Patents

Literature

56results about How to "Added stirring function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic flotation method and device and application thereof

The invention relates to an ultrasonic flotation method and a device and application thereof, which comprise the following steps: arranging an ultrasonic device in or outside a floatation tank body, starting the ultrasonic device when the floatation device carries out the mineral floatation, using ultrasonic waves to irradiate floatation pulp, providing a high-energy elastic mechanical wave to the pulp, initiating an ultrasonic cavitation effect, generating a large number of cavitation bubble particle flows which flow at high speed, and effectively washing the surfaces of the ore particles in the pulp to enable target ore particles to expose the fresh surfaces; at the same time, using ultrasonic energy to improve the activity of medicament in the pulp, quickening adsorption process of the medicament and the surfaces of the target ore particles to further improve the effects of breaking, restructuring and floating of mineralized bubbles in a pulp system, and thus realizing the optimization of flotation process.

Owner:佛山市兴民科技有限公司

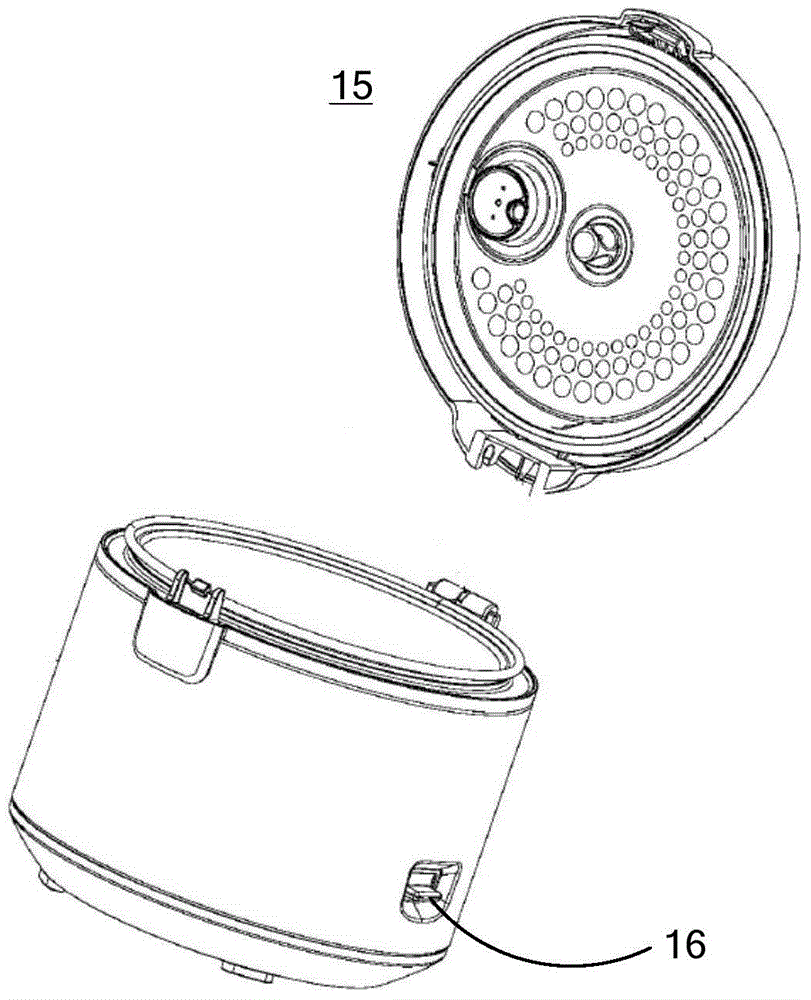

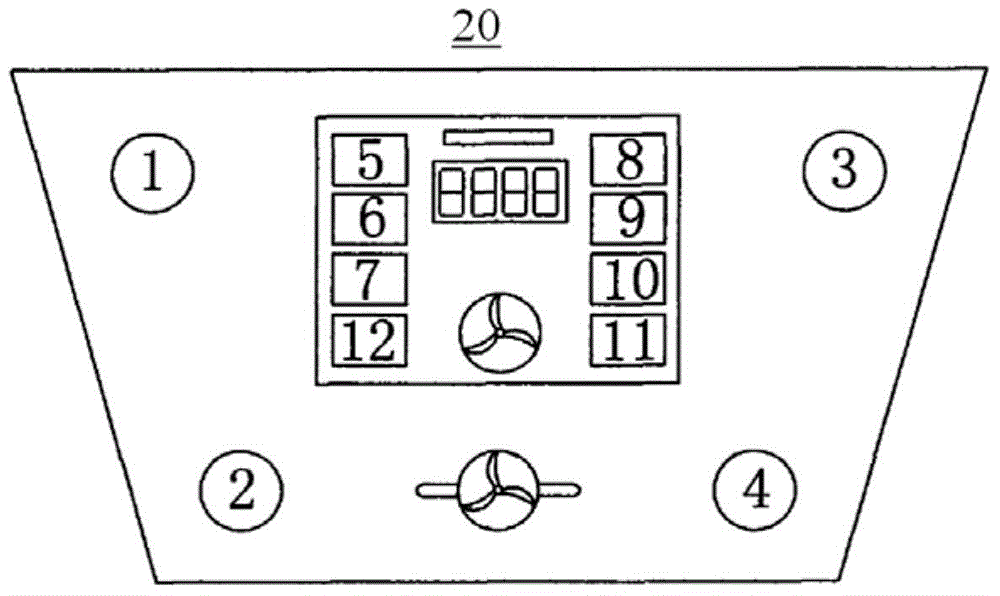

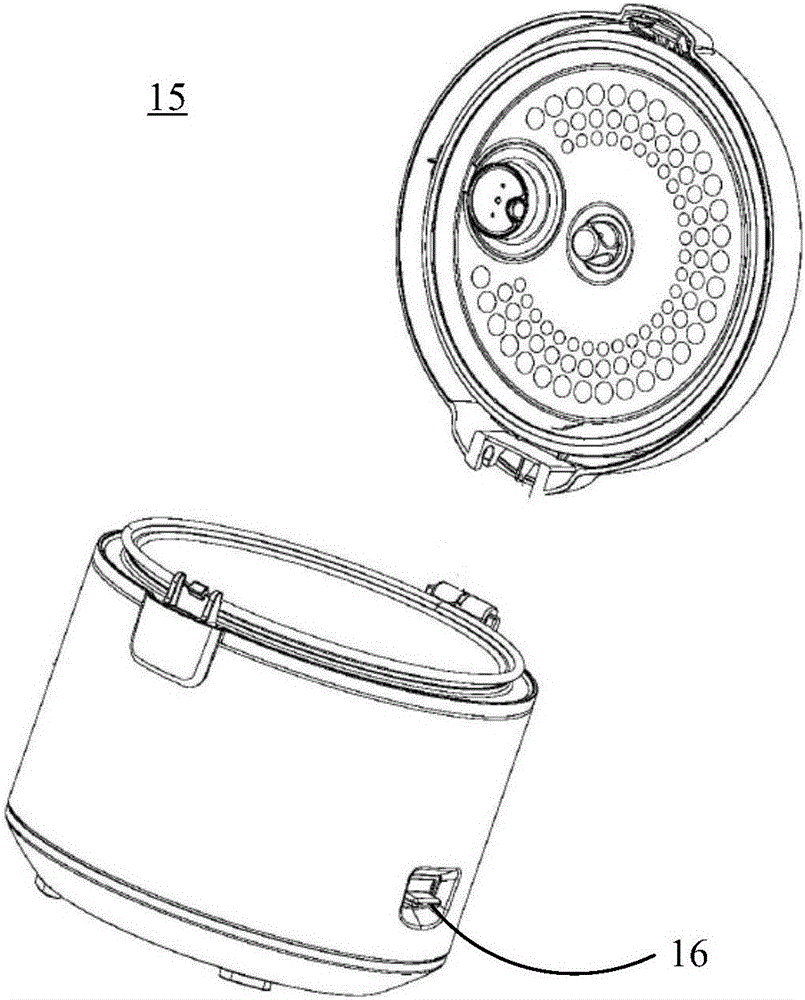

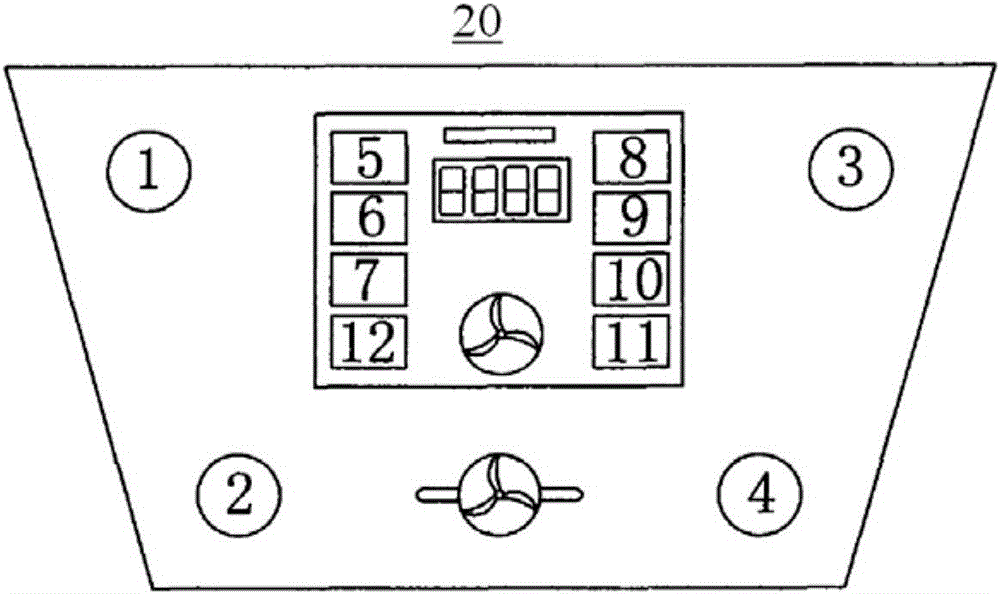

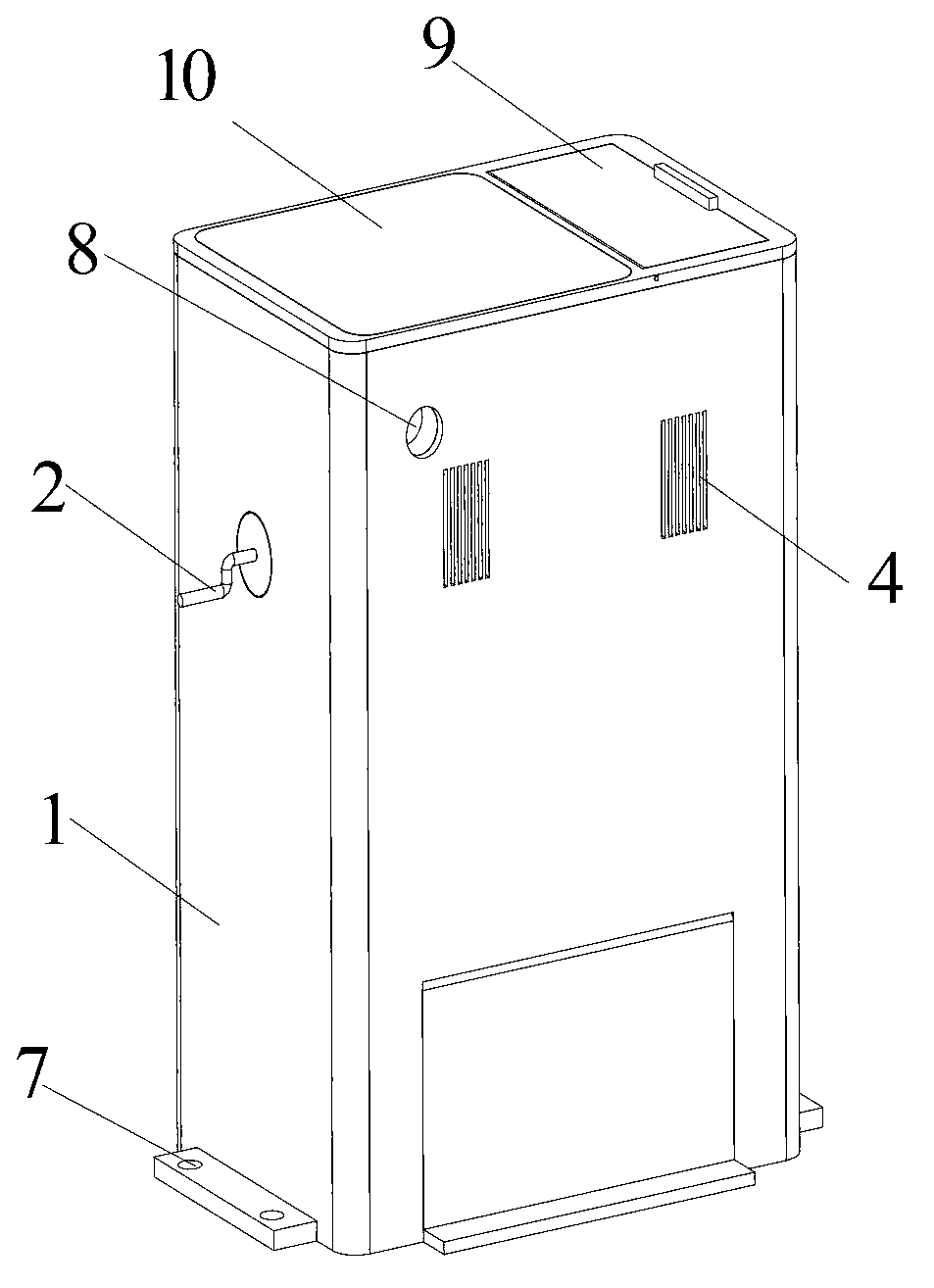

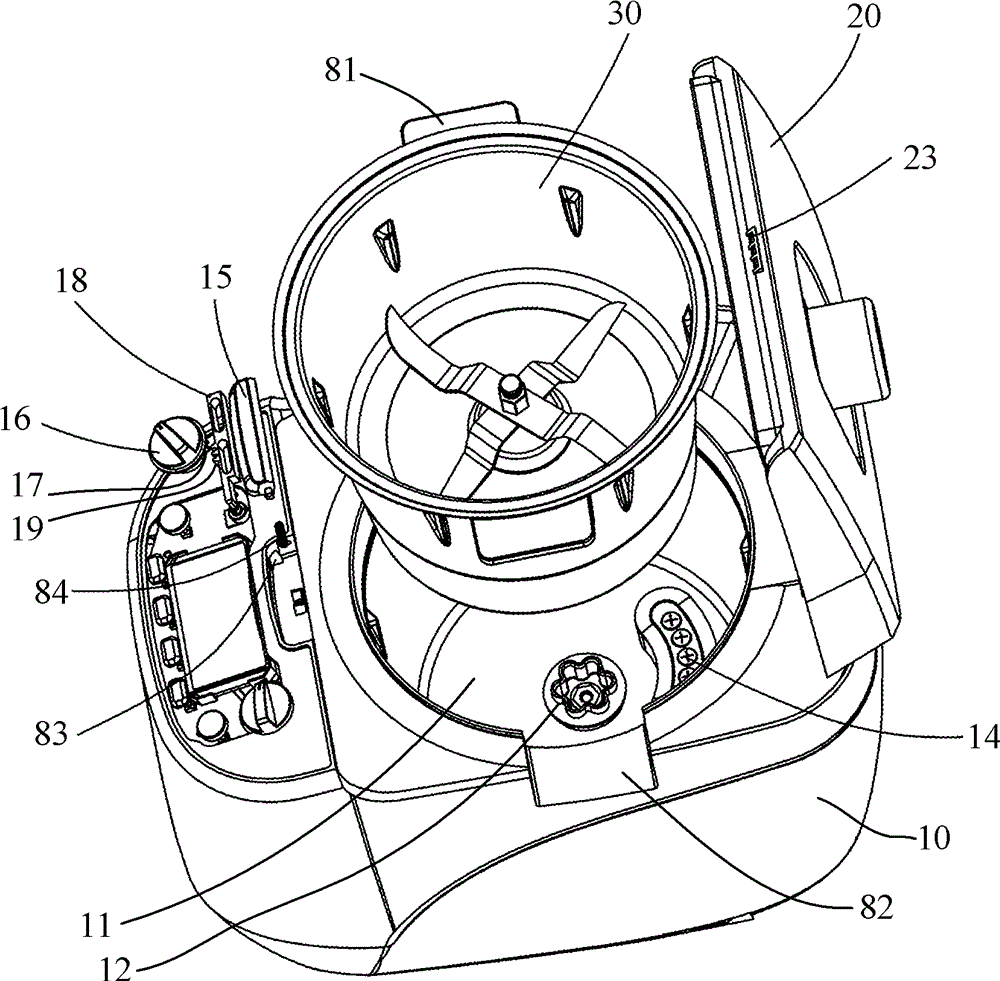

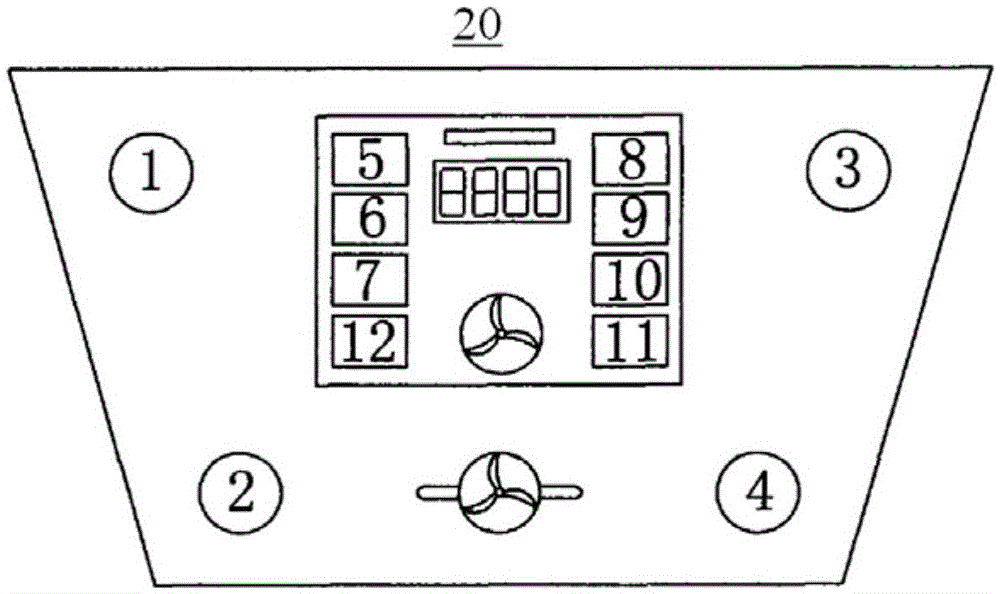

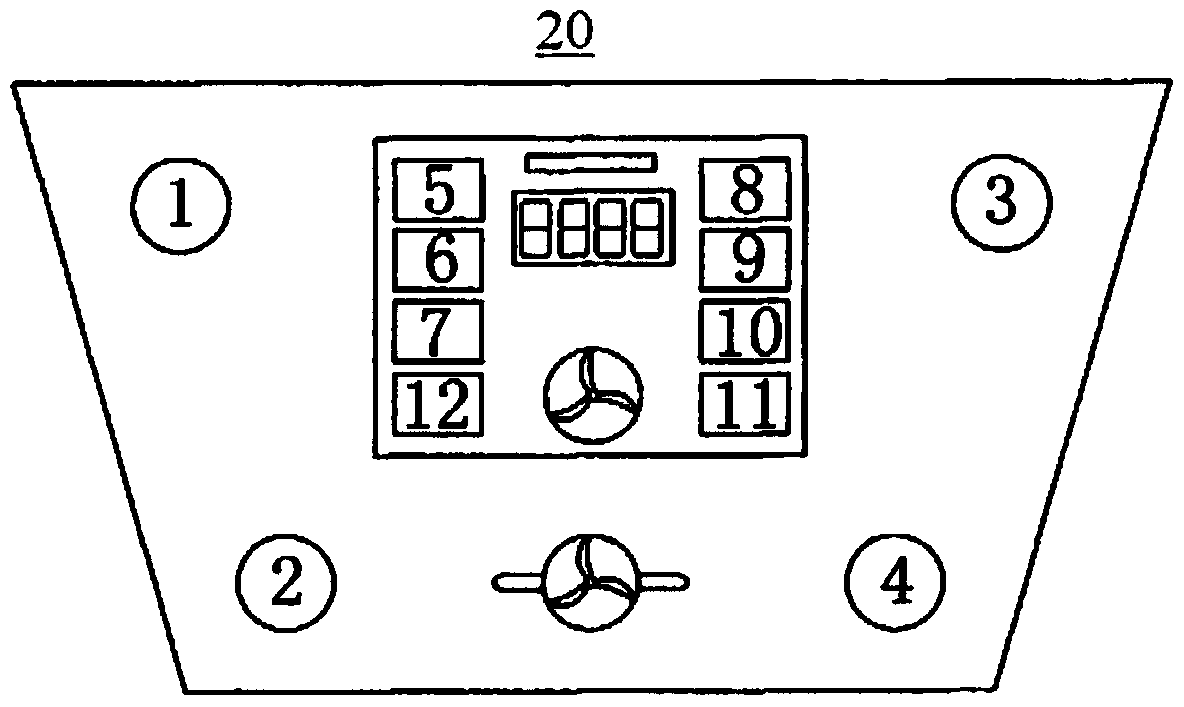

Food processor

The invention discloses a food processor which comprises a cooling pot and a machine body. The cooling pot is used for accommodating and processing food materials. The machine body is provided with a casing, the casing comprises a first casing and a second casing which are connected with each other, the second casing defines a cooling pot installing part, and the bottom of the cooling pot is placed in the cooling pot installing part. The food processor further comprises a touch screen type computer, and the touch screen type computer is arranged on a first side of the first casing and used for controlling the food processor through touch operation. Users can conveniently utilize the touch screen type computer to operate the food processor, and accordingly the dependency on other portable intelligent electrical appliances such as a mobile phone is relieved.

