Auxiliary glass decoration structure

A decoration and glass technology, applied in the field of glass auxiliary decoration structure, can solve the problems of glass damage, unable to maintain tension, easy loosening of plastic film, etc., and achieve the effect of strong hardness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

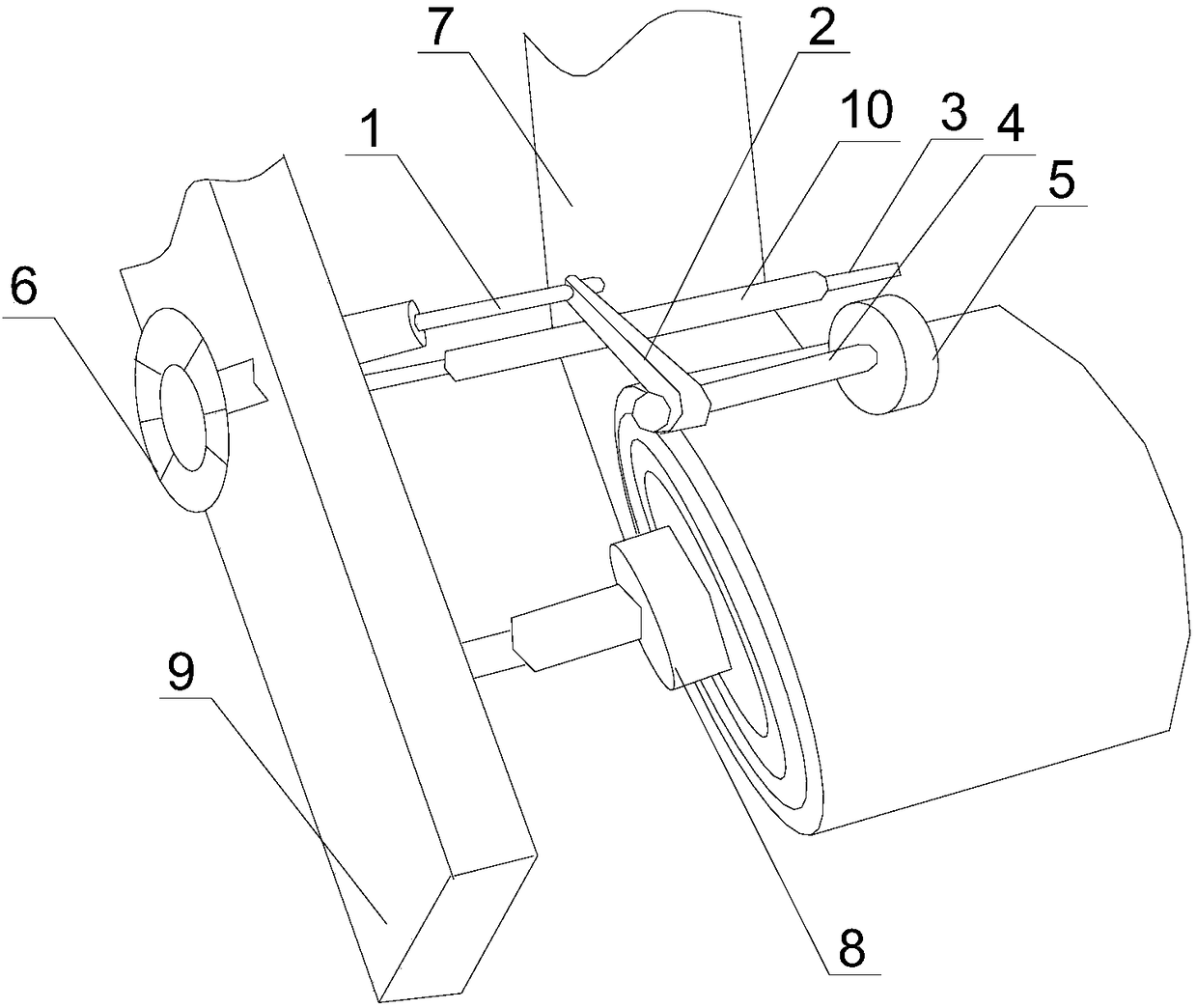

[0018] Such as figure 1 As shown, the present embodiment includes a tension rod 3 and a speed adjustment mechanism. The two ends of the tension rod 3 and the speed adjustment mechanism are respectively arranged on the external packaging machine 9. The speed adjustment mechanism includes a support rod 1, a rotating disk 6, a connecting rod 2 and the pressing mechanism, one end of the supporting rod 1 is hinged with the pressing mechanism through the connecting rod 2, and the other end of the supporting rod 1 is threadedly connected with the rotating disk 6. The tension bar 3 is separated from the roller 8 of the external packaging machine 9 by a certain distance, so that the plastic film 7 maintains a certain tension. At the same time, it is also necessary to ensure that the plastic film 7 will not be damaged. The rubber ring 10 on the tension rod 3 can be in soft contact with the plastic film 7, so as to avoid damage to the plastic film 7 when the tension rod 3 is transmitted;...

Embodiment 2

[0020] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the pressing mechanism includes a pulley 5 and a wheel shaft 4 connected to each other, and the wheel shaft 4 is connected to the support rod 1 through a connecting rod 2 . The set pulley 5 can move together with the roller 8 of the external packaging machine 9, and the interaction force between the pulley 5 and the roller 8 can be adjusted by adjusting the turntable 6. The greater the frictional force, the greater the restriction on the speed at which the cylinder 8 rotates, and vice versa. Described pulley 5 is a plastic pulley. The texture of the pulley 5 made of plastic is relatively soft, and when the relative force between the pulley 5 and the drum 8 is relatively large, the pulley 5 will not cause damage to the plastic film 7 , marks and other disturbances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com