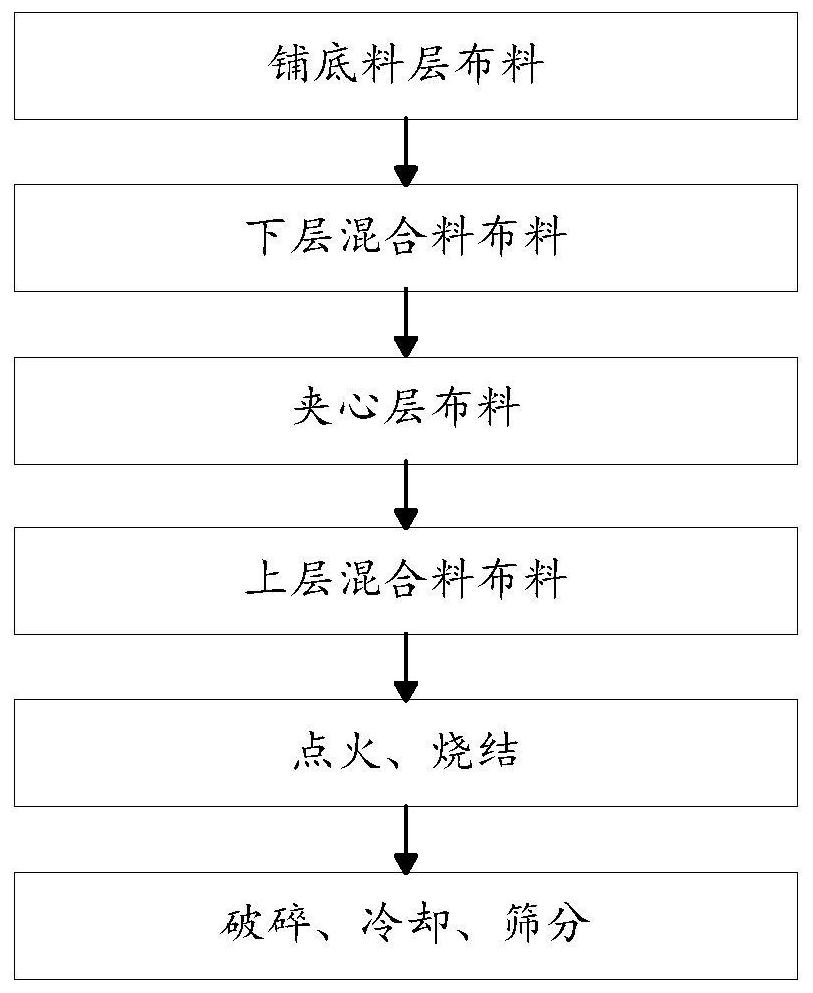

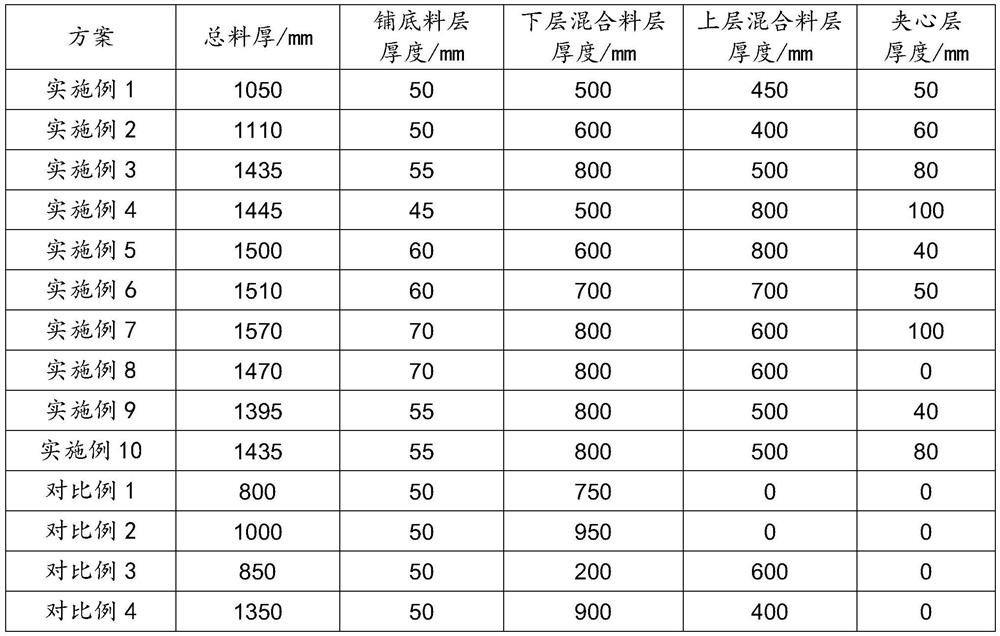

Super-thick material layer sintering material, sintering method and sintering ore

