Energy-saving and emission-reducing sintering machine flue gas circulation method and system

A technology of circulation system and flue gas circulation, which is applied in the maintenance of heating chamber, waste heat treatment, furnace control device, etc., and can solve problems such as overhumidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

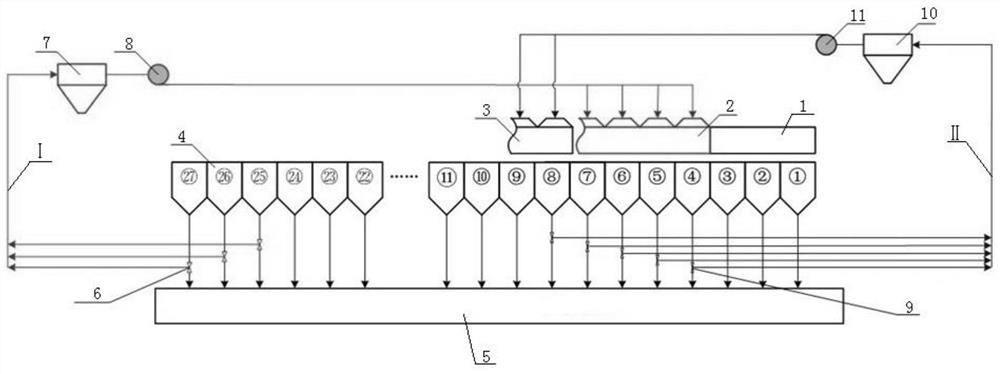

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

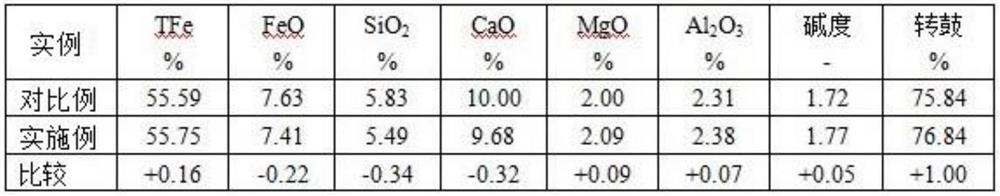

[0026] A sintering machine flue gas circulation method for energy saving and emission reduction. The sintering machine flue gas circulation system is divided into a hot section flue gas circulation system I and a cold section flue gas circulation system II; the hot section flue gas circulation system I is used to recycle the sintering machine The high-temperature and high-oxygen flue gas at the tail is drawn out, and after dust removal, it is sent to the hot section flue gas hood 2 of the machine head, so that the flue gas enters the material layer of the sintering machine, reduces the consumption of solid fuel through heat input, and improves the quality of the surface sinter; The cold-section flue gas circulation system II is used to discharge the low-temperature and low-oxygen flue gas from the head of the sintering machine, and send it to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com