Plastic sheet embedded particle composite electrode and preparation method thereof

A composite electrode and particle technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy separation of composite particles and the inability to fill the reactor space evenly, and achieve the benefit of Fully contact mass transfer, improve mass transfer and wastewater treatment effect, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

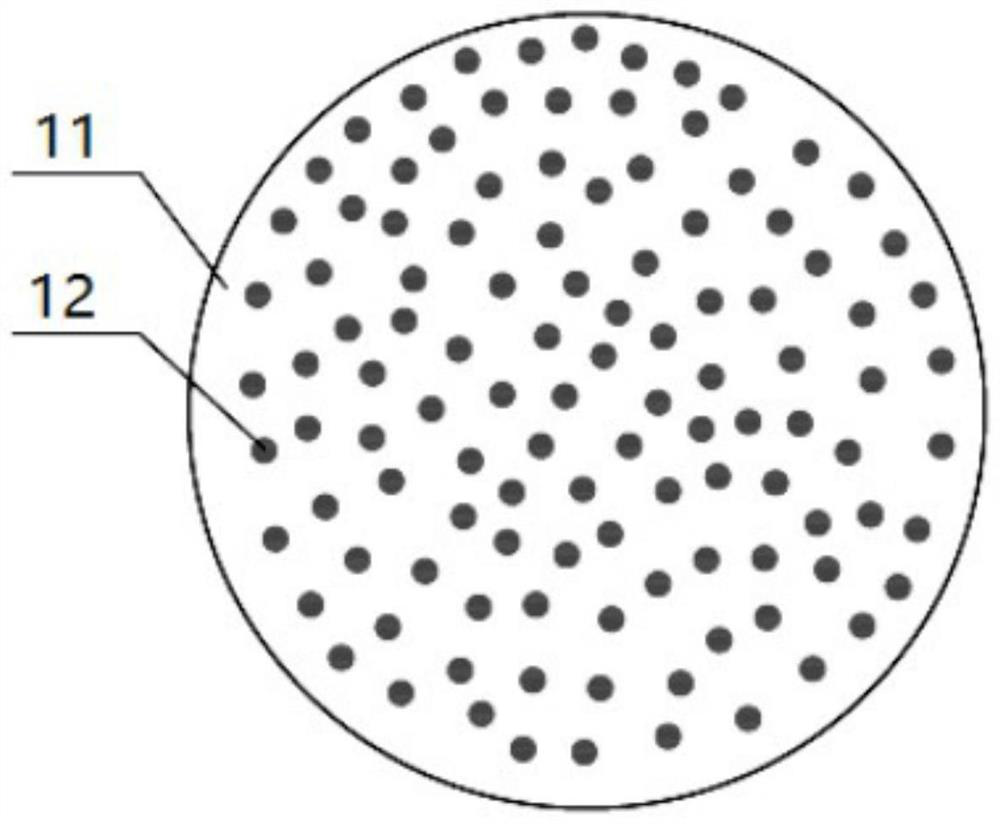

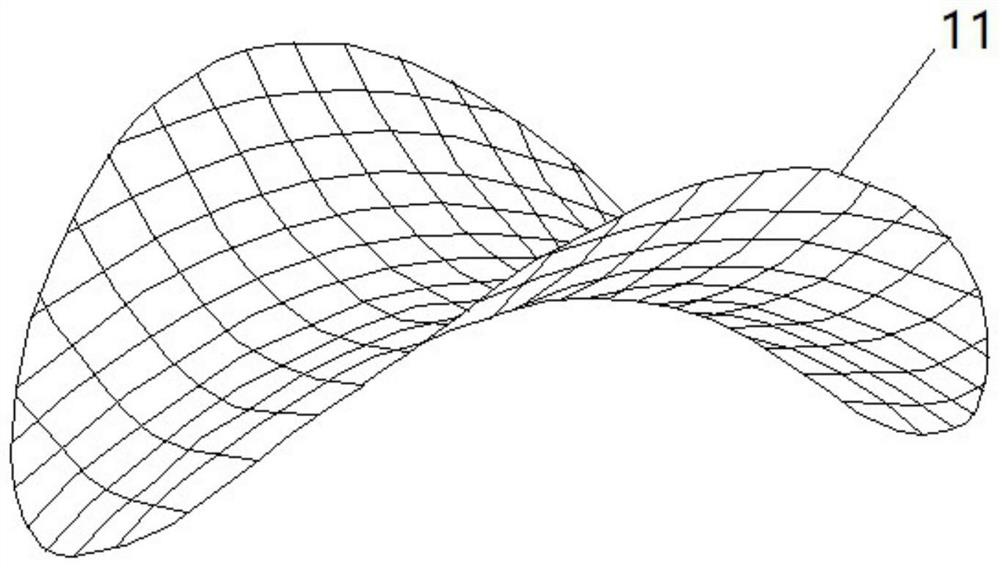

[0028] refer to figure 1 , a preferred embodiment of the present invention provides a composite electrode with embedded particles in a plastic sheet, which is used to be suspended in a reactor of a three-dimensional electrode. The composite electrode with embedded particles in a plastic sheet includes: a plastic sheet 11 for mounting and supporting, a plastic sheet 11 is made of plastic material, and is a space curved sheet with a space curved surface. The surface of the plastic sheet 11 is embedded with dispersed and granular particles 12. The particles 12 are used for mass transfer after contact with the wastewater in the reactor, and the particles 12 are connected with the plastic sheet 11 to form a composite particle electrode.

[0029]The invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com