The invention discloses a super-thick material layer sintering material, a sintering method thereof and sintering ore. The sintering material sequentially comprises a grate-layer material layer, a lower mixed material layer and an upper mixed material layer from bottom to top. The lower mixed material layer comprises N partition material bars and to-be-sintered mixed materials, the N partition material bars are vertically arranged at intervals to partition the to-be-sintered mixed materials, the N partition material bars are composed of the first sintering ore, the thicknesses of the N partition material bars are 500-800 mm, the widths of the N partition material bars are 40-60 mm, the distance between any two adjacent partition material bars is 300-1,000 mm, and N is a positive integer. By means of the method, the high sintering speed capable of reaching 26.1 mm / min under a thick material layer more than 1,000 mm thick is achieved, meanwhile, the yield is high and can reach 85%, the fuel consumption is low, and the drum index of the obtained sintering ore is 82%-87%.

Owner:SHOUGANG CORPORATION

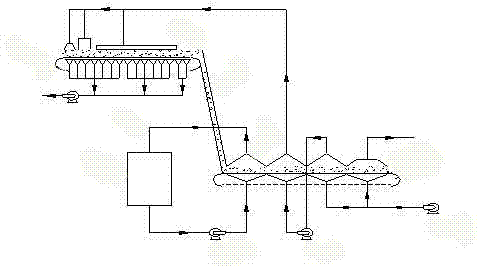

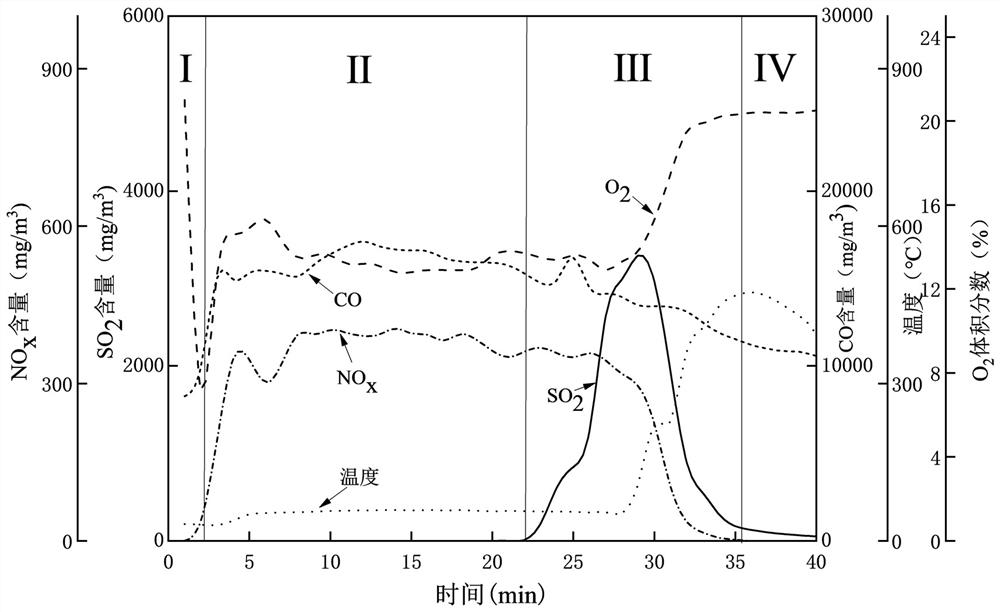

Sintering flue gas circulation method and device

PendingCN109668444AAchieve emission reductionDoes not affect the quality of sintered oreWaste heat treatmentExhaust fumesFlue gas

The invention provides a sintering flue gas circulation method and device. Waste gas which accounts for 10%-20% of the sintering length at the head part of a sintering machine is circulated to the tail part of the sintering machine for use, and the waste gas which accounts for 10%-20% of the sintering length at the tail part of the sintering machine is circulated to the head part of the sinteringmachine for use. The oxygen content of the Waste gas at the head part is low, the oxygen content of the head and the tail circulating region is increased to 20%-25% level by adopting an oxygen-enriched technology, and the sintering condition of the sintering and the quality of the sintered ore are ensured. The invention provides the sintering flue gas circulation method and device, so that the sintering energy conservation and emission reduction are realized; and meanwhile, the oxygen-enriched technology is adopted, so that the production quality of the sintered ore is not influenced.

