Patents

Literature

36 results about "Tension reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relief of emotions of tension. A multitude of methods might be utilized for this reason. TENSION REDUCTION: "Tension reduction techniques are very beneficial to many women during their menstrual cycles.".

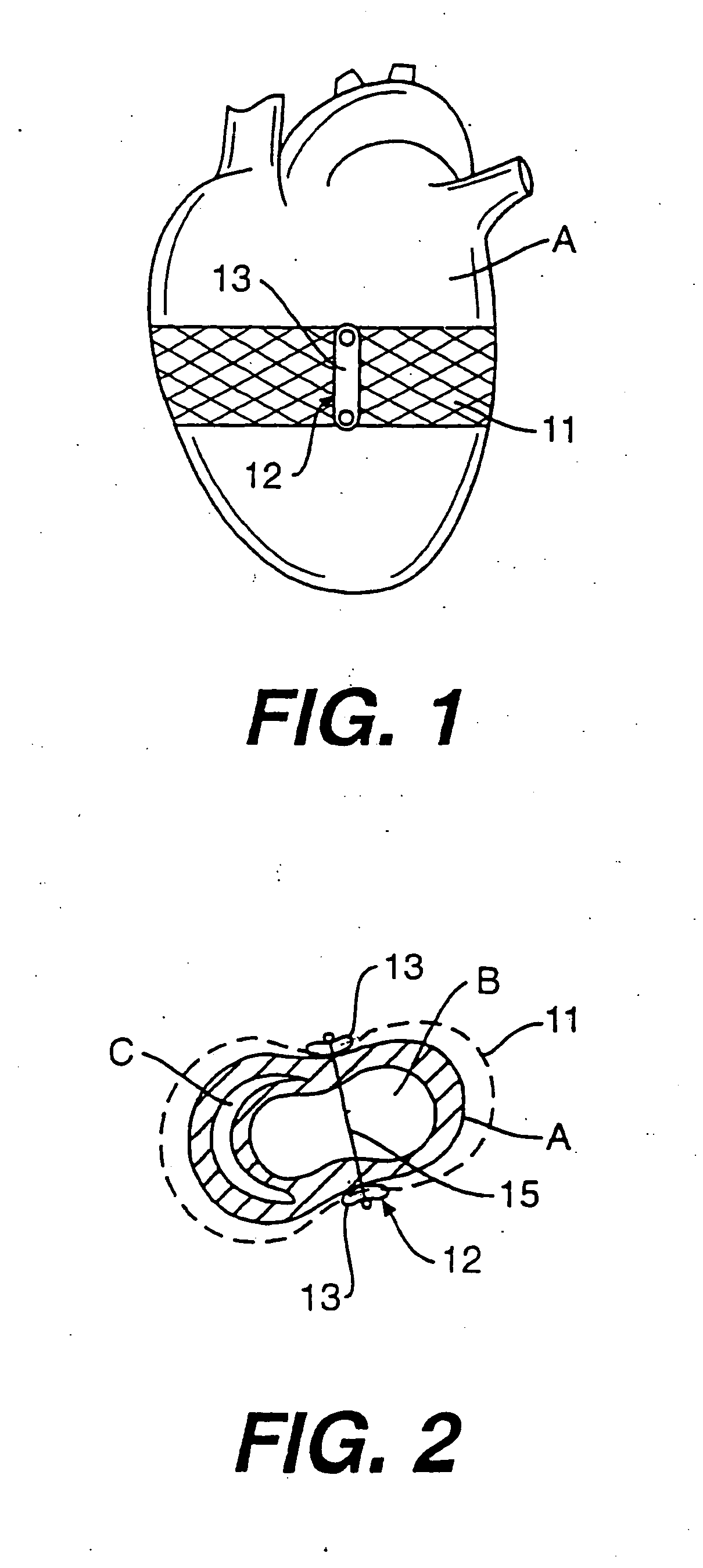

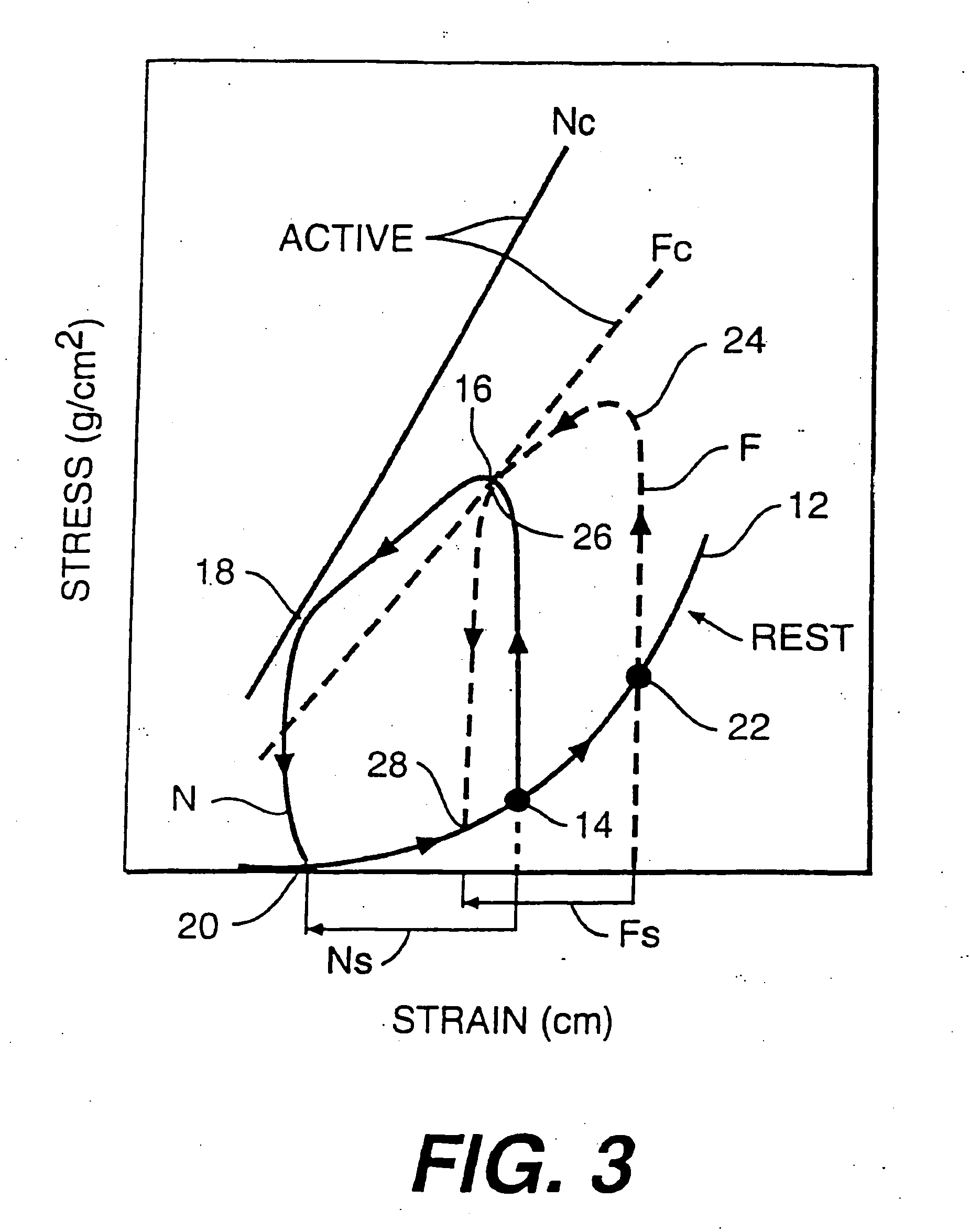

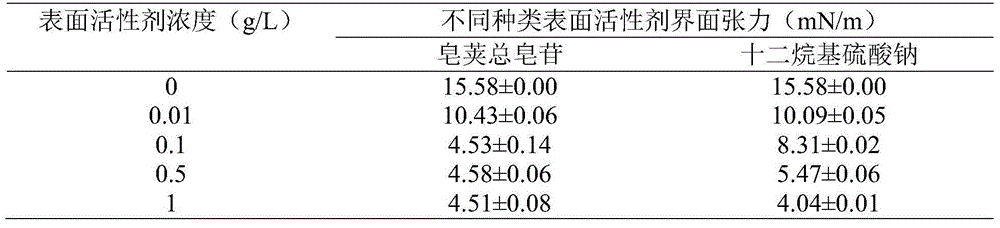

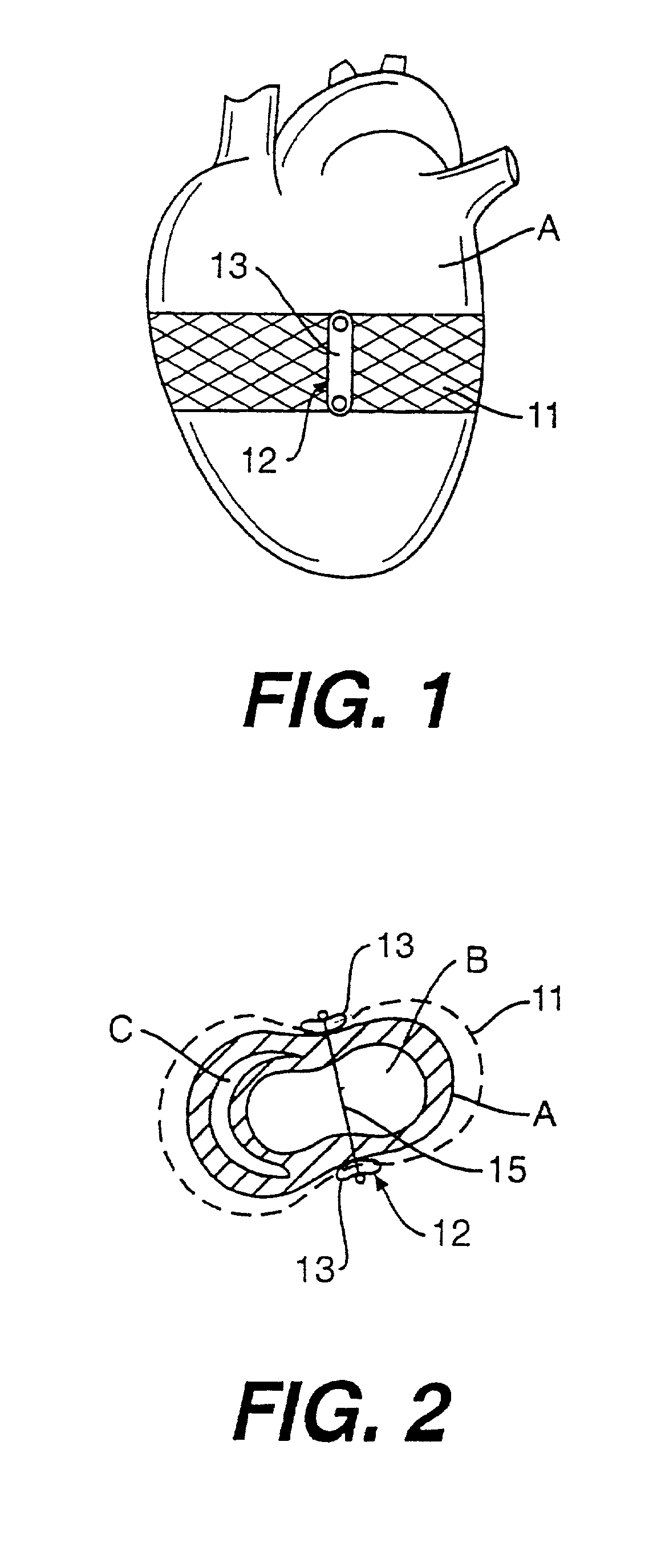

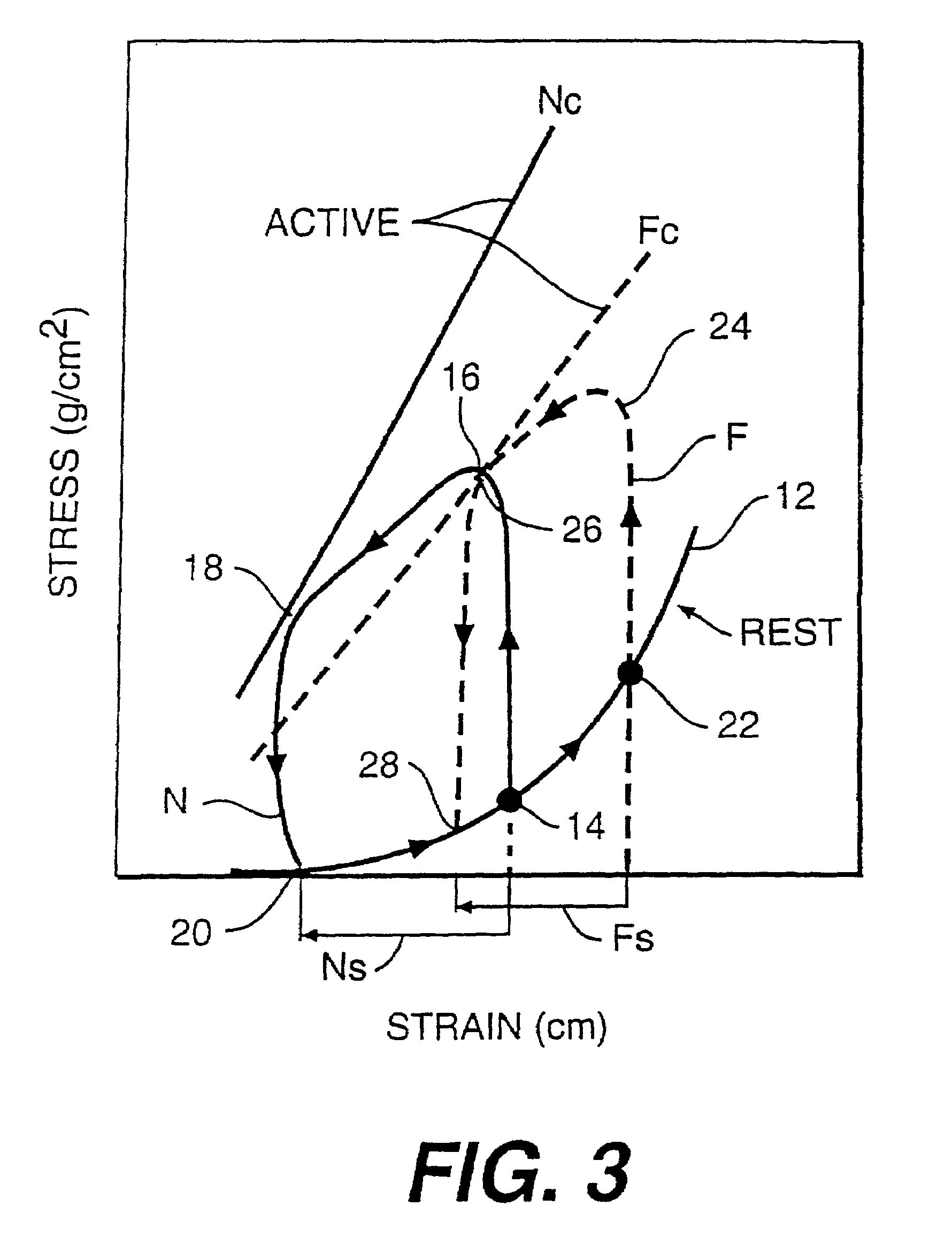

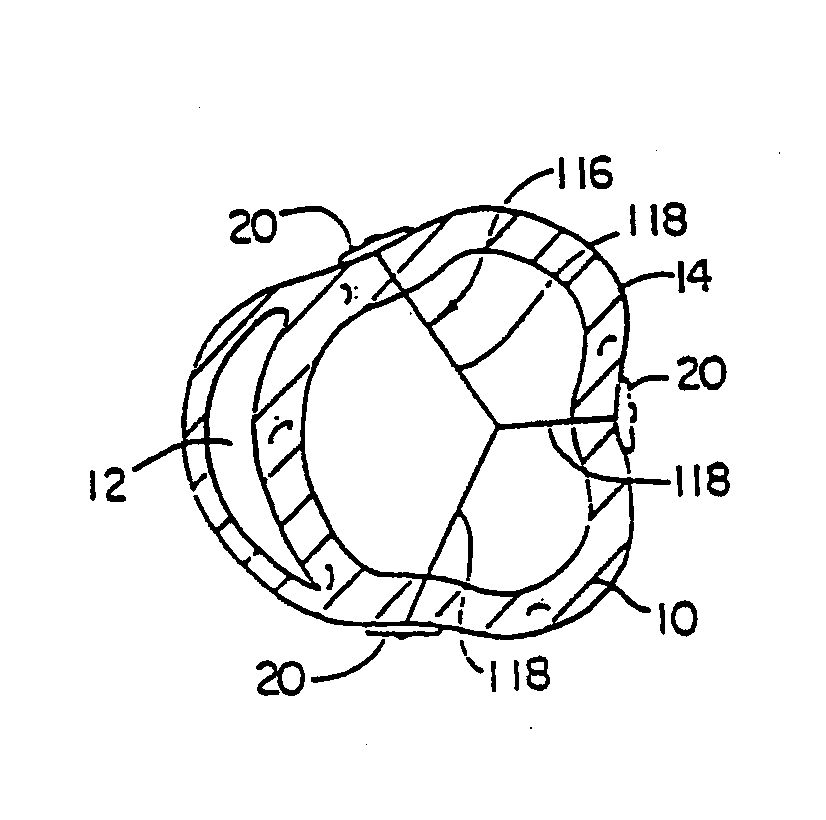

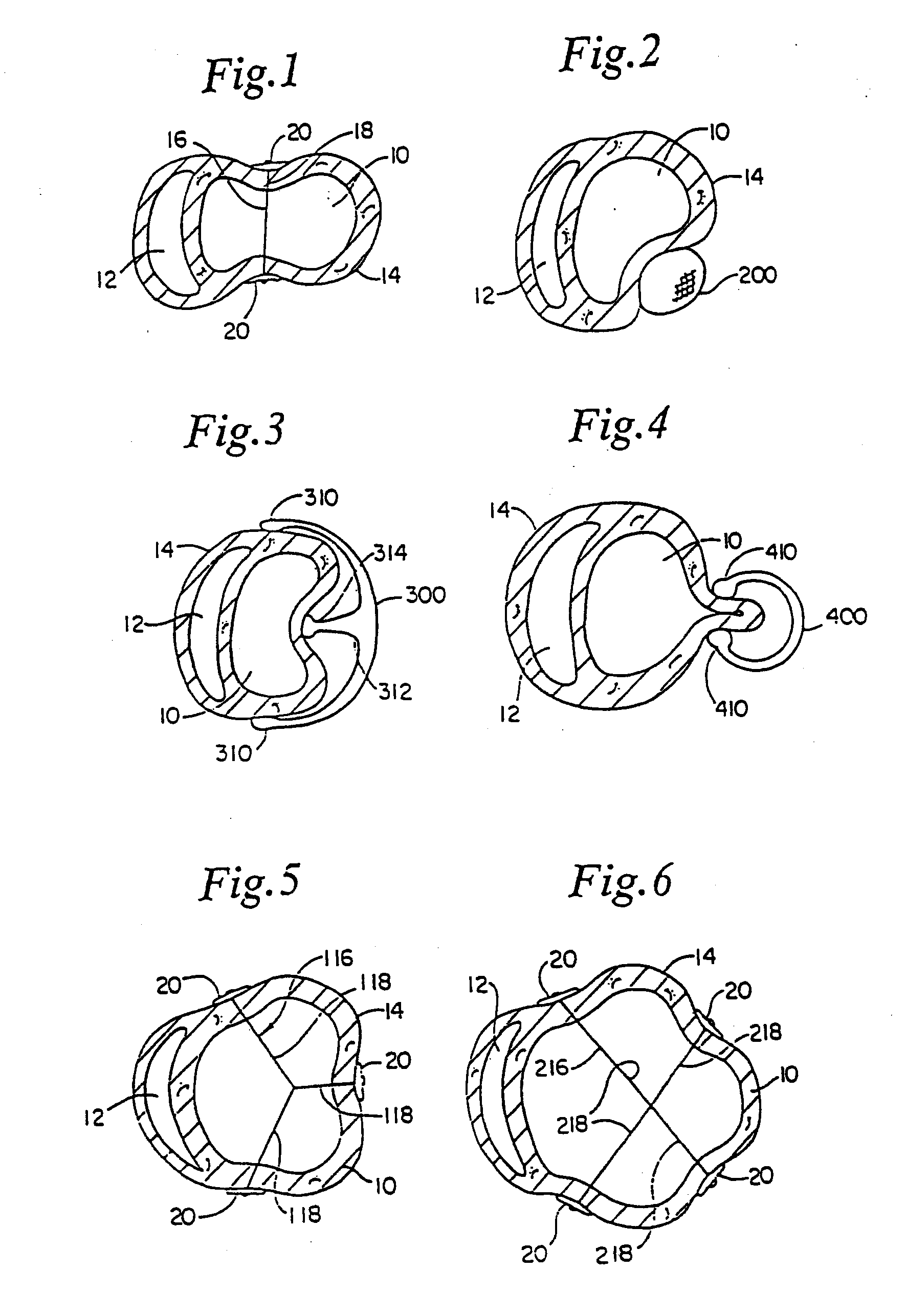

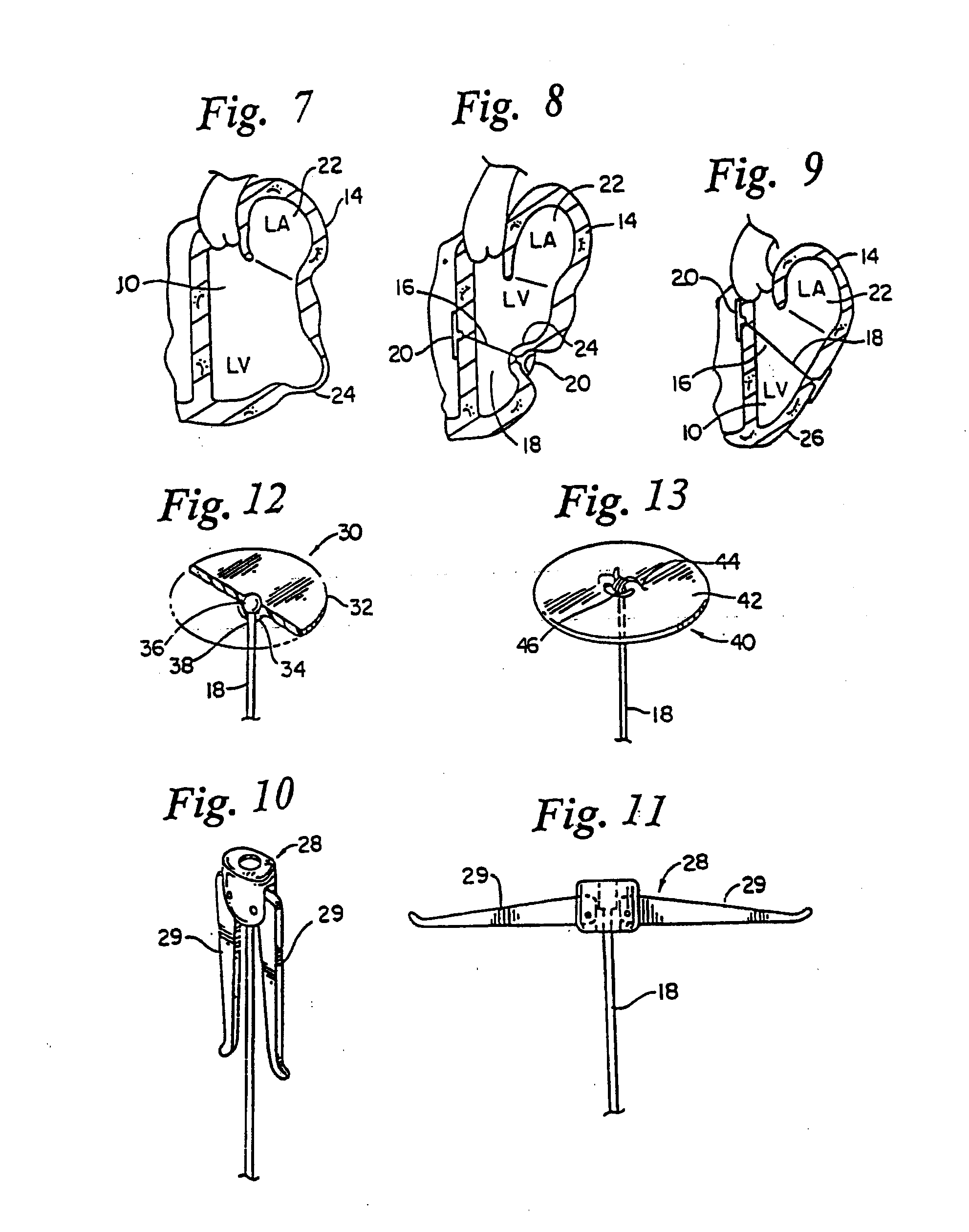

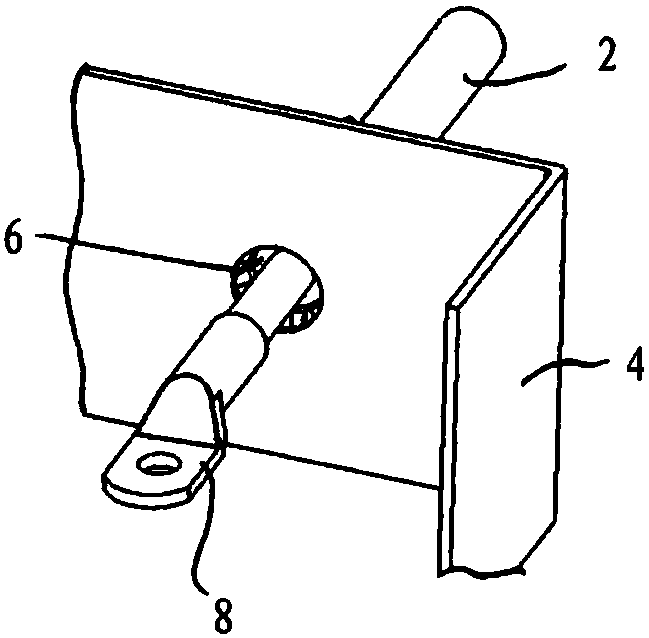

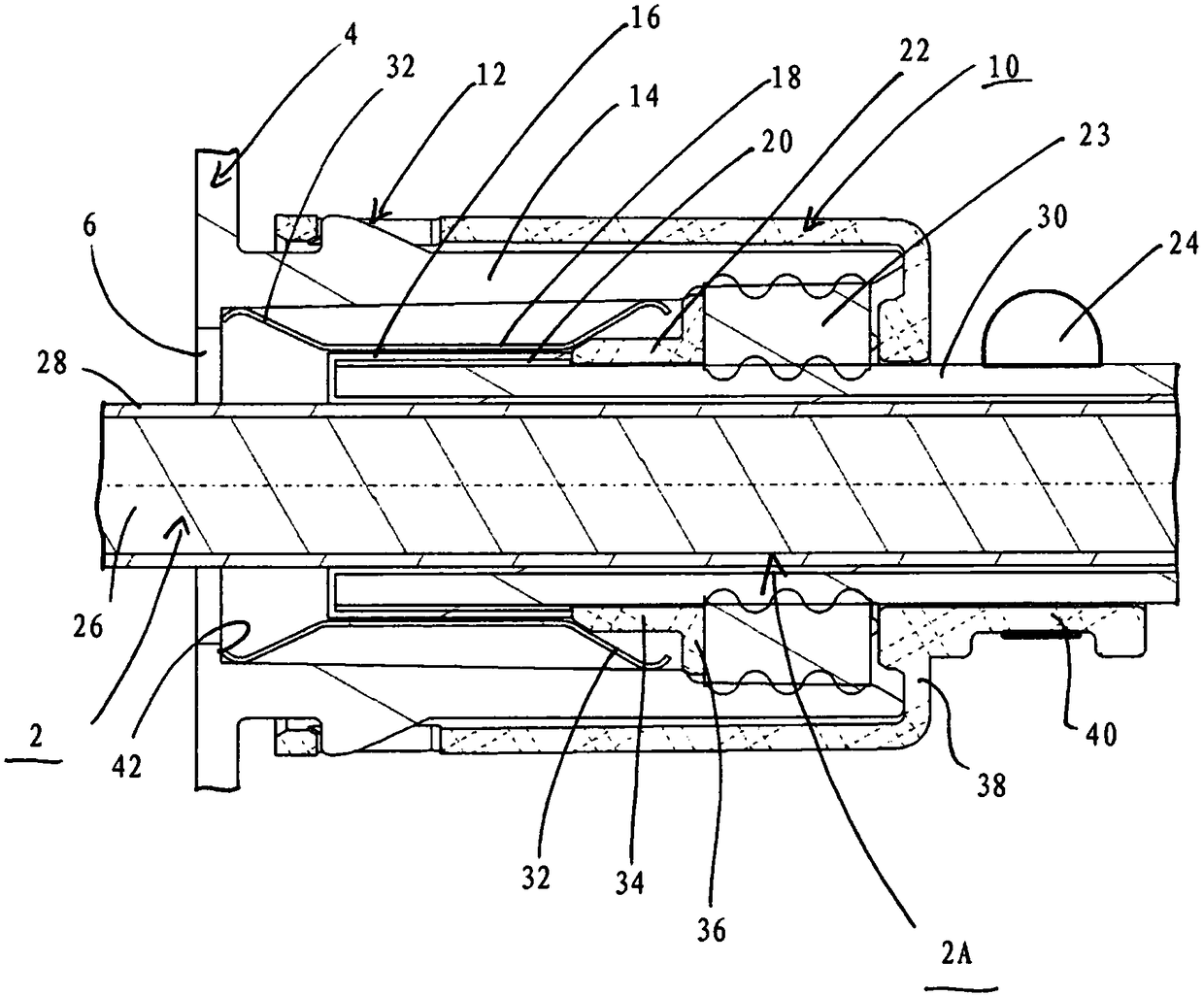

