Method for treating fly sh by sludge

A technology for sludge treatment and fly ash, which is applied in the field of resource utilization of fly ash, can solve problems such as hindering the hydration process of the silicate system, increasing the leaching rate of harmful substances, and reducing the strength of solidified bodies, so as to benefit subsequent resources Utilization, realization of curing and detoxification, and improvement of long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

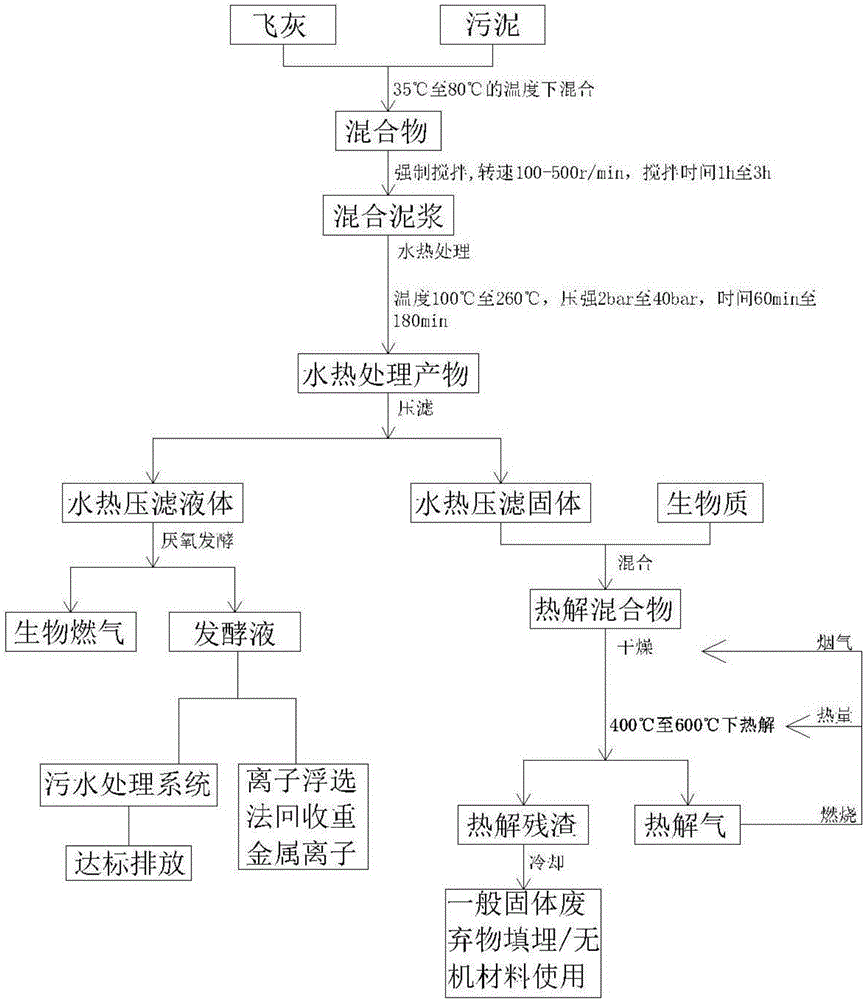

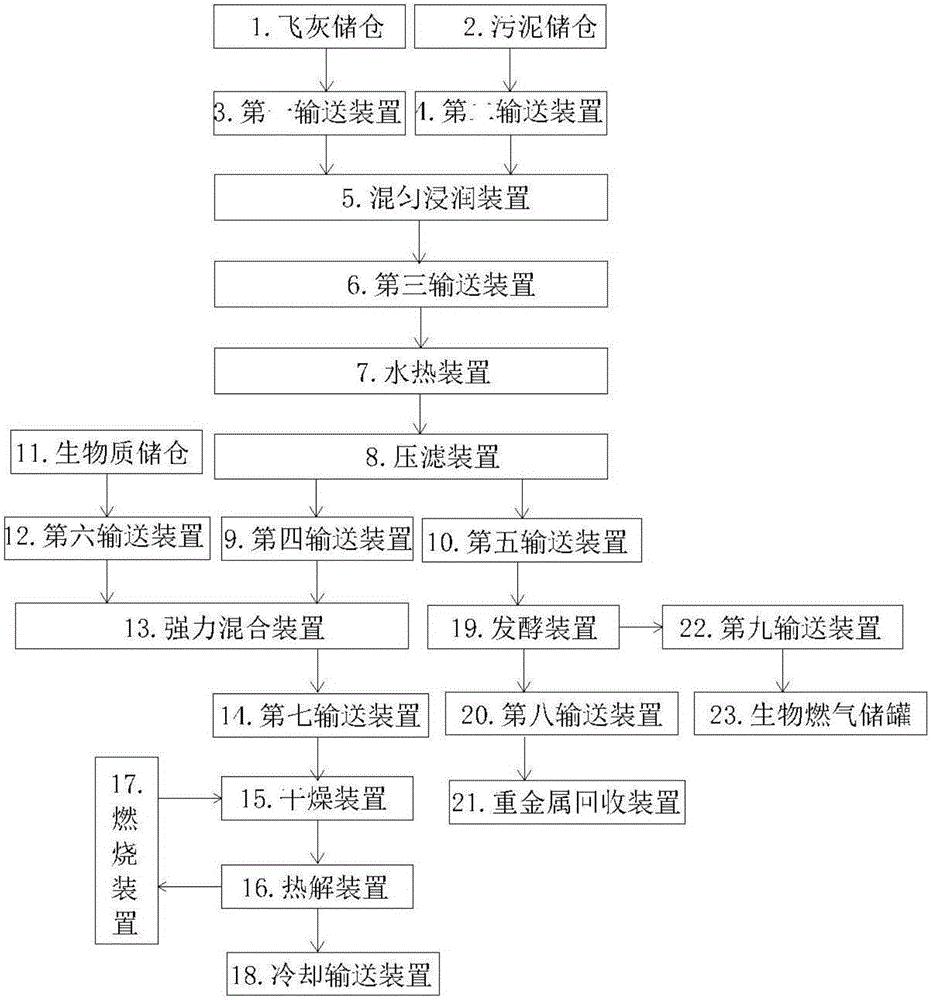

Embodiment 1

[0075] Mix a certain amount of sludge with fly ash accounting for 5% of the sludge mass, and vigorously stir at a speed of 100r / min at a temperature of 35°C for 3 hours to obtain a mixed slurry; the mixed slurry is subjected to hydrothermal treatment, and the process conditions of the hydrothermal treatment are : The temperature is 100° C., the pressure is 2 bar, and the time is 60 min to obtain a hydrothermal treatment product. The hydrothermally treated product is subjected to solid-liquid separation through press filtration to obtain a hydrothermally press-filtered liquid and a hydrothermally press-filtered solid. The hydrothermal pressure filtration liquid is placed in an anaerobic fermentation tank for anaerobic fermentation to produce biogas and stored; the fermentation liquid produced after fermentation is put into the sewage treatment system of the sewage treatment plant for treatment and discharged after reaching the standard. Mix the hydrothermal press-filtered solid...

Embodiment 2