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

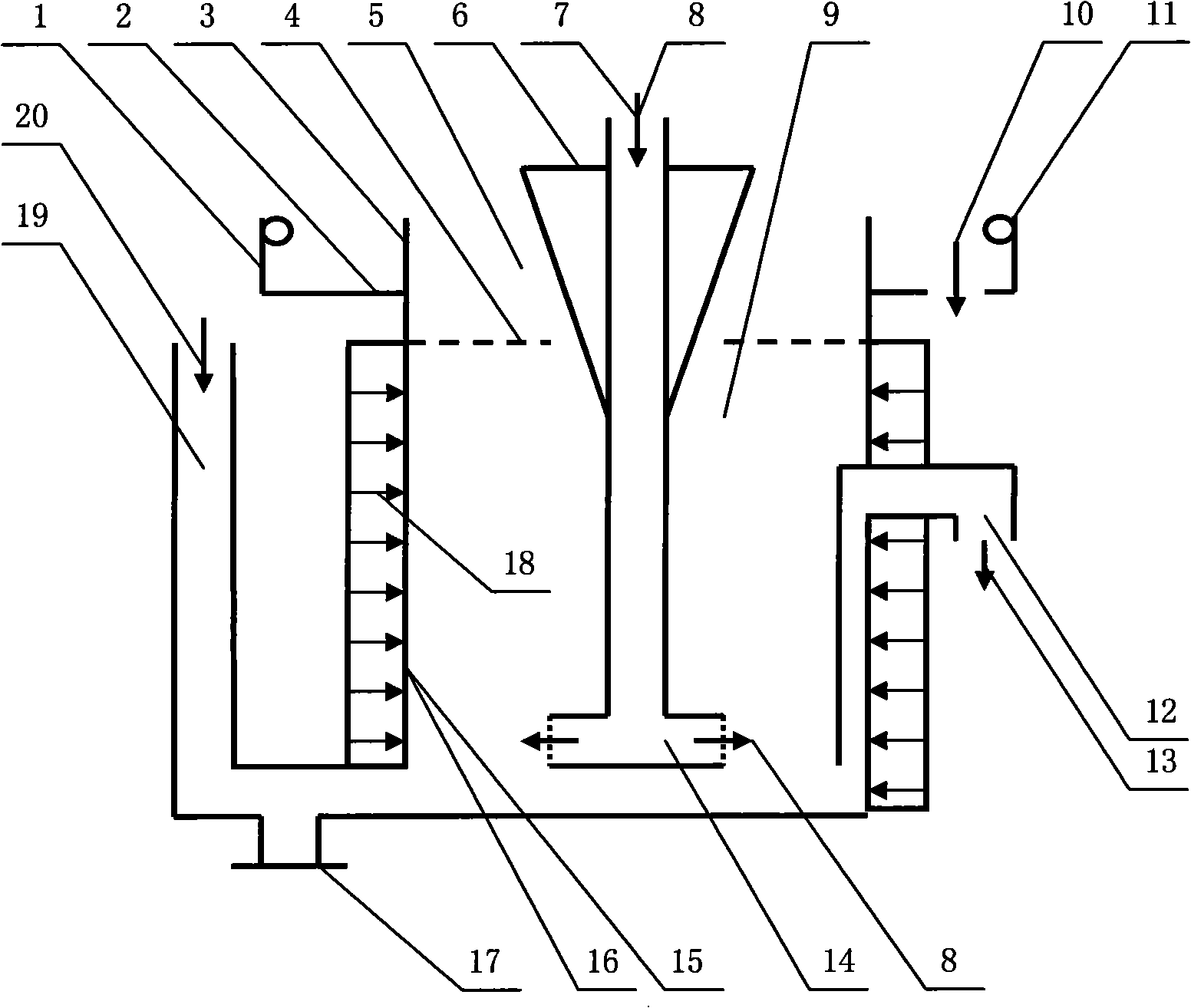