Owner:ZENITH STEEL GROUP CORP

Energy-saving and emission-reducing sintering machine flue gas circulation method and system

PendingCN112815729AReduce fuel consumptionImprove temperature distributionMaintainance of heating chambersCharge treatment typePhysicsProcess engineering

The invention relates to an energy-saving and emission-reducing sintering machine flue gas circulation method and system. The sintering machine flue gas circulation system is divided into a hot section flue gas circulation system and a cold section flue gas circulation system. The hot section flue gas circulation system is used for leading out high-temperature and high-oxygen flue gas at a machine tail of a sintering machine, and feeding the flue gas into a hot section flue gas cover at a machine head after dust removal; and the cold section flue gas circulation system is used for leading out low-temperature and low-oxygen flue gas at the machine head of the sintering machine, and sending the flue gas into a cold section flue gas cover at the machine tail after dust removal. According to the energy-saving and emission-reducing sintering machine flue gas circulation method and system provided by the invention, a flue gas segmented internal circulation mode is adopted, so that gradient utilization of sintering flue gas is realized; and flue gas waste heat is fully utilized, so that energy consumption in the sintering process is saved, emission of organic pollutants such as NOx, dioxin, carbon monoxide and the like is remarkably reduced, and the purposes of energy conservation and emission reduction are realized.

