Device for electrical contacting of the cable shield on the housing and pre-assembled cables

A shielding and pre-installation technology, applied in the field of pre-installed cables, can solve problems such as consumption, and achieve the effect of simple design structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

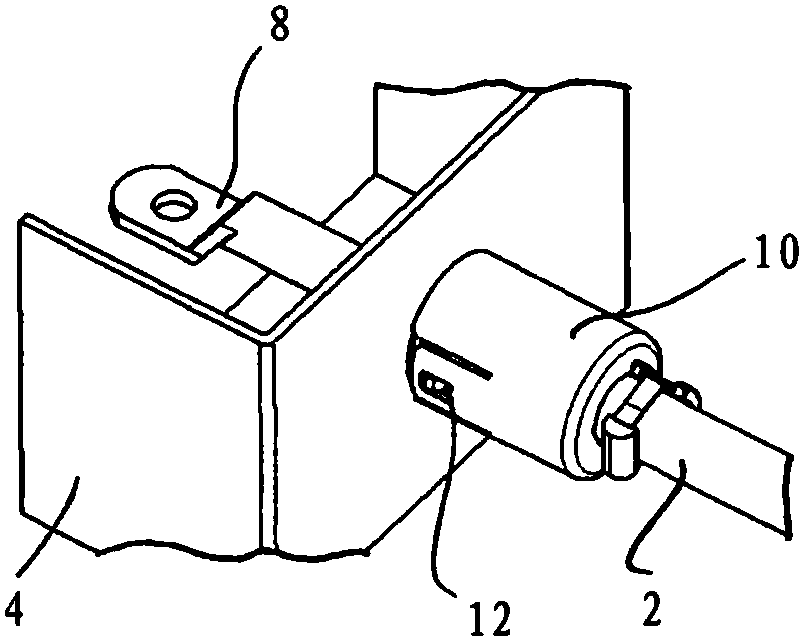

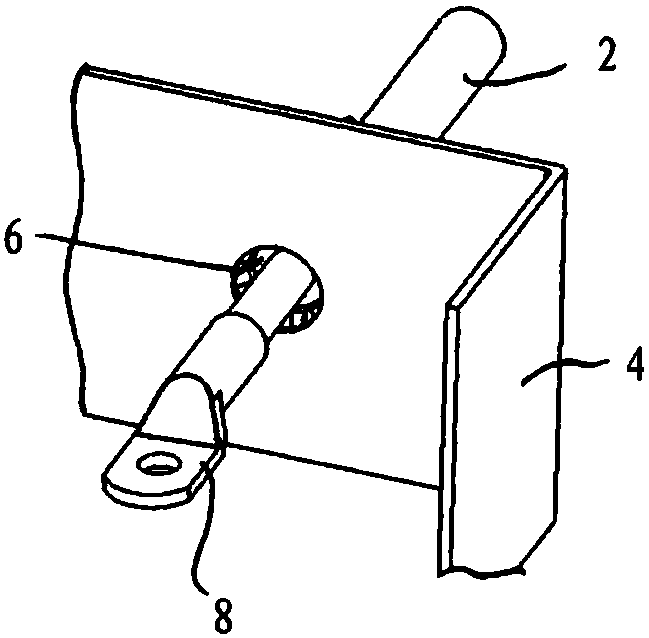

[0049] according to Figure 1A with 1B , the high-voltage cable 2 is connected to a preferably metallic housing 4 and guided through a cable entry 6 of the housing 4 into the interior. Usually the cable 2 is terminated in the inner space by a contact element 8, for example a contact shoe, such as Figure 1A , Figure 1B shown. The cable 2 is connected to the terminal via the contact element 8 , for example by means of a screw connection. The metal housing is, for example, a metal casting housing, in particular a die-cast aluminum housing.