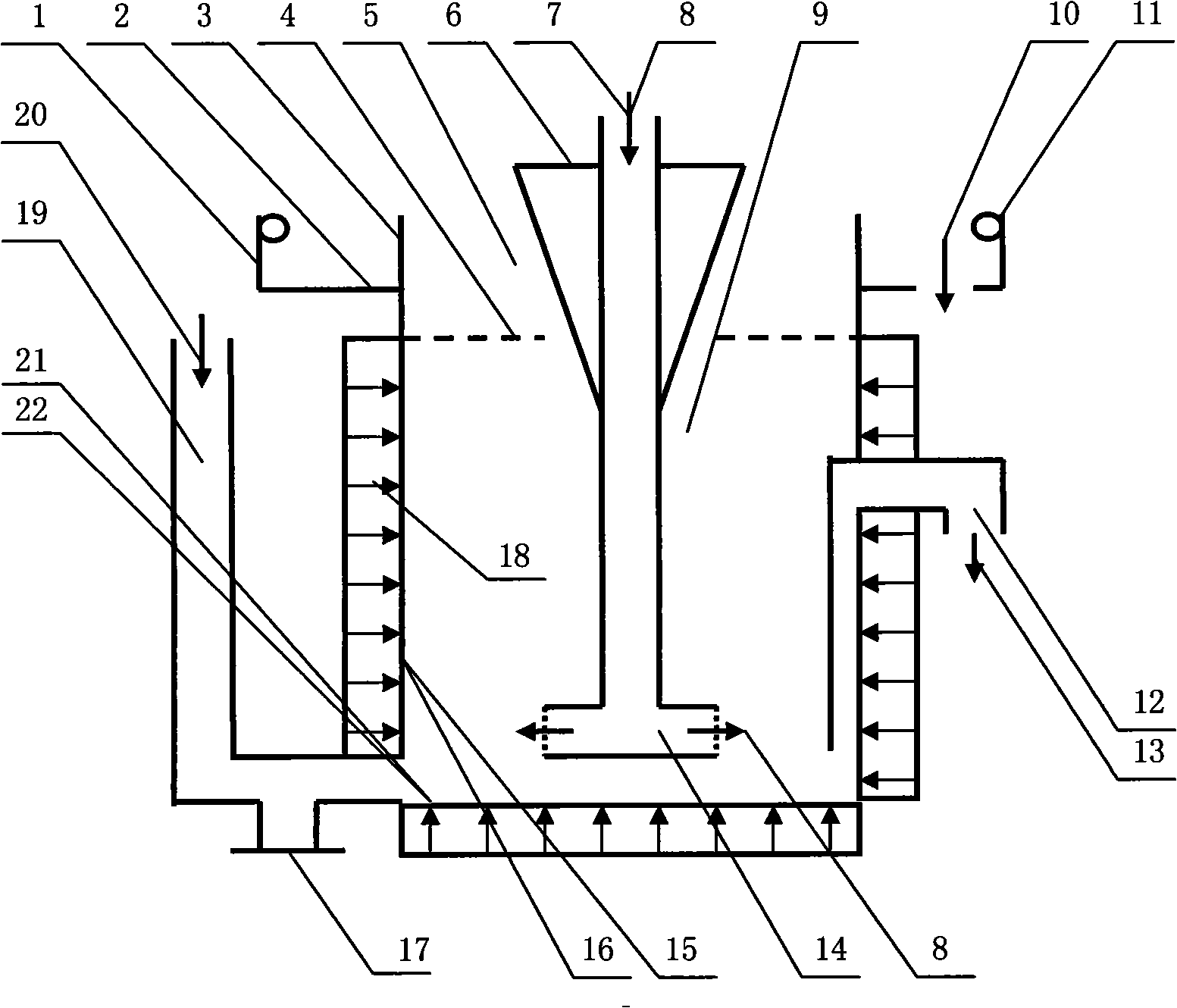

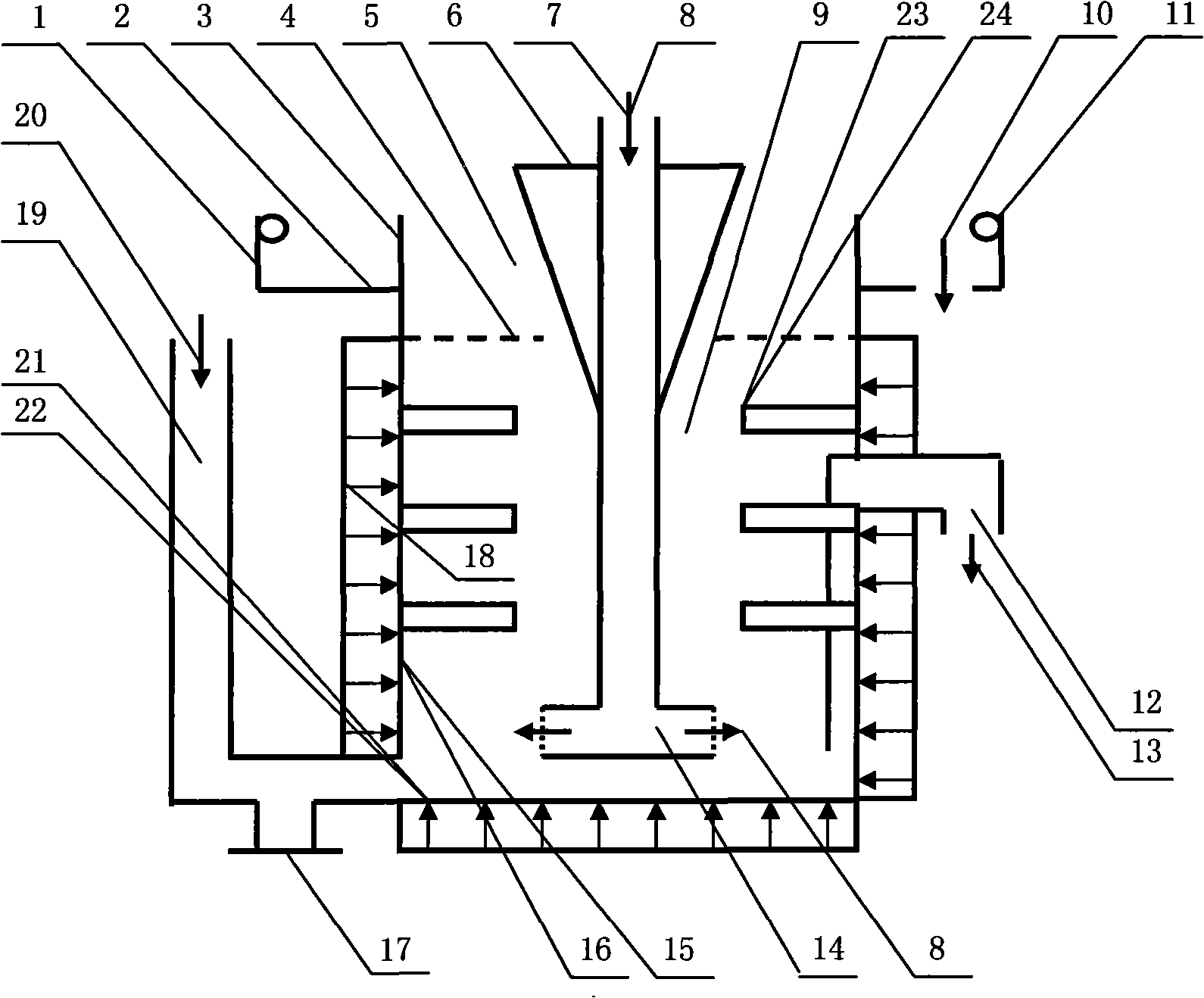

