Sintering flue gas circulation method and device

A technology of sintering flue gas and circulation device, applied in lighting and heating equipment, waste heat treatment, furnaces, etc., can solve problems such as failure and negative impact on sintering production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

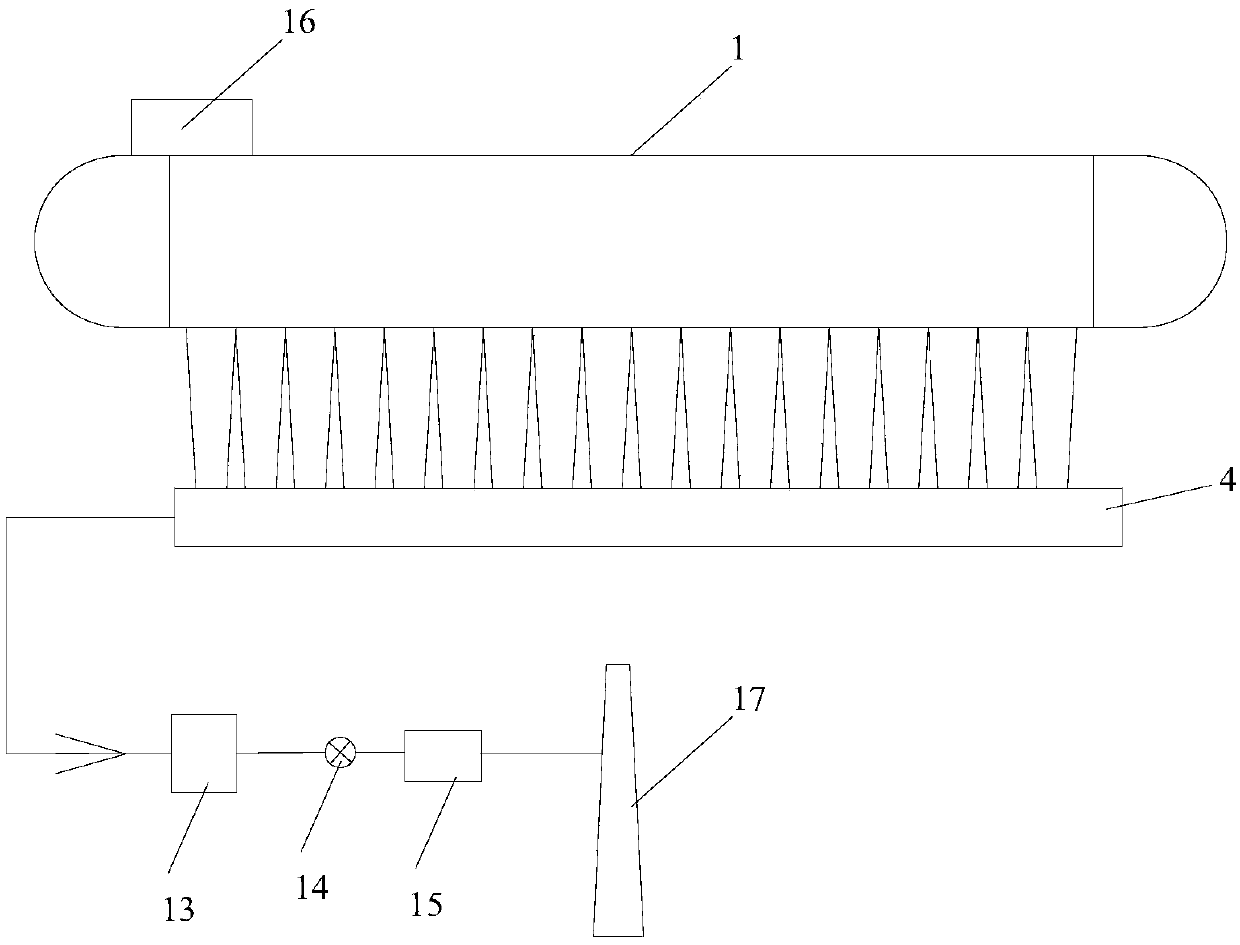

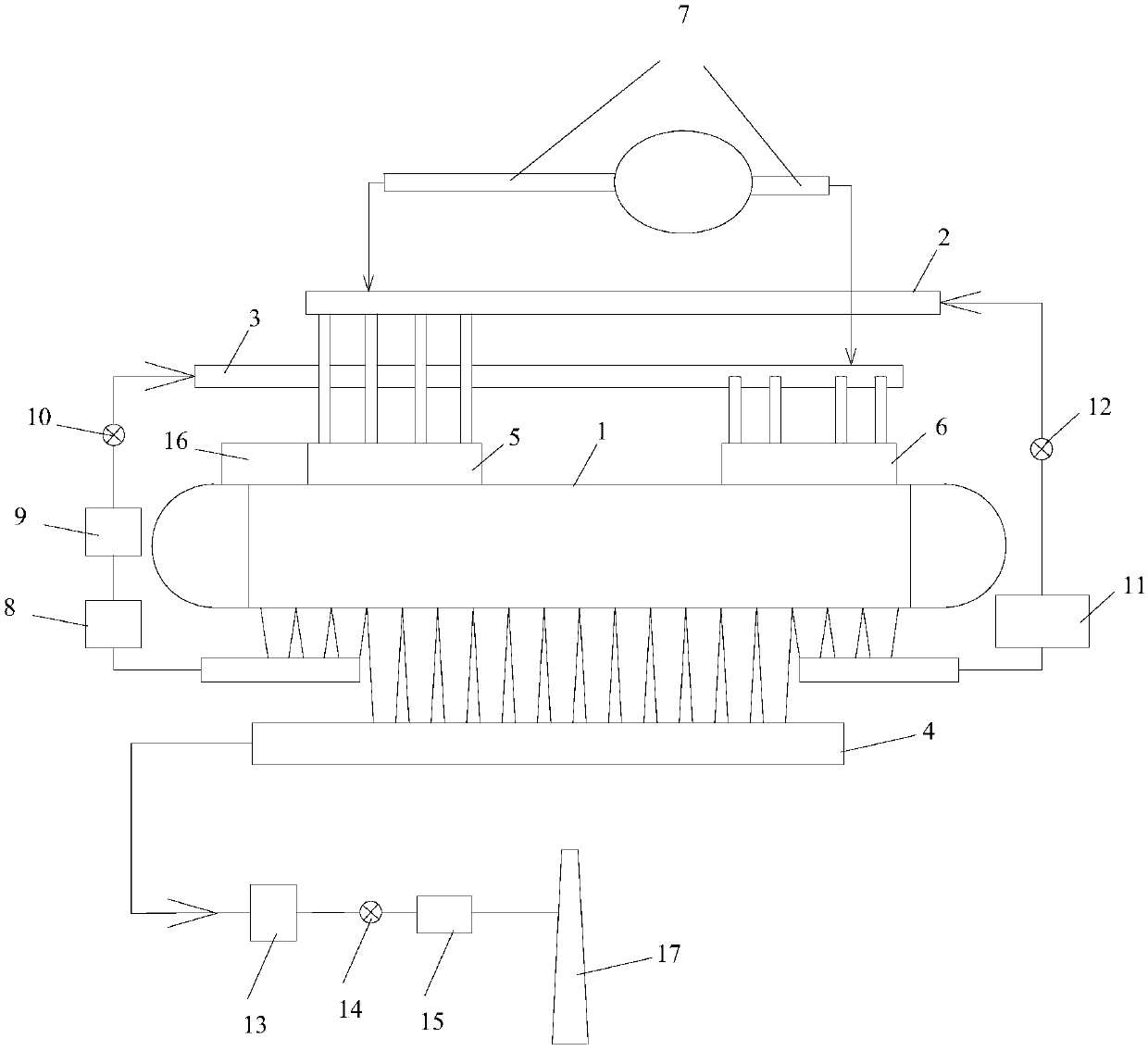

[0016] see figure 2 ( figure 1 with figure 2 The arrows in the figure represent the flow direction of oxygen or sintering flue gas), a sintering flue gas circulation device, including a sintering machine 1, a first circulating flue 2, a second circulating flue 3 and a main flue 4. The air inlet and outlet of the first circulating flue 2 are respectively connected to the air outlet of the wind box at the head of the sintering machine and the circulating flue gas hood 5 at the tail of the sintering machine, and the air inlet and outlet of the second circulating flue 3 They are respectively connected to the air outlet of the bellows at the tail of the sintering machine and the circulating flue gas hood 6 at the head of the sintering machine, and the air outlet end of the first circulating flue 2 and the air outlet end of the second circulating flue 3 are respectively connected to the oxygen pipe 7 , the air inlet of the main flue 4 is connected with the air outlet of the air ...

Embodiment 2

[0020] See figure 2 , this embodiment is basically the same as the sintering flue gas circulation device in Embodiment 1, the only difference is that: the wind box at the head of the sintering machine occupies 15% of the total length of sintering, and the wind box at the tail of the sintering machine occupies 15% of the total length of sintering. The sintering flue gas circulation method based on the sintering flue gas circulation device of this embodiment is as follows: the waste gas at the head of the sintering machine, which accounts for 15% of the sintering length, circulates to the tail of the sintering machine after dust removal and dehumidification; the oxygen content of the waste gas is 13 %, mixed with 10.8% of the exhaust gas with a concentration of 95% oxygen, and adjusted the oxygen content of the exhaust gas to 21%. The exhaust gas at the tail of the sintering machine, which accounts for 15% of the sintering length, circulates to the head of the sintering machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com