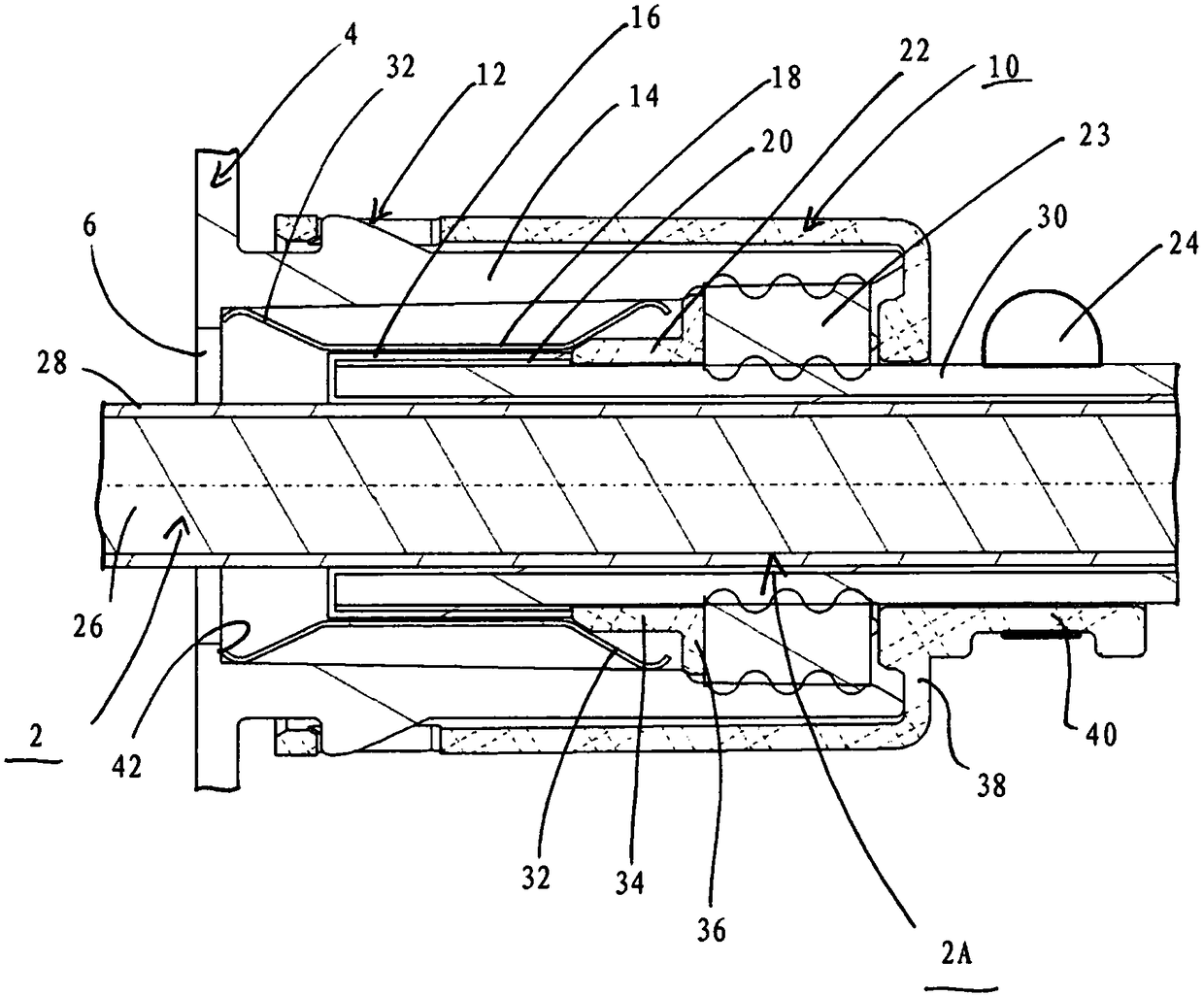

[0050] especially by figure 2 and combine Figure 1A It can be seen that for the mechanical fastening of the cable 2 to the housing 4 , an eg pot-shaped closure cover 10 is arranged on the cable 2 , which is reversibly fastened to the housing 4 via a snap connection 12 . For this purpose, the cable entry 6 comprises a cable bushing 14 which extends in the cable longitudinal direction in a telescopic manner towards the outside. On its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com