Owner:中国冶金矿业鞍山冶金设计研究院有限责任公司

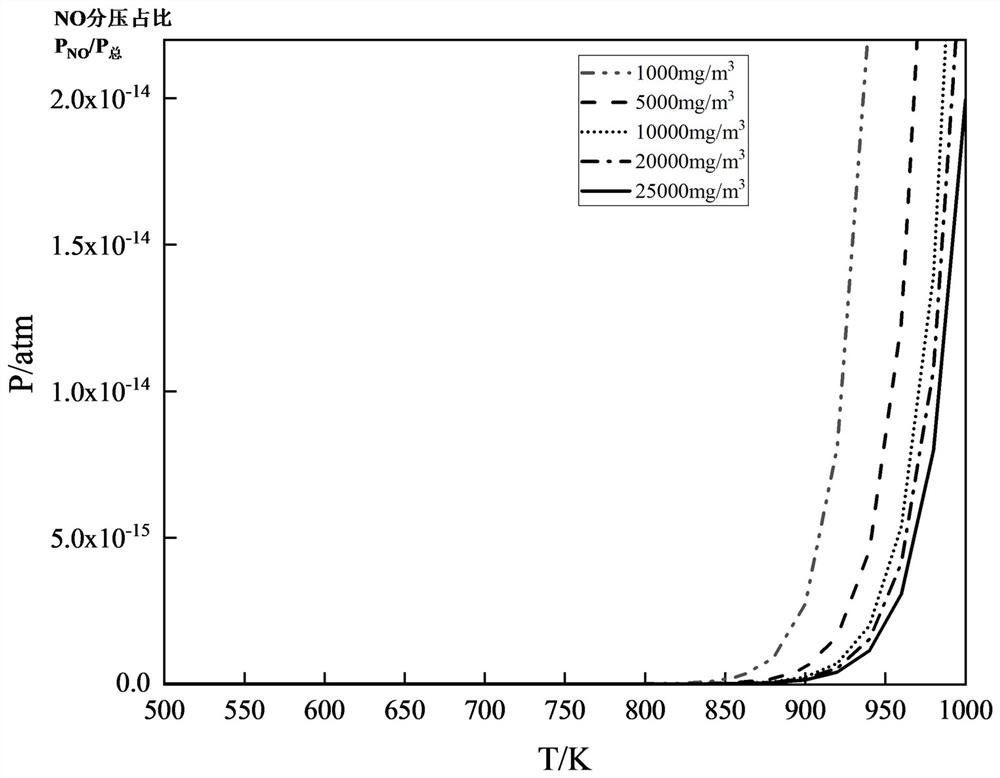

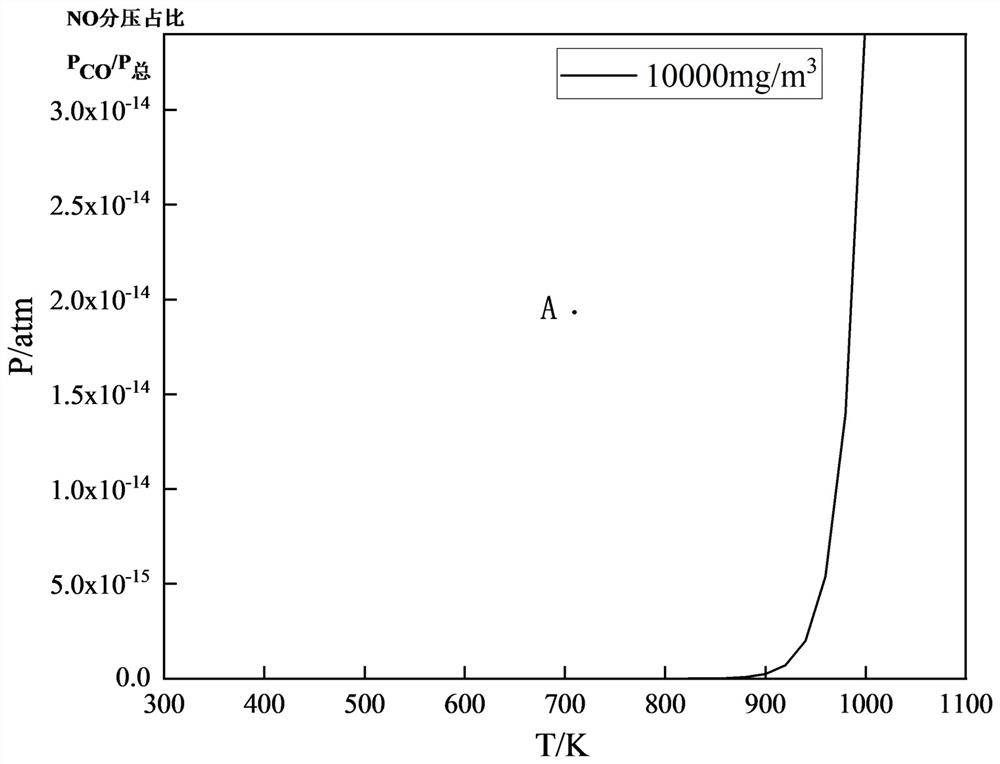

Method for denitration in sintering process by using multiple flue gases

ActiveCN114485196AImprove denitrification efficiencyEfficient emission reductionWaste heat treatmentThermodynamicsFlue gas

The invention discloses a method for denitration in a sintering process by using various flue gases. The method comprises the following steps: carrying out component analysis on flue gases of different furnaces and kilns; assembling and mixing the flue gas in a gas holder, monitoring the components and the temperature of the flue gas at an outlet of the gas holder in real time, adjusting a flue gas assembling scheme, determining that the components CO and the temperature of the assembled flue gas meet the requirements, and enabling the assembled flue gas to pass through a sintering pallet in production; after flue gas in the first middle stage of sintering production comes out of an ore deposit, the flue gas is led to a sinter circular cooler for NO removal, and the flue gas with NO removed is subjected to waste heat recovery to form external circulation; and flue gas in the later stage of sintering production is used as sintering circulating flue gas to return to the gas holder and is subjected to flue gas assembly together with industrial flue gas to form internal circulation. The effect of treating waste with waste is obvious, and a new thought is provided for efficient emission reduction of NOx in the sintering process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sintered ring cold machine air leakage rate on-line diagnostic method

InactiveCN101290253BReduce power consumptionImprove sinter qualityMuffle furnacesRetort furnacesHeat lossesThermal equilibrium

The invention relates to cooling control equipment for metallurgy in sintered ore preparation, in particular to a method for diagnosing the air leakage rate of a sintered ring cooling machine. The method for on-line diagnosing the air leakage rate of the sintered ring cooling machine comprises the following steps that: the sintered ring cooling machine is divided into a plurality of sections; beginning from a sintered ore inlet of each section, a hypothetic temperature of a node in an outlet of each section after the sintered ore is cooled is set; according to a thermal equilibrium method, the sintered ore temperature of each node is calculated step by step till the sintered ore temperature in the outlet is calculated out; the calculated result is compared with the actual measuring result; if the trial temperature error and the trial heat loss error of the sintered ore in the outlet are in a preset range, the calculation is terminated and the sintered ore temperature of each node can be obtained; if the errors are beyond the preset range, the node temperature is reset and the calculation is carried out again; according to the sintered ore temperature in each node, the ineffective air rate, that is the air leakage rate of each section, is further calculated; and the sum of the air leakage rate of the sections is the total air leakage rate. The method for diagnosing the air leakage rate of the sintered ring cooling machine provides foundation for controlling harmful air leakage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

