Control method for restart of strip steel processing line furnace area after shutdown

A technology for processing lines and steel strips, applied in heat treatment process control, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as strip pleats, broken strips, and major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

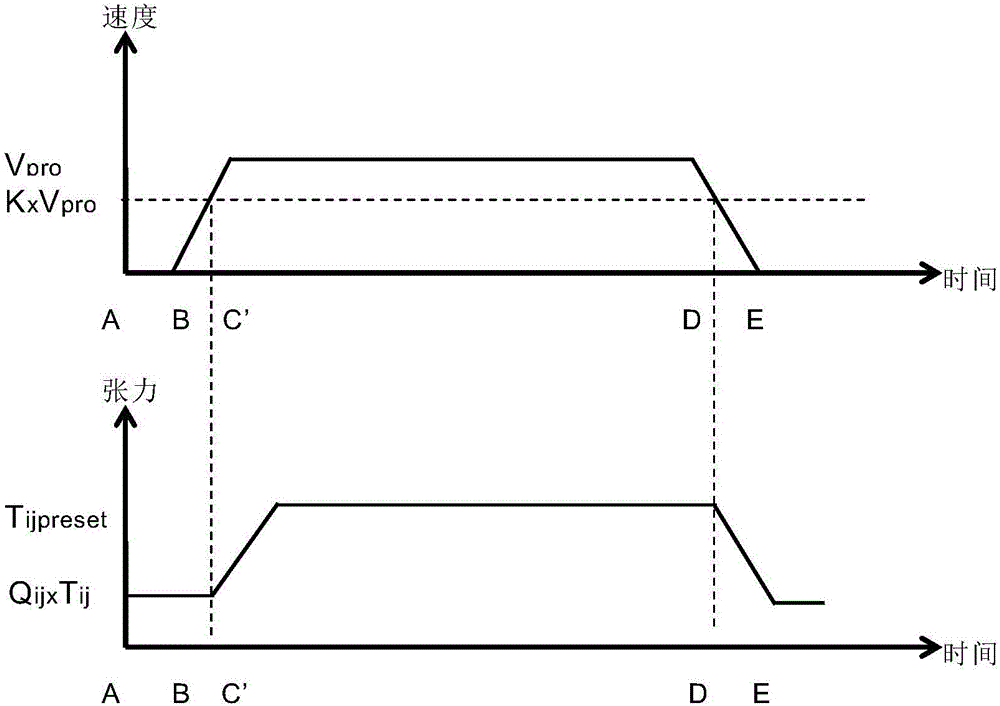

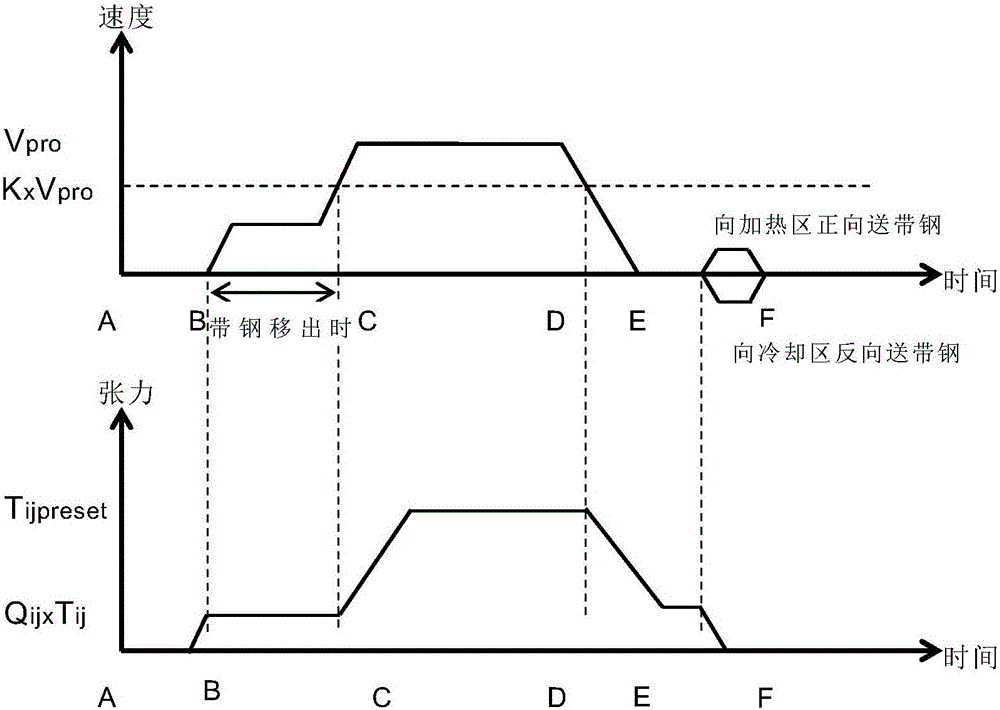

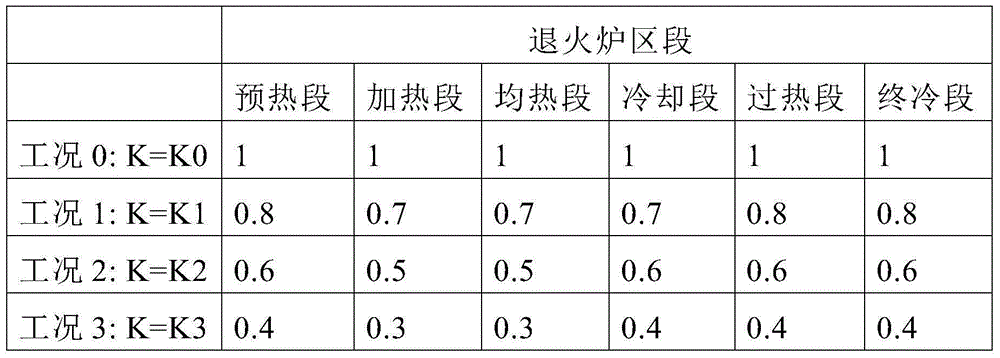

[0023] Embodiment: a control method for restarting after shutdown of the furnace area of a strip processing line, characterized in that: the annealing furnace is composed of a preheating section, a heating section, a soaking section, a cooling section, an overheating section, and a final cooling section. For different working conditions, the normal production process setting value is multiplied by a certain tension reduction coefficient,

[0024] The tension reduction coefficient depends on the working condition K of the strip and the section of the annealing furnace: Tij=Qij*Tijpreset,

[0025] Wherein: i=state (K0, K1, K2 or K3);

[0026] j=section (inlet preheating section, heating section, soaking section, cooling section, superheating section, final cooling section);

[0027] Tij = reduced tension setting value;

[0028] Qij = tension reduction coefficient;

[0029] Tijpreset = tension setting value during normal production stipulated by the process,

[0030] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com