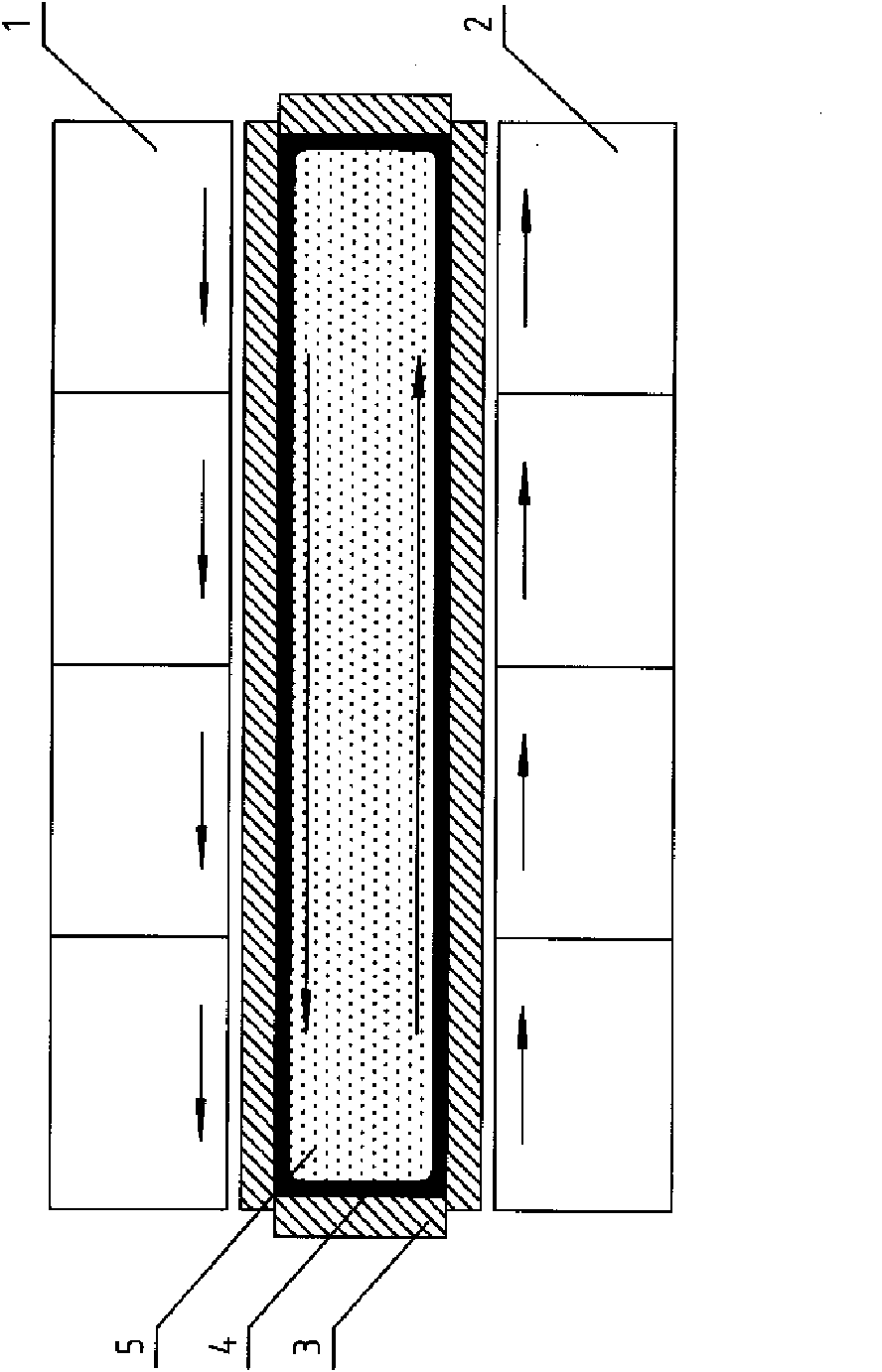

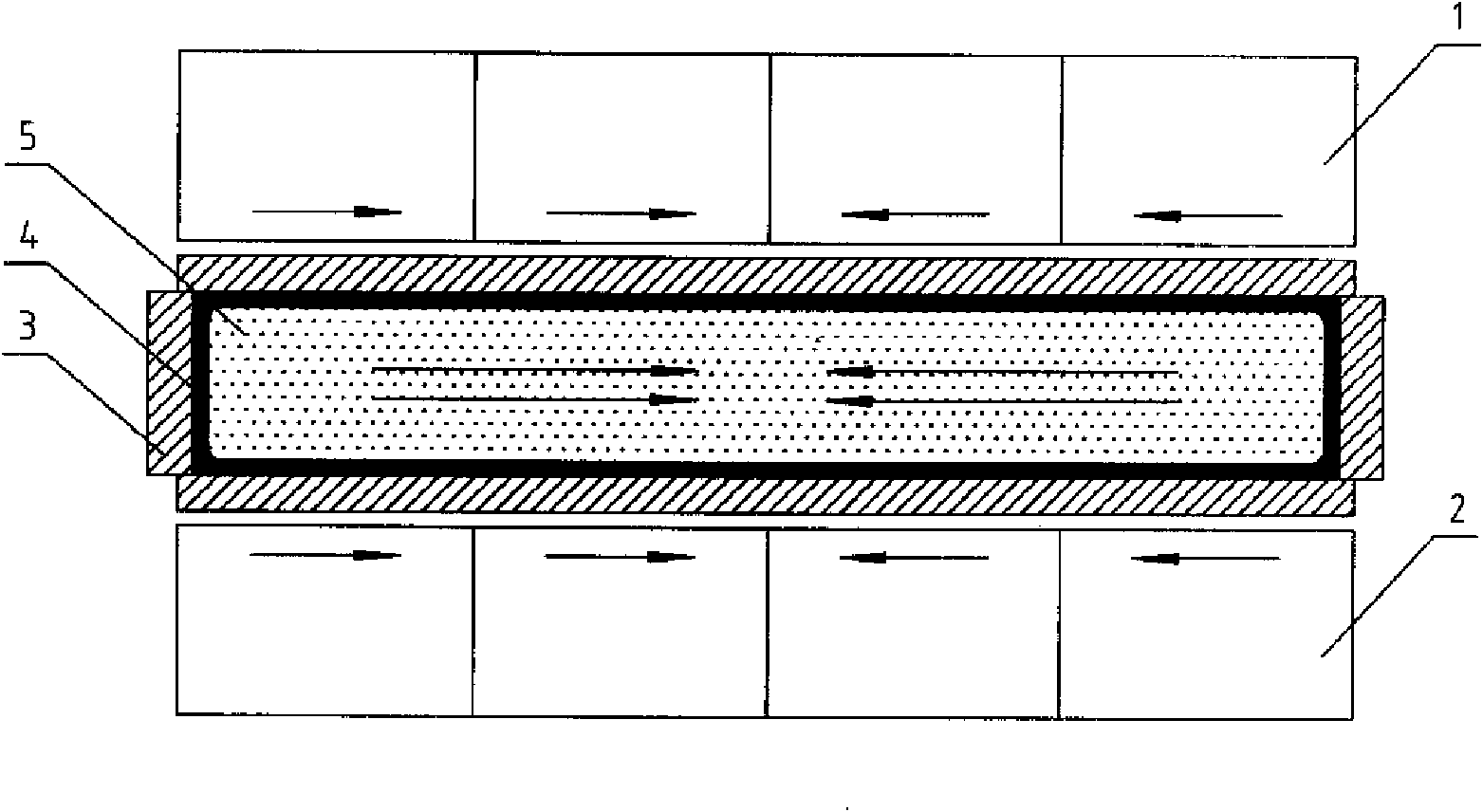

