Electromagnetic stirring and flow control device technology for multi-mode bar plate continuous casting crystallizer

A technology of electromagnetic stirring and slab continuous casting, which is applied in the fields of electromagnetic stirring and flow controllers of multi-mode slab continuous casting molds, which can solve the limited improvement of the internal quality of the slab and the failure to eliminate the superheat of molten steel, inclusions and air bubbles Aggregation and other problems, to achieve the effect of increasing the metallurgical effect, reducing the transformation cost, and enhancing the stirring function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

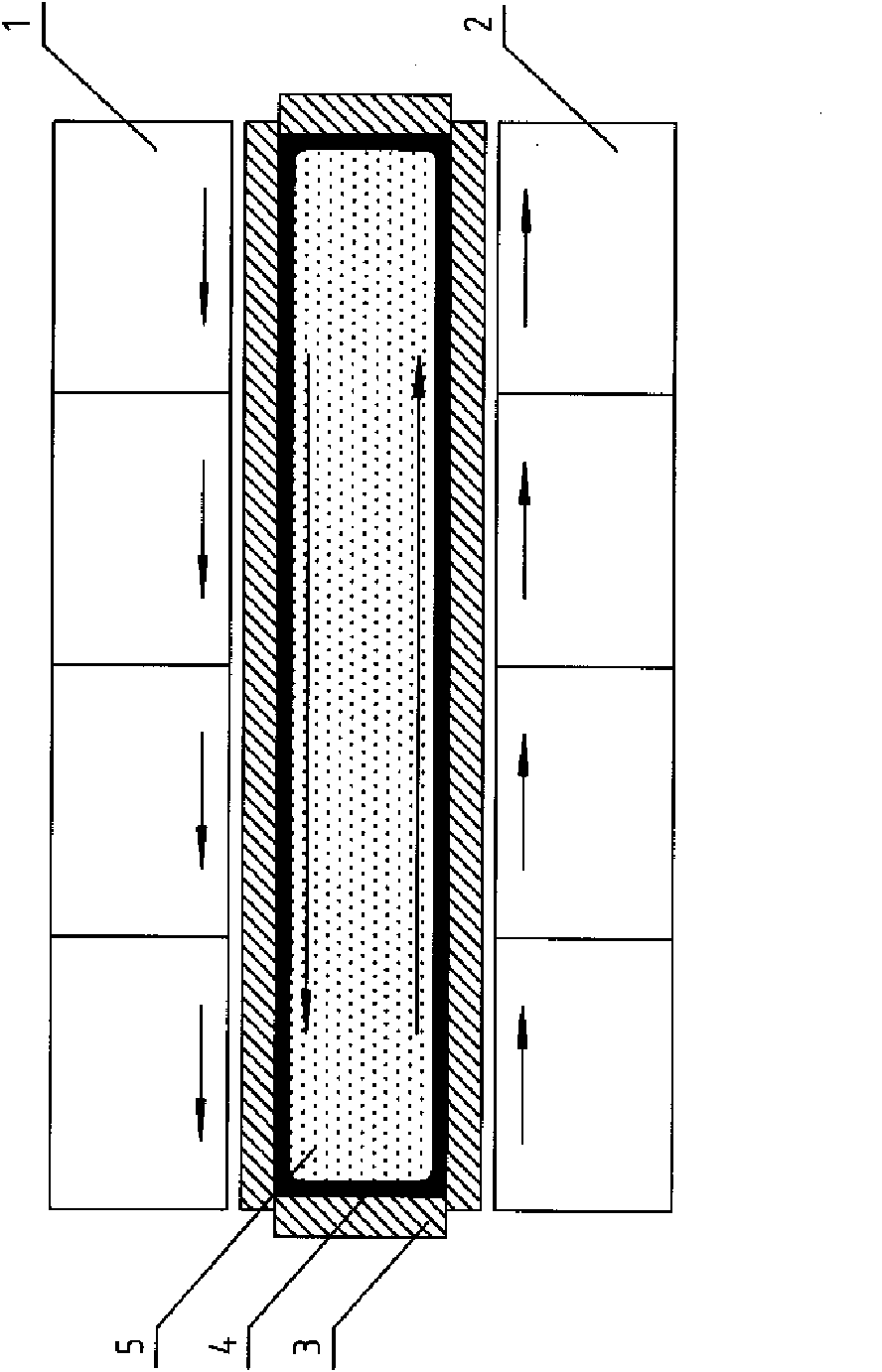

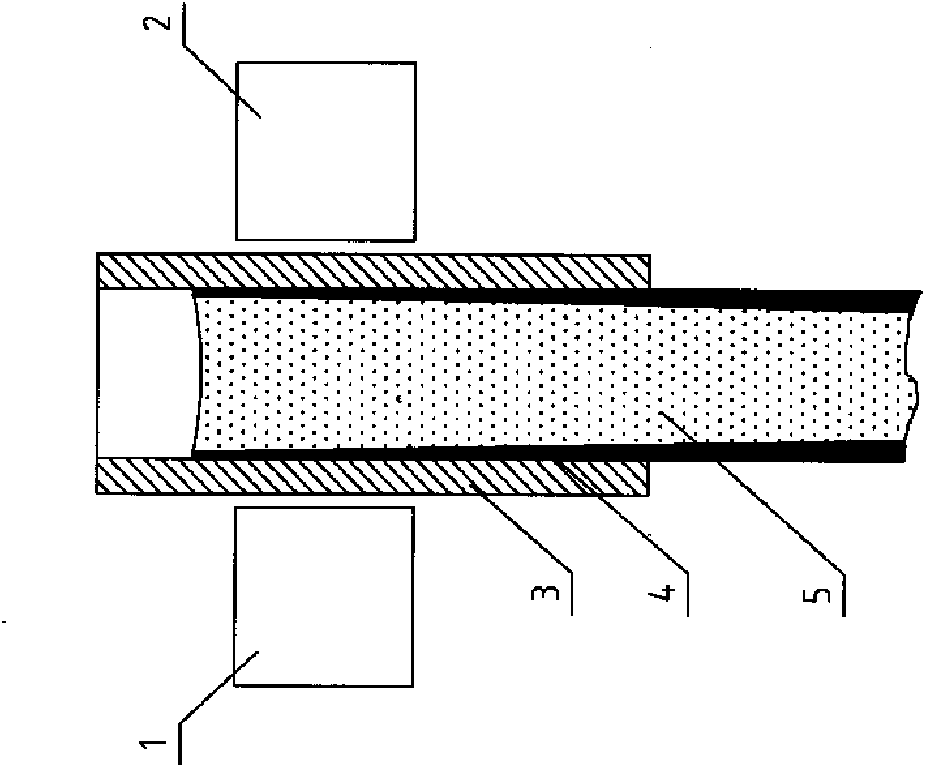

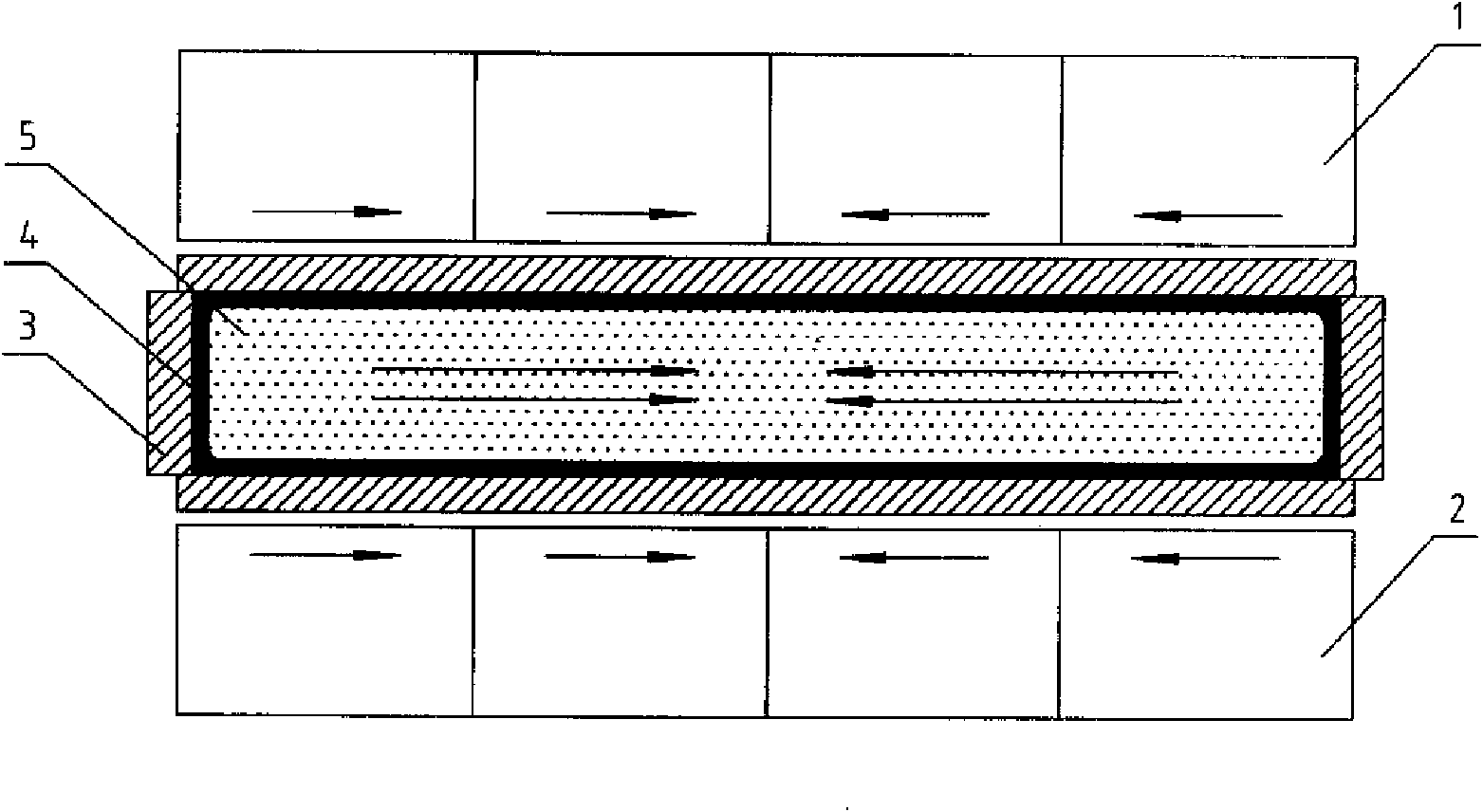

[0015] Depend on Figures 1 to 6 It can be seen that the present invention includes:

[0016] The electromagnetic stirring inductor is divided into an inner arc inductor 1 and an outer arc inductor 2, and the inner arc inductor 1 and the outer arc inductor 2 are respectively arranged on both sides of the mold copper plate 3, and the molten steel 5 flows from the inductor and the mold copper plate 3 intermediate passes where:

[0017] The inner arc sensor 1 and the outer arc sensor 2 are respectively set to at least four magnetic field areas, and the magnetic field size and magnetic field direction of each magnetic field area can be adjusted independently, and by changing the magnetic field settings, it can be combined: single rotation stirring mode, electromagnetic Deceleration mode, electromagnetic acceleration mode, two-zone rotation stirring mode and four-zone rotation stirring mode.

[0018] The single rotation stirring mode described in the present invention is that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com