Band steel return control apparatus after shutdown of continuous annealing furnace

A control device, continuous furnace withdrawal technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., to achieve the effect of preventing belt breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

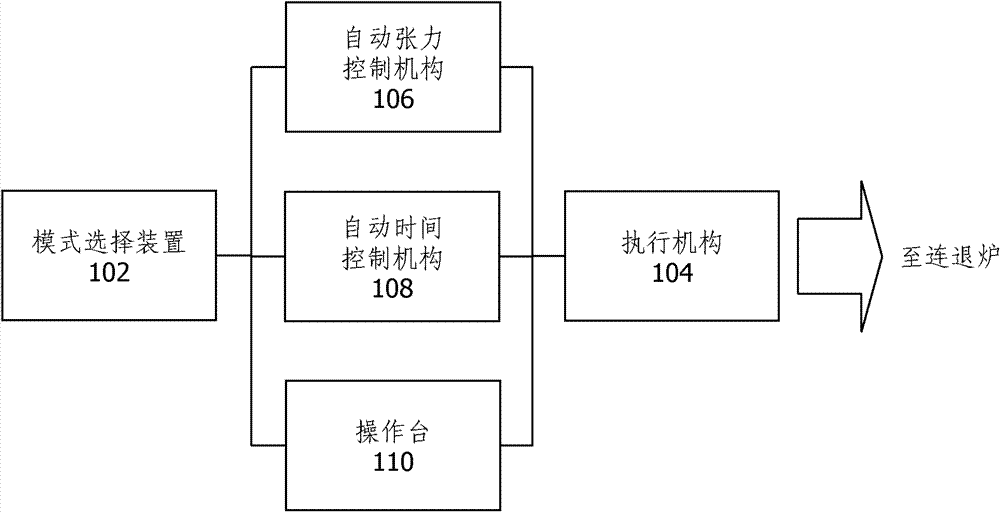

[0020] refer to figure 1 As shown, the present invention discloses a strip return control device after the continuous annealing furnace is shut down, including: a mode selection device 102 , an actuator 104 , an automatic tension control mechanism 106 , an automatic time control mechanism 108 and an operation console 110 .

[0021] The mode selection device 102 receives the mode selection instruction, and selects one of the automatic tension mode, the automatic time mode and the manual mode.

[0022] The actuator 104 is connected to the equipment of the continuous annealing furnace, and the actuator 104 instructs the equipment of the continuous annealing furnace to perform a strip return operation or a tension reduction operation.

[0023] The automatic tension control mechanism 106 is connected to the mode selection device 102 and the actuator 104. When the mode selection device 102 selects the automatic tension mode, the automatic tension control mechanism 106 controls the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com