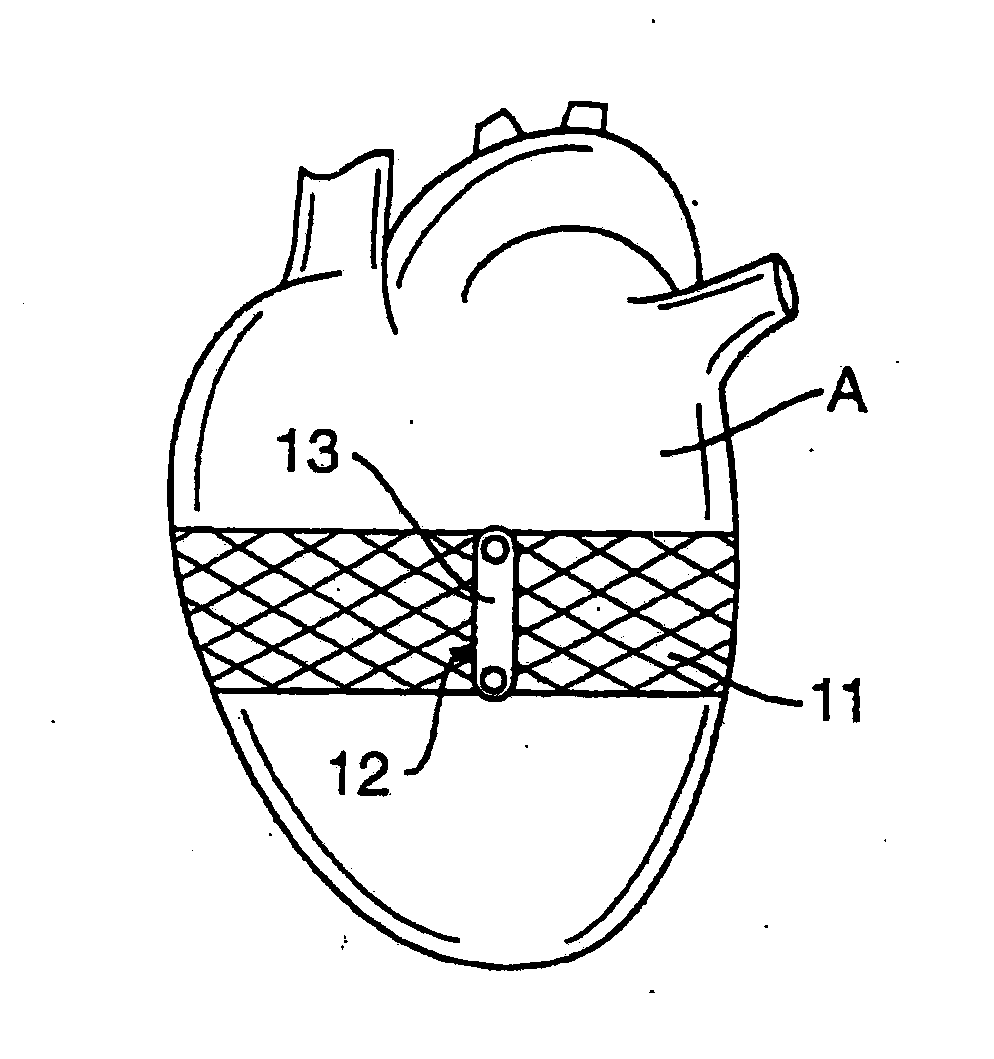

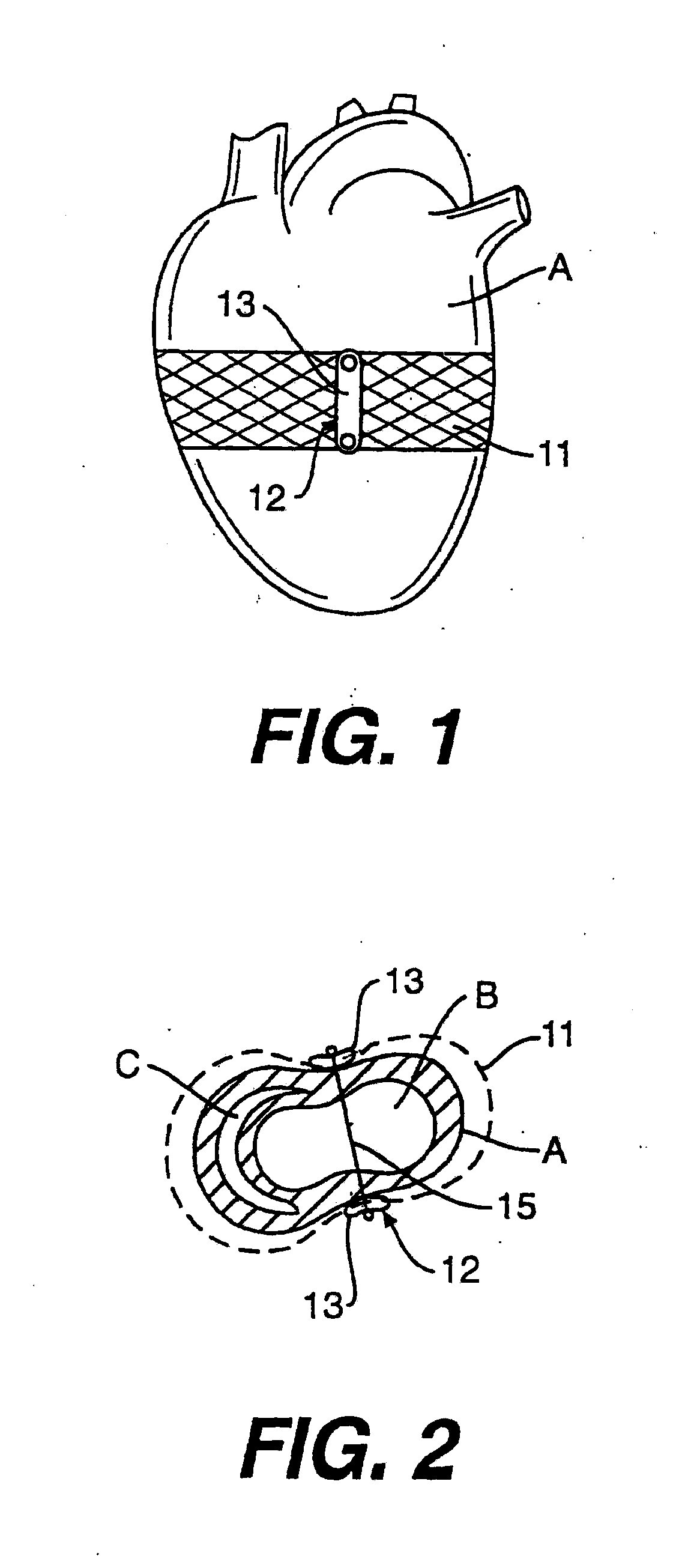

Heart wall tension reduction apparatus and method

InactiveUS7695425B2Reduce tensionReduce energy consumptionSuture equipmentsHeart valvesHeart chamberFailing heart

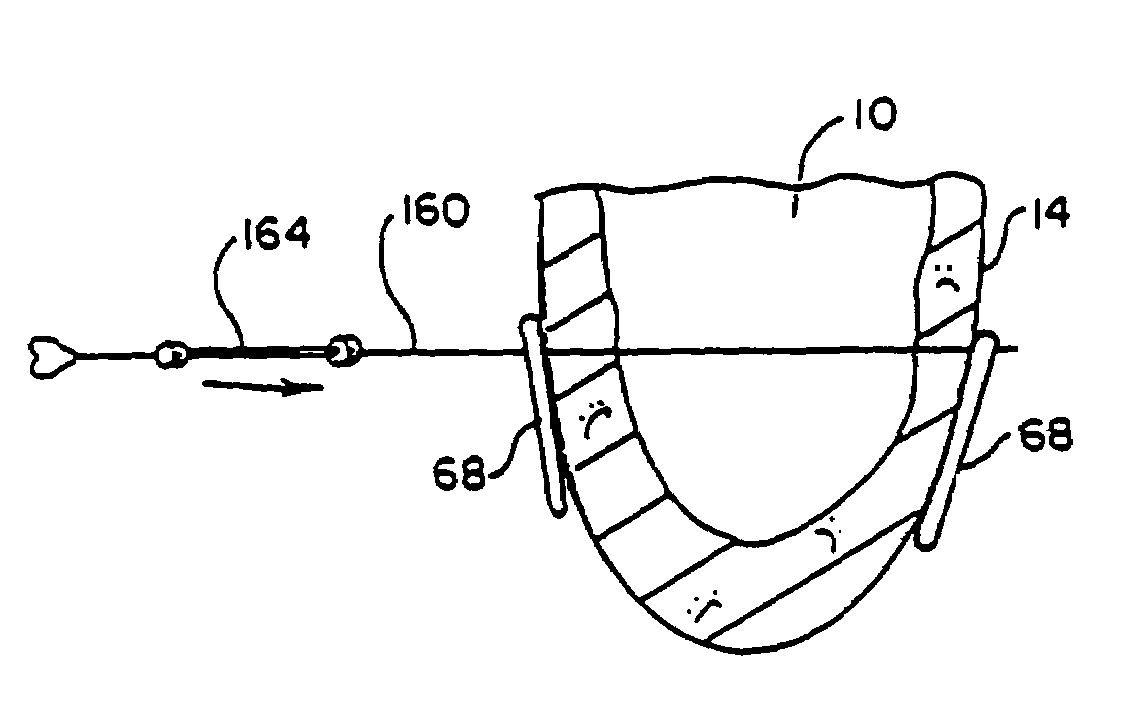

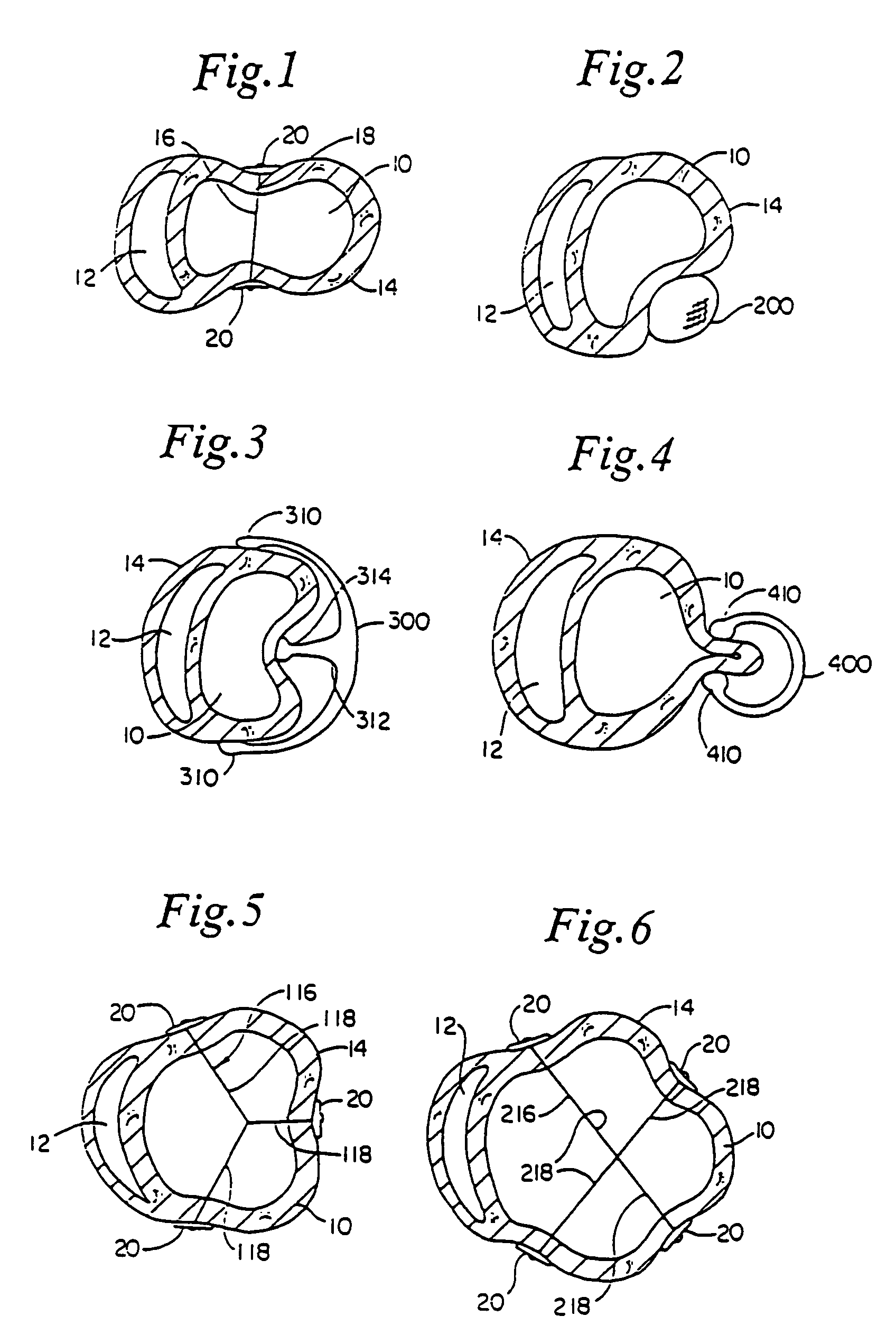

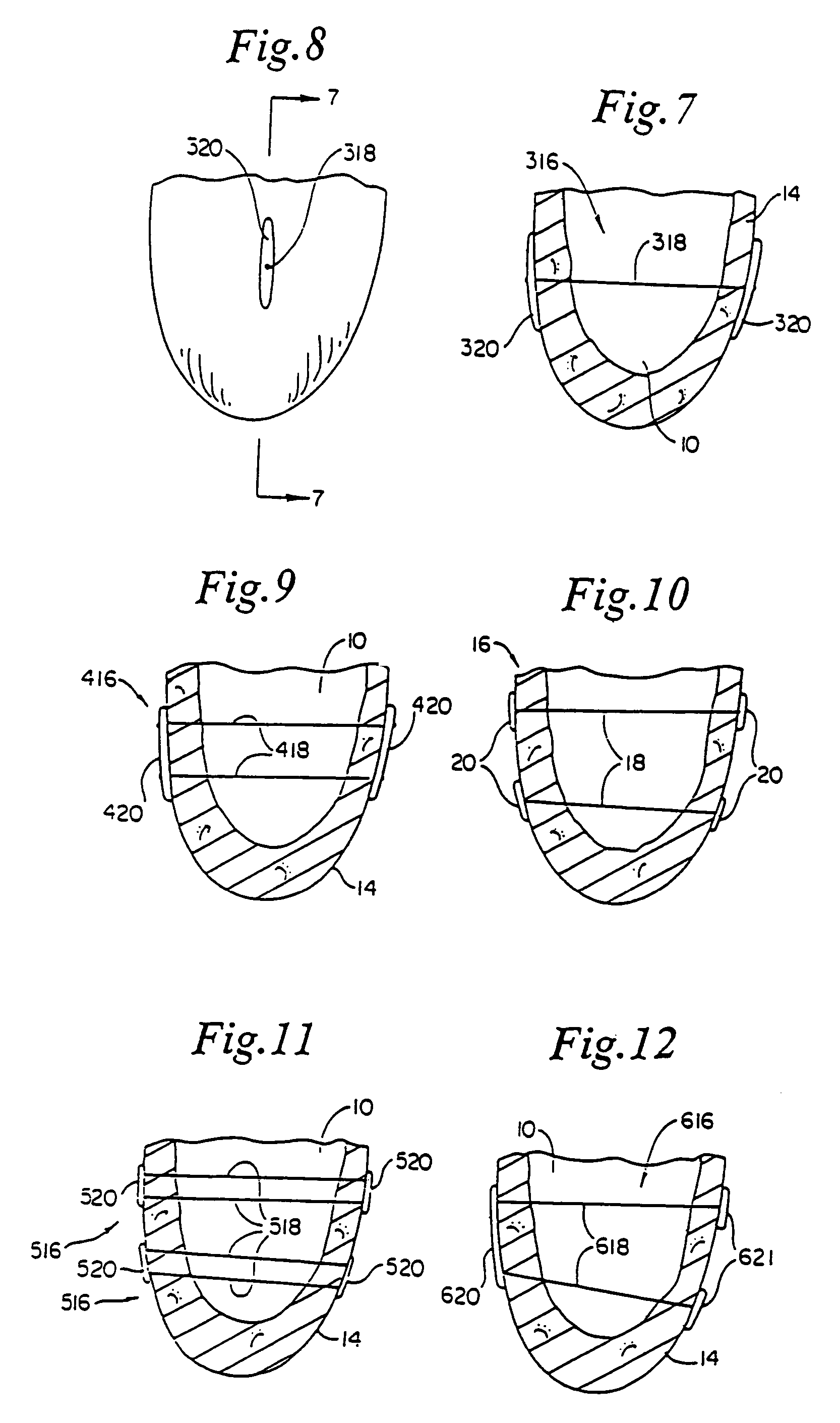

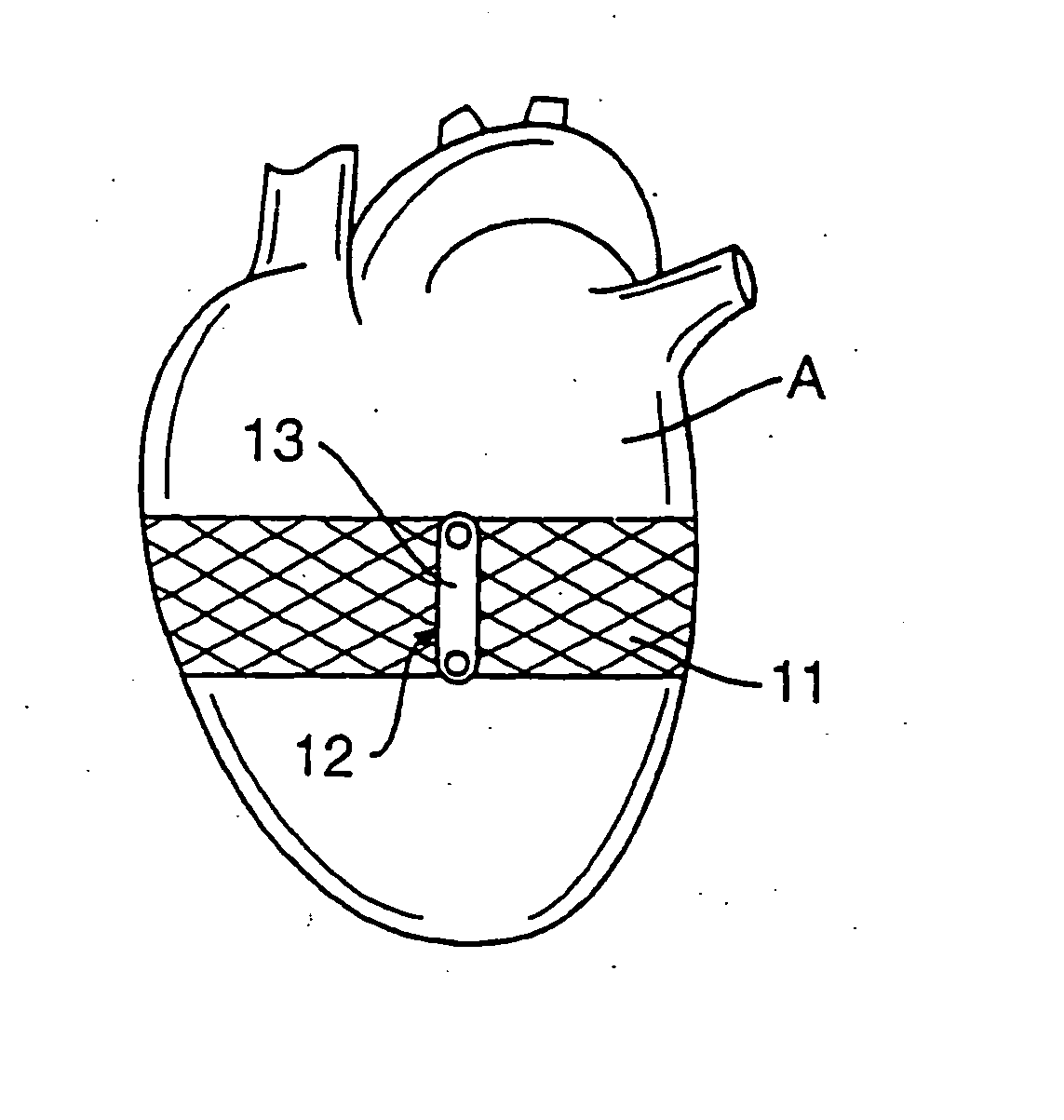

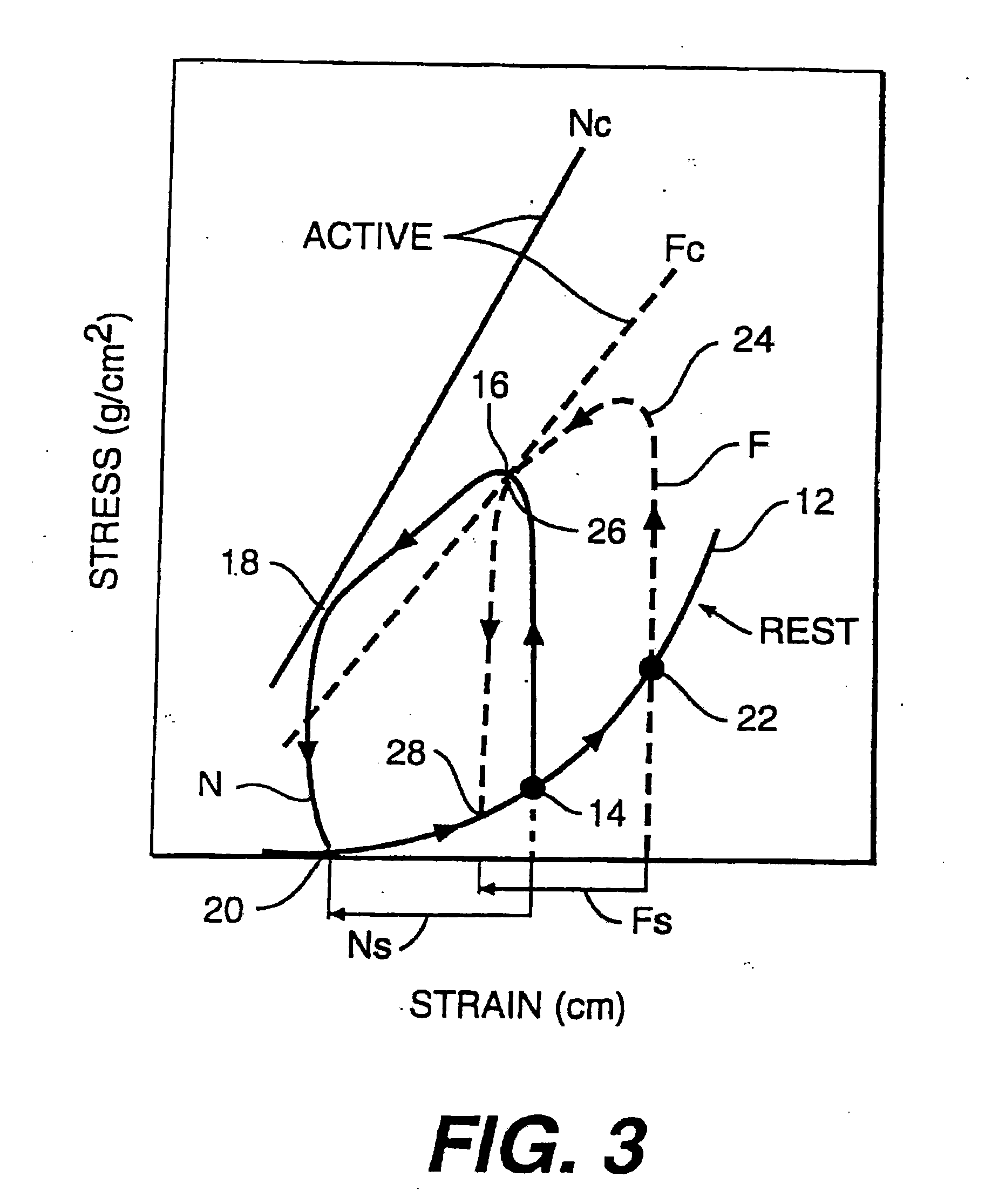

An apparatus for treatment of a failing heart by reducing the wall tension therein. In one embodiment, the apparatus includes a tension member for drawing at least two walls of a heart chamber toward each other. Methods for placing the apparatus on the heart are also provided.

