Application of plant source surface active agent

A surfactant and plant-derived technology, applied in the field of plant resource utilization, can solve the problems that surfactants have not received enough attention, have not been used in the petroleum industry, and restricted the application of microbial oil recovery technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

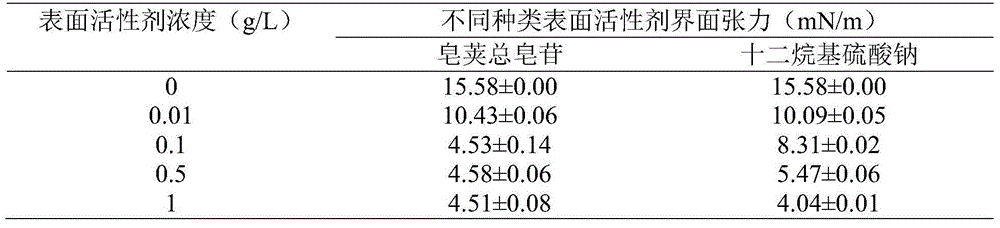

[0031] The acacia pods are crushed and dried for later use. Using 75% methanol as the extraction solvent, the total saponins were extracted by ultrasonic-assisted technology. Using oleanolic acid as a standard, the content of total saponins extracted was detected by UV spectrophotometry. The results show that when the extraction temperature is 60°C, the power is 180W, the extraction time is 30min, and the ratio of mass g to volume mL is 1:30, the highest extraction efficiency is 11.08%.

[0032] Concentrate the crude extract of total saponins and recover methanol, add water to dissolve, and use foam separation technology to preliminarily purify the total saponins of saponins. The recovery rate and purity ratio of total saponins are used as indicators to evaluate the foam separation technology. The results showed that when the feed concentration was 2g / L, the gas velocity was 1L / min, the feed height ratio was 0.8, and the pH was 6, the recovery rate of total saponins of Acacia...

Embodiment 2

[0034] Crush the acacia pods, use 75% methanol as the extracting solution to soak in a material-to-liquid ratio of 1:30, and then use microwave-assisted extraction technology to extract total saponins. In the test, oleanolic acid was used as a standard, and the content of total saponins extracted was detected by ultraviolet spectrophotometry. Under the conditions of extraction power 450W, extraction temperature 60°C, and extraction time 6min, the organic solvent extract was obtained, and the extraction rate was 5.23%. The crude extract was purified with PHD-100 macroporous adsorption resin, and the adsorption flow rate was 0.5mL / min. The volume ratio of the adsorption liquid to the resin is 1:1, and the eluent is 70% methanol solution. The eluate is concentrated and vacuum-dried to obtain light brown powdery crude saponin. Purification may increase the crude saponin content to 83.2%. The resulting extract contains saponins and other substances.

Embodiment 3

[0036] Grind the pods of acacia, pass through a 60-80 mesh sieve, and extract the total saponins of acacia in water. When the ratio of solid to liquid is 1:30, the temperature is 60℃, and the extraction time is 24h, the extraction rate of saponin is 2.31%. The obtained saponin crude extract was extracted by foam separation and purification technology and n-butanol to obtain refined saponin, and the specific experimental conditions were as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com