Oxygen-enriched sintering technique

An oxygen-enriched and technical technology, applied in the field of oxygen-enriched sintering, can solve problems such as large fuel consumption, and achieve the effects of increasing utilization factor, reducing solid fuel consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

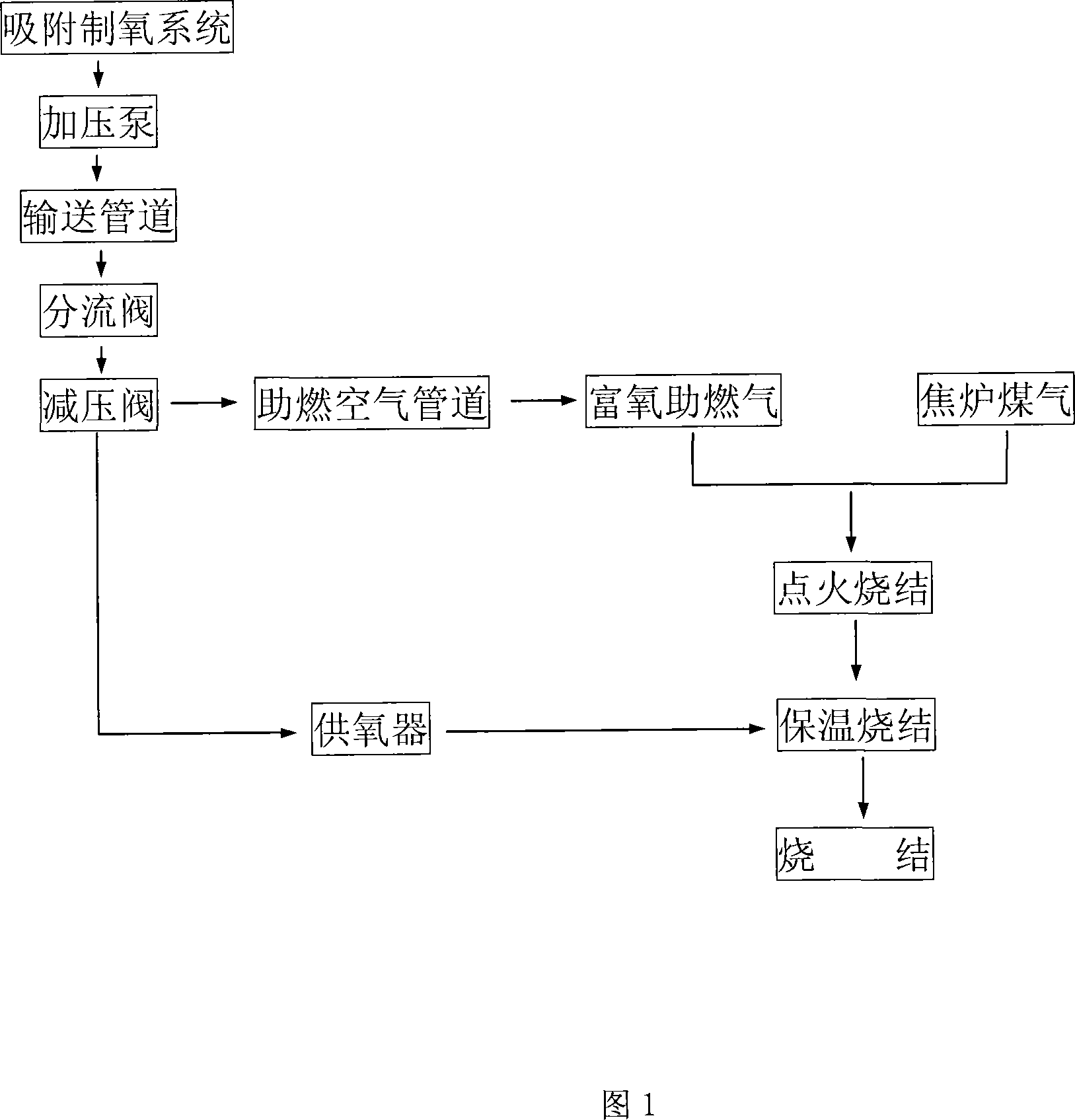

[0016] An oxygen-enriched sintering technology, including ignition oxygen-enrichment and heat preservation oxygen-enrichment, that is, oxygen-enriched sintering is used in both the ignition section and the heat preservation section of the belt sintering machine. The oxygen-enriched sintering technology scheme is as follows:

[0017] 1) Ignition and oxygen enrichment: the oxygen produced by the adsorption oxygen production system with a purity of 93% is sent to the combustion-supporting pipeline through the booster pump, delivery pipeline, diverter valve, and pressure-reducing valve, and the oxygen in the combustion-supporting pipeline is mixed with the combustion-supporting air to form The required oxygen-enriched combustion gas, the oxygen content in the oxygen-enriched combustion gas is 22%%; the oxygen-enriched combustion gas is mixed with coke oven gas according to the ratio of oxygen-enriched combustion gas: coke oven gas at 2.7:1 and then ignited;

[0018] 2) Insulation a...

Embodiment 2

[0020] An oxygen-enriched sintering technology, including ignition oxygen-enrichment and heat preservation oxygen-enrichment, that is, oxygen-enriched sintering is used in both the ignition section and the heat preservation section of the belt sintering machine. The oxygen-enriched sintering technology scheme is as follows:

[0021] 1) Ignition and oxygen enrichment: the oxygen produced by the adsorption oxygen production system with a purity of 93% is sent to the combustion-supporting pipeline through the booster pump, delivery pipeline, diverter valve, and pressure-reducing valve, and the oxygen in the combustion-supporting pipeline is mixed with the combustion-supporting air to form The required oxygen-enriched combustion gas, the oxygen content in the oxygen-enriched combustion gas is 24%; the oxygen-enriched combustion gas is mixed with coke oven gas according to the ratio of oxygen-enriched combustion gas: coke oven gas at 3.0:1 and then ignited;

[0022] 3) Insulation an...

Embodiment 3

[0024] An oxygen-enriched sintering technology, including ignition oxygen-enrichment and heat preservation oxygen-enrichment, that is, oxygen-enriched sintering is used in both the ignition section and the heat preservation section of the belt sintering machine. The oxygen-enriched sintering technology scheme is as follows:

[0025] 1) Ignition and oxygen enrichment: the oxygen produced by the adsorption oxygen production system with a purity of 93% is sent to the combustion-supporting pipeline through the booster pump, delivery pipeline, diverter valve, and pressure-reducing valve, and the oxygen in the combustion-supporting pipeline is mixed with the combustion-supporting air to form The required oxygen-enriched combustion gas, the oxygen content in the oxygen-enriched combustion gas is 25%; the oxygen-enriched combustion gas is mixed with coke oven gas according to the ratio of oxygen-enriched combustion gas: coke oven gas at 4.2:1 and then ignited;

[0026] 4) Insulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com