Method and device for dechlorinating and decarbonizing solid samples

A sample, solid-state technology, applied in the field of chlorine and carbon removal, can solve problems such as limiting large-scale utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is used to illustrate the method provided by the present invention for removing chlorine and carbon from solid samples

[0040] The chloride ion content in the titanium extraction tailings used in this embodiment is 2.96% by weight, and the free carbon content is 6.94% by weight. The titanium extraction tailings also contain 26.92% by weight of CaO, 8.01% by weight of MgO, 26.75 wt% SiO 2 , 5.98 wt% TiO 2 , 13.6 wt% Al 2 o 3 With 2.3% by weight of TiC and 0.7% by weight of FeO, 0.61% by weight of MnO and 0.77% by weight of TiO, the content of soluble chloride is 7.42% by weight.

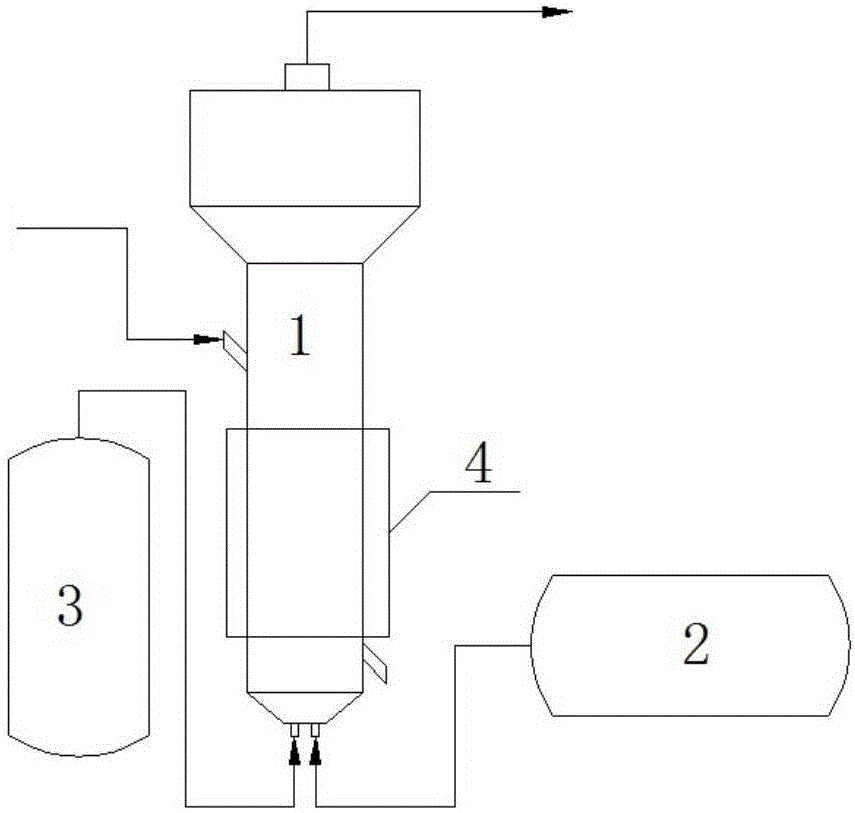

[0041] 5 kg of titanium tailings are sent into the fluidized bed 1 through the solid inlet of the fluidized bed 1, and the first part of air is introduced from the gas inlet of the fluidized bed 1 to make it fluidized, and the first part of the air is made by an air compressor 2 of compressed air. The gas velocity of the first part of air introduced is 0.15m / s. Use resist...

Embodiment 2

[0044] This embodiment is used to illustrate the method provided by the present invention for removing chlorine and carbon from solid samples

[0045] The chloride ion content in the titanium extraction tailings used in this embodiment is 2.50% by weight, and the free carbon content is 7.81% by weight. The titanium extraction tailings also contain 32.25% by weight of CaO, 9.11% by weight of MgO, 24.12 wt% SiO 2 and 7.03 wt% TiO 2 , 12 wt% Al 2 o 3 With 2% by weight of TiC and 0.35% by weight of FeO and 0.31% by weight of MnO, the content of soluble chloride is 5.02% by weight.

[0046] 5 kg of titanium tailings are sent into the fluidized bed 1 through the solid inlet of the fluidized bed 1, and the first part of air is introduced from the gas inlet of the fluidized bed 1 to make it fluidized, and the first part of the air is made by an air compressor 2 of compressed air. The gas velocity of the first part of air introduced is 0.3m / s. Use electric resistance furnace 4 to...

Embodiment 3

[0049] This embodiment is used to illustrate the method provided by the present invention for removing chlorine and carbon from solid samples

[0050] The chloride ion content in the titanium extraction tailings used in this embodiment is 3.52% by weight, and the free carbon content is 6.49% by weight. The titanium extraction tailings also contain 28.02% by weight of CaO, 7.11% by weight of MgO, 27.0 wt% SiO 2 , 5.05 wt% TiO 2 , 14.01 wt% Al 2 o 3 And 1.98% by weight of TiC, 0.12% by weight of FeO, and 0.43% by weight of TiO, the content of soluble chloride is 6.27% by weight.

[0051] The chlorine and carbon removal treatment was carried out according to the method of Example 1, the difference being that the gas velocity of the first part of air introduced was 0.2m / s. Use resistance furnace 4 to heat the fluidized bed to 650°C, then feed water vapor at 130°C from the gas inlet of fluidized bed 1, the gas velocity of water vapor is 0.04m / s, and the time for feeding steam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com