Magnesium-containing fluxed pellet material preparation method

A technology of magnesium flux and pellets, which is applied in the field of batching of magnesium-containing flux pellets for blast furnace smelting in metallurgical enterprises, can solve problems such as high sintering temperature, influence of sinter strength, increased fuel consumption, etc., to reduce sintering fuel consumption, Effect of improving sinter quality and reducing coke ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

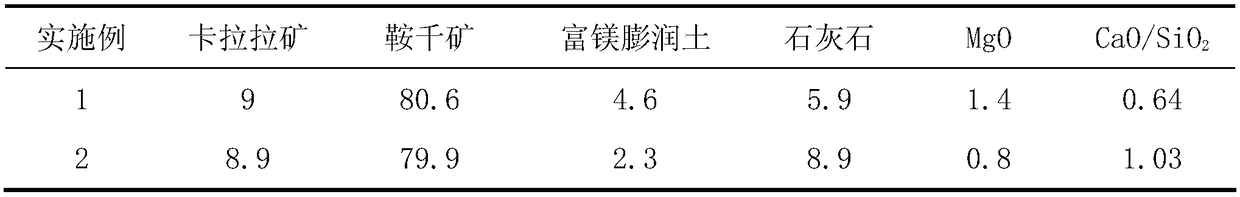

[0012] Examples See Table 1 for the magnesium-containing flux pellet ingredients wt%.

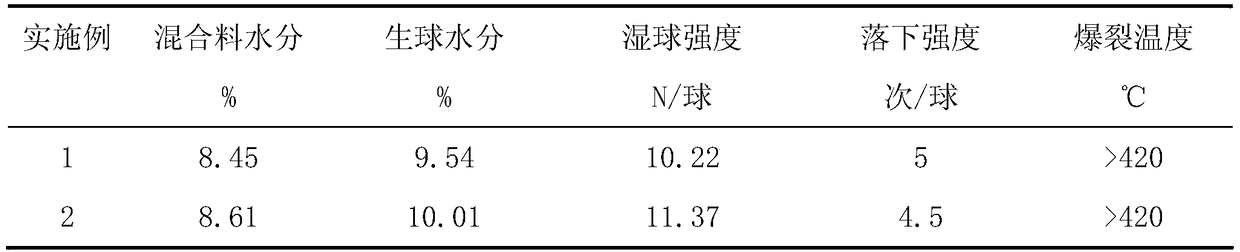

[0013] The pelletizing index of magnesium-containing flux pellets is shown in Table 2;

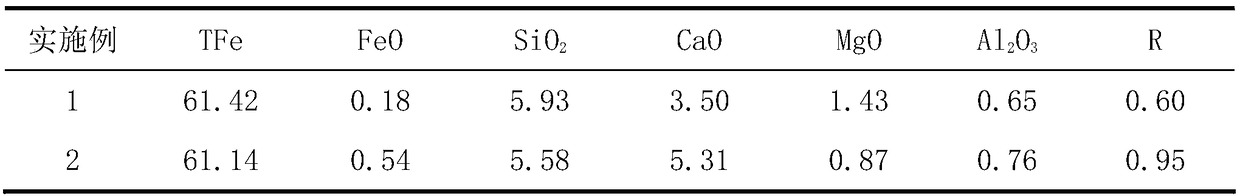

[0014] The chemical composition indexes of the magnesium-containing flux pellets are shown in Table 3;

[0015] Examples The physical indicators of magnesium-containing flux pellets are shown in Table 4.

[0016] Table 1 magnesium-containing flux pellet ingredients wt%

[0017]

[0018] Table 2 Pelletization index of magnesium-containing flux pellets

[0019]

[0020] Table 3 The chemical composition index (wt%) of magnesium-containing flux pellets

[0021]

[0022] Table 4 Physical indicators of magnesium-containing flux pellets

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com