Controlled rolling method in hot rolling process of seamless pipe

A technology for controlling the rolling and hot rolling process, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of uneven structure, difficult to meet the performance standards, difficult to form, etc., to improve the structure and improve the comprehensive performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The chemical composition of the 23Mn2SiCrV steel used in the experiment is shown in Table 1.

[0028] Table 1 Chemical composition of steel grade 23Mn2SiCrV

[0029] Component Content (wt.%) C 0.20~0.25 Si 1.20~1.40 Mn 2.00~2.20 Cr 0.50~0.70 V 0.02~0.05 P≤0.025 S≤0.015

[0030] The 23Mn2SiCrV steel grade used in the test is a high-strength steel with a B / M composite phase structure, which can be widely used in mechanical parts and engineering construction. The excellent strength and toughness of this material mainly relies on the two-phase combination of bainite and martensite, which cuts off the martensite matrix with bainite and prevents crack propagation, so as to have a stable retained austenite film and a carbon-free ultra-fine structure It is realized by replacing conventional bainite with bainite. The laboratory preparation process is billet forging at 1200℃, homogenization at 700℃ for 2h, and furnace cooling. After proper heat treatment, a composite structure...

Embodiment 2

[0054] The chemical composition of the 9Ni steel used in the experiment is shown in Table 1.

[0055] Table 6 Chemical composition of 9Ni steel

[0056] Component Content (wt.%) C≤0.13 Si 0.13~0.32 Mn≤0.90 Ni 8.40~9.60 P≤0.025 S≤0.025

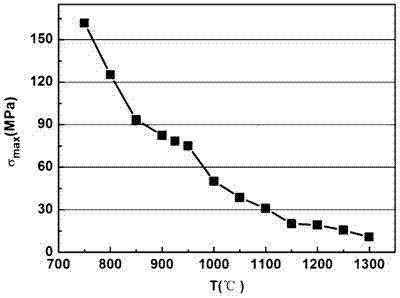

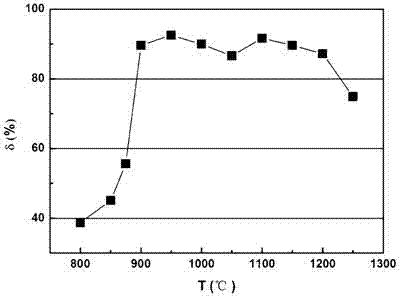

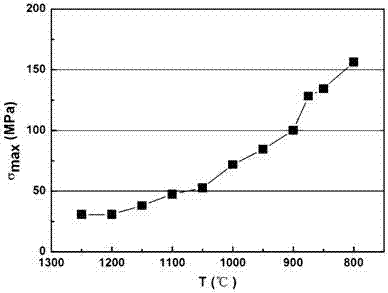

[0057] The 9Ni steel used in the test is a low-temperature steel, which is widely used in the storage and transportation of liquefied petroleum gas (LNG). The normal use temperature is -162°C. The main feature is that it still has good impact toughness at -196°C. ASTM A33 stipulates that the lateral expansion of the alloy seamless pipe -195℃ Charpy impact test is above 0.38mm as qualified. The literature shows that the rough rolling opening temperature of 9Ni steel plate is between 1150~1100℃, the rough rolling final rolling temperature is above 975℃, the finishing rolling opening temperature is 850℃, and the finishing rolling temperature is above 730℃.

[0058] The Assel unit production line used in this experiment plan produces φ152×16mm se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com