Method for removing harmful components in iron-containing solid waste

A technology of solid waste and solid components, applied in the direction of improving process efficiency, etc., can solve problems such as corrosion equipment, high content of harmful components, affecting roasting reduction process and product quality, etc., to improve iron grade and low processing cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

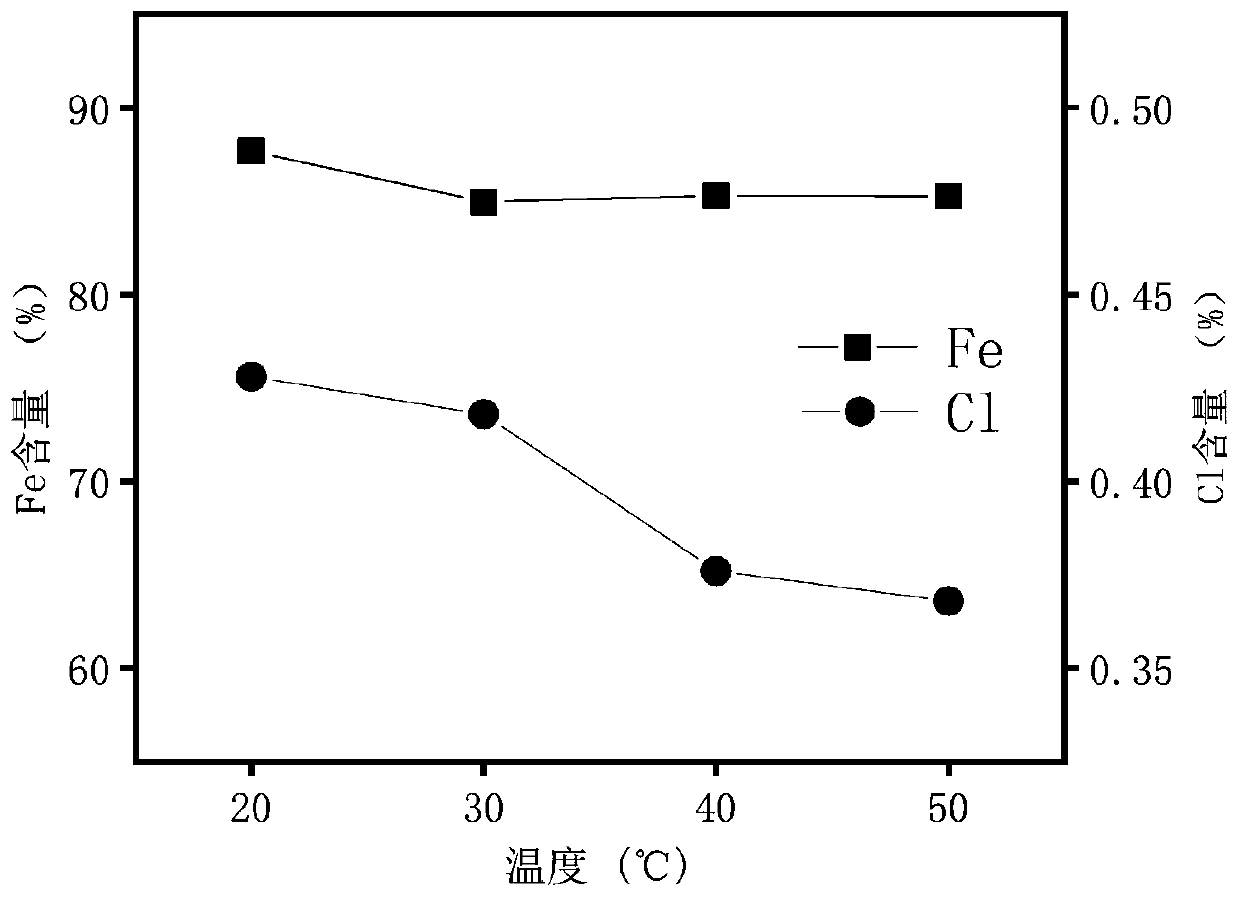

[0044] (1) using a solar greenhouse to dry the pickling sludge to a moisture content of 14.15%, and crushing the obtained dry pickling sludge to a particle size of 35 mesh to obtain dry pickling sludge particles;

