Metallurgical composite pelletizing prepared through twice pelletizing method, as well as preparation method and application thereof

A technology of composite pellets and pellets, which is applied in the direction of manufacturing converters, improving process efficiency, furnaces, etc., can solve the problems of high construction and operation cost, sensitivity, and difficulty in industrialization implementation, and achieve the improvement of technical and economic indicators of blast furnace smelting. , the effect of reducing costs and increasing the proportion of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

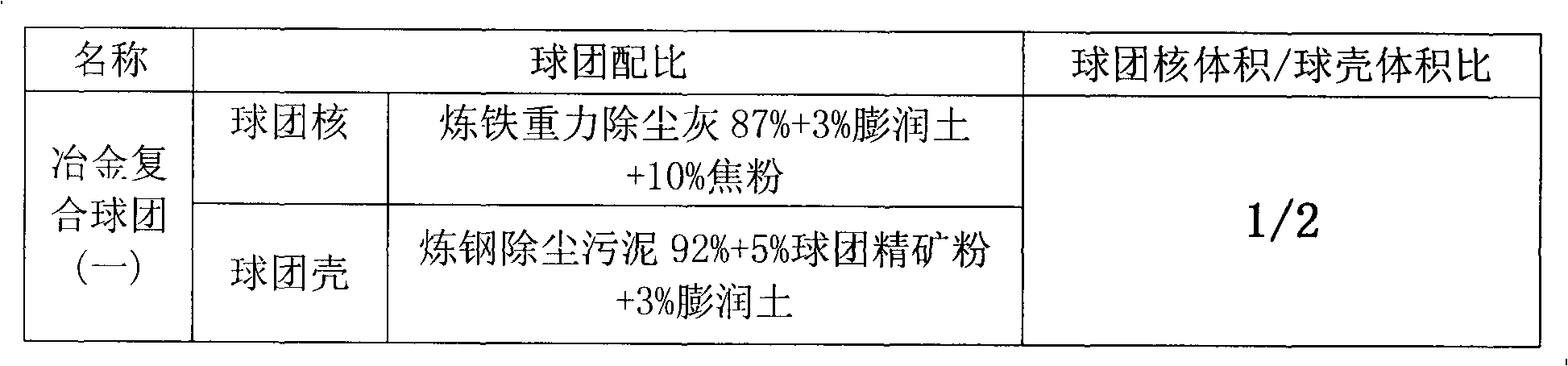

Embodiment 1

[0074]

[0075] The results of the metallurgical composite pellets after firing: 1. The iron grade increased from 43.7% to 58.3%

[0076] 2. The content of ferrous oxide decreased from 13.4% to 7.36%

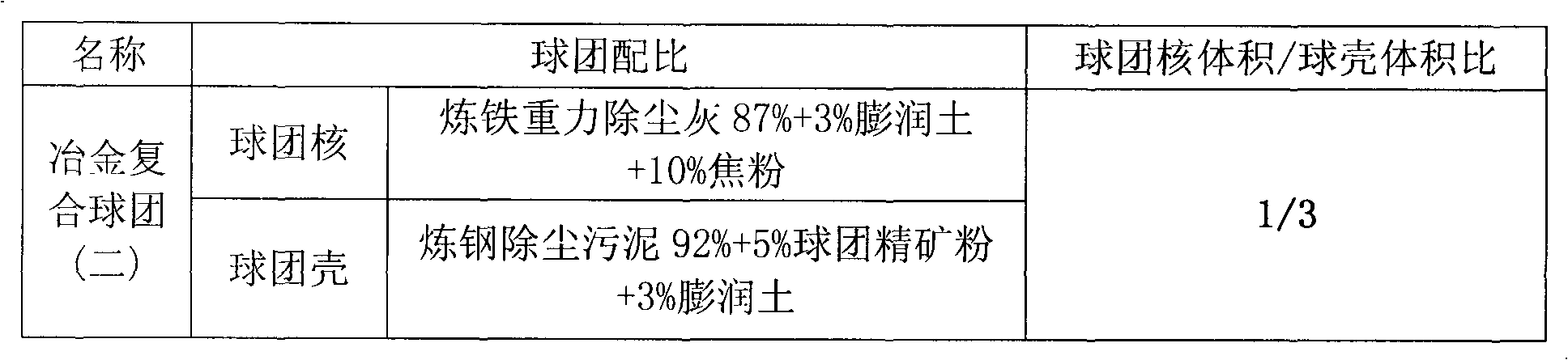

Embodiment 2

[0078]

[0079] The results of the metallurgical composite pellets after firing: 1. The iron grade increased from 46.3% to 60.1%

[0080] 2. The content of ferrous oxide decreased from 17.9% to 0.9%

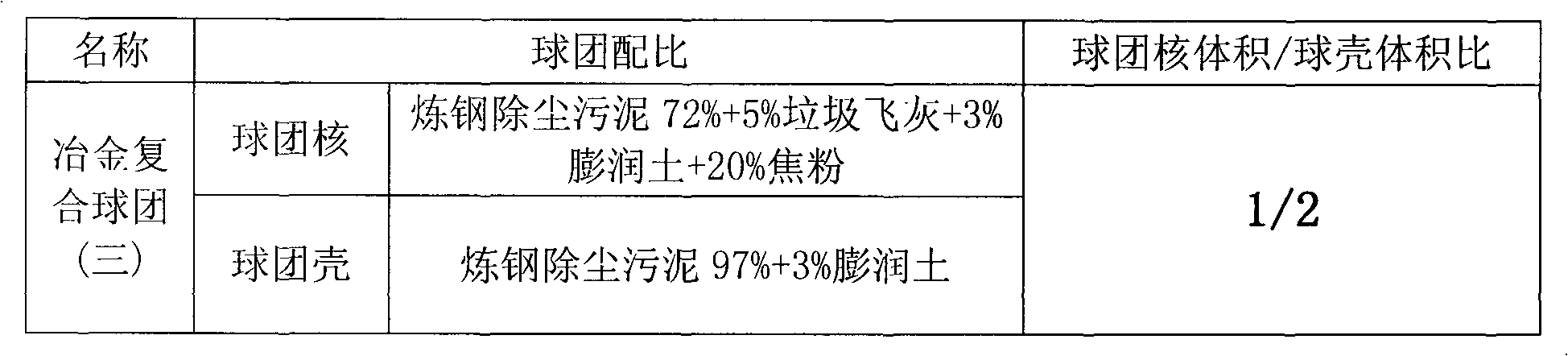

Embodiment 3

[0082]

[0083] The results of the metallurgical composite pellets after firing: 1. The iron grade is increased from 38.7% to 48.89%

[0084] 2. The content of ferrous oxide decreased from 16.4% to 5.57%

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com