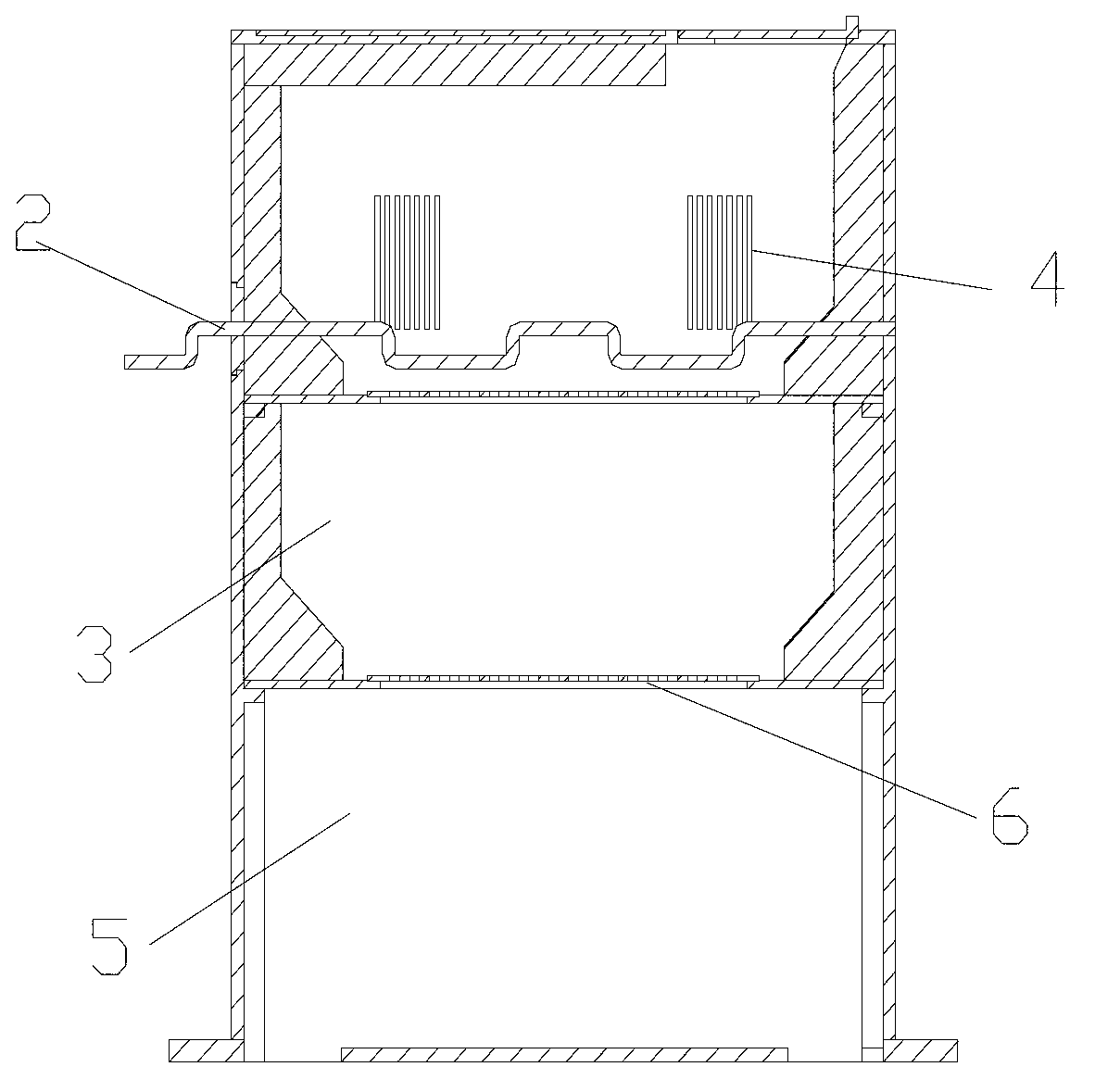

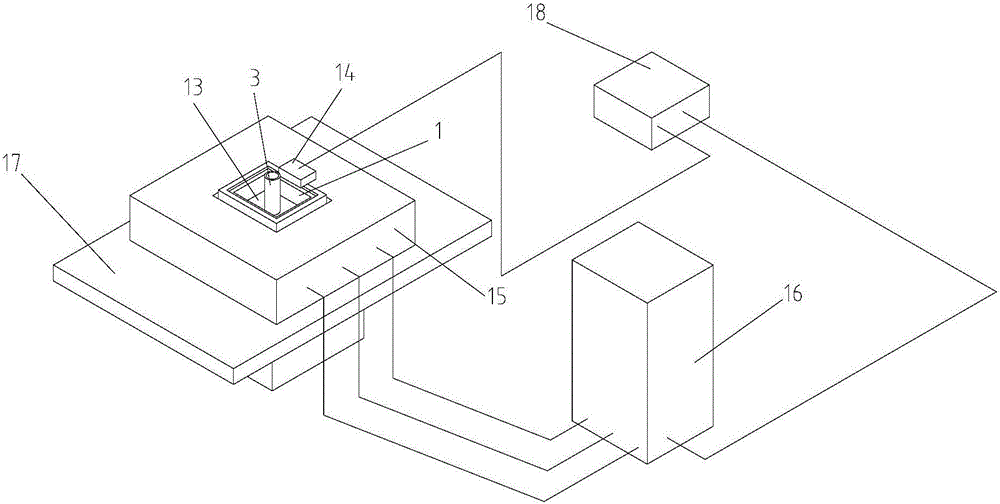

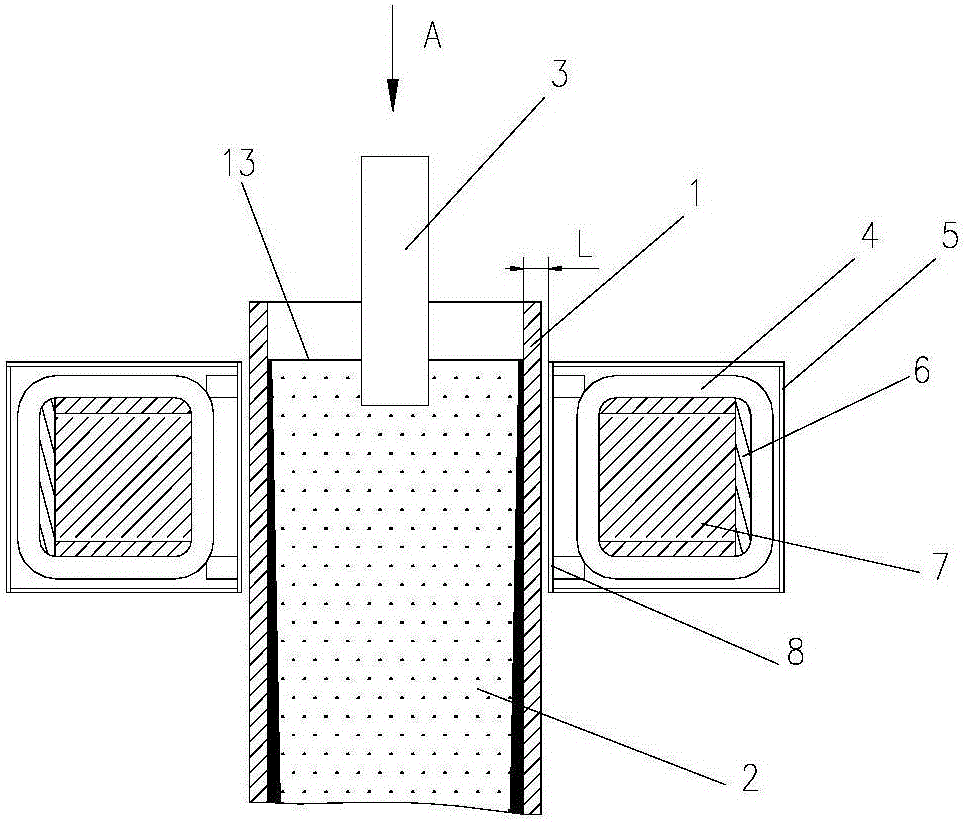

