Soaking sintering method based on layered composite heat supply

A thermal sintering and sintering machine technology, applied in the field of sintering, can solve problems such as uneven temperature distribution in the combustion zone, narrow combustion zone, and adverse effects on the overall quality of sintering ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0136] According to the first embodiment of the present invention, a soaking sintering method based on layered composite heat supply is provided.

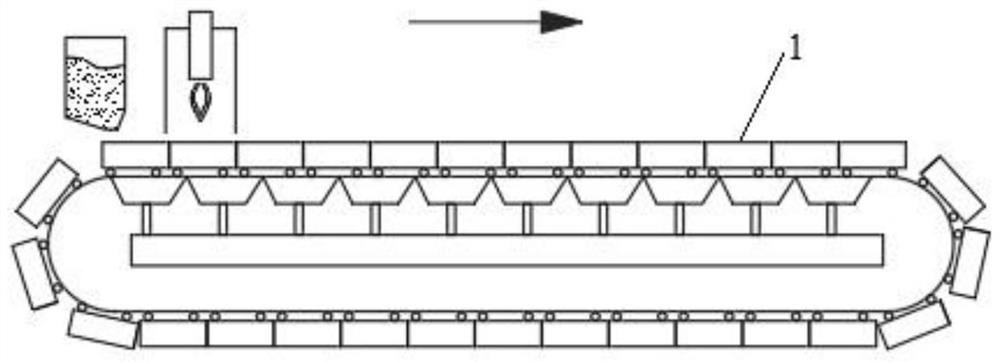

[0137] A soaking sintering method based on layered composite heat supply. The sintering mixture is sintered in the sintering machine. Along the direction of the depth of the sintering machine trolley 1, the sintering mixture is divided into multiple hierarchical units. Distribute heat supply ratio for heat supply sintering.

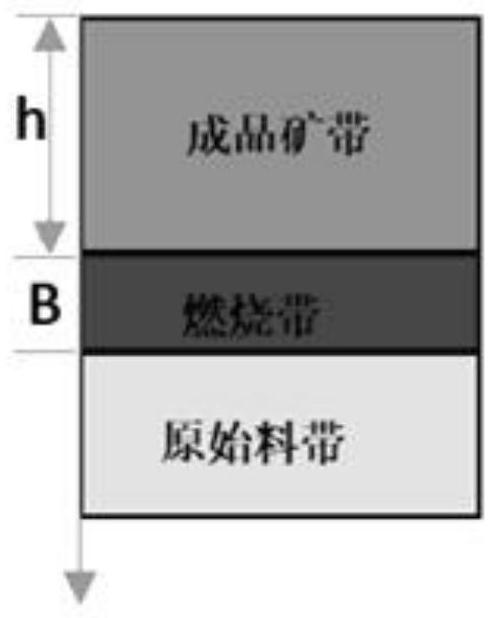

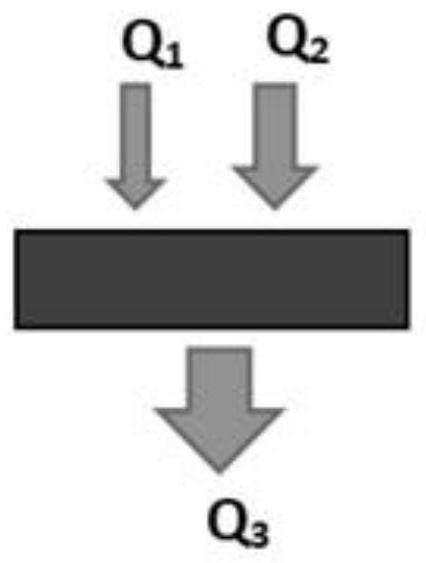

[0138] In the present invention, along the direction of the depth of the sintering machine trolley 1, the sintering mixture is divided into four hierarchical units, which are divided into four units from top to bottom: surface layer, upper middle layer, middle layer and lower layer. The percentage of heat supplied by the surface sintering mixture to the total heat required by the sintering mixture in the sintering process is a1; The percentage of the heat supplied by the sintering mixture to the total heat re...

Embodiment 1

[0205] Such as Figure 4 Shown, a kind of soaking sintering method based on layered compound heat supply, this method comprises the following steps:

[0206] 1) Mixing and distributing: mix the iron-containing raw materials, flux and solid fuel, and distribute the prepared sintering mixture on the sintering machine trolley 1;

[0207] 2) Ignition and sintering: an ignition device 6 is provided directly above the sintering machine trolley 1 located upstream of the sintering machine; The surface sintering mixture L1 starts to sinter; the surface sintering mixture L1 in the sintering machine trolley 1 is heated by the ignition device 6, and the solid fuel in the sintering mixture provides heat for sintering; The lower air box draws the air above the sintering mixture on the trolley into the bellows, so that the sintering mixture in the sintering machine trolley 1 is sintered from the surface layer of the trolley to the lower layer of the trolley;

[0208] 3) Thermal insulation ...

Embodiment 2

[0214] Repeat Example 1, except that in step 1), the mass ratio of the solid fuel to the total amount of sintered mixture is 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com