Method for detecting cohesiveness index of iron ore powder

A detection method and cohesiveness technology, which is applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problem of lack of effective detection and evaluation methods for mineral powder cohesiveness, affecting the air permeability of sintered material layer, and the uncertainty of mineral powder granulation Performance and other issues, to achieve the effect of improving the quality of sinter, increasing production capacity, and ensuring air permeability

Inactive Publication Date: 2019-01-29

SHOUGANG CORPORATION

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention provides a detection method for iron ore powder cohesion index, which is used to solve the lack of effective detection and evaluation methods for ore powder cohesion in the prior art, and the granulation performance of the ore powder cannot be determined, which affects sintering Technical problems of air permeability of material layer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

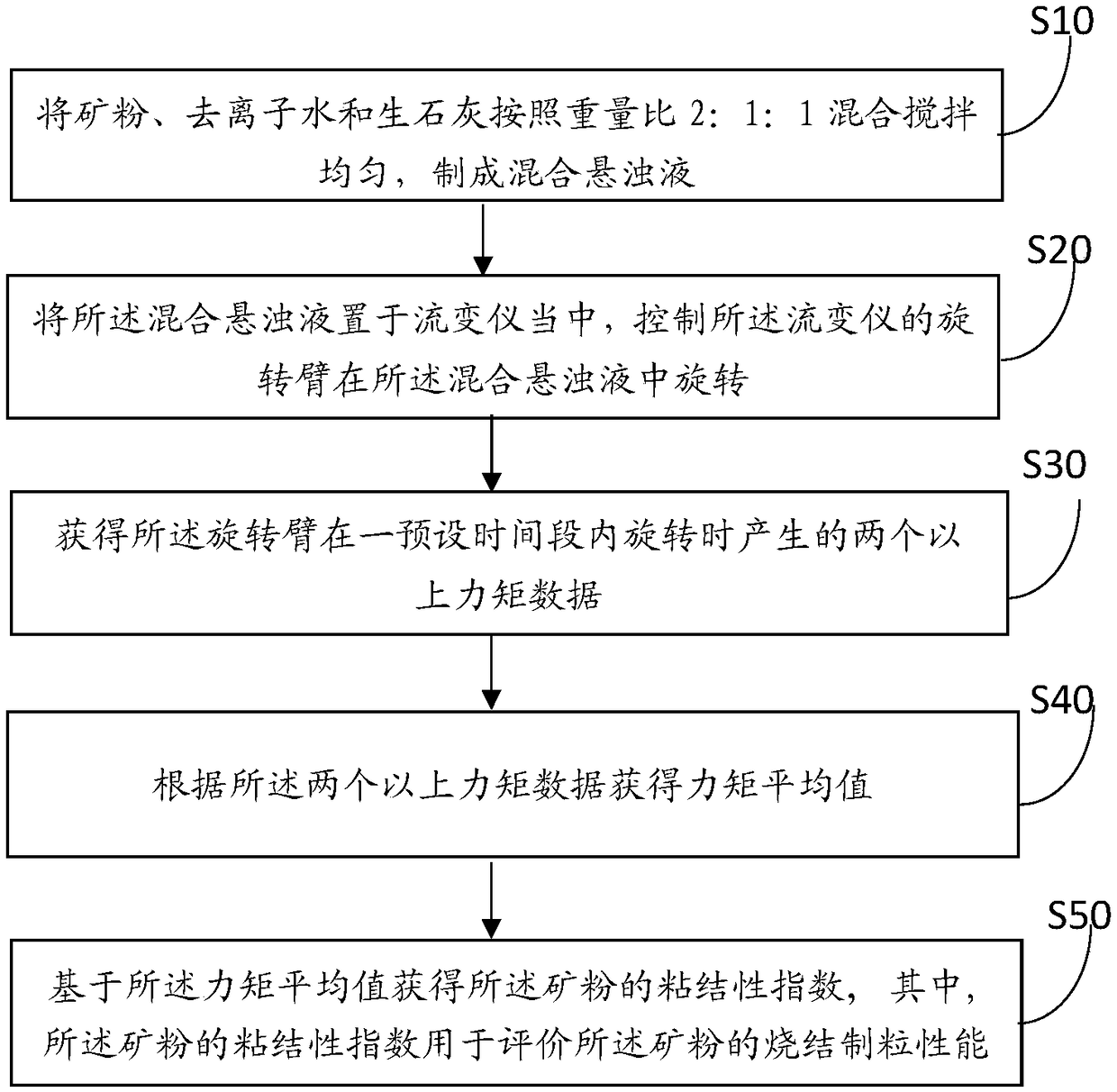

[0028] figure 1 It is a schematic flow chart of a method for detecting the cohesiveness index of iron ore powder in the embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0029] Step 10: Mix and stir the mineral powder, deionized water and quicklime according to the weight ratio of 2:1:1 to make a mixed suspension.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for detecting the cohesiveness index of iron ore powder. The method comprises the following steps: the ore powder, deionized water and lime are evenly mixed and stirred according to the weight ratio of 2 to 1 to 1 to be made into a mixed suspension; the mixed suspension is placed into a rheometer, and a rotating arm of the rheometer is controlled to rotate in the mixed suspension; two or more torque data generated by the rotating arm during rotation within a preset time period are obtained; a torque mean value is obtained according to the two or more torque data; and the cohesiveness index of the ore powder is obtained based on the torque mean value. The technical problems that effective detection and evaluation methods for the cohesiveness of the ore powder are lacked, the granulation performance of the ore powder cannot be determined, and the permeability of a sinter material layer is affected are solved. The technical effects that the sintering granulation performance of the ore powder is obtained through the cohesiveness index, the permeability of the sinter material layer is guaranteed through the reasonable parameter ratio, and the sinter orequality is improved are achieved.

Description

technical field [0001] The invention relates to the technical field of sintering, in particular to a method for detecting the cohesiveness index of iron ore powder. Background technique [0002] The granulation process is one of the important links in the sintering process. The quality of the granulation effect directly affects the air permeability of the sintered material layer. Air permeability is particularly important for increasing the production capacity of sintering machine and improving the quality of sintering ore. There are many factors affecting the granulation effect, which are not only related to the granulation parameters such as the size of the mixer, the inclination angle of the mixer, the rotational speed, and the ratio of lime and moisture, but also closely related to the granulation performance of the iron ore powder itself. The granulation performance of mineral powder can be evaluated by the cohesiveness of mineral powder. [0003] However, in the proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N11/14

CPCG01N11/14

Inventor 潘文马怀营赵霞赵志星史凤奎张晓臣石江山梁洁赵俊花赵勇陈绍国张志东程峥明欧书海高新洲

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com