Organic binder, application of organic binder in pellet preparation, organic-inorganic composite binder and application of organic-inorganic composite binder

An organic binder and inorganic composite technology, applied in the organic binder and its application in the preparation of pellets, in the field of organic-inorganic composite binders, can solve the problem of reducing the compressive strength of preheating balls and roasting balls , furnace condition deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In terms of mass percentage, the organic binder provided by the present invention includes 1-2% polyether, preferably 1.2-1.8%, more preferably 1.5%. In the present invention, the polyether is preferably an EO / PO block polyether, and the molecular weight of the polyether is preferably 1000-2000, more preferably 1200-1800, and even more preferably 1500. The present invention has no special requirements on the source of the polyether, and can use conventional commercially available polyether in this field or self-preparation; when the polyether is self-prepared, the preparation method of the polyether preferably includes the following steps:

[0033] One or more of ethylene oxide, propylene oxide and butylene oxide are used as raw materials to carry out ring-opening polymerization under the action of a catalyst to obtain polyether.

[0034] In terms of mass percentage, the organic binder provided by the invention also includes 16-17% of water, preferably 16.5%.

[0035] ...

Embodiment 1~3

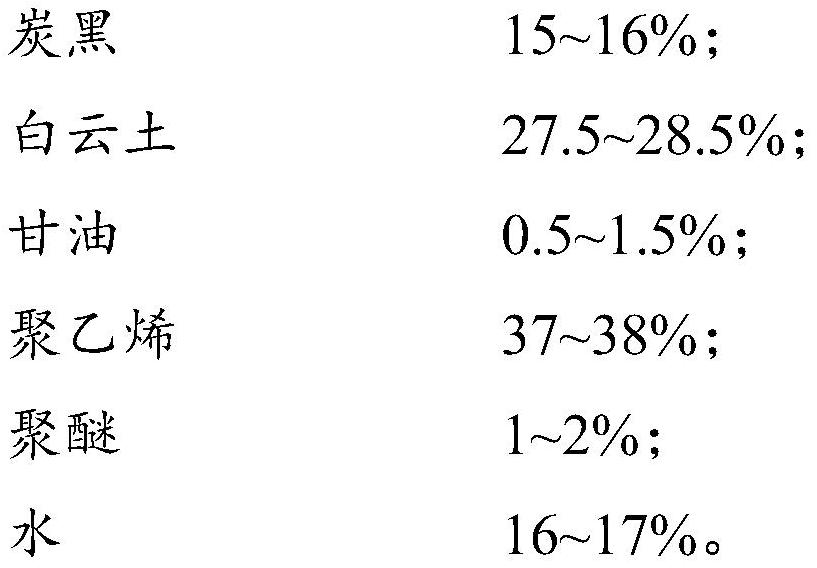

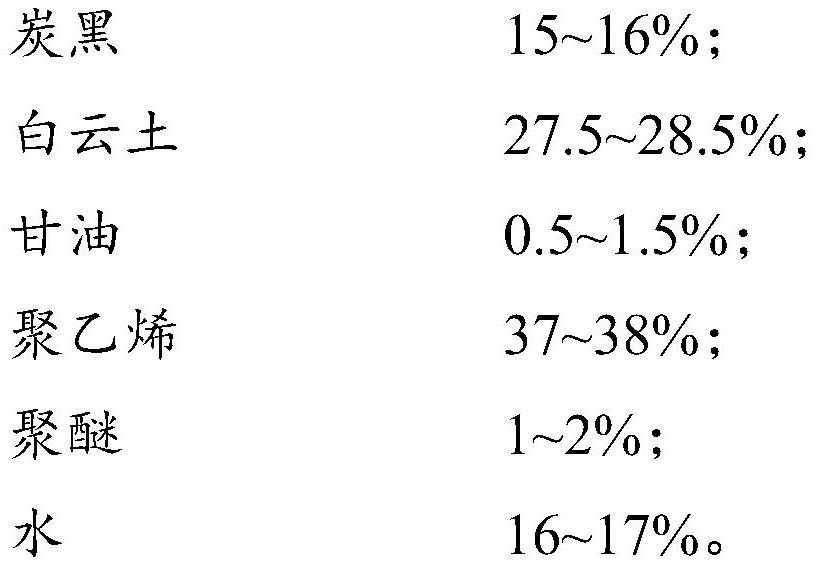

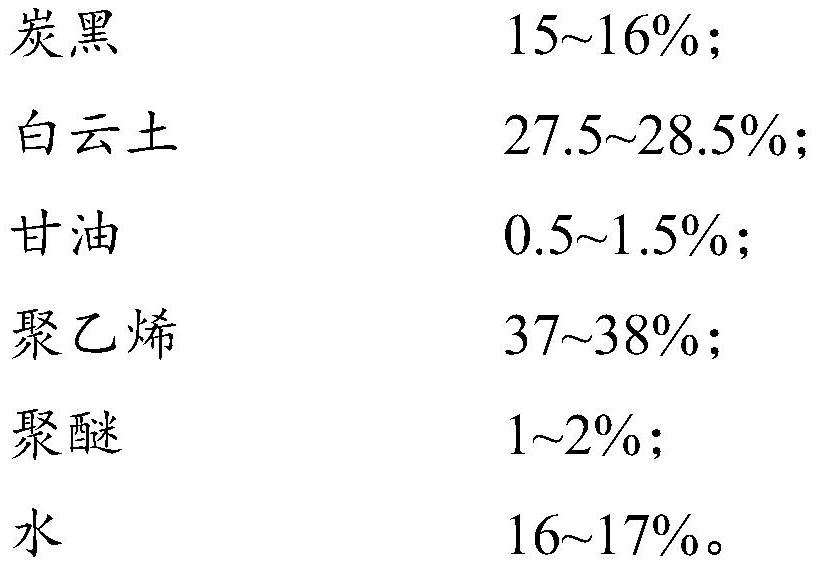

[0059] According to the dosage in Table 1, the raw materials were mixed and finely ground to prepare an organic binder, wherein the number average molecular weight of polyethylene was 7 million, polyether EO / PO block polyether, the number average molecular weight of the polyether for 1500.

[0060] The raw material consumption of table 1 embodiment 1~3 organic binder

[0061]

[0062]

Embodiment 4~6

[0086] The natural calcium-based bentonite is mixed with the organic binder obtained in Example 2, and ground until the content of particles with a particle size below -0.074 mm is not less than 100%, to obtain an organic-inorganic composite binder. The dosage of natural calcium-based bentonite and organic binder is shown in Table 3.

[0087] The raw material consumption of the organic-inorganic composite binder obtained in table 3 embodiment 4~6

[0088] Example 4 Example 5 Example 6 Natural calcium-based bentonite / g 100 100 100 Organic binder / g 0.3 0.4 0.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com