Owner:EDWARDS LIFESCIENCES LLC

Heart wall tension reduction apparatus and method

InactiveUS20050131277A1Reduce maximum wall stressReduce tensionSuture equipmentsHeart valvesCardiac cycleFailing heart

Devices and methods for treatment of a failing heart by reducing the heart wall stress. The device can be one which reduces wall stress throughout the cardiac cycle or only a portion of the cardiac cycle.

Owner:EDWARDS LIFESCIENCES LLC

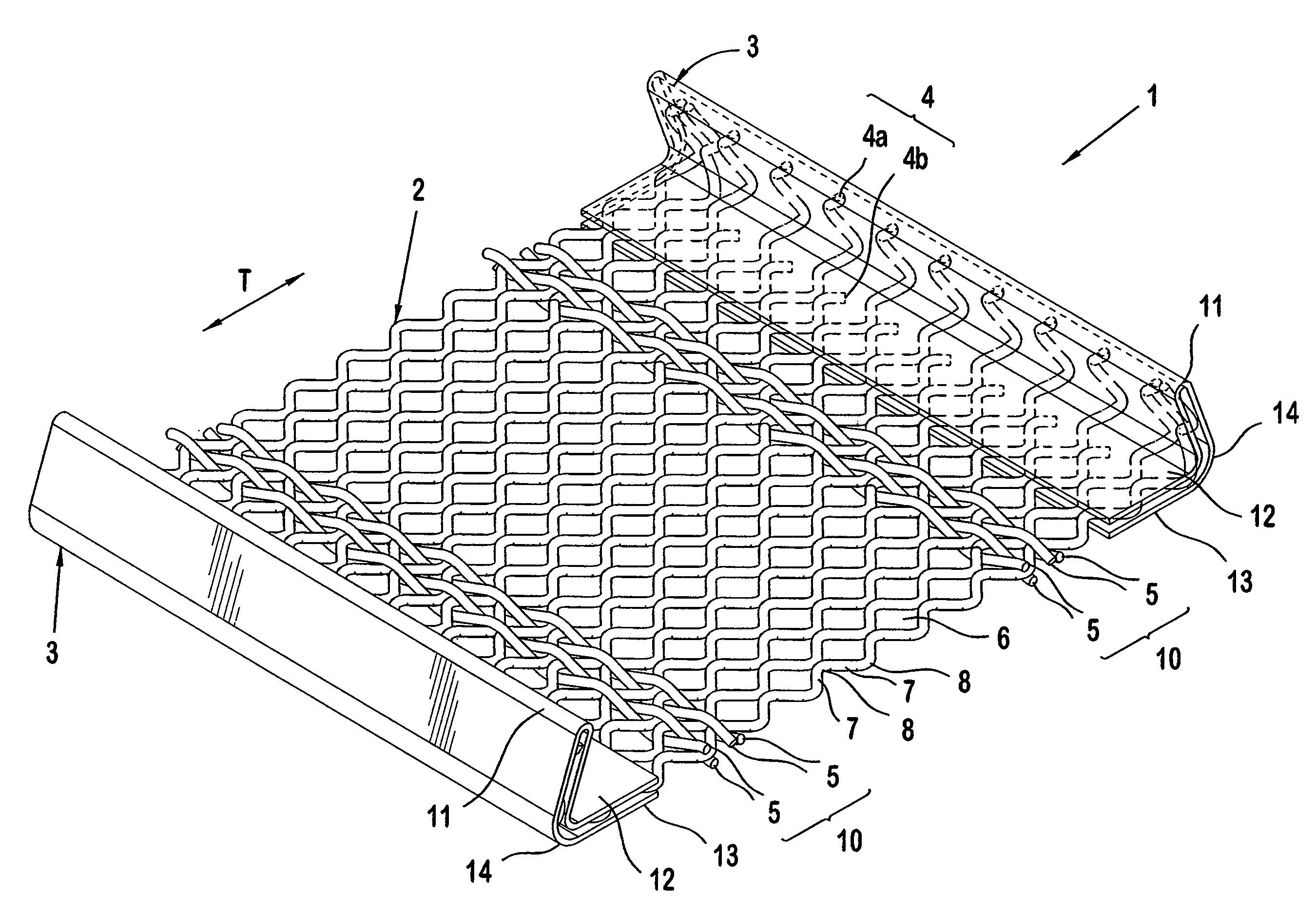

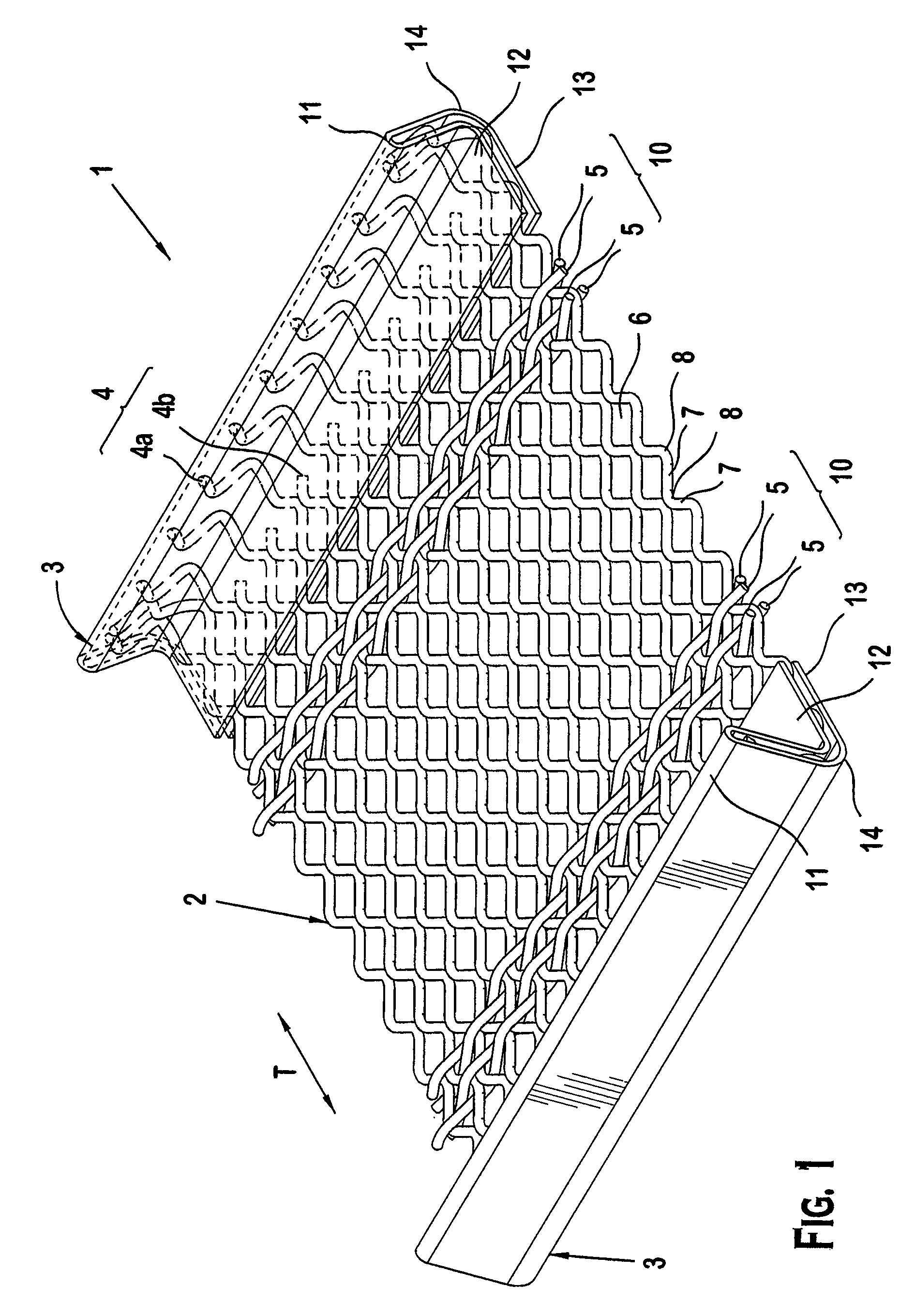

Screen for a Vibratory Separator Having Tension Reduction Feature

Owner:LUMSDEN CORP

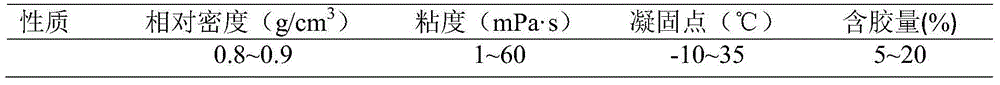

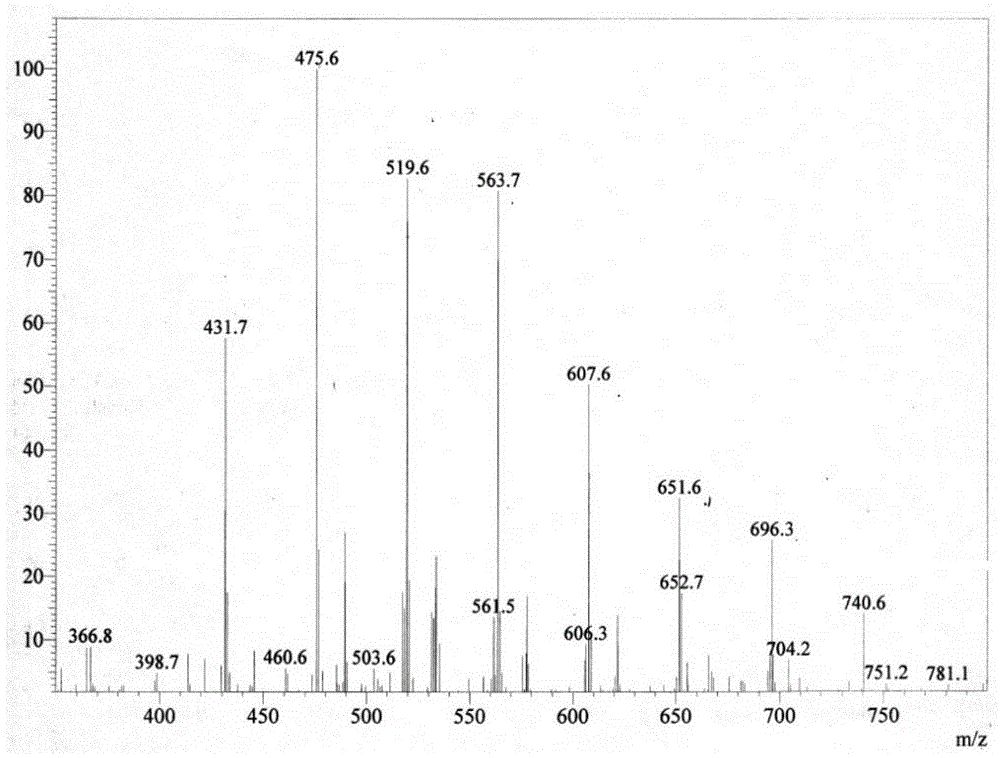

Application of plant source surface active agent

InactiveCN104874329AHas an activation effectIncrease gasification rateNon-ionic surface-active compoundsOther chemical processesEmulsionResource utilization

The invention relates to a total saponnis extraction technology of a honeylocust extract and an application field thereof. The total saponnis extraction technology is characterized in that the total saponnis is a plant source nonionic type surface active agent, and has the interfacial tension reduction property, emulsion activity, wetting property, temperature-resistant and salt-tolerant property, dispersant solubilizing and the like, so as to provide the applicability in the fields of recovery, storage and transportation of crude oil; the green surface active agent from the plant, namely the honeylocust, is applied to the bulk industrial purpose, so the resource utilization rate of the honeylocust is improved, the recovery rate of crude oil is improved, the storage and transportation cost of crude oil is reduced, and the pollution to the environment is reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Heart wall tension reduction apparatus and method

InactiveUS7883539B2Reduce tensionReduce energy consumptionSuture equipmentsHeart valvesCardiac cycleFailing heart

Devices and methods for treatment of a failing heart by reducing the heart wall stress. The device can be one which reduces wall stress throughout the cardiac cycle or only a portion of the cardiac cycle.

Owner:EDWARDS LIFESCIENCES LLC

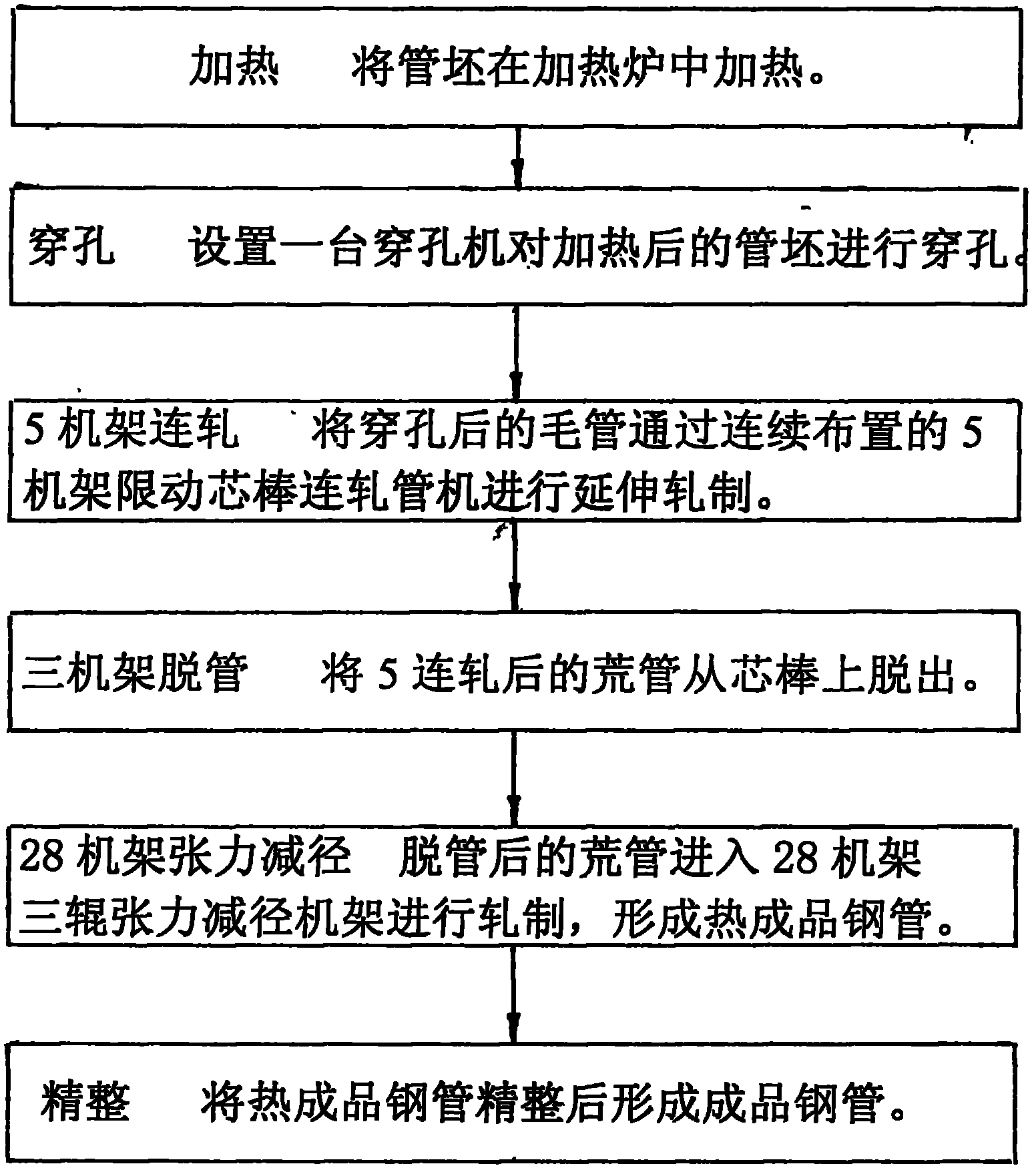

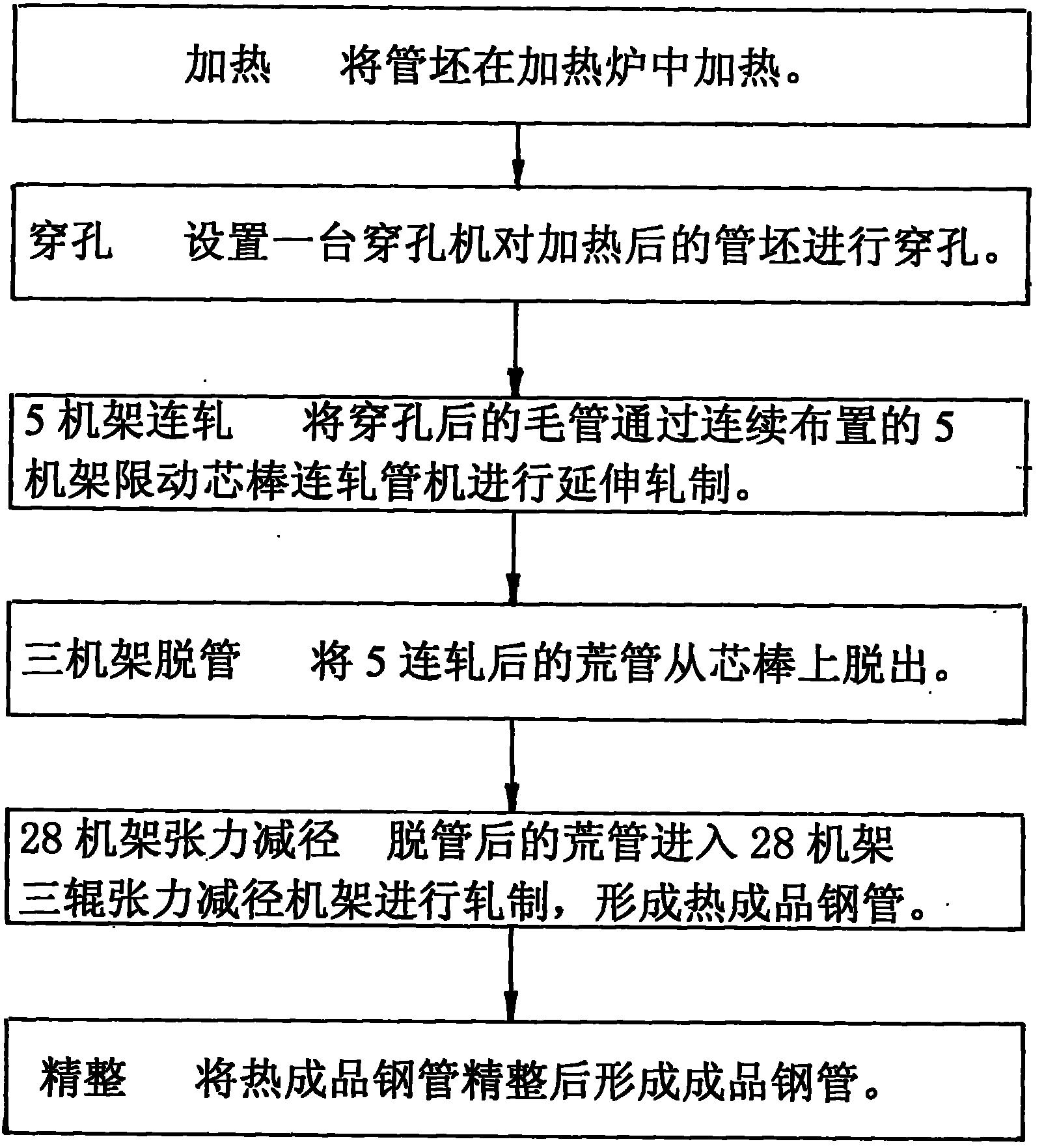

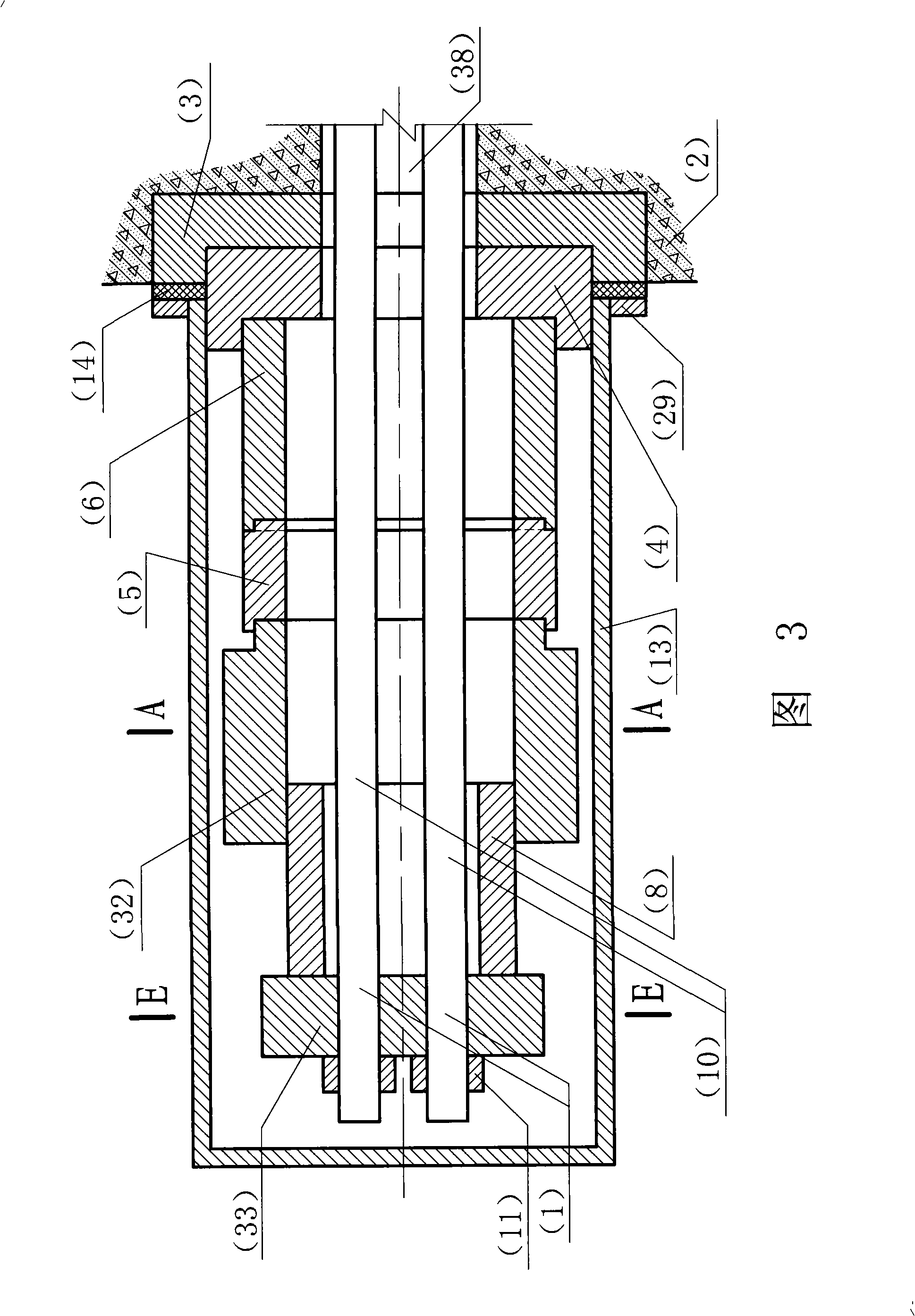

Manufacturing process of small-caliber hot rolling seamless steel tubes

The invention discloses a manufacturing process of a small-caliber hot rolling seamless steel tubes, which is used for solving the problems of high energy consumption, low finished product rate and environmental pollution of the traditional process for producing the small-caliber hot rolling seamless steel tubes through punching plus cold drawing. The manufacturing process of the small-caliber hot rolling seamless steel tubes comprises the following steps of: heating: heating tube blanks in a heating furnace; punching: punching the heated tube blanks by installing a puncher; five rack tandem rolling: previously punching punched hollow billets on a retained mandrel, and carrying out continuously extending rolling on the punched hollow billets through a continuously arranged five rack retained mandrel tube tandem rolling mill; three rack tube disassembly: disassembling pierced billets subjected to five tandem rolling from the retained mandrel to enter a next process-twenty-eight rack tension reducing process; twenty-eight rack tension reduction: placing the pierced billets subjected to the five tandem rolling into twenty-eight three-roller tension reducing racks for rolling so as to form hot finished steel tubes; and finishing: finishing the hot finished steel tubes to form finished steel tubes.

