Sintered ring cold machine air leakage rate on-line diagnostic method

A technology of a sintering ring cooler and a diagnostic method, which is applied to lighting and heating equipment, furnace types, instruments, etc., can solve the problem that the cooling process affects the rate of sintered ore powder, the life of power consumption equipment, and the distribution of air volume. The cooling effect of sintered ore cannot be known, The powder ratio affects the output and cost of sintered ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

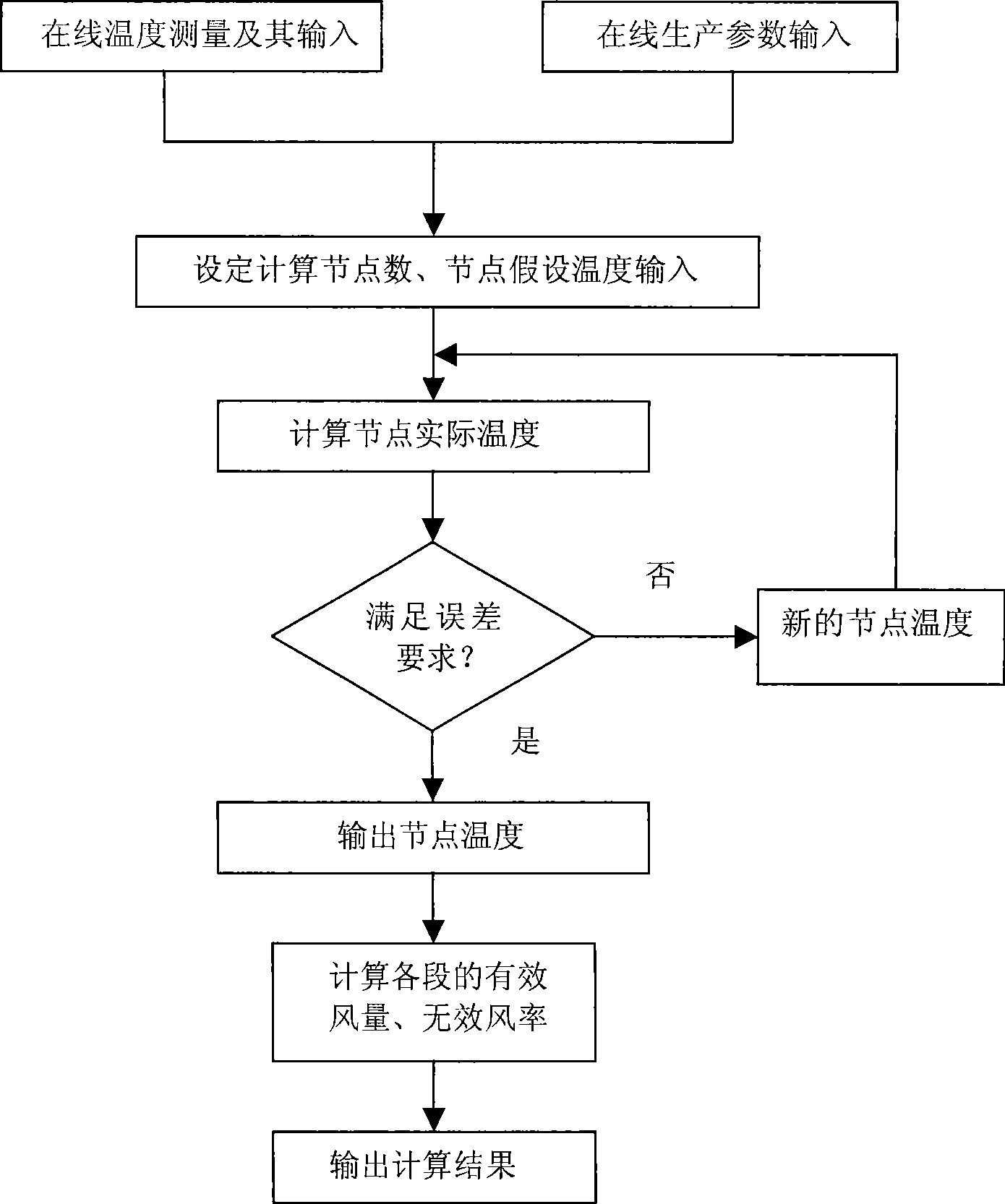

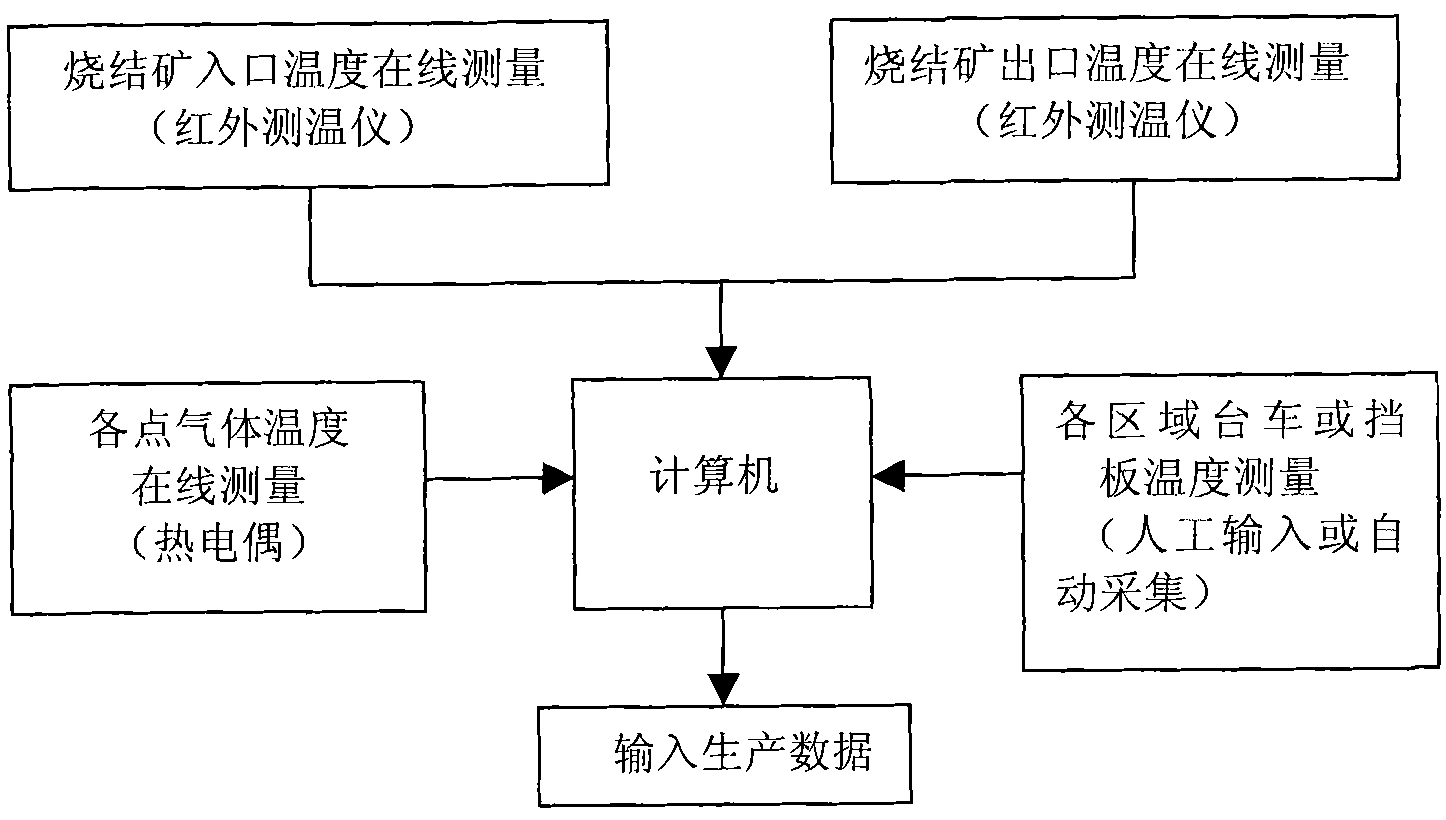

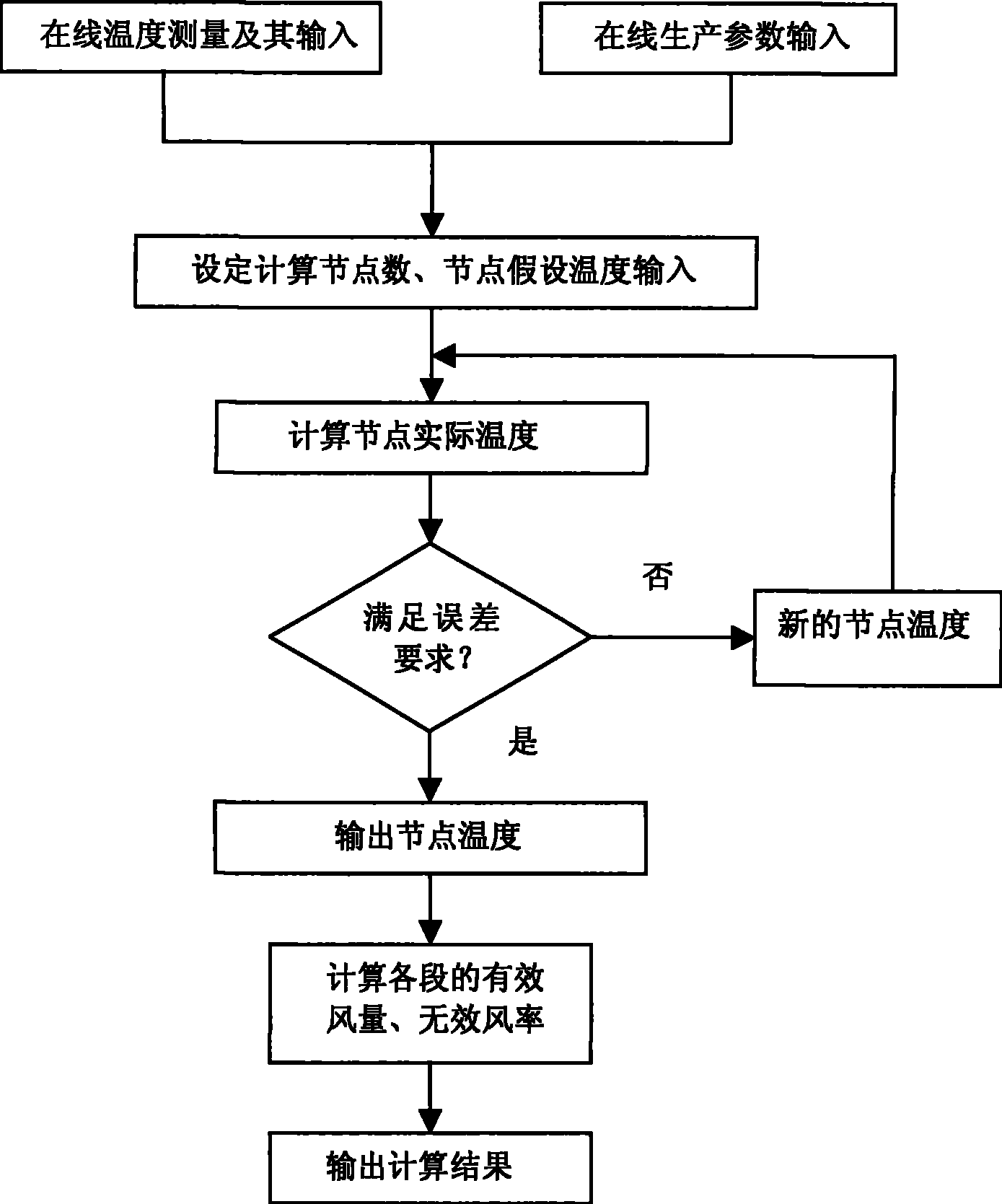

Method used

Image

Examples

Embodiment

[0047] The hot air volume test of the ring cooler is difficult to measure in an environment with high temperature and high dust content; and the hot air in the open section is directly in contact with the atmosphere, there are many influencing factors in the test process, and the accuracy of the test results is low. Therefore, the entire annular cooler system is divided into six sections as subsystems to calculate separately, to try to calculate the ore temperature of each section, and to verify it by the heat loss of the entire system.

[0048] The sinter temperature of each node obtained through trial calculation is shown in Table 1.

[0049] Table 1 Sinter temperature of each node

[0050] Location

Entrance

1 o'clock

2:00

3 points

4 o'clock

5 o'clock

6 o'clock

Export

temperature, ℃

731.25

565.45

385.35

246.46

161.6

115.32

86.45

87.64

[0051] Trial calculation temperature error of export sinter:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com