Manufacturing method of L80-13Cr oil pipes

A manufacturing method and oil pipe technology, which is applied in the field of oil pipe manufacturing, can solve problems such as the difficulty of pipe cutting and segmenting, abnormal production, and low impact toughness, and achieve the effects of reducing production costs, increasing production capacity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0028] Prepare L80-13Cr tubing by following steps:

[0029] (1) heating the tube blank;

[0030] (2) perforating the heated tube blank to make a steel pipe;

[0031] (3) Carry out continuous rolling to steel pipe;

[0032] (4) reheating the rolled steel pipe in the temperature range of 960-1000°C;

[0033] (5) Perform a stretching and reducing process on the steel pipe, and control the temperature of the steel pipe after stretching and reducing to greater than 850°C;

[0034] (6) Carry out cooling bed quenching to steel pipe;

[0035] (7) Perform tempering heat treatment on the steel pipe in a bright annealing furnace with nitrogen protection, and the tempering temperature is 760-800°C;

[0036] (8) Straighten the steel pipe, cut the head and tail, and process it in sections.

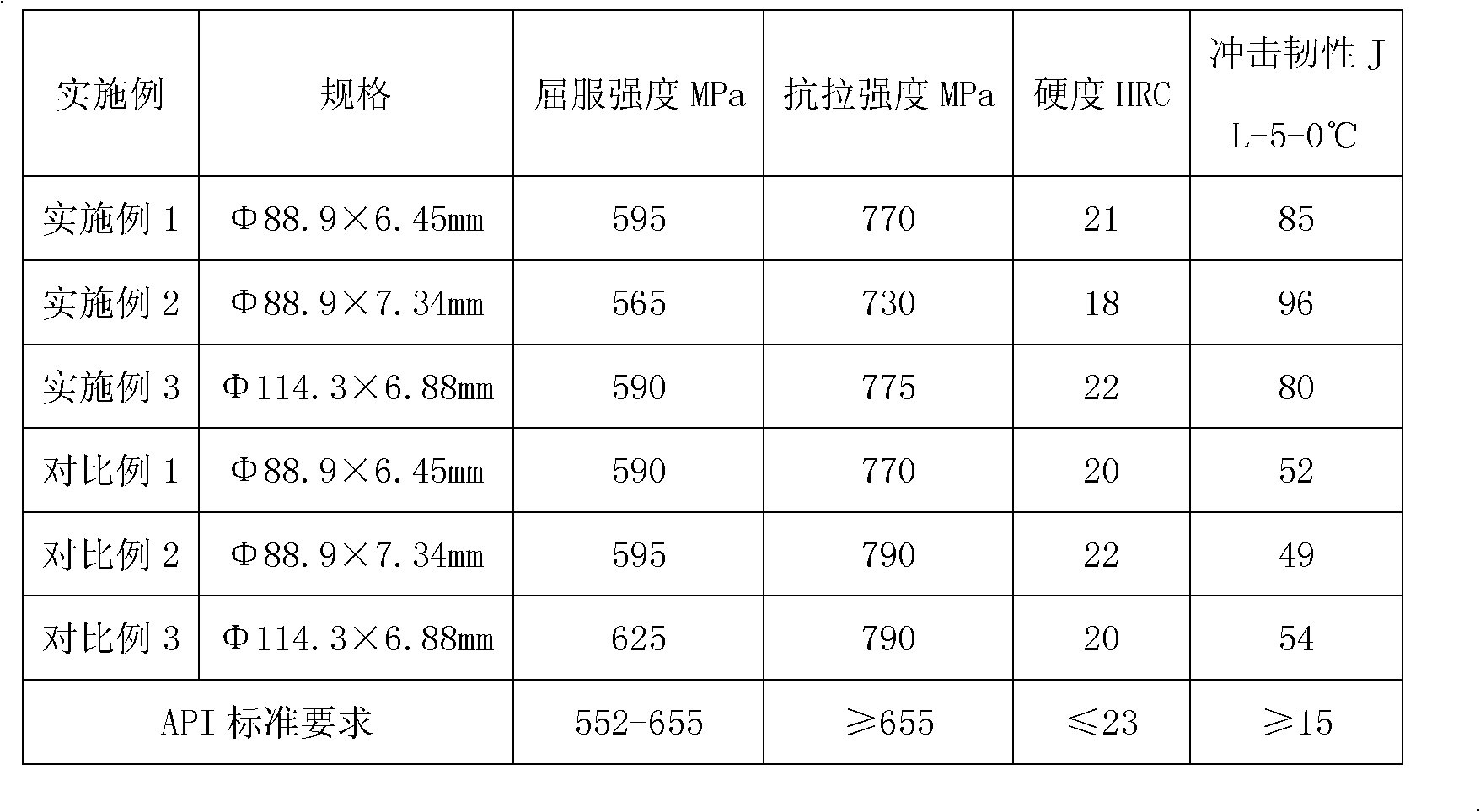

[0037] Table 3 has shown the concrete process parameter of the embodiment 1-3 of this technical solution.

[0038] table 3.

[0039] Example

Specification

Reheating temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com