Owner:胡顺珍

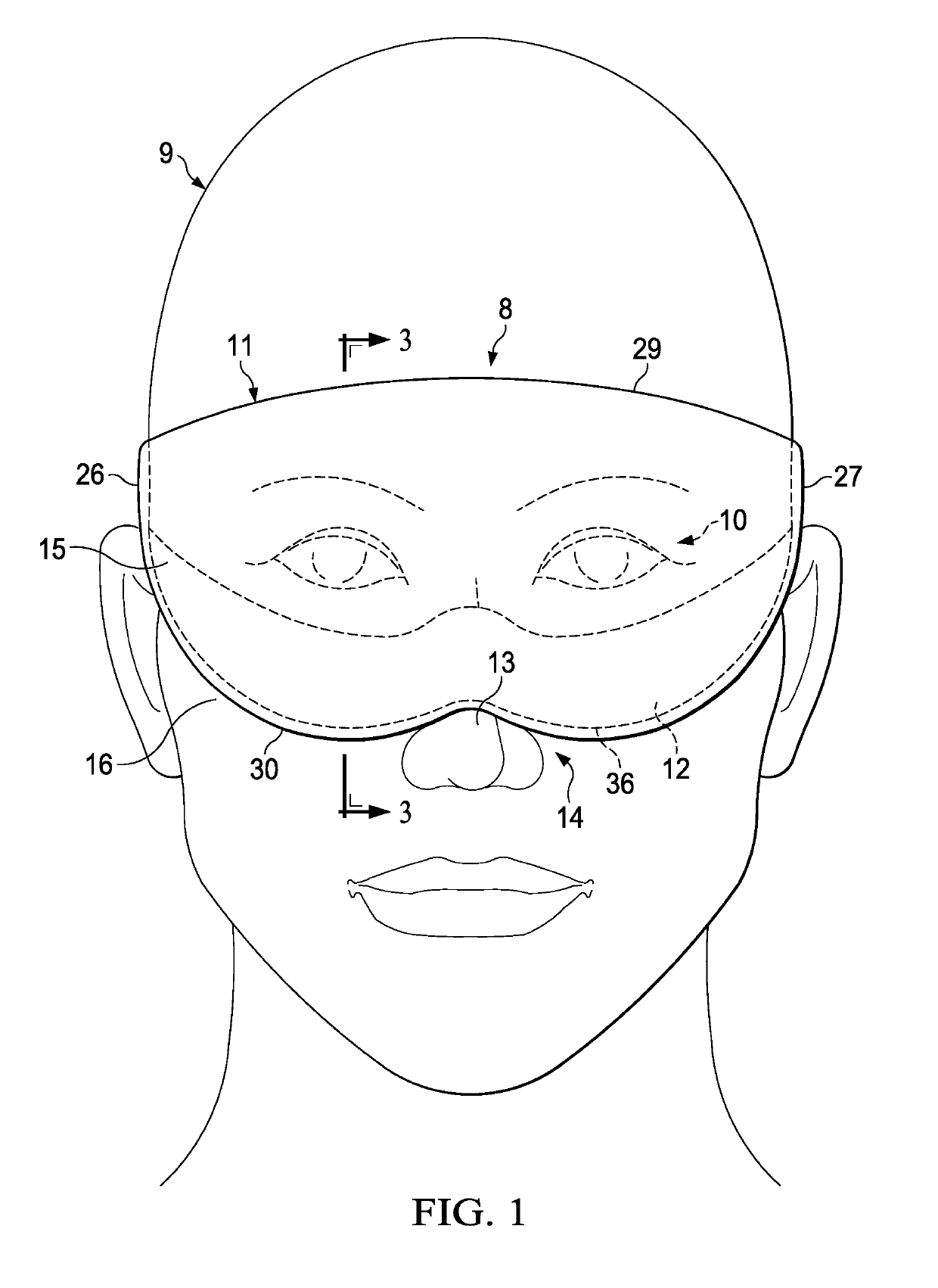

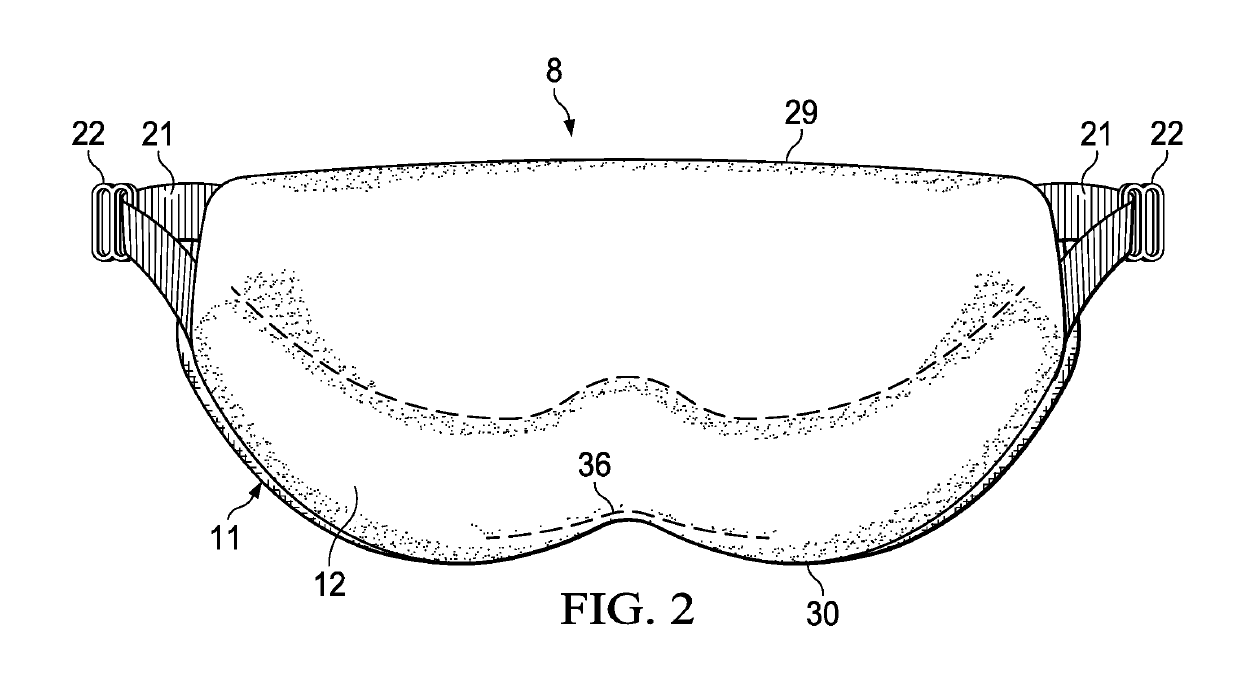

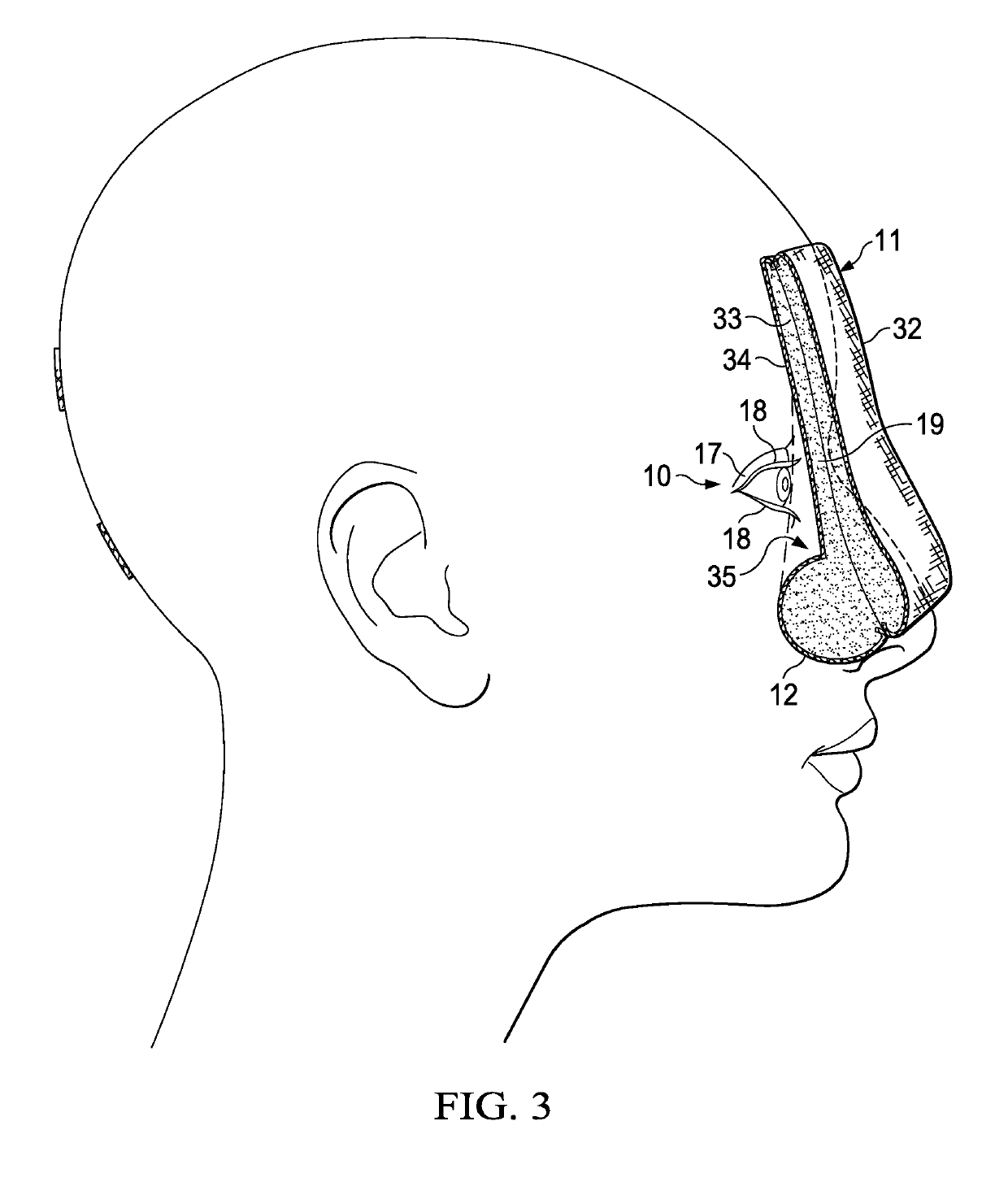

Ergonomic sleep mask

InactiveUS20190231595A1Easy to cleanConvenient lightingOrganic active ingredientsEye-masksEngineeringTension reduction

The present invention is a sleep mask with many unique features including tension reduction from the securing bands, a light blocking pillow, ergonomic / pre-curved shaping, an eye space, ear comfort features, slip over comfort which can account for various hair styles and various head positions of the wearer, and therapeutic, beauty and relaxing features. The overall experience for the wearer is an extraordinary fit due to data and design.

Owner:THE ART OF ALCHEMY

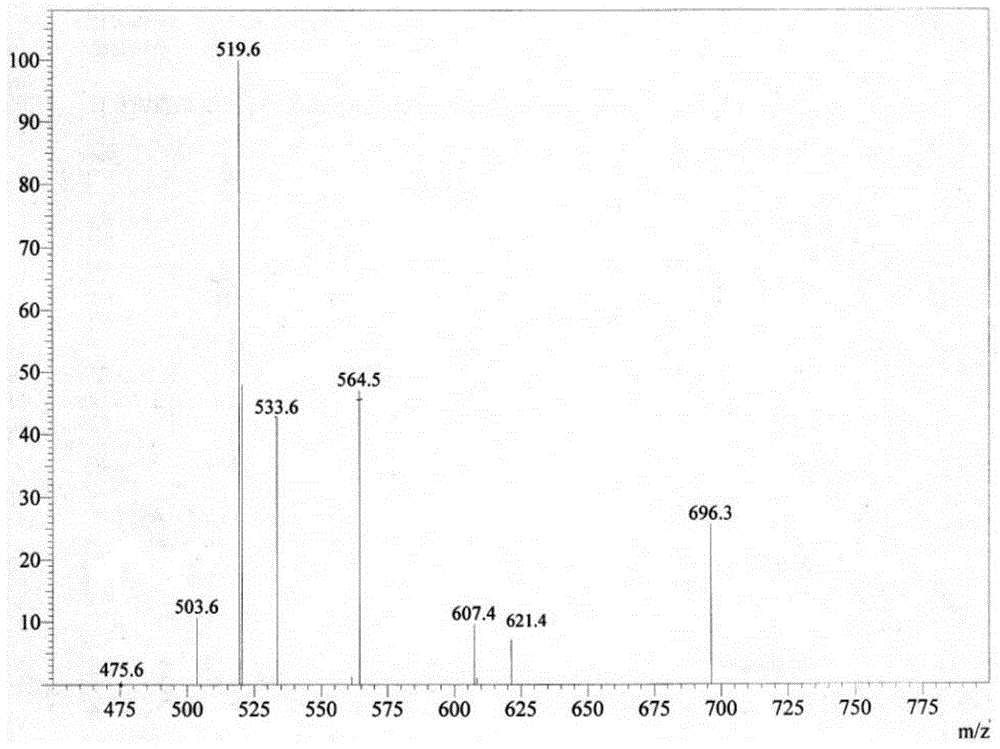

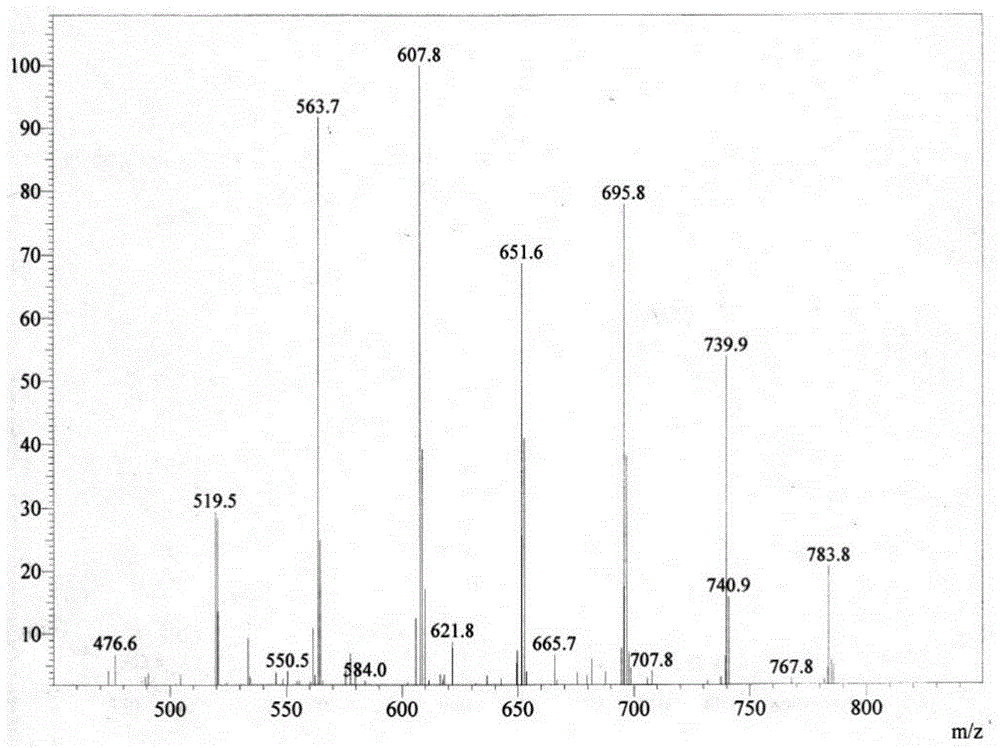

Aryl alkyl alcohol polyoxyethylene ether carboxylate and preparation and application thereof

ActiveCN104529756AGood anti-adsorption performanceGood water solubilityOrganic compound preparationDrilling compositionSolubilityAryl

Owner:PETROCHINA CO LTD

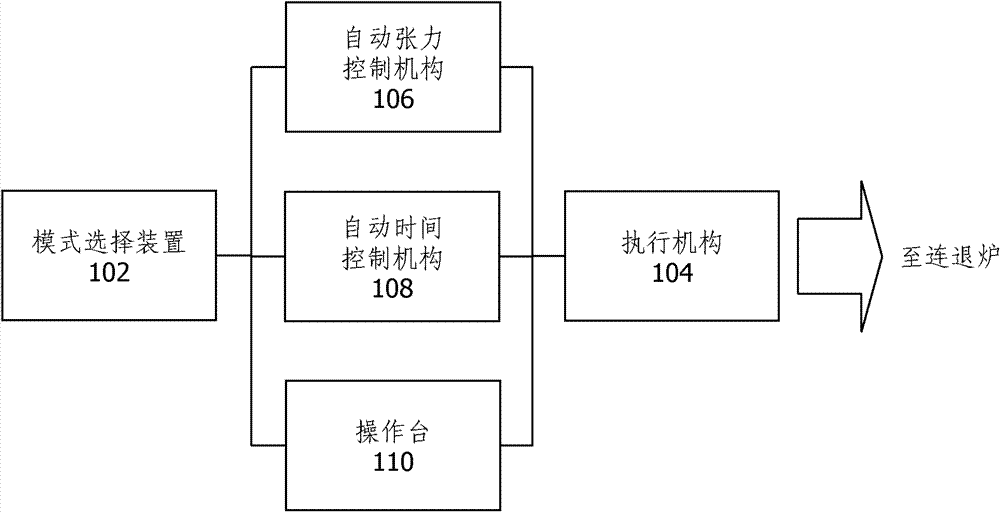

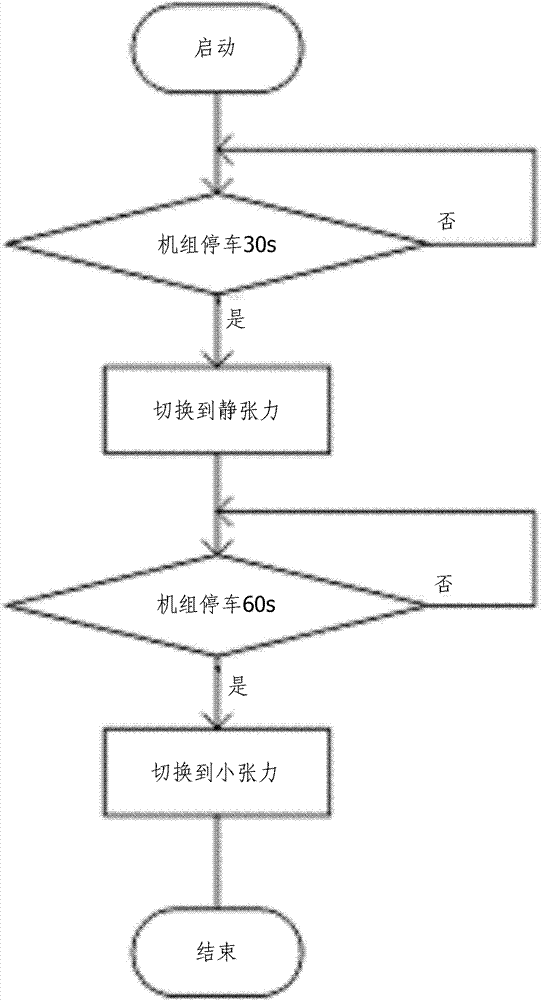

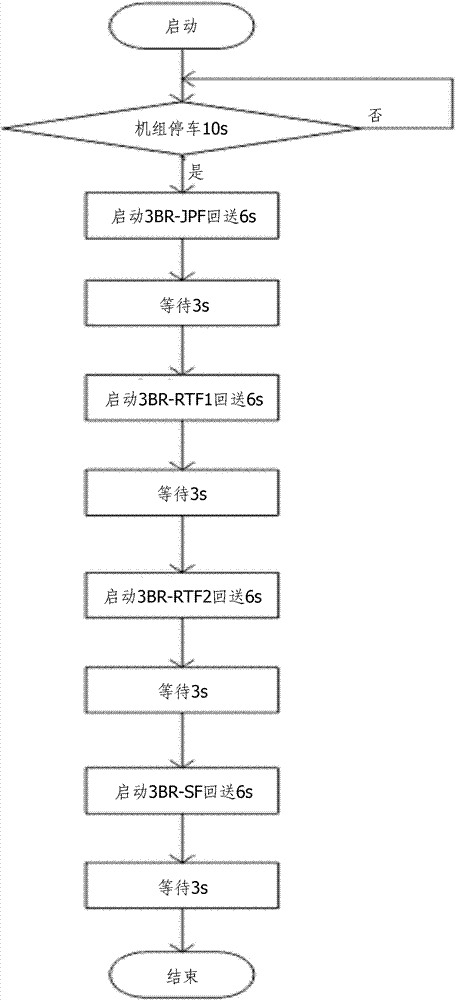

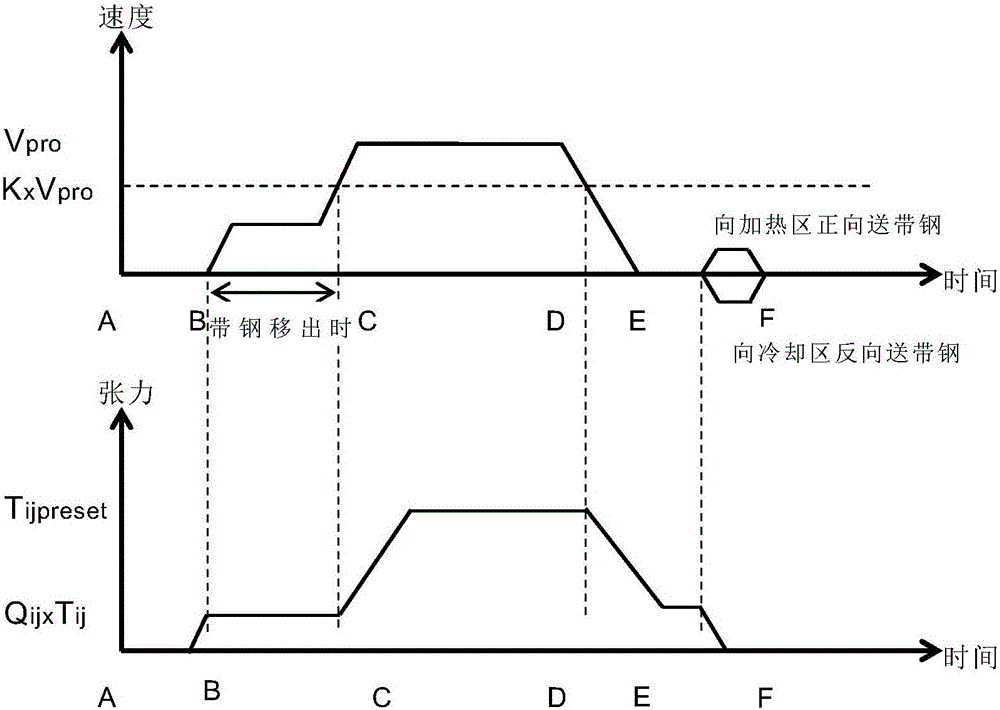

Band steel return control apparatus after shutdown of continuous annealing furnace

ActiveCN102776352AAvoid deformationAvoid displacementFurnace typesHeat treatment furnacesStrip steelTime control

The invention discloses a band steel return control apparatus after the shutdown of a continuous annealing furnace. The apparatus comprises a mode selection device, an execution mechanism, an automatic tension control mechanism, an automatic time control mechanism and an operation table, wherein the mode selection device can select one of an automatic tension mode, an automatic time mode and a manual mode; the execution mechanism indicates equipment of the continuous annealing furnace to execute a band steel return operation or a tension reduction operation; the automatic tension control mechanism controls the execution mechanism to gradually reduce the tension of the continuous annealing furnace in time period; the automatic time control mechanism controls the execution mechanism to uniformly return the equal-length band steel with the work segment as a base in time period; and the operation table receives a manual operation instruction, and controls the return operation of the execution mechanism to be carried out according to the manual operation instruction when the mode selection device selects the manual mode. According to the invention, the band steel can be automatically returned to the furnace after the abnormal shutdown of the technical segment of the continuous annealing furnace, so problems comprising band breakage, furnace deformation, furnace roller displacement and the like can be effectively prevented.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD +1

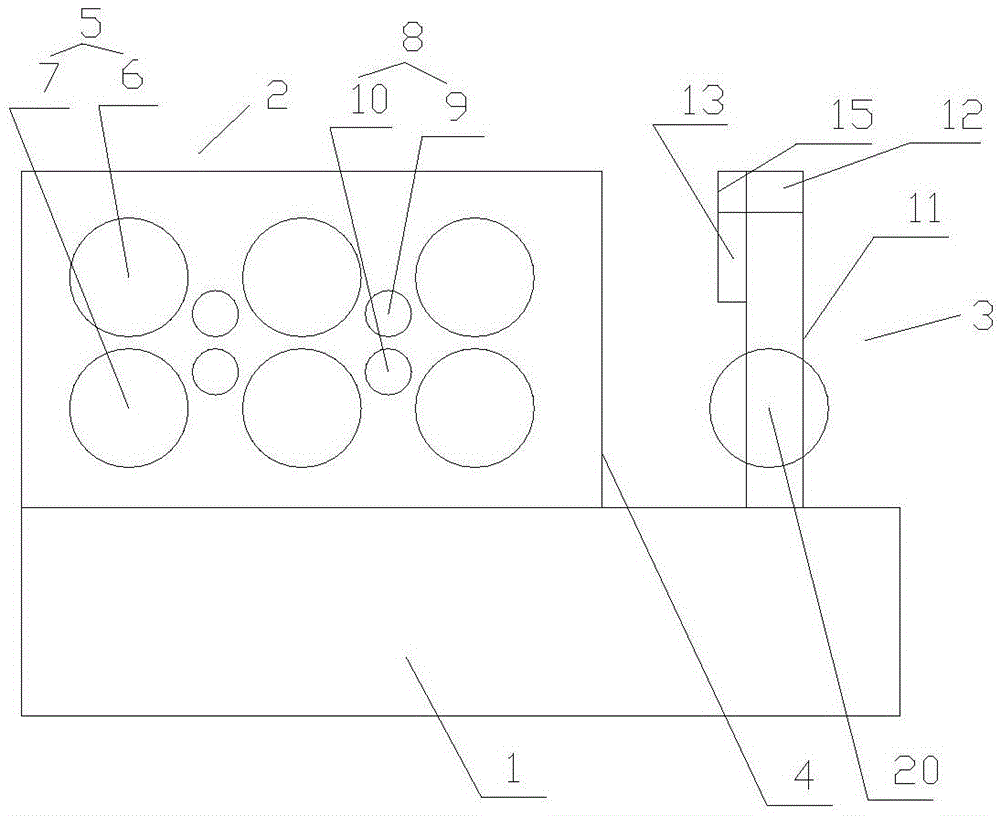

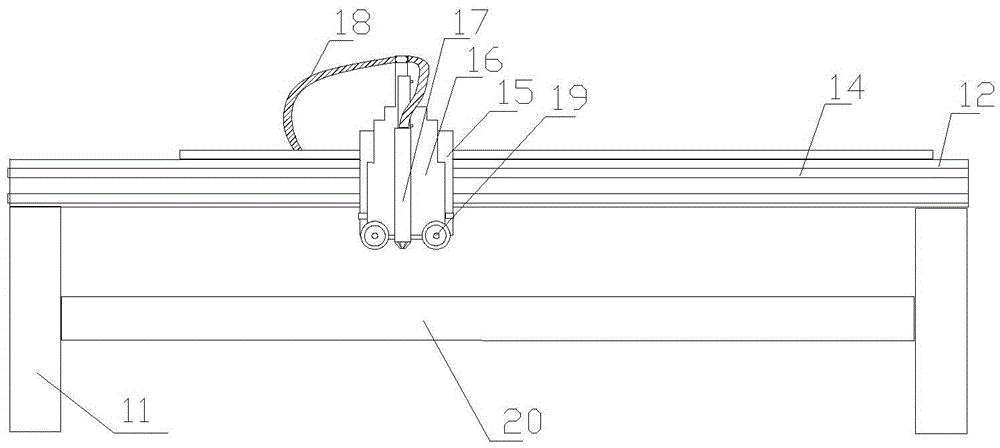

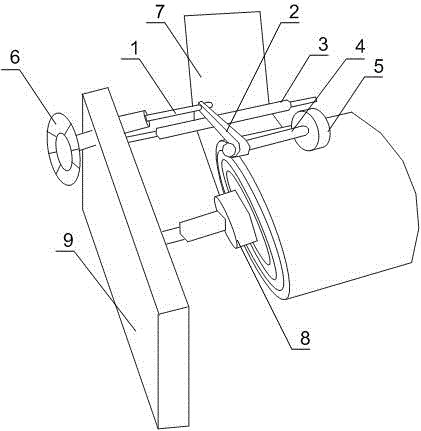

Plate uncoiling, flattening and cutting integrated machine

InactiveCN105563132AEasy control to openEasy control offOther manufacturing equipments/toolsEngineeringTension reduction

The invention discloses a plate uncoiling, flattening and cutting integrated machine which comprises a base. An uncoiling and flattening mechanism used for uncoiling and flattening plates is arranged at one end of the base, and a cutting mechanism used for cutting the plates is arranged at the other end of the base. The plate uncoiling, flattening and cutting integrated machine is used for firstly uncoiling and flattening the plates to be uncoiled and flattened and then cutting the plates. In this way, uncoiling and flattening are integrated with cutting, and thus production efficiency can be improved. In addition, the situations that the uncoiling and flattening mechanism is at a large distance from the cutting mechanism, the tension of the plates conveyed to the cutting mechanism is reduced, the cut plates are not flat or attractive enough, and consequently further smoothening, repairing and other treatment are needed, and time is wasted are prevented. Meanwhile, tension reduction is avoided, and starting and stopping of the machine are easily controlled.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

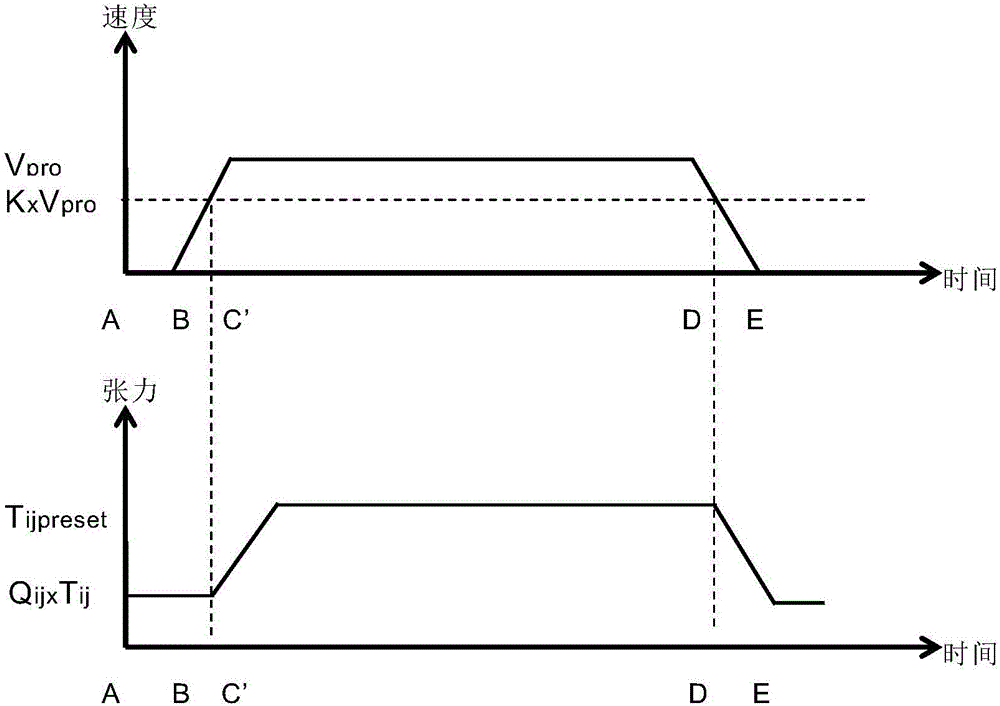

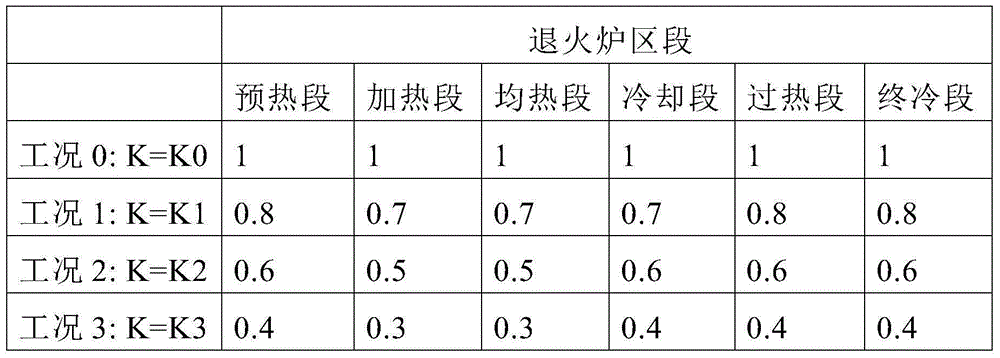

Control method for restart of strip steel processing line furnace area after shutdown

The invention discloses a control method for restart of a strip steel processing line furnace area after shutdown. The control method is characterized in that an annealing furnace comprises an entrance preheating section, a heating section, a soak section, a cooling section, a superheating section and a final cooling section, and a process set value of normal production is multiplied by a certain coefficient according to different work conditions, so that the purpose of speed and tension reduction is achieved. The control method has the benefits that overburnt strip steel passes through the annealing furnace smoothly, strip breakage and hot waved surfaces of the strip steel in the annealing furnace are reduced or prevented as far as possible, and a unit can recover the normal production rapidly and stably.

