A kind of fuel for sintering batching and adding method thereof

A technology of fuel and mixture, applied in the field of sintering, can solve the problems that have not been achieved, and have not mentioned the technology of adding semi-coke and CDQ powder, so as to achieve the effect of improving quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Applied to 120m 2 Sintering machine, the fuel for sintering batching is single semi-coke, the carbon content of semi-coke is 60wt%, the ash content is 25wt%; the semi-coke is used as fuel, put into the fuel bin of batching workshop, and put into the belt through the disc feeder Above, it is mixed with other kinds of ores and flux through the primary and secondary mixers, and arranged on the sintering trolley through the distributor to carry out the sintering production of the mixed ore. %, silicon dioxide is 5.6wt%, moisture is 8.5wt%, material layer height is 0.65m, RL=-4.0+0.55×23+0.112×0.5+0.056×(-0.1)+0.085×(-0.1)+0.65× (-5.0)=5.4419kg, that is, the fuel addition in every hundred kilograms of mixture is 5.44kg, and the results of use are shown in Table 1.

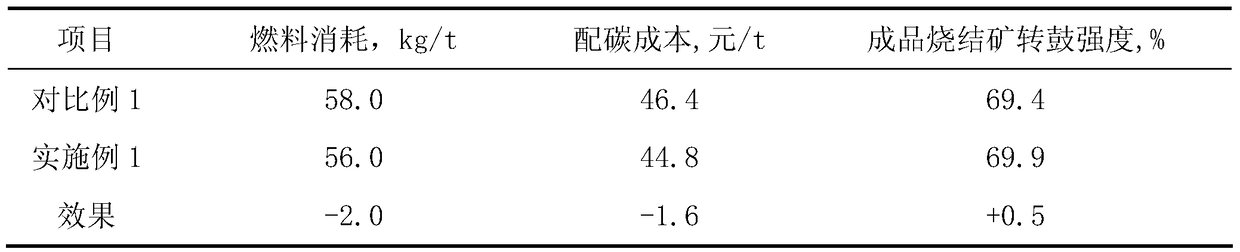

[0025] Table 1 120m 2 The effect of sintering machine

[0026]

[0027] Compared with the traditional comparative example 1 fuel blending technology, Example 1 flexibly adjusts the amount of fuel blended by...

Embodiment 2

[0029] Applied to 265m 2 Sintering machine, the fuel for sintering batching is single CDQ powder, the carbon content in CDQ powder is 75wt%, the ash content is 20wt%; CDQ powder is used as fuel, put into the fuel bin of batching workshop, and put into the belt through the disc feeder Above, it is mixed with other kinds of ores and flux through the primary and secondary mixers, and arranged on the sintering trolley through the distributor, and the sintering production of the mixed ore is carried out. The TFe content of the mixture is 56wt%, and the calcium oxide is 10.8wt %, silicon dioxide is 5.3wt%, moisture is 8.0wt%, material layer height is 0.68m, RL=-4.7+0.56×25+0.108×0.55+0.053×(-0.05)+0.08×(-0.05)+0.68× (-6.0)=5.27275kg, the fuel addition in every hundred kilograms of mixture is 5.27kg, and the use effect is shown in Table 2.

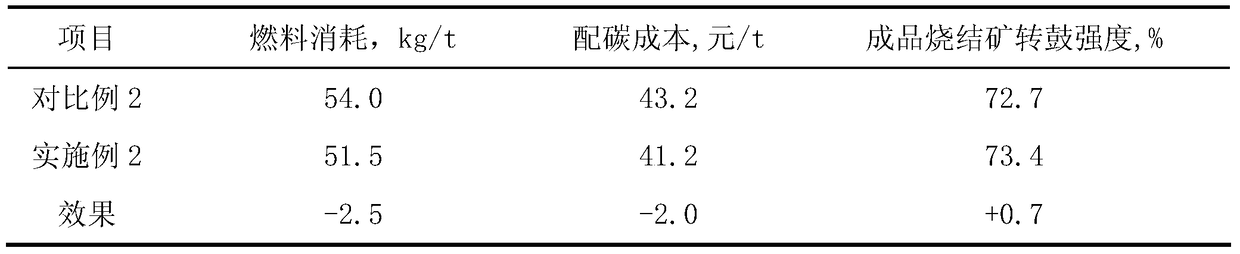

[0030] Table 2 265m 2 The effect of sintering machine

[0031]

[0032] Example 2 can reduce the fuel consumption per ton of mixed ore by ...

Embodiment 3

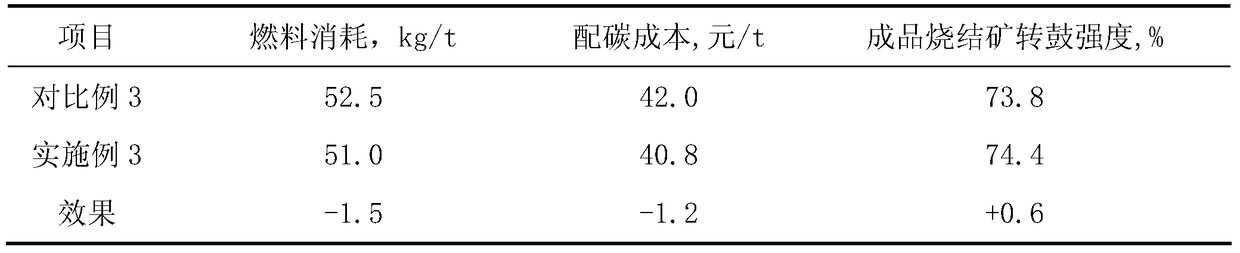

[0034] Applied to 328m 2Sintering machine, the fuel for sintering ingredients is a mixture of semi-coke and CDQ powder, wherein the proportion of semi-coke is 40wt%, the proportion of CDQ powder is 60wt%, the carbon content of semi-coke is 70%, and the ash content is 20%. The carbon content in the CDQ powder is 80wt%, and the ash content is 15wt%. Mix the two as fuel, put them into the fuel bin of the batching workshop, put them on the belt through the disc feeder, and pass through a process with other kinds of ores and flux once. , the secondary mixer is mixed, and arranged on the sintering trolley through the distributor, and the sintering production of the mixed ore is carried out, wherein the content of the mixed material TFe is 57wt%, calcium oxide is 10.5wt%, and silicon dioxide is 5.2wt%. Moisture content is 8.3wt%, material layer height is 0.72m, RL=-5.40+0.57×26+0.105×0.60+0.052×0.0+0.083×0.0+0.72×(-6.0), the fuel addition in every hundred kilograms of mixture is 5.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com