Method for removing impurities by argon blowing by adopting continuous casting tundish air curtain barricade technology

A technology of continuous casting tundish and gas curtain retaining wall, applied in the field of metallurgical technology of continuous casting tundish of iron and steel metallurgy, can solve the problems of complex production process, influence removal of inclusions, low inclusion removal rate, etc. Metallurgical effect highlights the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

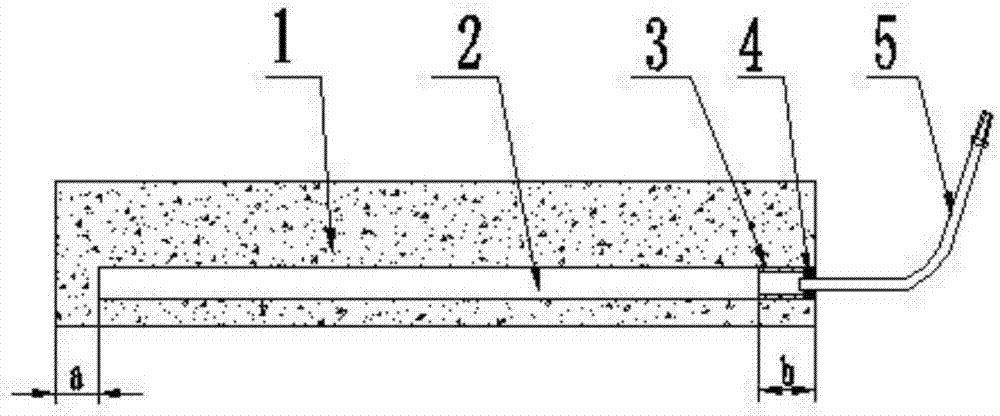

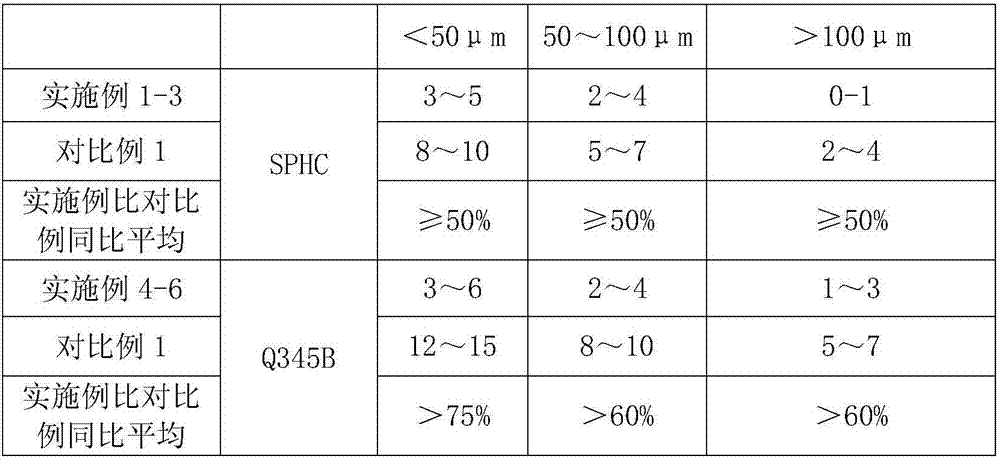

[0032] Such as figure 1 As shown, a method for removing inclusions by blowing argon on a continuous casting tundish gas curtain wall, used for pouring and producing low carbon steel, includes the following steps:

[0033] 1) While the continuous casting ladle is pouring, argon is blown into the strip gas curtain wall. The initial argon flow is 30NL / min and the pressure is 0.25Mpa. When the molten steel in the tundish reaches the normal molten steel level, adjust The flow rate of large argon gas is 50NL / min, and it is advisable to slightly fluctuate the molten steel level in the area directly above the strip gas curtain wall;

[0034] 2) In the first furnace of the tundish pouring, after the molten steel level in the tundish overflows the ladle nozzle, add 50kg of high-alkalinity and low-carbon tundish covering agent from the molten steel injection area in the tundish. Add 20kg of high-alkalinity and low-carbon tundish covering agent to the molten steel surface in the upper area, a...

Embodiment 2

[0039] The method for removing inclusions by blowing argon on the continuous casting tundish gas curtain wall as described in Example 1, the difference is:

[0040] A method for removing inclusions by blowing argon on a continuous casting tundish gas curtain wall, used for pouring and producing low carbon steel, includes the following steps:

[0041] 1) While the continuous casting ladle is pouring, argon is blown into the strip gas curtain wall. The initial argon flow is 50NL / min and the pressure is 0.5Mpa. When the molten steel in the tundish reaches the normal molten steel level, adjust The large argon gas flow rate is 100NL / min, and the argon gas flow rate should be controlled according to the slight fluctuation of the molten steel level in the area directly above the strip gas curtain wall;

[0042] 2) In the first furnace of the tundish pouring, after the molten steel level in the tundish overflows the nozzle of the large ladle, add 30kg of high-alkalinity and low-carbon tundis...

Embodiment 3

[0046] The method for removing inclusions by blowing argon on the continuous casting tundish gas curtain wall as described in Example 1, the difference is:

[0047] A method for removing inclusions by blowing argon on a continuous casting tundish gas curtain wall, used for pouring and producing low carbon steel, includes the following steps:

[0048] 1) While the continuous casting ladle is being poured, argon is blown into the strip-shaped gas curtain wall. The initial argon flow is 40NL / min and the pressure is 0.4Mpa. When the molten steel in the tundish reaches the normal molten steel level, adjust The large argon gas flow rate is 80NL / min, and the argon gas flow rate should be controlled by the slight fluctuation of the molten steel level in the area directly above the strip gas curtain wall;

[0049] 2) In the first furnace of the tundish pouring, after the molten steel in the tundish overflows the nozzle of the large ladle, add 80kg of the high-alkalinity and low-carbon tundish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com