Ultralow carbon welding rod for welding heat resisting steel and stainless steel

An electric welding rod, ultra-low carbon technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of high cost, achieve the effect of preventing carbon migration layer, simple composition design, and excellent metallurgical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1 Tube-to-tube butt joint. The specification of the pipe material is Φ64×5, and the length is 200 mm; the bevel is opened, and the welding electrode of the present invention is dried at 350° C. for 1 hour before welding. Welding parameters: use Φ3.2 welding rod, welding current is 90-120 amps, welding voltage is 23-25 volts, welding two layers and two layers. At the same time, E347-17 and E5515-B2-V electrodes were used to weld the comparison specimens of the same base metal respectively.

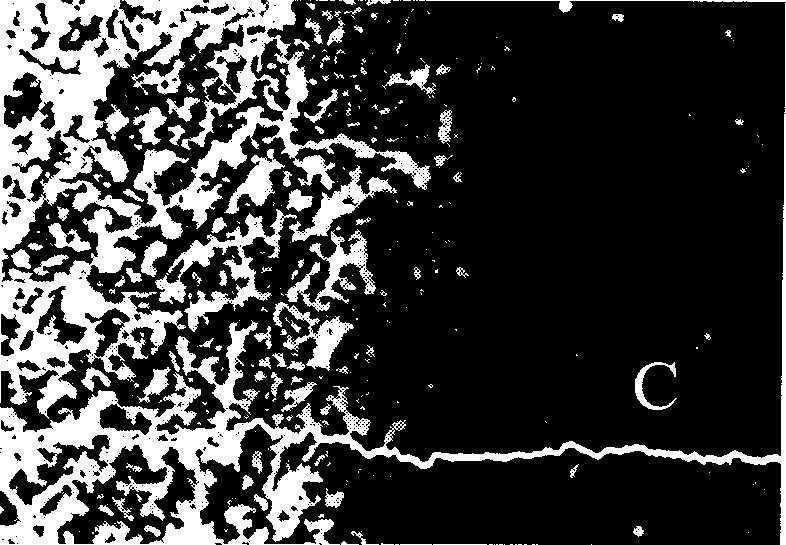

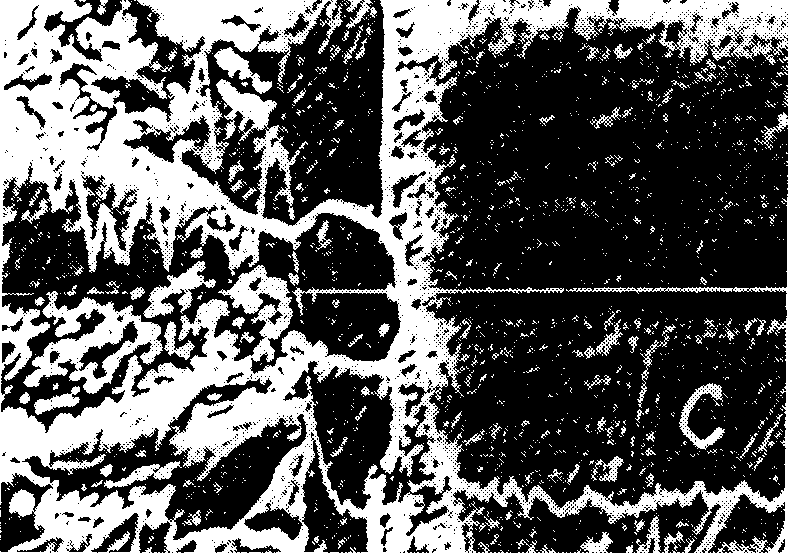

[0013] For pipe fittings welded with three kinds of electrodes, the metallographic photos of the carbon element scanning near the fusion zone on the side of the austenite base metal are shown in figure 1 , figure 2 , image 3 . Depend on figure 1 It is shown that the content of carbon elements on both sides of the fusion zone is balanced, and there is no carbon migration layer, while figure 2 and image 3 Both showed a carbon migration layer.

[0014] The normal t...

Embodiment 2

[0016] Embodiment 2 Plate docking. The size of the welding plate used is 300×100 mm, the thickness is 16 mm, and the bevel is 60°. The electric rod of the present invention and the E5515-B2-V electrode are used for multi-layer and multi-pass welding, and the high-temperature tensile test of the deposited metal of the welded joint is completed on a Gleeble 1500 thermal simulation testing machine. The test results are shown in Table 2. With the microhardness test near the fusion zone of the plate joint welded by the welding rod of the present invention, the method of taking points across the fusion line line is adopted, and the test line is 8 millimeters away from the upper surface of the test plate, and the distance between the test points is 0.05 millimeters. The test results are shown in the table 3.

[0017] sample

[0018] test

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com