Owner:通用电气(武汉)自动化有限公司

Reducing prestress structure system before prestressed reinforcement withdrawing tension

The invention provides a structural system for reducing prestress before tension reduction of prestressed reinforcement, which consists of a novel fixing end capable of being repeatedly assembled and disassembled and a tensioning end structural system. In the structural system, when the design value of the tensile strength of the prestressed reinforcement is reached, before reducing tensile force and removing clamping pieces, the tensile force of the prestressed reinforcement is reduced in advance, before the final tension reduction, the pulling force value of the prestressed reinforcement is reduced until the material elongation generated by the left tensile strength value is enough for successful tension reduction, thereby fully utilizing the strength design standard value of the prestressed reinforcement, improving material utilization ratio, reducing the consumption of the prestressed reinforcement, reducing the structural specification of the whole structural system including the fixing end and the tensioning end and a prestressed reinforcement pore path; the unsuccessful tension reduction and the failed repeated use of the prestressed reinforcement caused by the beyond-the-limit working pulling force of the prestressed reinforcement are avoided; and the structural system provides new technological conditions for the non-bonding after-tension method prestress structural system used for the combination and disassembly of concrete precast components to save resources and lower cost.

Owner:赵正义

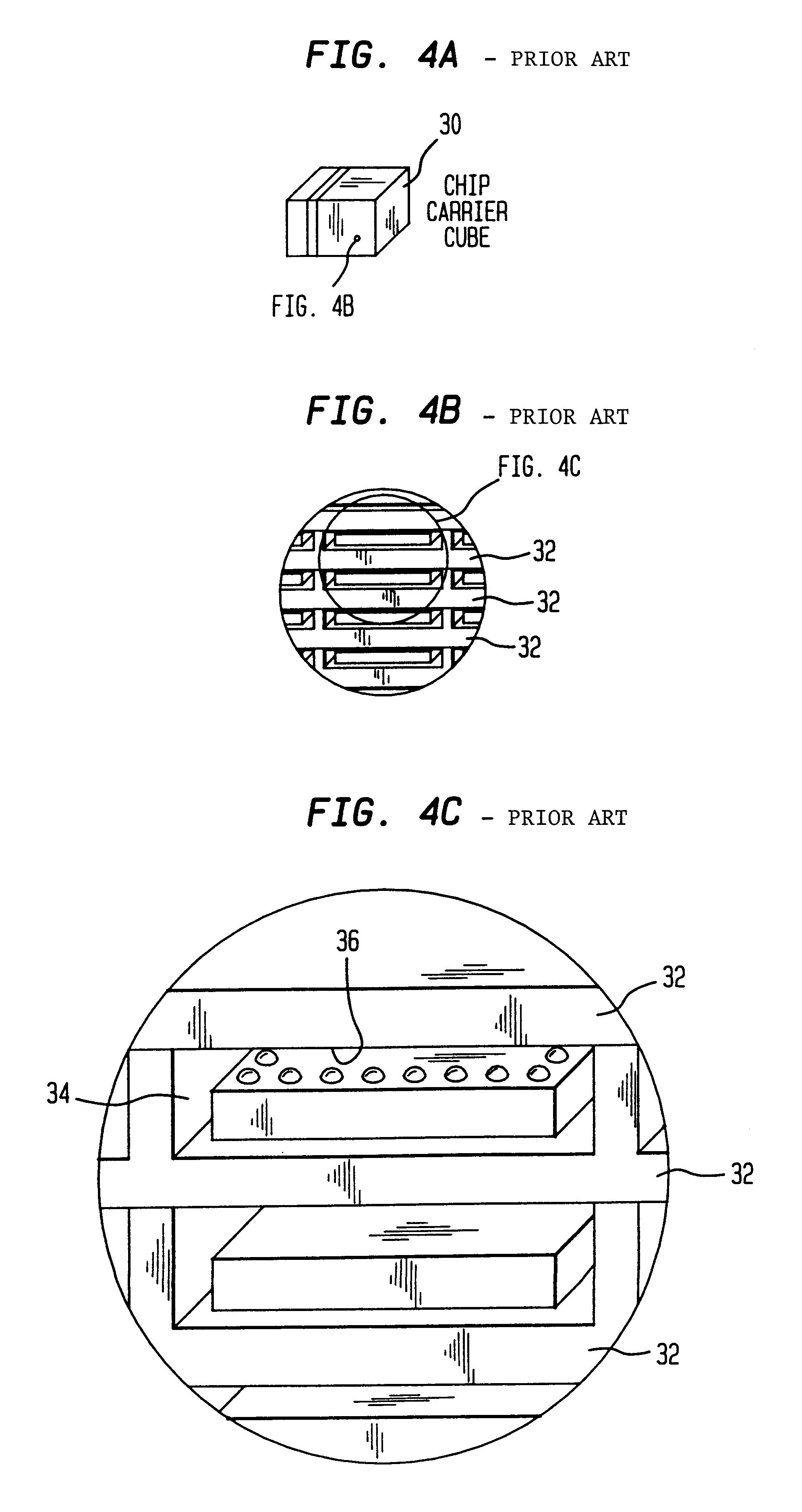

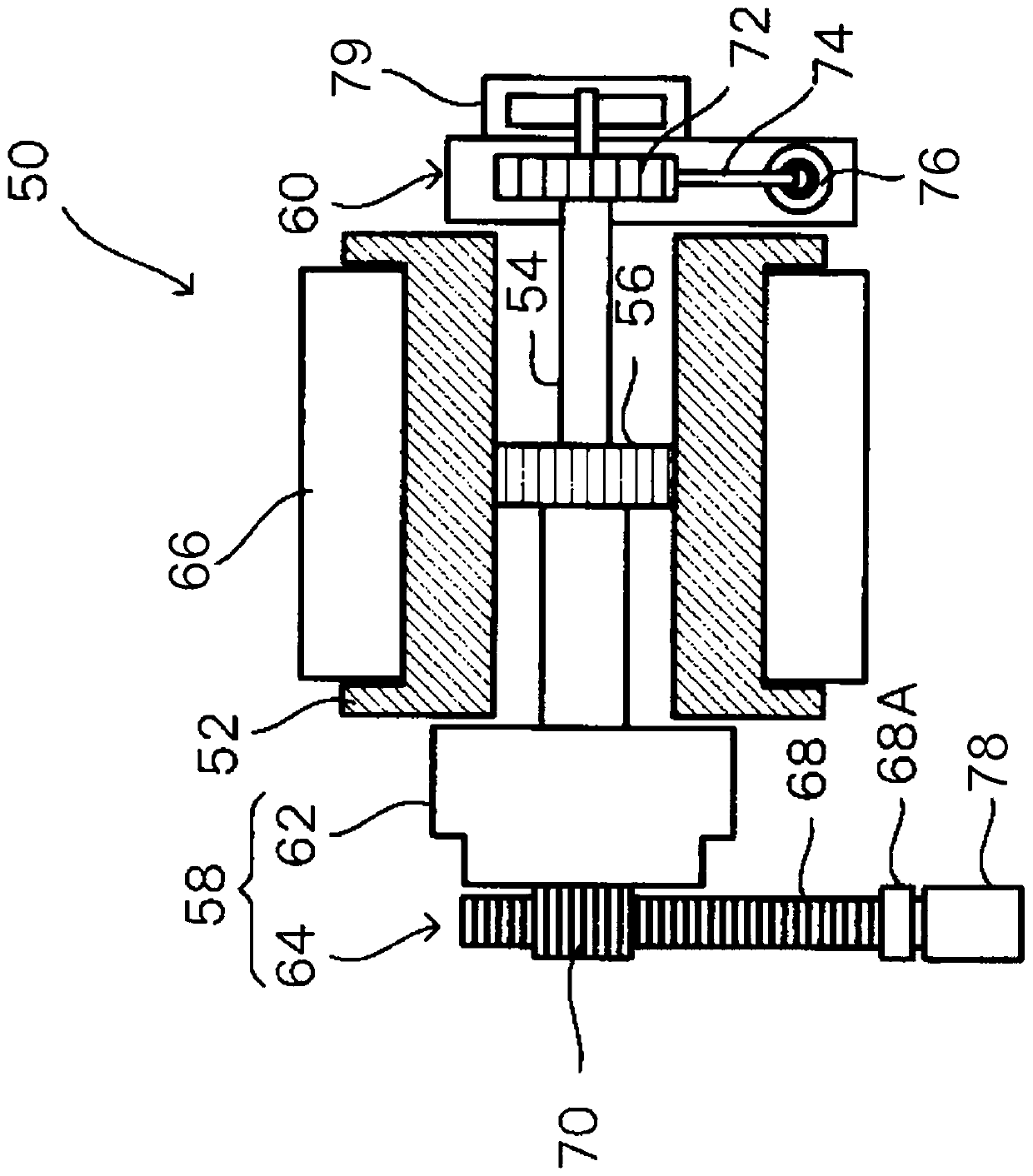

Heart wall tension reduction apparatus

InactiveUS20150105611A1Reduce tensionReduce energy consumptionSuture equipmentsHeart valvesHeart chamberFailing heart

An apparatus and method for treatment of a failing heart. In one embodiment, the apparatus and method includes a deploying a tension member for drawing at least two portions of the heart toward each other across a heart chamber.