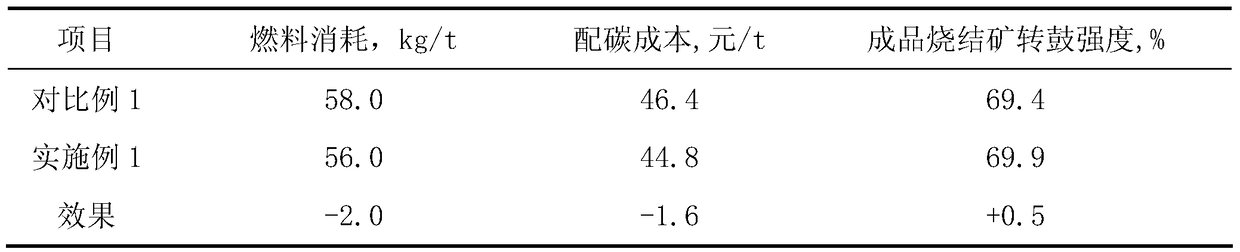

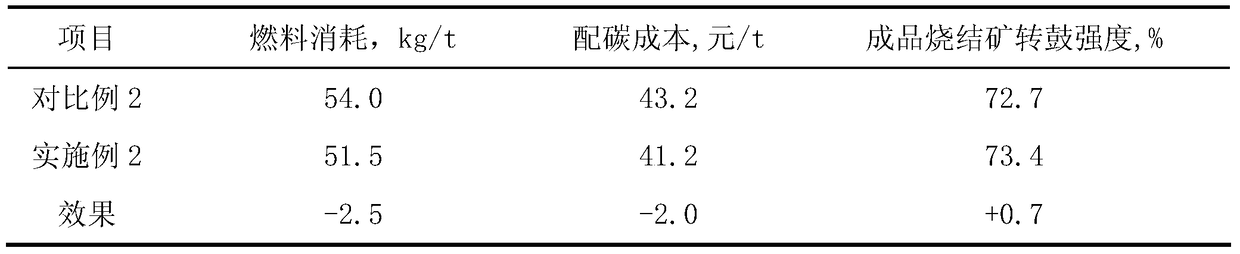

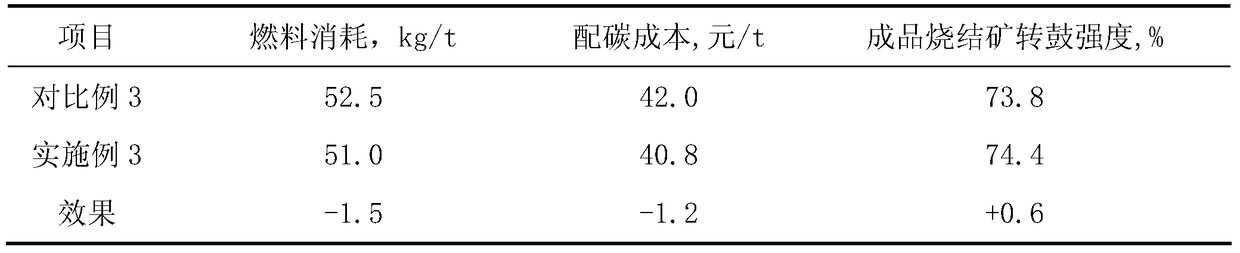

A kind of fuel for sintering batching and adding method thereof

ActiveCN107012318BFlexible adjustment of dosageReduce carbon distribution costsSolid fuelsMetallurgyMixed materials

The invention provides fuel for sintering ingredients and an adding method of the fuel. According to the fuel for the sintering ingredients, one of semi-coke and CDQ powder is used, or a mixture of the semi-coke and the CDQ powder is used, and in use, the mixture comprises 40-80% wt% of the semi-coke and 20-60% of the CDQ powder. The fuel is put into a fuel bin of an ingredient workshop and put onto a belt through a disc feeder; the fuel is evenly mixed with other kinds of ore and a fusing agent through a primary mixing machine and a secondary mixing machine; then the mixed material is put on a sintering trolley through a distribution device, and sintering production of the mixed ore is conducted; and the adding amount of the fuel in the mixed material is worked out according to the formula of RL=K1+QT*K2+YHG*K3+EYHG*K4+SF*K5+GD*K. By the adoption of the fuel, the fuel dosage can be adjusted flexibly according to the different core conditions during sintering, mixing and bending, so that the carbon blending cost per ton of the mixed ore is lowered by over RMB 1 yuan, the low cost of the ore blending for sintering is achieved, and the quality of the sintered ore can be improved effectively.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com