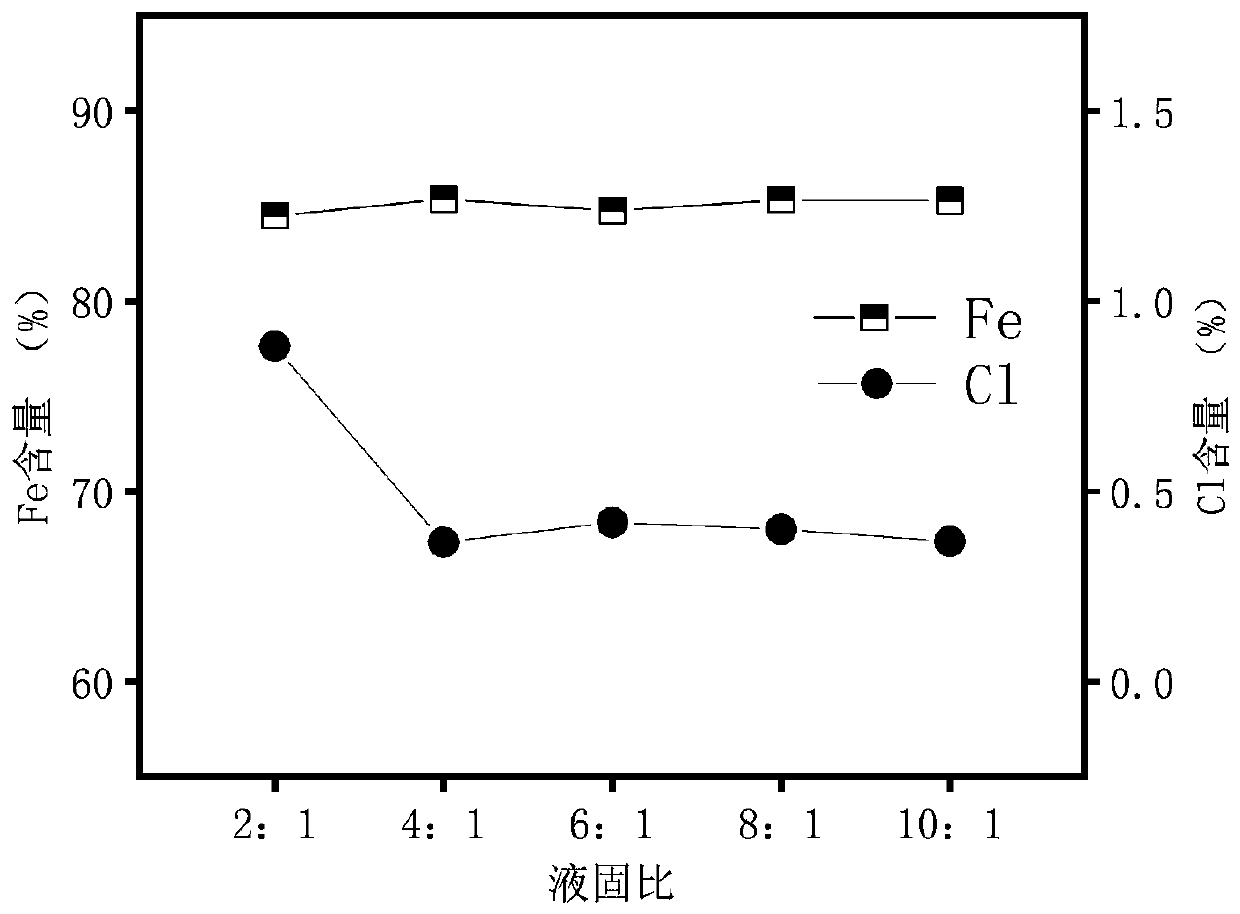

[0045] (2) Add 10 g of the dried pickling sludge granules into the immersion bottle, add 90 mL of tap water, place the immersion bottle in an overturning oscillator, and oscillate at room temperature with an oscillation frequency of 35 times / min Dipping and washing for 60 minutes, vacuum filtration after shaking, the filter membrane is a microfiltration membrane, and liquid components and solid components are obtained;

[0046] (3) Using tap water to wash the solid component 5 times, the volume of the water added each time is 90mL, to obtain the washing liquid and the solid material;

[0047] (4) press-filtering the solid material to obtain a filter cake and filtrate, drying the gained filter cake to a water content<5%, and the gained solid component is pickling slu...