Owner:EDWARDS LIFESCIENCES LLC

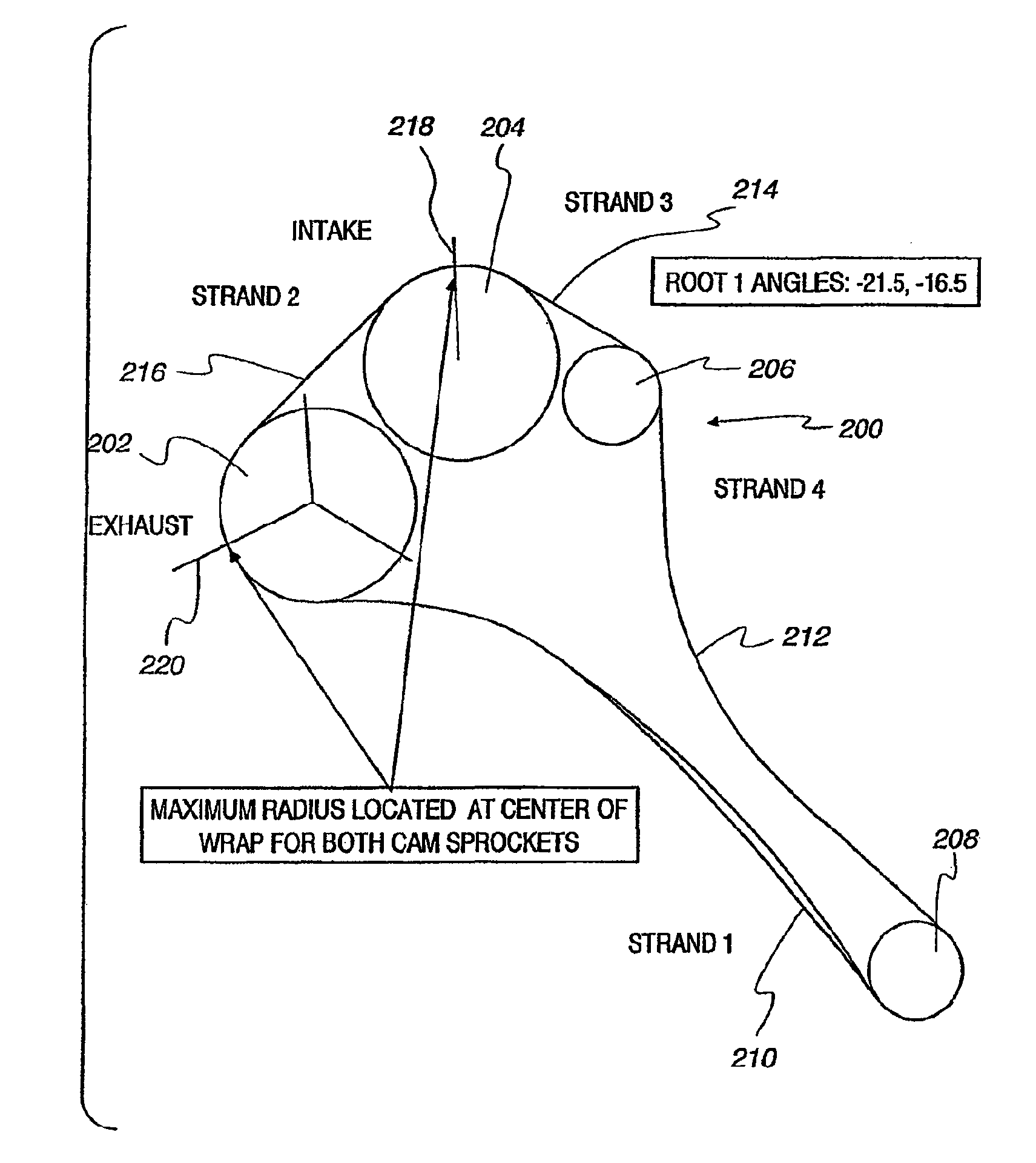

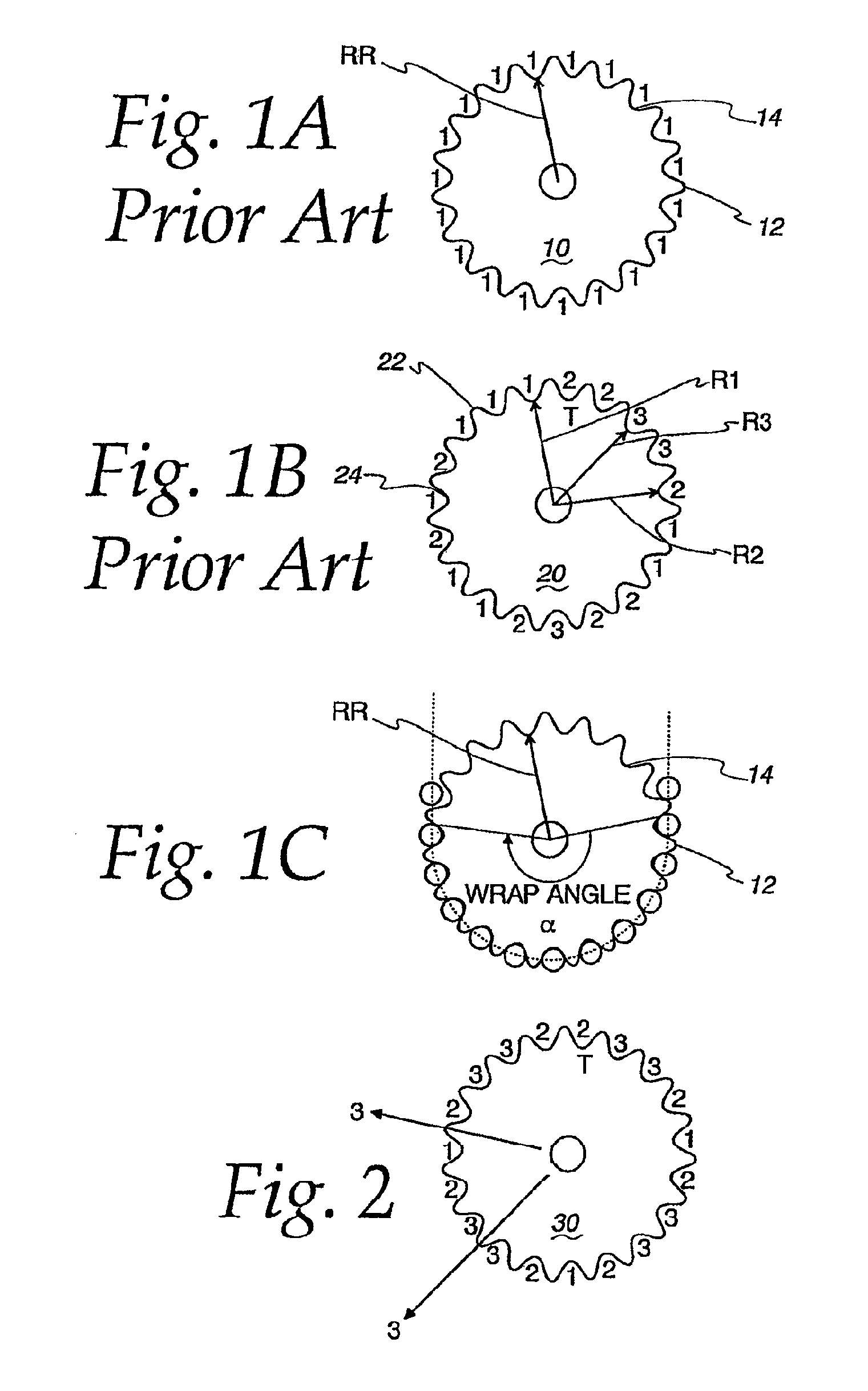

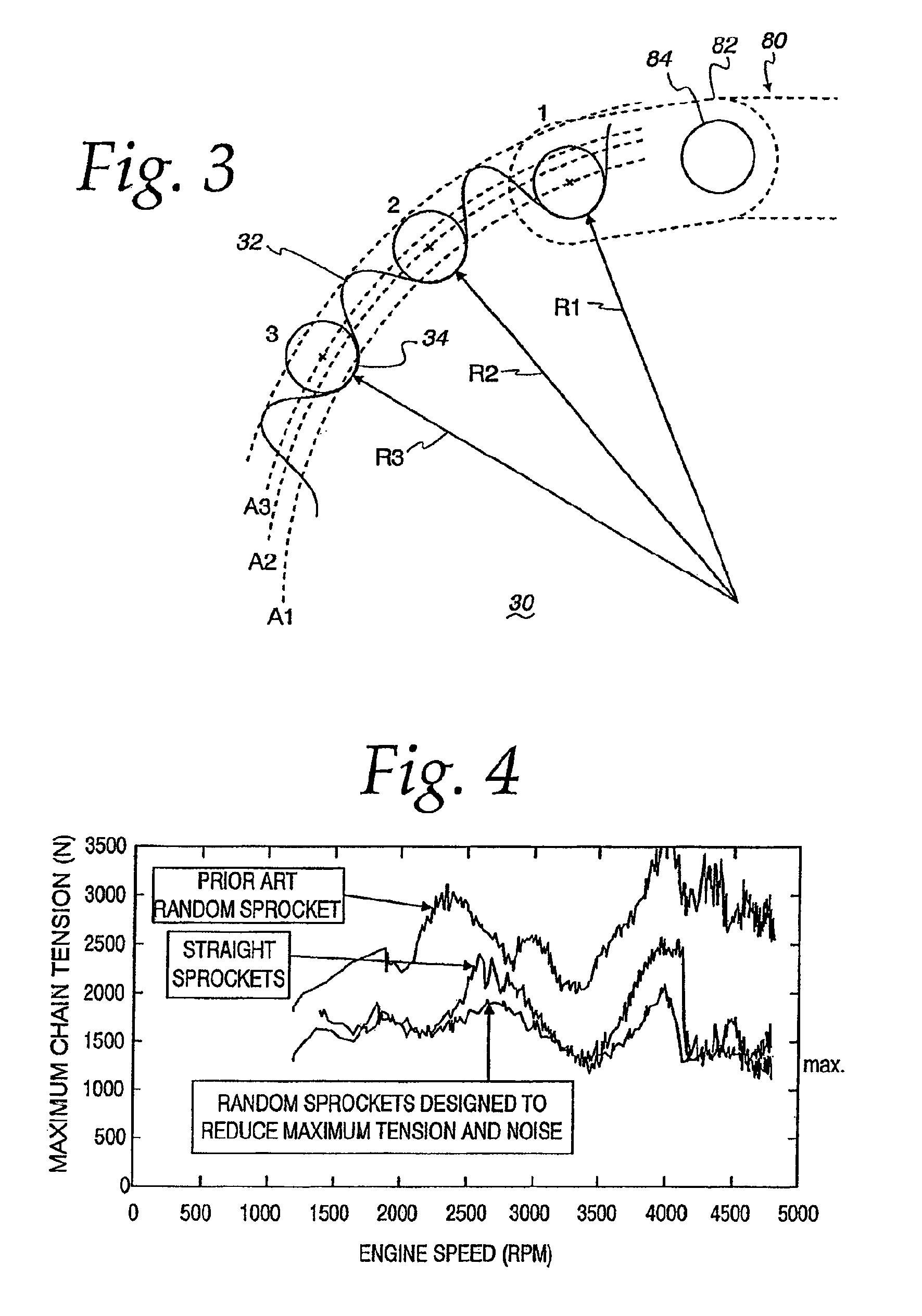

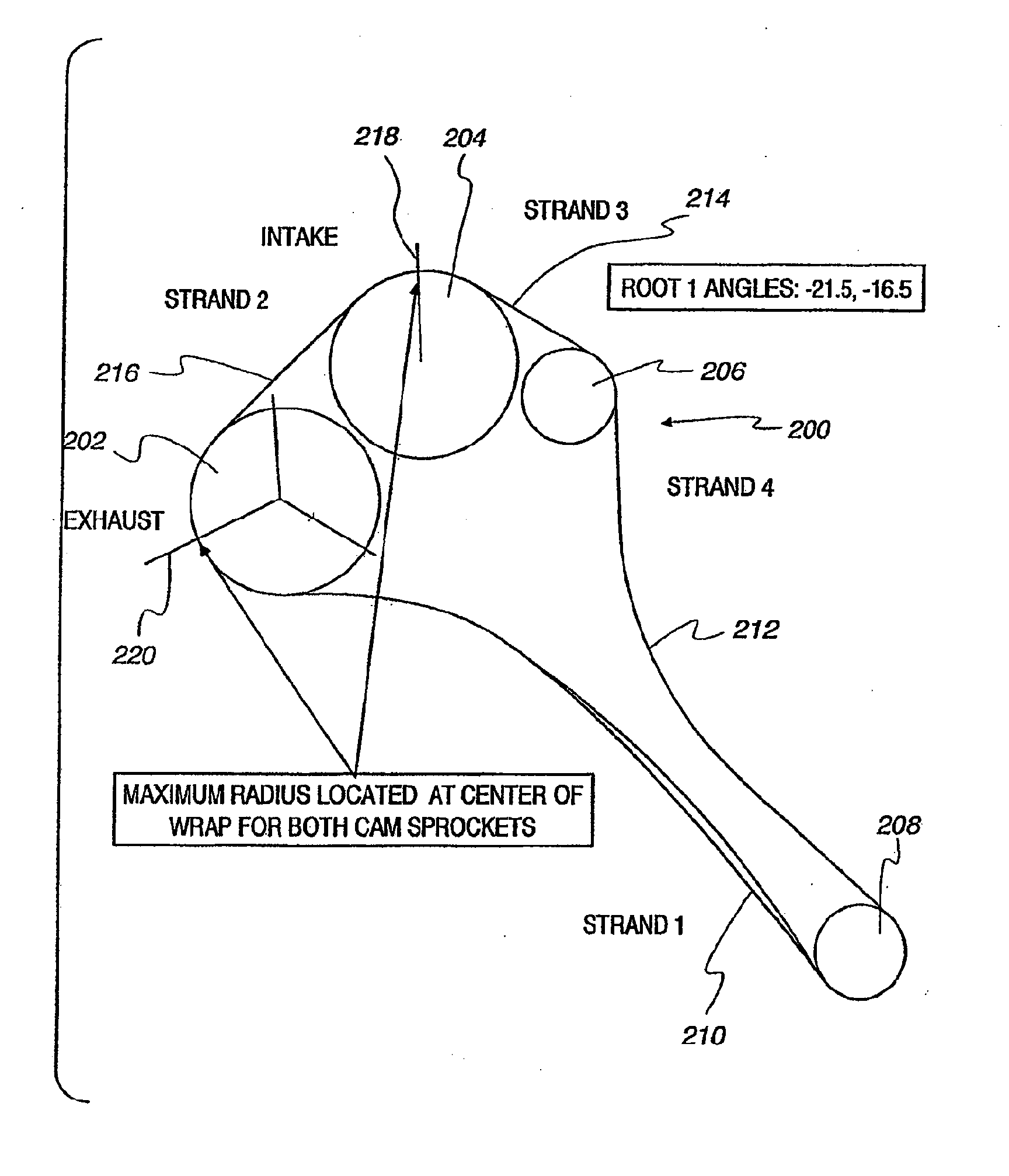

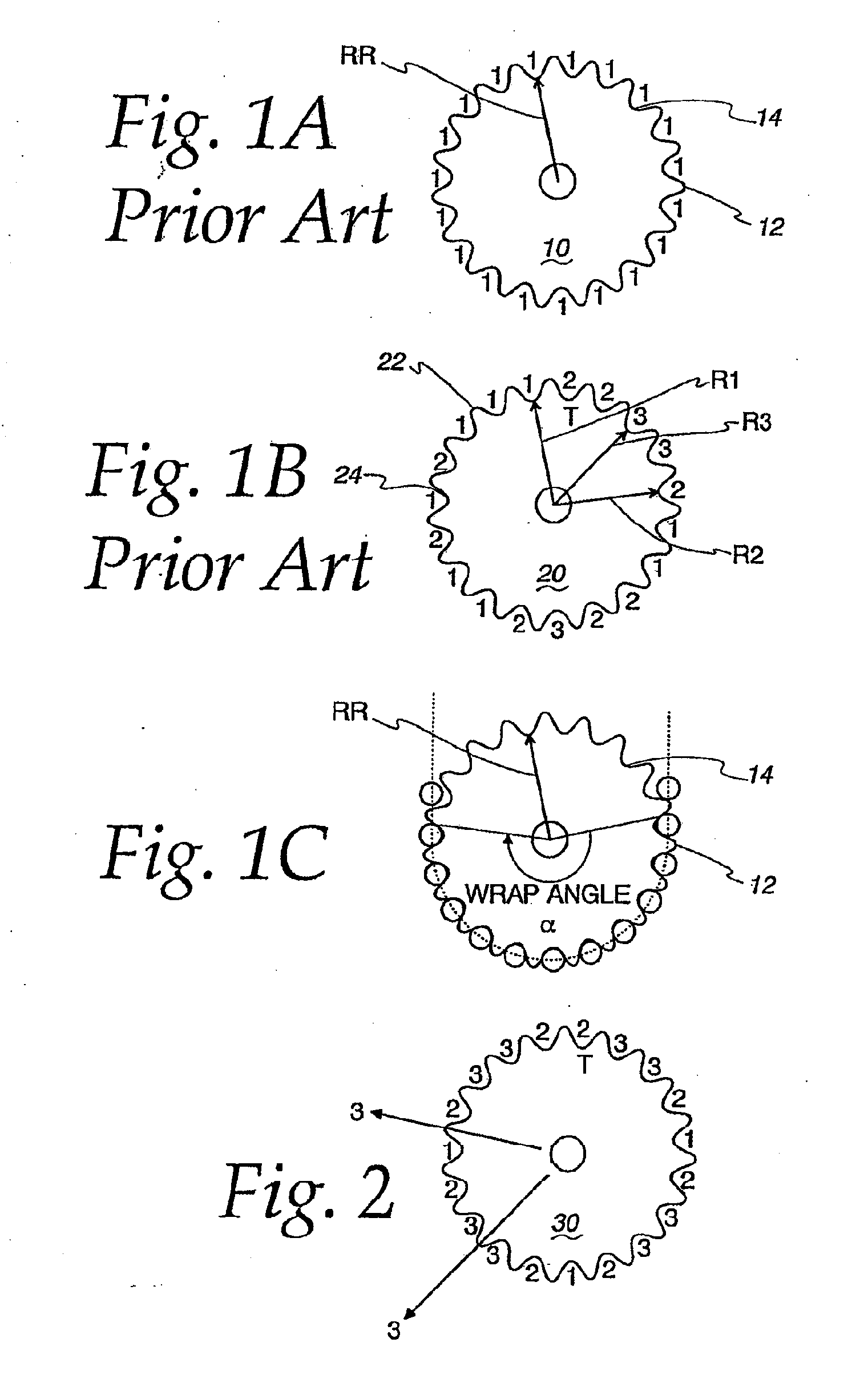

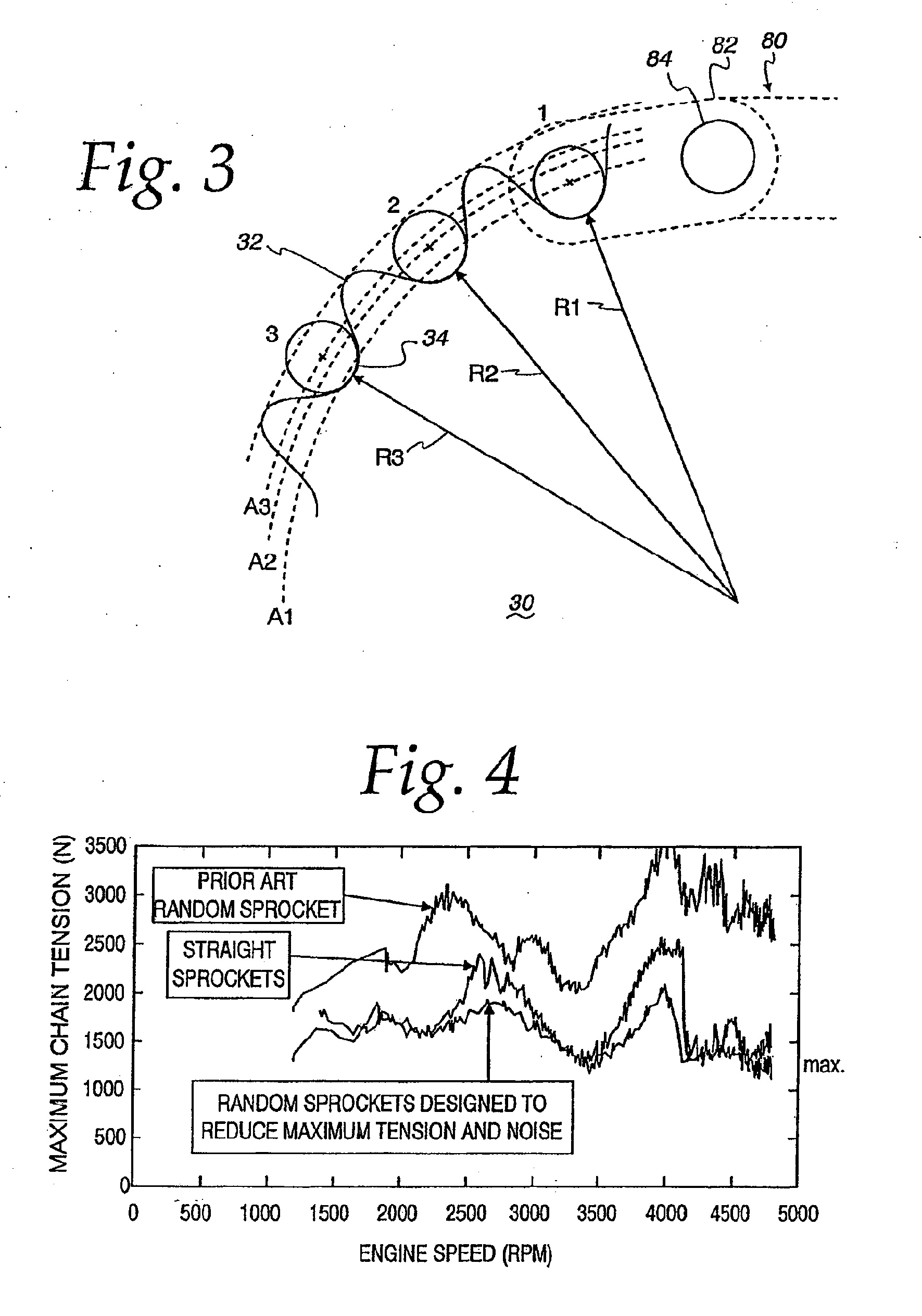

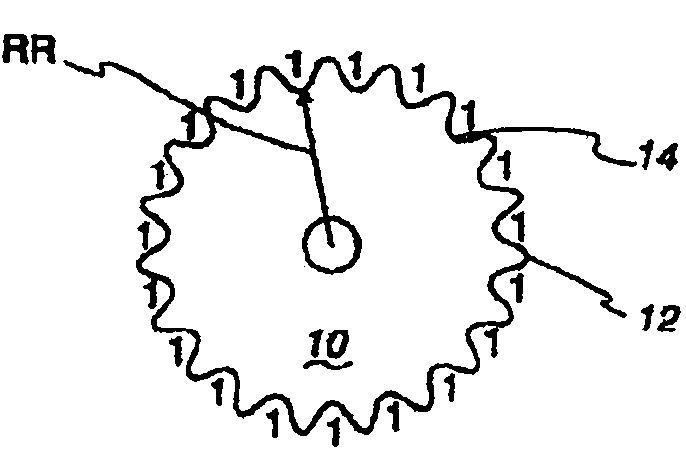

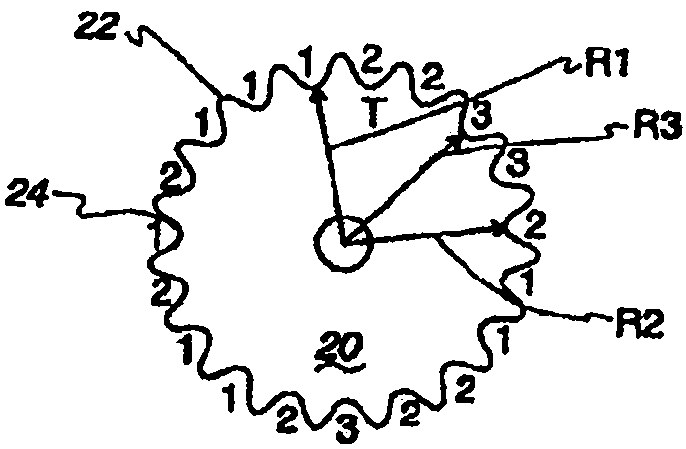

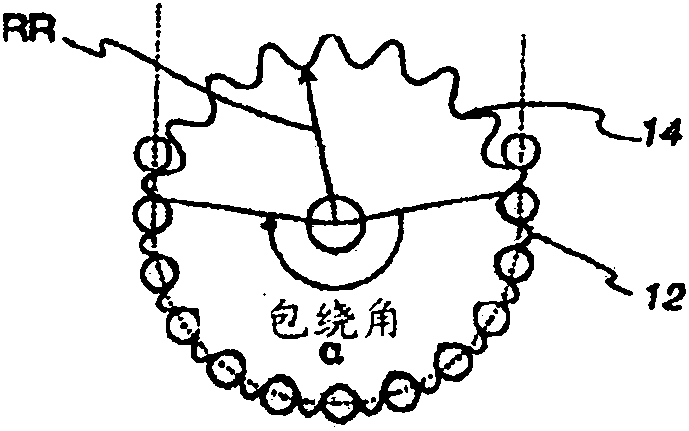

Multiple tension reducing sprockets in a chain and sprocket system

Owner:BORGWARNER INC

Multiple Tension Reducing Sprockets in a Chain and Sprocket System

In chain and sprocket systems with at least two resonance modes, two or more tension reducing sprockets are oriented to cancel each other at a first resonance mode and have no effect to increase tensions at such first resonance mode. The tension reduction sprockets, however, are oriented with each other so that tensions will be reduced at a second resonance mode. Hence, two or more tension reducing sprockets are used to reduce tensions at a second resonance mode from sources outside the chain and sprocket system while minimizing tension increases at first resonance mode.

Owner:BORGWARNER INC

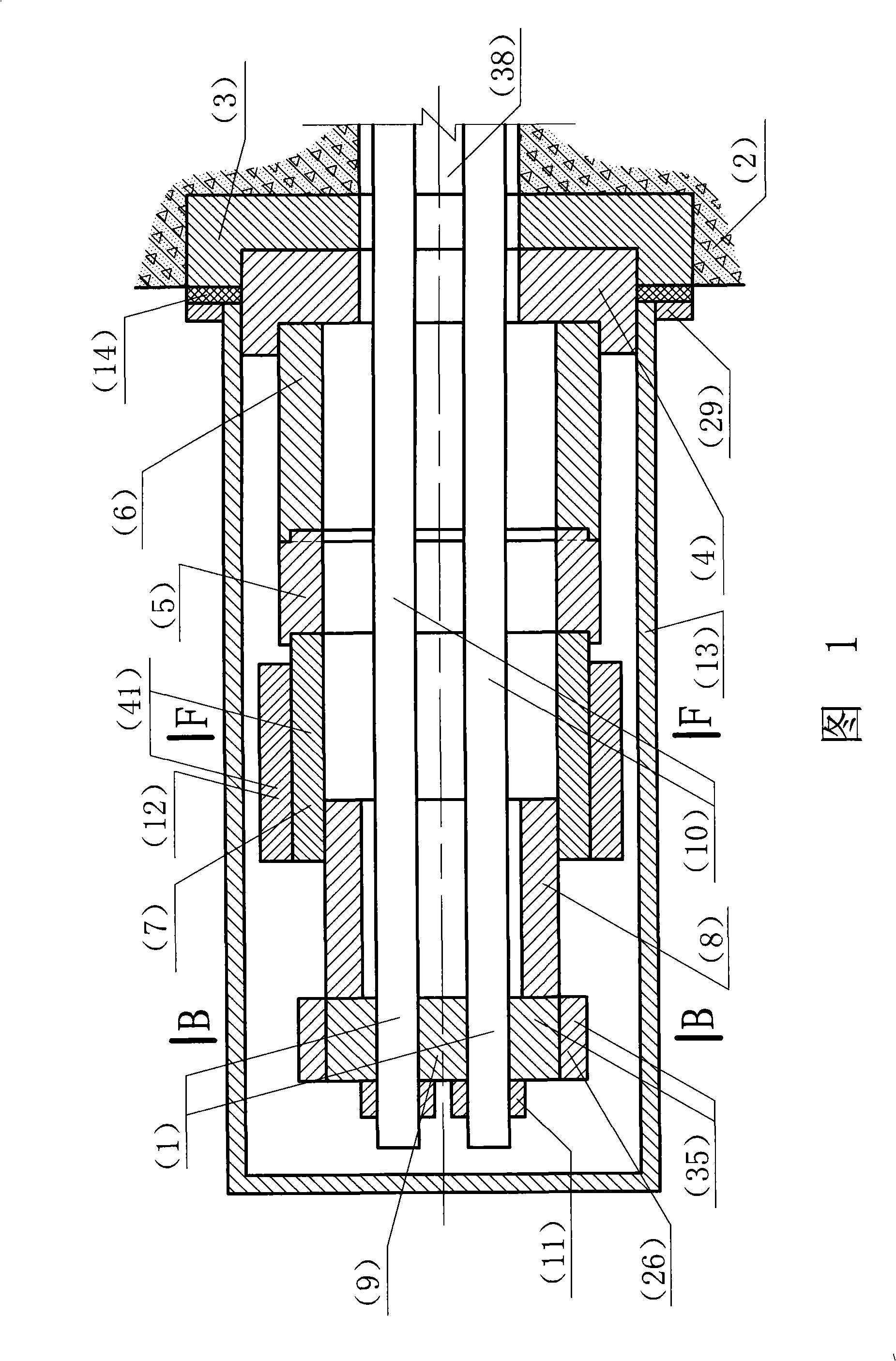

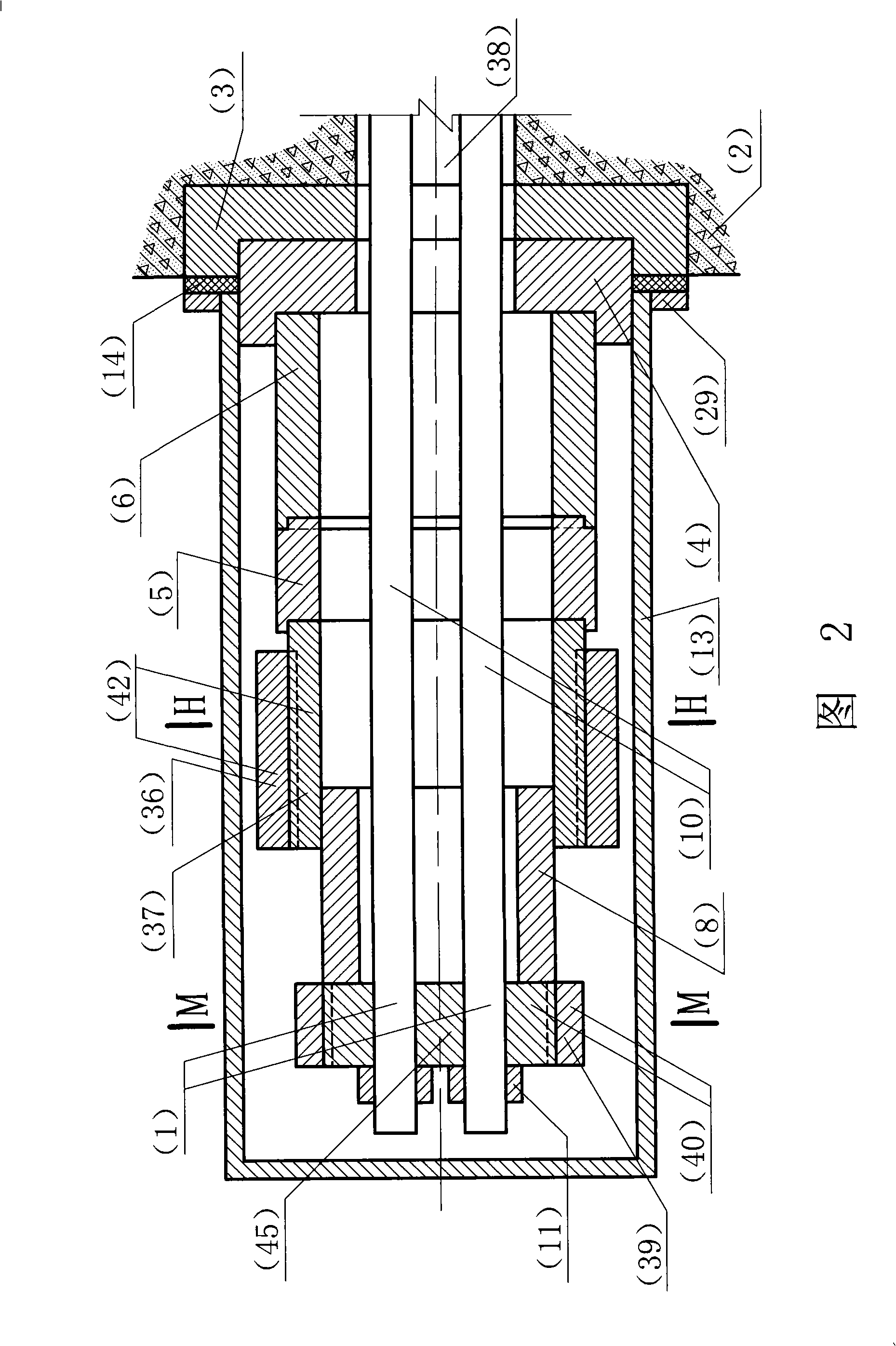

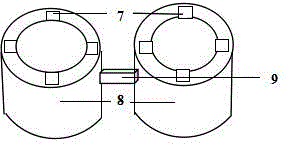

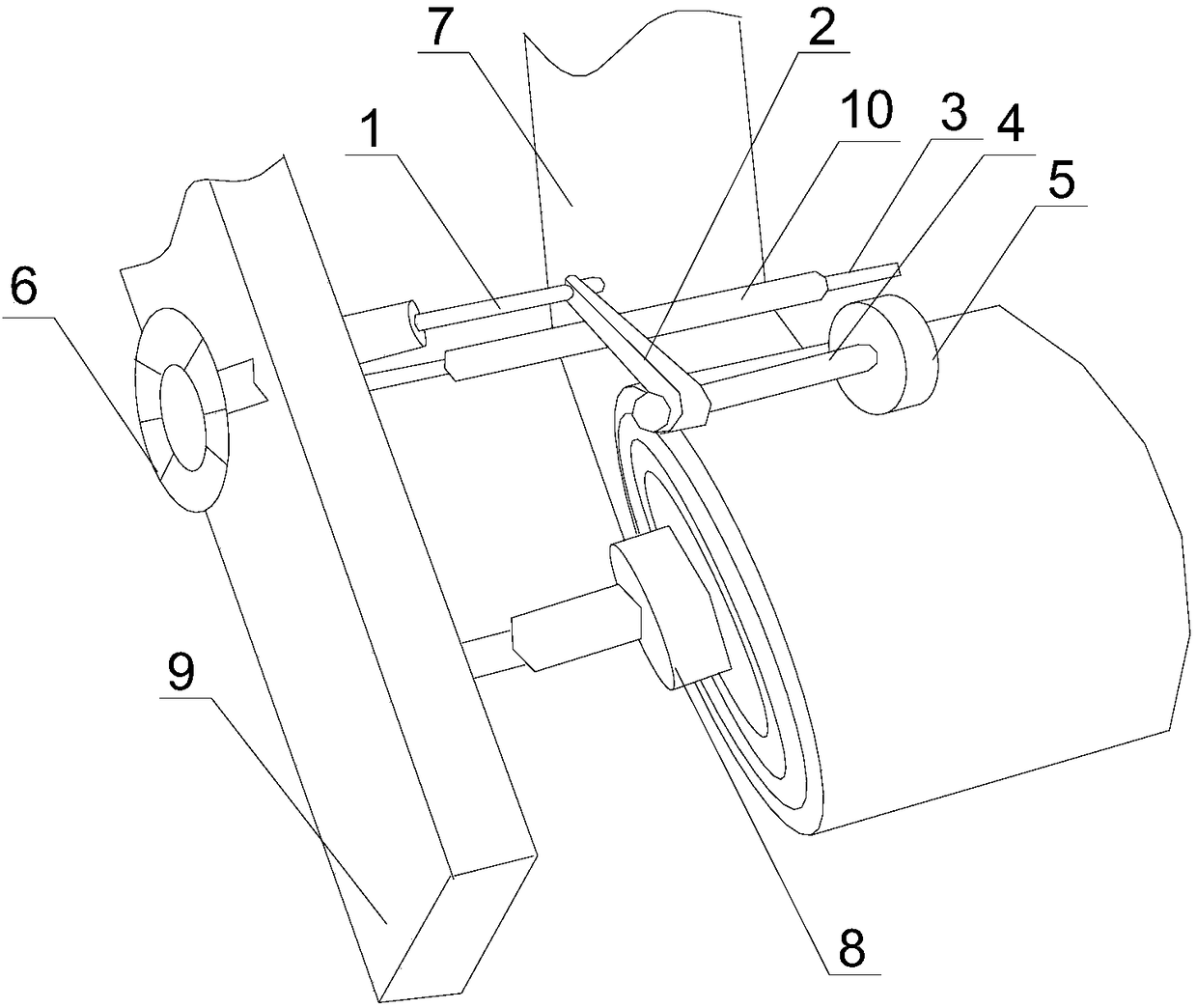

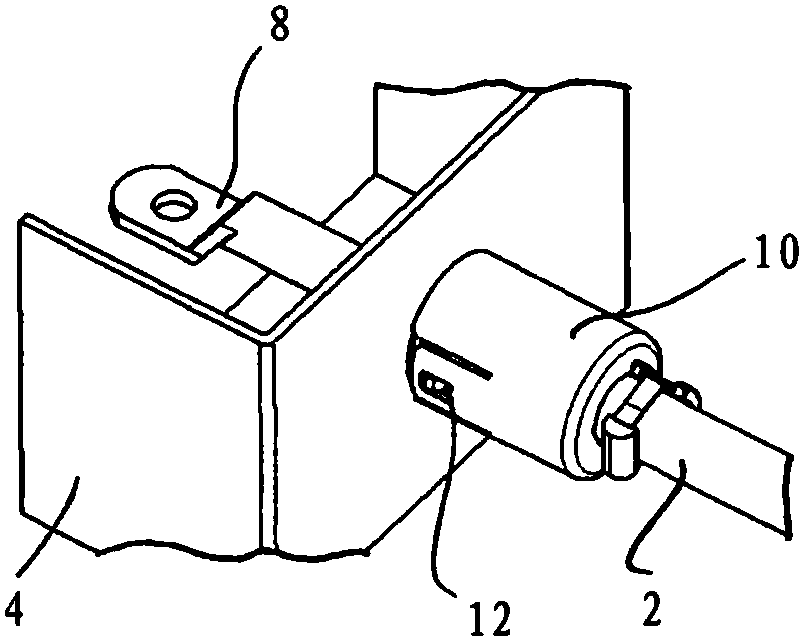

Tension reduction device for skin wound

InactiveCN106137285AOvercoming stretchLong-term tension-reducing effectSuture equipmentsTension reductionUltimate tensile strength

The invention provides a tension reduction device capable of reducing tension of a skin wound and adjusting tension reduction strength at any time. Due to the tension reduction device, the defects that time during skin wound tension reduction in the prior art, a tension reduction thread is loose and cannot be adjusted according to the requirement of tension reduction strength of the skin wound at any are solved. The tension reduction device comprises two sleeve rods, two sleeves, two tension reduction threads and four skin tubes, wherein the sleeves are connected together through a connecting beam; four square bulges are arranged at the lower part of each sleeve rod body, and can be matched with four grooves, as high as the sleeves, in the sleeves; the tension reduction threads penetrating through thread holes in the bottoms of the sleeve rods are wound on spools by rotating rotation handles, so that the tension reduction strengths of the tension reduction threads are maintained and adjusted; moreover, a pair of the skin tubes sleeve each tension reduction thread, so that the tension reduction threads can be prevented from cutting skin on two sides of the tension reduction threads during skin wound tension reduction. The tension reduction device has the functions of accelerating healing of the skin wound and reducing the scar of the skin wound.

Owner:凯赛尔江·艾合买提

Multiple tension reducing sprockets in a chain and sprocket system

In chain and sprocket systems with at least two resonance modes, two or more tension reducing sprockets are oriented to cancel each other at a first resonance mode and have no effect to increase tensions at such first resonance mode. The tension reduction sprockets, however, are oriented with each other so that tensions will be reduced at a second resonance mode. Hence, two or more tension reducing sprockets are used to reduce tensions at a second resonance mode from sources outside the chain and sprocket system while minimizing tension increases at first resonance mode.

Owner:BORGWARNER INC

Petroleum pollution cleaning agent

ActiveCN108624412AEffective protectionGood removal effectOrganic detergent compounding agentsNon-ionic surface-active compoundsPetroleum PollutionTension reduction

The invention discloses a petroleum pollution cleaning agent, which is characterized by comprising the following components in parts by mass: 30 to 99 parts of D-limonene, and 1 to 70 parts of emulsifier, wherein the emulsifier is prepared from the following components in parts by mass: 20 to 50 parts of cocoyl ethoxylate-9, 20 to 40 parts of cocoyl ethoxylate-3, 10 to 15 parts of cocamidopropyl DEA, and 15 to 30 parts of ethanol. The petroleum pollution cleaning agent can remove petroleum pollutions easily, safely and efficiently by strong surface penetration, instantaneous dissolving, dispersing, wettability changing, interfacial tension reduction and other measures on adhered petroleum.