[0078] Mix a certain quality of sludge with fly ash accounting for 10% of the sludge mass, and vigorously stir at a temperature of 50°C at a speed of 250r / min for 2 hours to obtain a mixed slurry; the mixed slurry is subjected to hydrothermal treatment, and the process conditions of the hydrothermal treatment are : The temperature is 160° C., the pressure is 6 bar, and the time is 100 min to obtain a hydrothermal treatment product. The hydrothermally treated product is subjected to solid-liquid separation through press filtration to obtain a hydrothermally press-filtered liquid and a hydrothermally press-filtered solid. Anaerobic fermentation is performed on the hydrothermal pressure filtration liquid to generate biogas, which is stored; the fermented liquid produced after fermentation is recovered by ion flotation to recover heavy metal ions in the fermented liquid, and then the waste water is discharged after reaching the standard. Mix the hydrothermal press-filtered solid w...

Embodiment 3

[0081] Mix a certain quality of sludge with fly ash accounting for 20% of the sludge mass, and vigorously stir at a temperature of 65°C at a speed of 400r / min for 1 hour to obtain a mixed slurry; the mixed slurry is subjected to hydrothermal treatment, and the process conditions of the hydrothermal treatment are : The temperature is 220° C., the pressure is 23 bar, the time is 140 min, and the hydrothermal treatment product is obtained. The hydrothermally treated product is subjected to solid-liquid separation through press filtration to obtain a hydrothermally press-filtered liquid and a hydrothermally press-filtered solid. Anaerobic fermentation is performed on the hydrothermal pressure filtration liquid to generate biogas, which is stored; the fermented liquid produced after fermentation is recovered by ion flotation for heavy metal ions in the fermented liquid, and then the waste water is discharged after reaching the standard. The pyrolysis mixture was obtained by mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com