Embodiment 2

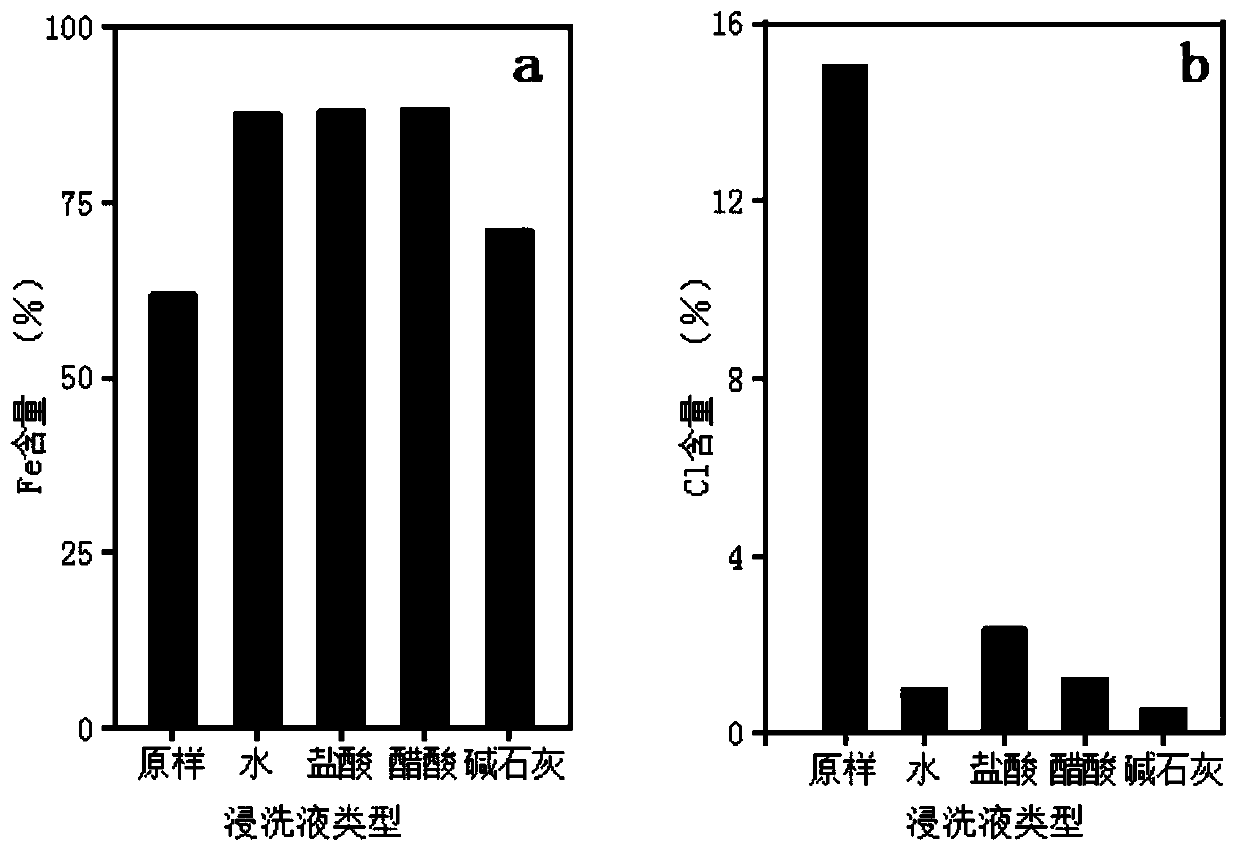

[0050] Remove chlorine and sodium harmful components according to the method of embodiment 1, the difference with embodiment 1 is that soaking agent is hydrochloric acid solution (90mL, 0.8wt%).

Embodiment 3

[0052] Remove chlorine and sodium harmful components according to the method of embodiment 1, the difference with embodiment 1 is that soaking agent is acetic acid solution (90mL, 1.2wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com