Owner:上海申仰实业有限公司

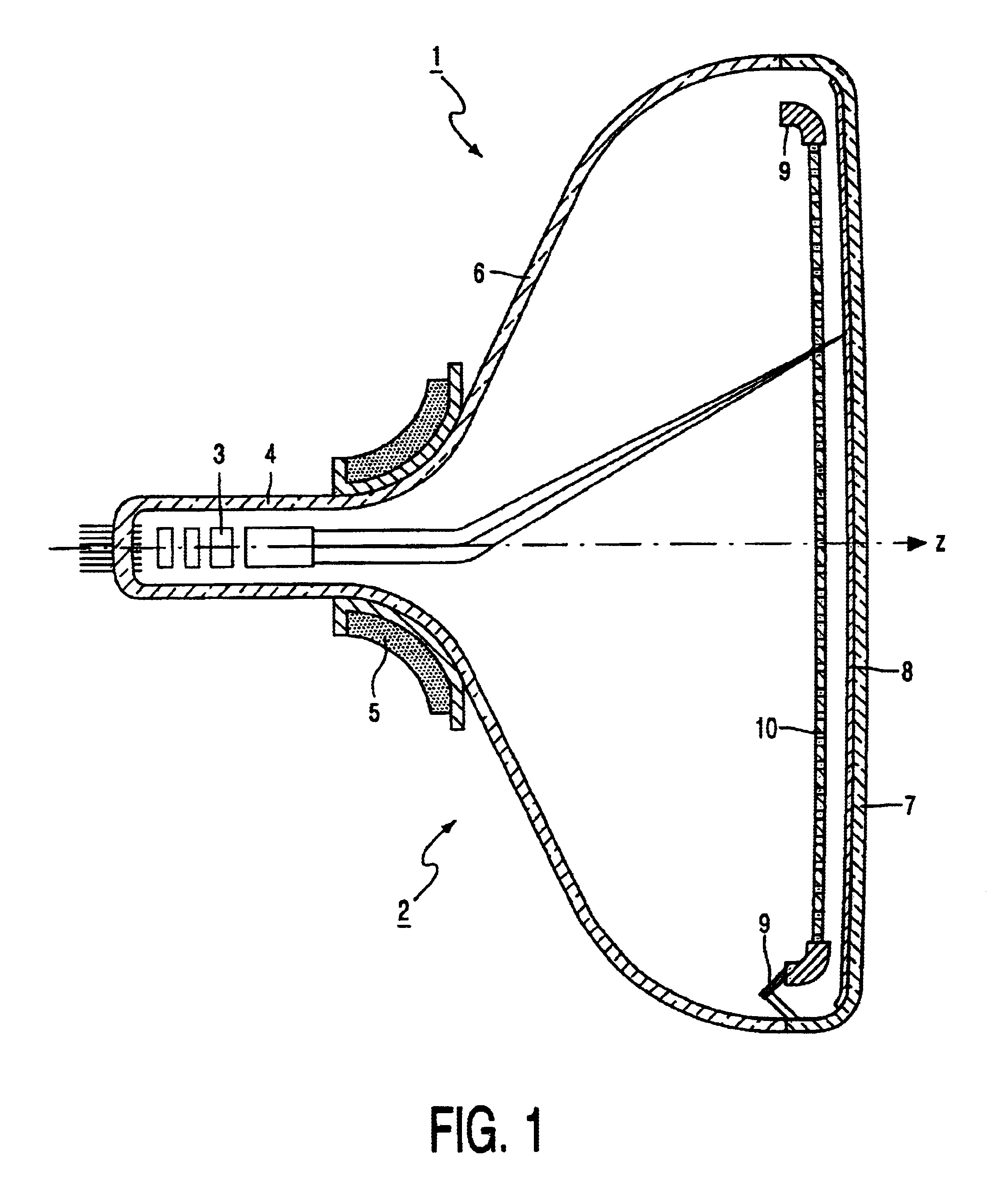

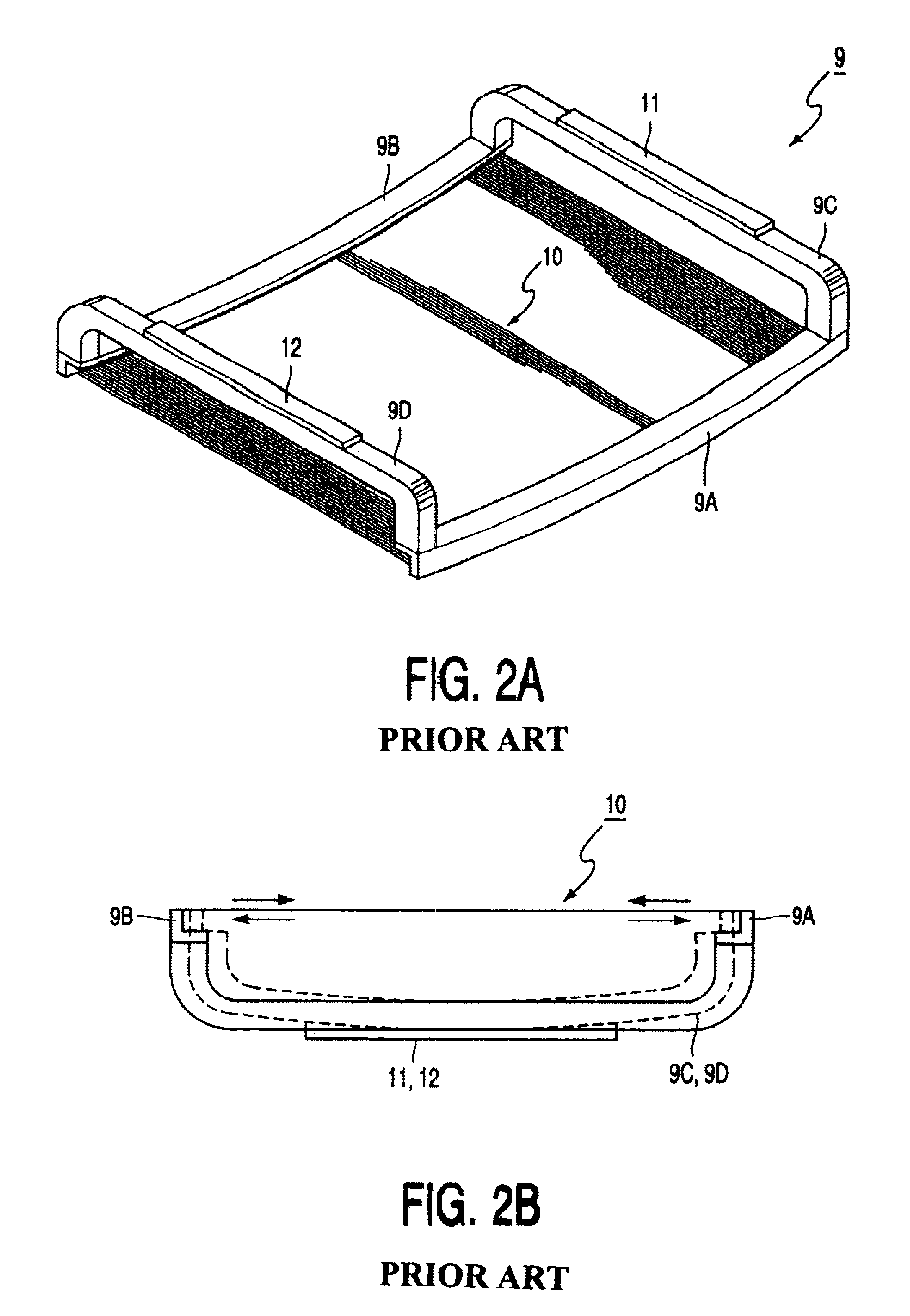

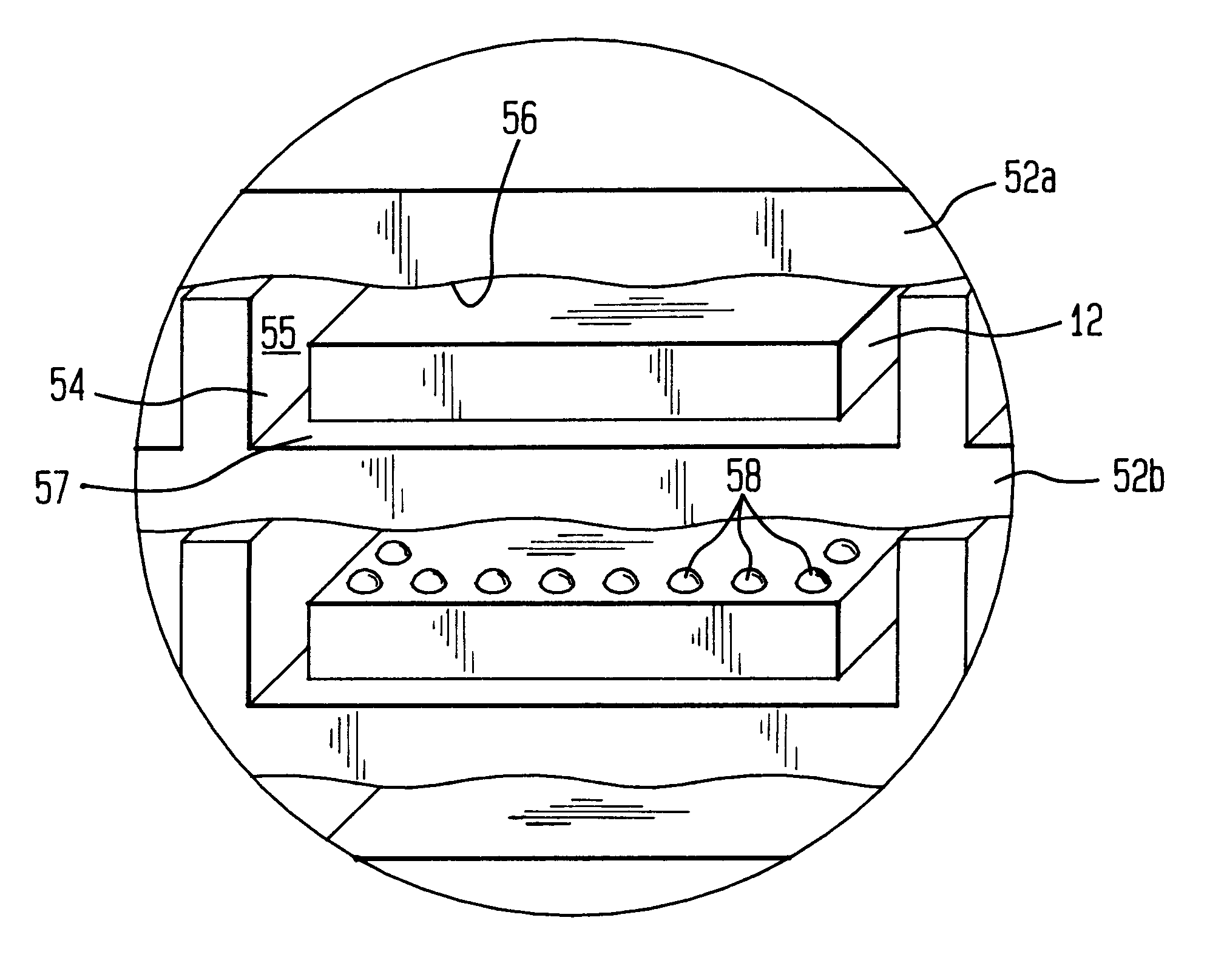

Color selection electrode implementing a temperature based tension reduction of a shadow mask

InactiveUS6686684B2Reduce distanceDistanceElectrode and associated part arrangementsEngineeringTension reduction

A cathode ray tube comprises a color selection electrode with a shadow mask fixed to a frame and put under tension. The frame comprises a bimetal element (or bimetal elements) which are constructed such that at a raised temperature the tension is released by reducing the distance between sides of the frame to which the mask is attached. The reduction in distance at the center of the sides exceeds, preferably by a factor 1.5 to 3, the reduction in distance at the corners of said sides.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

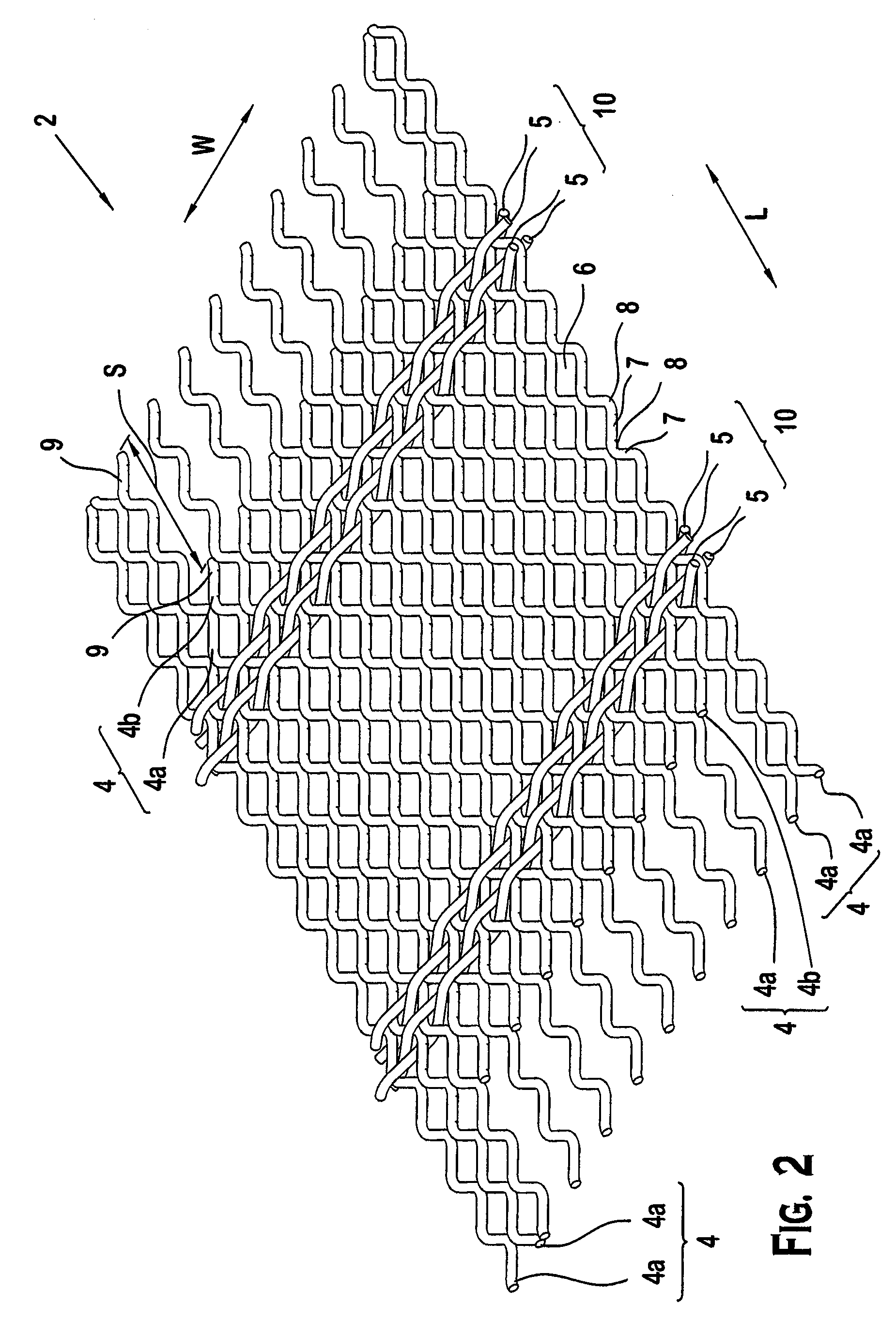

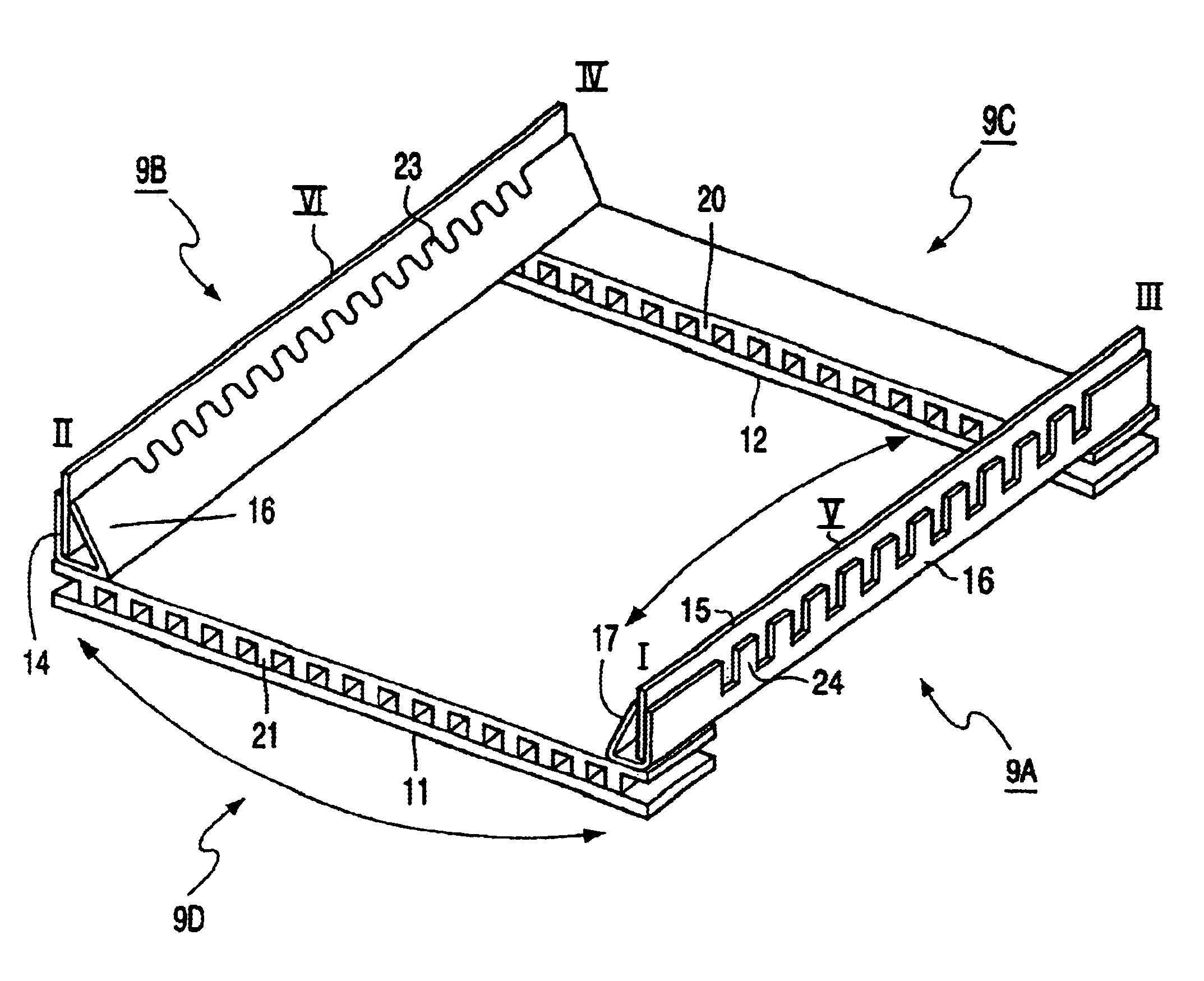

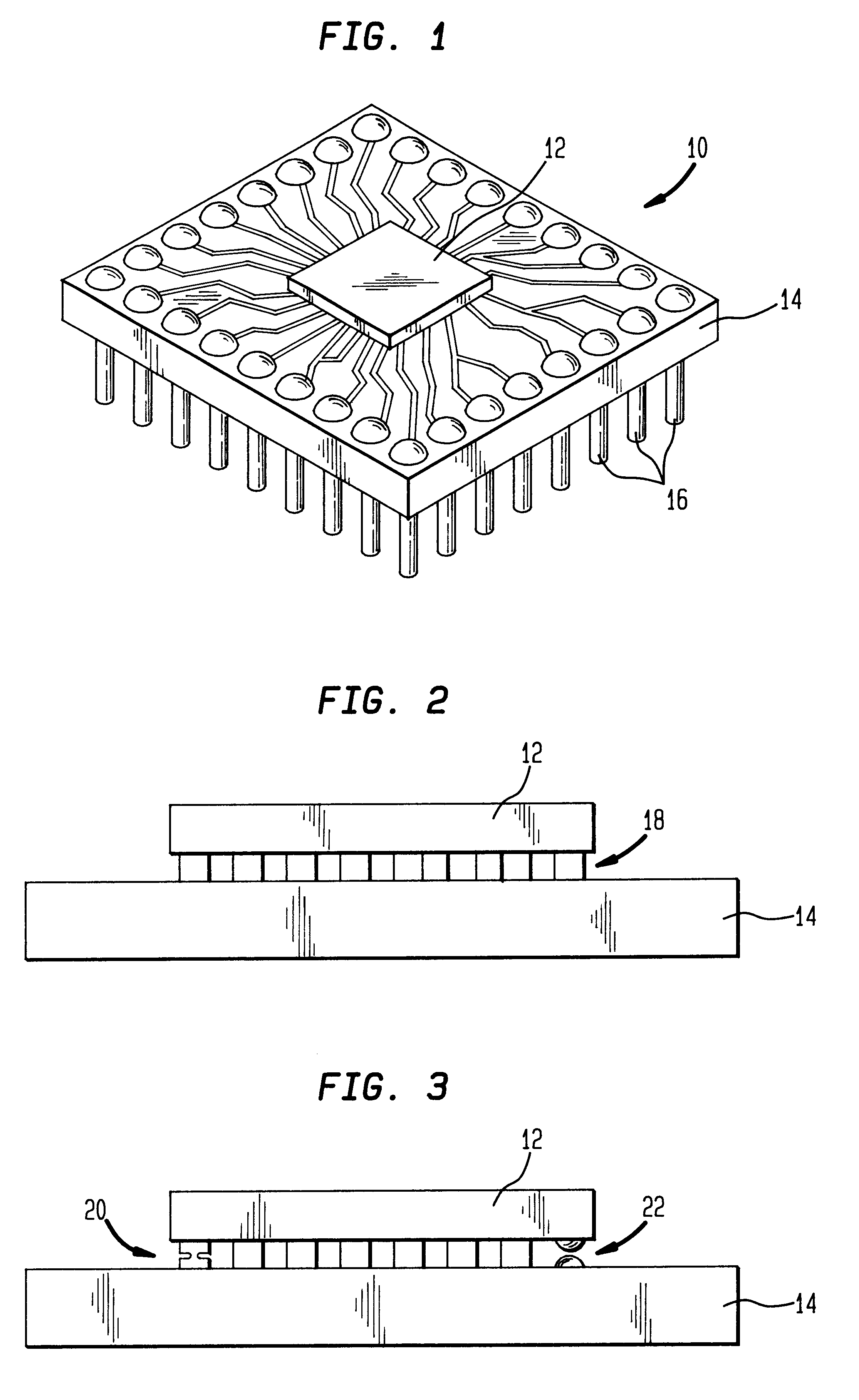

Component carrier having a wave pattern tension reduction surface

InactiveUS6176374B1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

Owner:IBM CORP

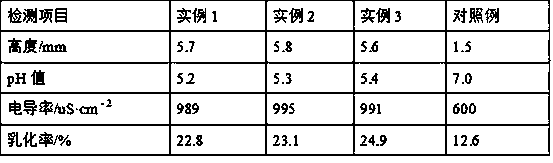

Preparation method for alcohol-free fountain solution

InactiveCN108944112AReduce emulsificationImprove permeabilityPrinting pre-treatmentAlcohol freeBetaine formation

The invention relates to a preparation method for an alcohol-free fountain solution, and belongs to the technical field of printing. The synergistic interaction effect of micelle forming capacity andsurface tension reduction capacity of an anionic surfactant, namely lauryl sodium sulfate and a zwitterionic surfactant, namely lauramidopropyl betaine is adopted for preparing the alcohol-free fountain solution, an anticreaming agent and an oil-water balance agent are added into a combinational surfactant, a betaine type amphoteric surfactant can be dissolved in an acid, neutral or alkaline aqueous solution, and the seepage force, the decontamination capacity, the antistatic performance and the like are better. The pH of a system of the adjusting fountain solution is 4.5-6, the disperse uniformity of the fountain solution can be improved, meanwhile, later-period mixing with printing ink is facilitated, and emulsification of the printing ink is reduced; and phosphoric acid enables acacia gum to dissolve to obtain more arabic acid to supplement for a hydrophilic glue film of an empty part of a plate face, a compact oleophobic and hydrophilic film can be formed on the surface of the fountain solution, and the adhesive force of the film and the printing plate is strengthened.

Owner:黄智慧

Packing material tension keeping structure

InactiveCN104417782AControl speedReduce tensionWrapping material feeding apparatusWebs handlingPack materialEngineering

The invention discloses a packing material tension keeping structure comprising a guide roller and a speed limit mechanism. The guide roller and the speed limit mechanism are arranged on an external packer which comprises a supporting rod, a hand wheel, a connecting rod and a down-pressing device, one end of the supporting rod is hinged to the down-pressing device through the connecting rod, and the other end of the supporting rod is in threaded connection with the hand wheel. The guide roller and a roller of the external packer are spaced by a certain distance to enable a packing material to keep certain tension. The rotating speed of the roller of the external packer can be controlled through the speed limit mechanism, and speed limit effect is achieved. The hand wheel is rotated to drive the supporting rod to rotate, and the down-pressing device moves up and down under the linkage action of the connecting rod. When the down-pressing device moves downwards, the speed of the roller is limited, and tension reduction of the packing material due to too fast rotation is avoided; when the down-pressing device moves upwards, limit to the speed of the roller is reduced, and feeding requirements of quick packing of the packer can be met.

Owner:熊凌聪

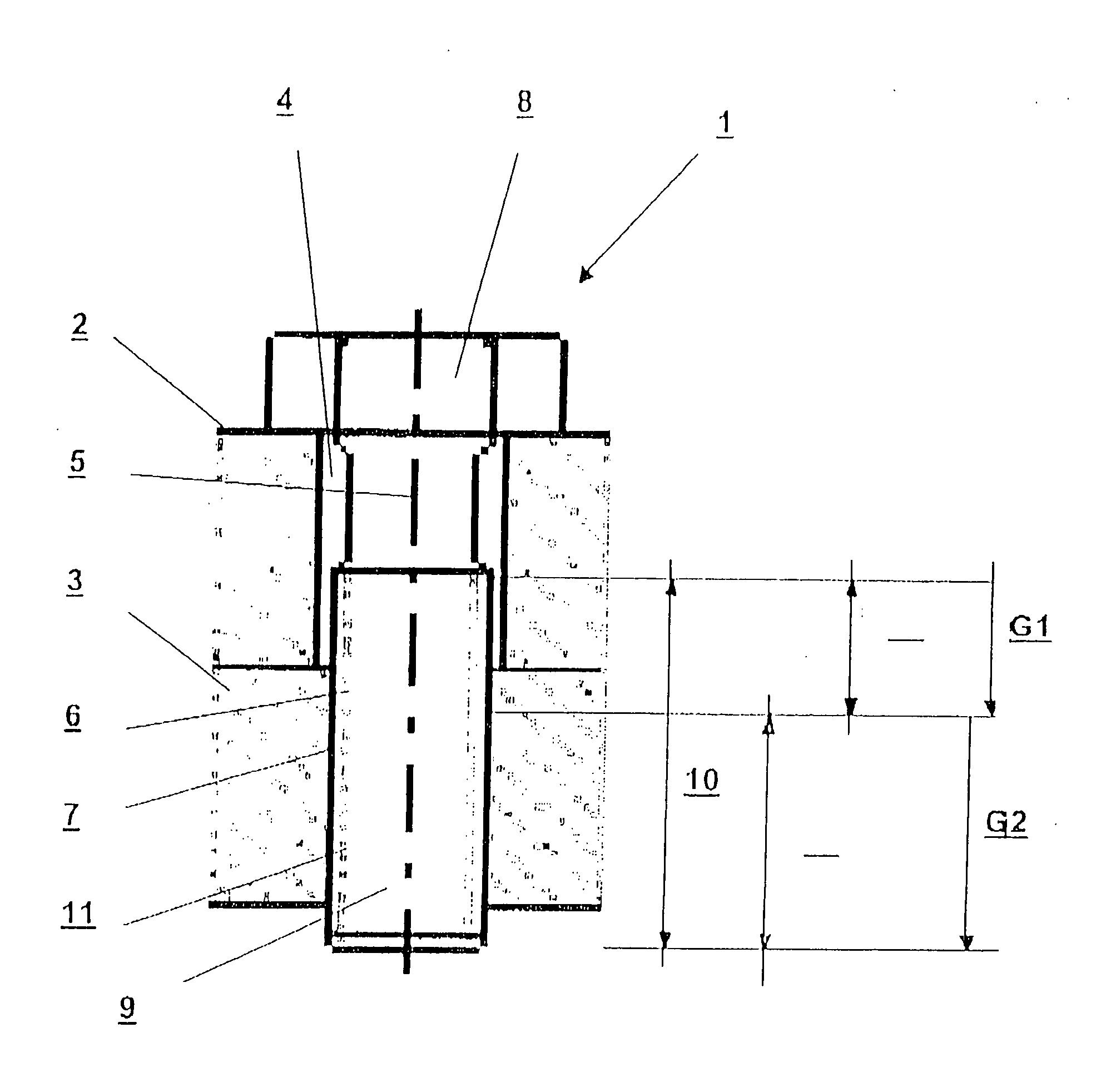

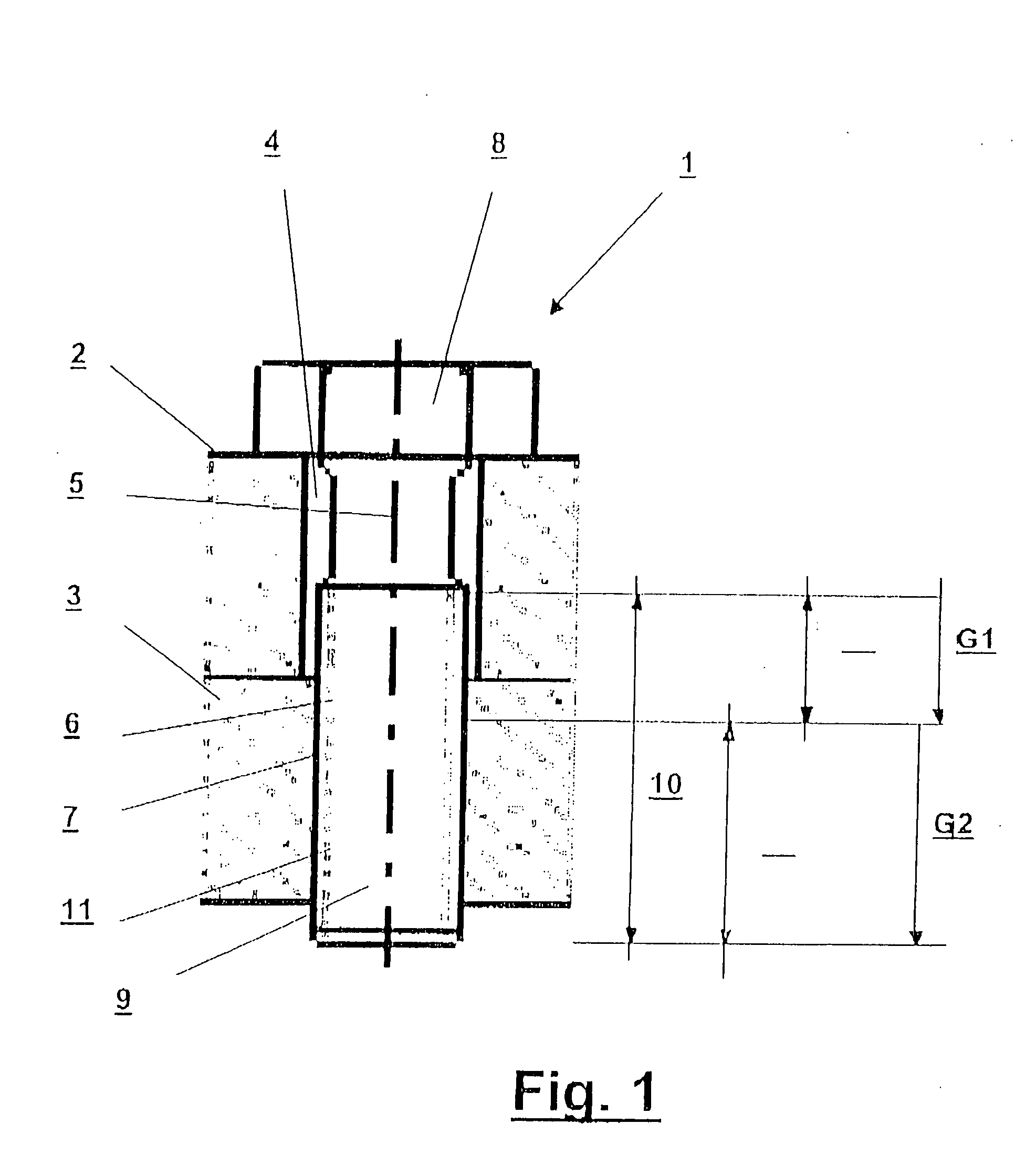

Notch tension reduction by adapted thread pitch in screw connections

Screw elements used in screw connections are embodied in such a way that the incident notch tensions are distributed as uniformly as possible over the entire length of the screw. One of the screw elements involved in the screw connection has a thread pitch (G1) which over at least a portion of the screw fastening length differs from the thread pitch (G2) in the remainder of the screw fastening length.

Owner:ROBERT BOSCH GMBH

Application of sodium aescinate in preparation of spasmolysis medicines for treating gastrointestinal smooth muscle spasm

InactiveCN106727761AGood treatment effectLittle side effectsDigestive systemPlant ingredientsDiseaseSide effect

The invention discloses novel pharmaceutical application of sodium aescinate and in particular discloses application of sodium aescinate in preparation of spasmolysis medicines for treating gastrointestinal smooth muscle spasm. The sodium aescinate has an obvious tension reduction effect on gastric tissue spasm caused by acetyl choline and can be used for treatment of diseases caused by gastrointestinal smooth muscle spasm such as acute gastroenteritis, colonitis, peptic ulcer, acute intestinal obstruction and the like. The clinical tests prove that the sodium aescinate has an obvious effect of treating gastric and intestinal colic caused by smooth muscle spasm, the total effective rate reaches 96.7%, and compared with atropine, the sodium aescinate does not have any obvious curative effect difference while is small in side effects.

Owner:WUHAN AIMIN PHARMA

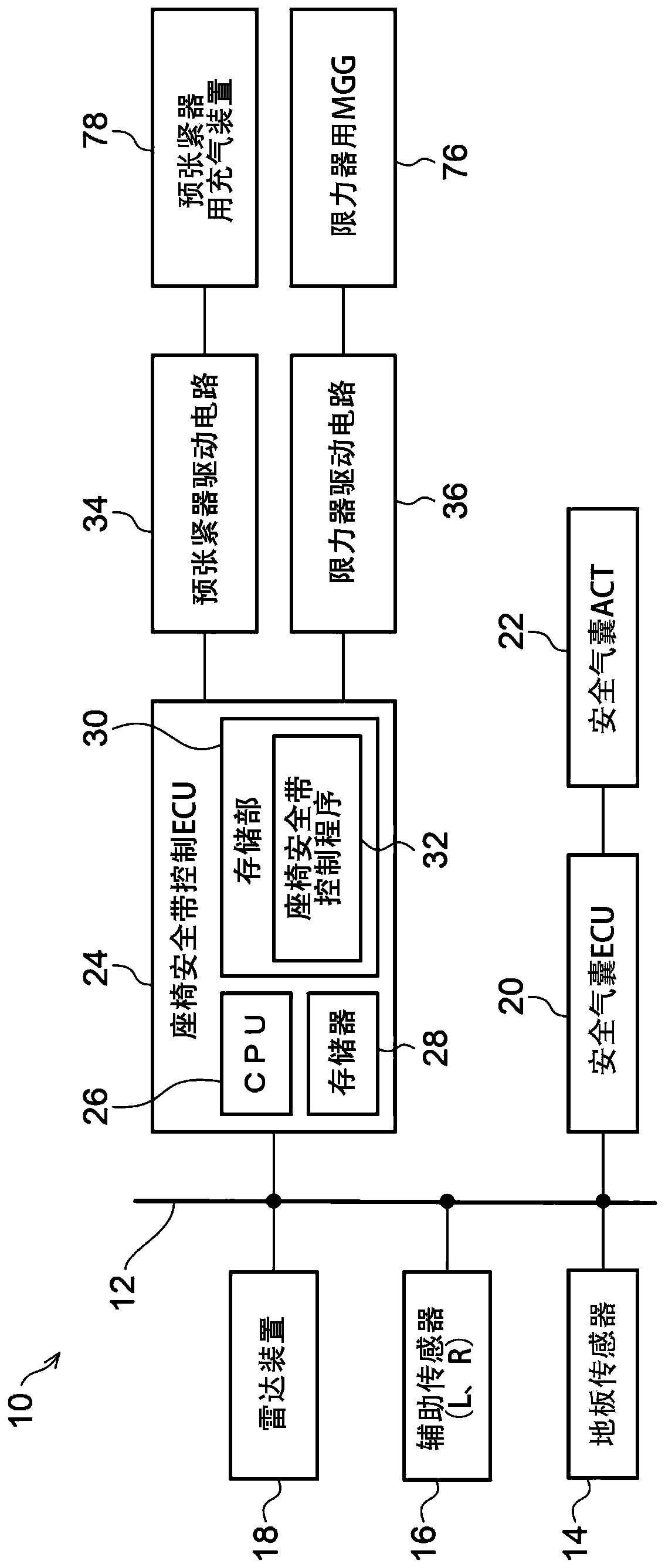

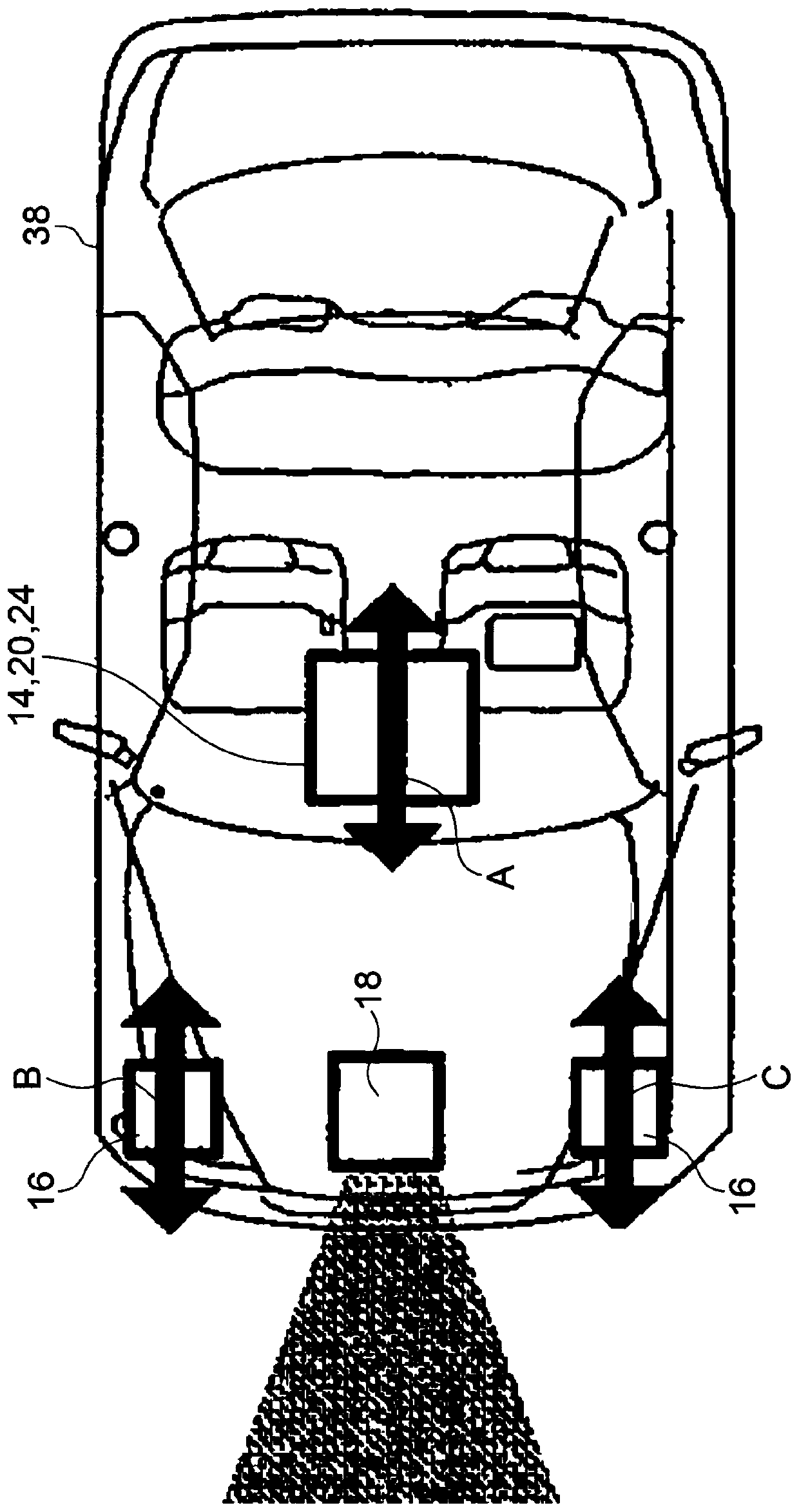

Seatbelt control device

A seatbelt control device is provided. A seatbelt retractor device includes a pre-tensioner section retracting a seatbelt to increase tension; and a force limiter section that can change a magnitude of a load at which to start reducing tension of the seatbelt retracted by the pre-tensioner section. A seatbelt control ECU activates the pre-tensioner section when a deceleration G detected by a floorsensor exceeds a first threshold, acquires a collision velocity from a radar device and sets a second threshold value to a lower value the greater the collision velocity. The seatbelt control ECU controls the starting load for tension reduction by the force limiter section to be a high load when the deceleration G has exceeded the second threshold within a determination time period after activation of the pre-tensioner section, and controls the starting load for tension reduction to be a low load when the deceleration G has not exceeded the second threshold within the determination time period.

Owner:TOYOTA JIDOSHA KK

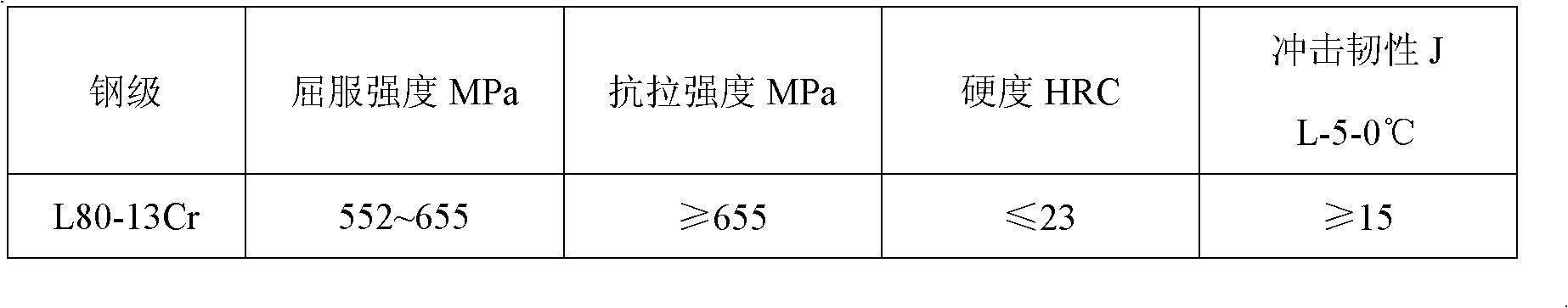

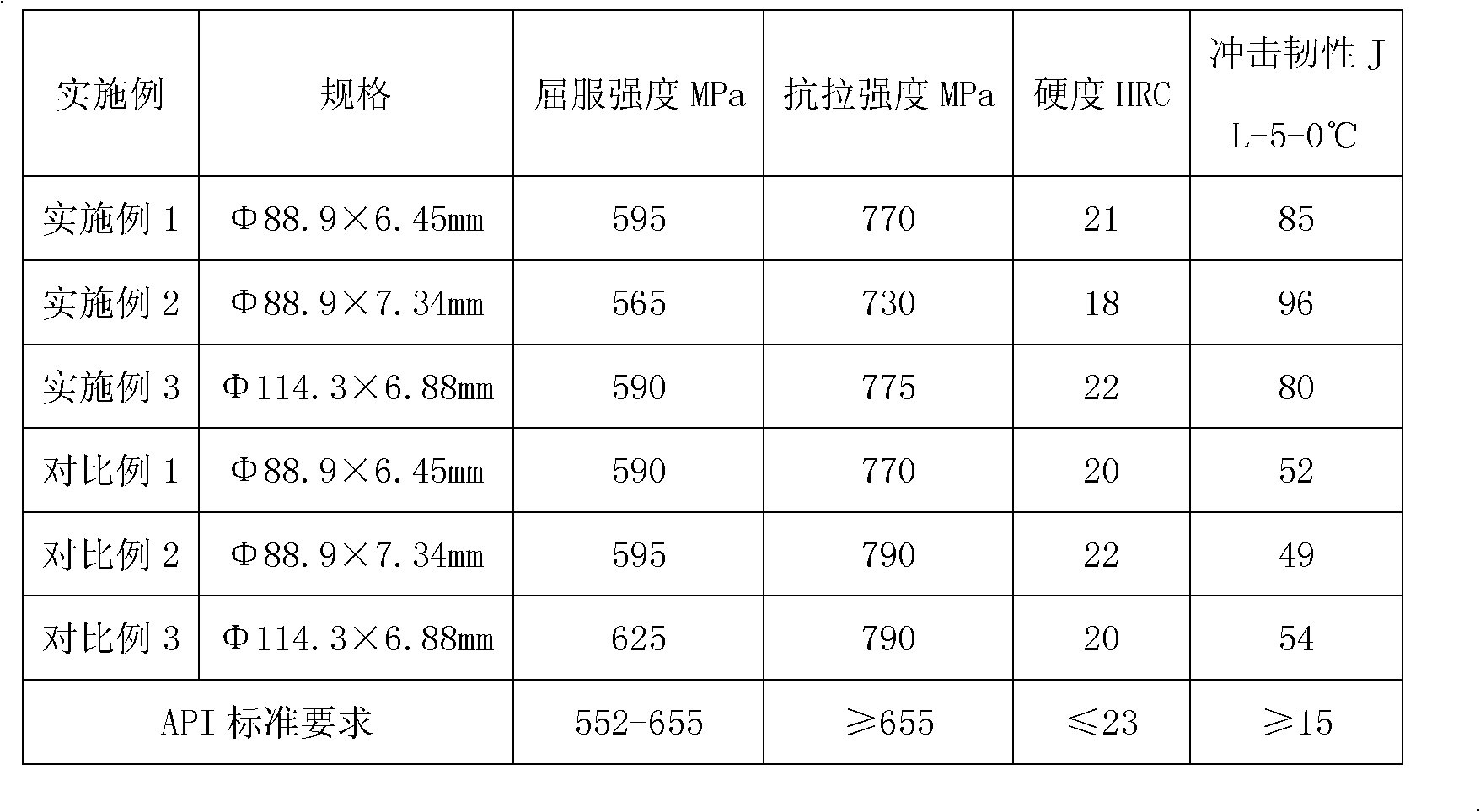

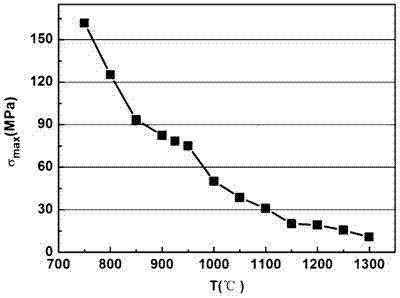

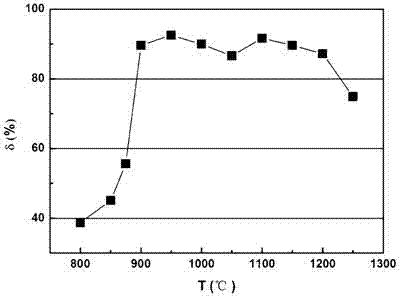

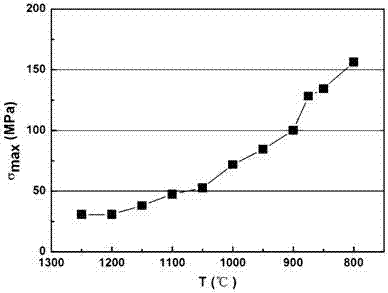

Manufacturing method of L80-13Cr oil pipes

The invention discloses a manufacturing method of L80-13Cr oil pipes. The manufacturing method comprises the steps of pipe blank heating, steel pipe penetration, tandem rolling of steel pipes, reheating of the steel pipes, tension reduction of the steel pipes, air hardening, tempering heat treatment, straightening of the pipes, cutting of heads and tails of the pipes and segmenting of the pipes. In the step of reheating the steel pipes, the heating temperature of the steel pipes is 960-1000 DEG C; in the step of tension reduction of the steel pipes, the temperature of the steel pipes after tension reduction is higher than 850 DEG C; and in the step of tempering heat treatment, the tempering temperature is 760-800 DEG C. Due to the adoption of the manufacturing method of the L80-13Cr oil pipes, the production cost of the products is obviously reduced while the productivity is substantially increased; and the mechanical property of the L80-13Cr oil pipes manufactured by the method can meet the API SPEC 5CT standard; and the impact toughness of the L80-13Cr oil pipes can be equal to and even substantially higher than that of the pipes subjected to common oil quenching or air quenching and tempering treatment.

Owner:BAOSHAN IRON & STEEL CO LTD

Controlled rolling method in hot rolling process of seamless pipe

ActiveCN105921524BEasy to shapeImprove performanceRoll mill control devicesMetal rolling arrangementsLower limitProduction line

The invention provides a controlled rolling method in a seamless pipe hot rolling process. According to the method, the following data are used for design: a perfect recrystallization temperature lower limit, a non-recrystallization temperature upper limit, temperatures of an inlet and an outlet of a perforator for rolling seameless pipe of the target specification by the conventional process on a production line planned to use, an inlet and an outlet of a pipe rolling machine and an inlet and an outlet of a tension reduction / sizing machine as well as rolling hole patterns for perforation, pipe rolling and tension reduction / sizing. A controlled rolling process is designed according to acquired data. The controlled rolling method comprises the following steps: performing rolling deformation adjustment and rolling temperature design by taking the two steps of perforation and pipe rolling as rough rolling and the step of tension reduction / sizing as fine rolling, and controlling the finish rolling temperature of rough rolling and open rolling temperature of fine rolling by a certain method to finally realize the controlled rolling process. The controlled rolling method has the beneficial effects that the microscopic tissue of the hot-rolled seamless pipe is improved, and the comprehensive mechanical property, particularly the impact strength, of a finished product pipe subjected to thermal treatment is improved. The properties of both 23Mn2SiCrV high-strength steel and ultralow-temperature 9Ni steel can be obviously improved by the use of the controlled rolling process.

Owner:TIANJIN PIPE GROUP CORP

Auxiliary glass decoration structure

InactiveCN108100359AAdapt to Feed DemandControl speedWrapping material feeding apparatusEngineeringPlastic film

The invention discloses an auxiliary glass decoration structure. The auxiliary glass decoration structure comprises a tension rod and a speed adjustment mechanism. The tension rod and the speed adjustment mechanism are arranged on an external packaging machine. The speed adjustment mechanism comprises a supporting rod, a rotary disk, a connecting rod and a pressing mechanism. One end of the supporting rod is hinged to the pressing mechanism through the connecting rod. The other end of the supporting rod is in threaded connection with the rotary disk. The tension rod is a distance from a rollerof the external packaging machine so that a plastic film can maintain a certain tension. The speed adjustment mechanism can control the rotating speed of the roller of the external packaging machineto achieve the effect of speed limiting. The pressing mechanism moves downwards to limit the speed of the roller so as to protect the plastic film against tension reduction caused by too high rotatingspeed. The pressing mechanism moves upwards to weaken limitation to the speed of the roller. The auxiliary glass decoration structure can meet the requirement of rapid packaging of the packaging machine for material feeding.

Owner:ZHONGJIANG ZHICHENG TEMPERING GLASS PROD

Device for electrical contacting of the cable shield on the housing and pre-assembled cables

ActiveCN105453343BMake sure to squeezeReliable contactMagnetic/electric field screeningConnections effected by permanent deformationElectricityElectric vehicle

In order to ensure a reliable connection of the shielding layer (16) of the high-voltage cable (2) to the housing (4), especially for electric vehicles or hybrid vehicles, the shielding layer (16) of the cable (2) is squeezed Between the inner sleeve (20) and the contact sleeve (18), wherein the electrically conductive connection to the housing (4) is formed via the contact sleeve (18). For this purpose, the contact sleeve (18), which is designed as a crimp sleeve, has a flange consisting of a spring leaf (32). At the same time, the inner sleeve ( 20 ) is also pressed against the cable sheath ( 30 ) of the cable ( 2 ) in order to achieve strain relief. Furthermore, the cable (2) can preferably be fastened to the housing (4) by means of a simple snap-in connection.

Owner:LEONI BORDNETZ SYST

Heart Wall Tension Reduction Apparatus and Method

InactiveUS20100274076A1Reduce tensionReduce energy consumptionSuture equipmentsHeart valvesCardiac cycleFailing heart

Devices and methods for treatment of a failing heart by reducing the heart wall stress. The device can be one which reduces wall stress throughout the cardiac cycle or only a portion of the cardiac cycle.

Owner:EDWARDS LIFESCIENCES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com