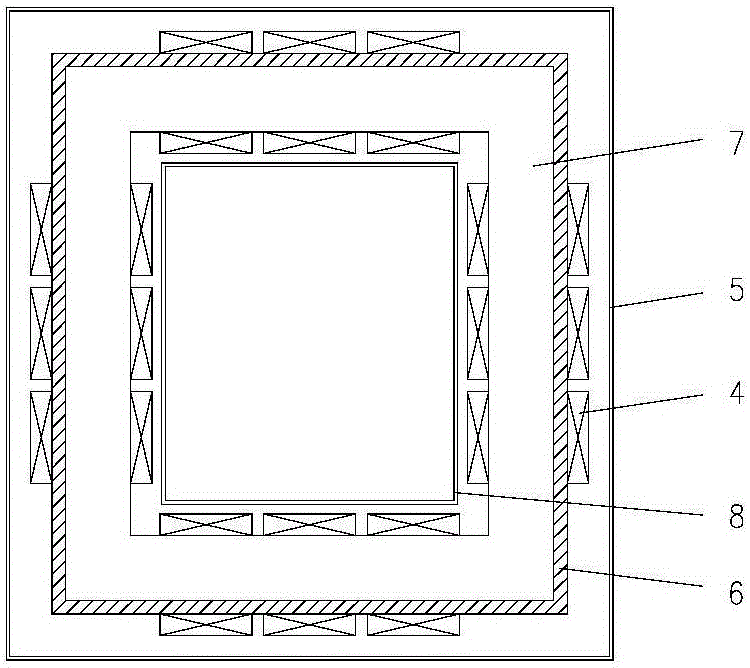

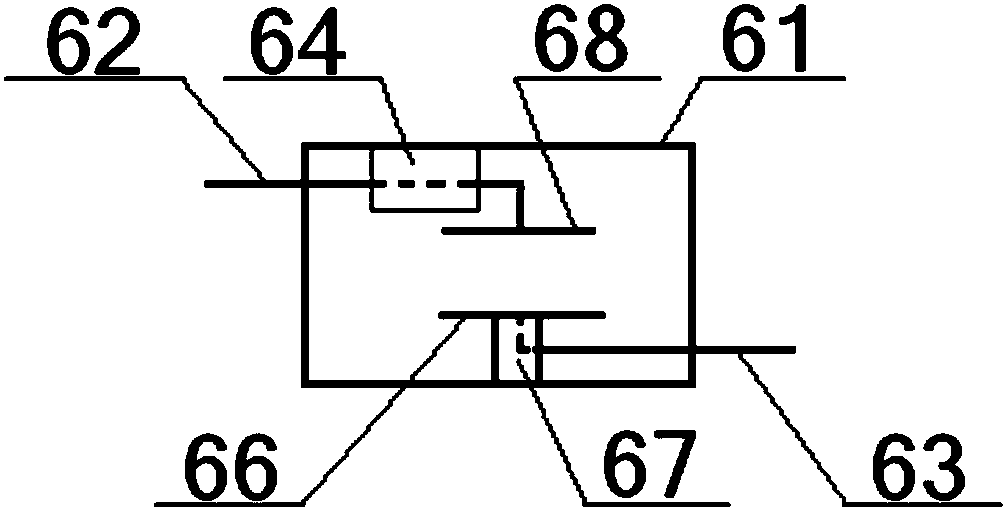

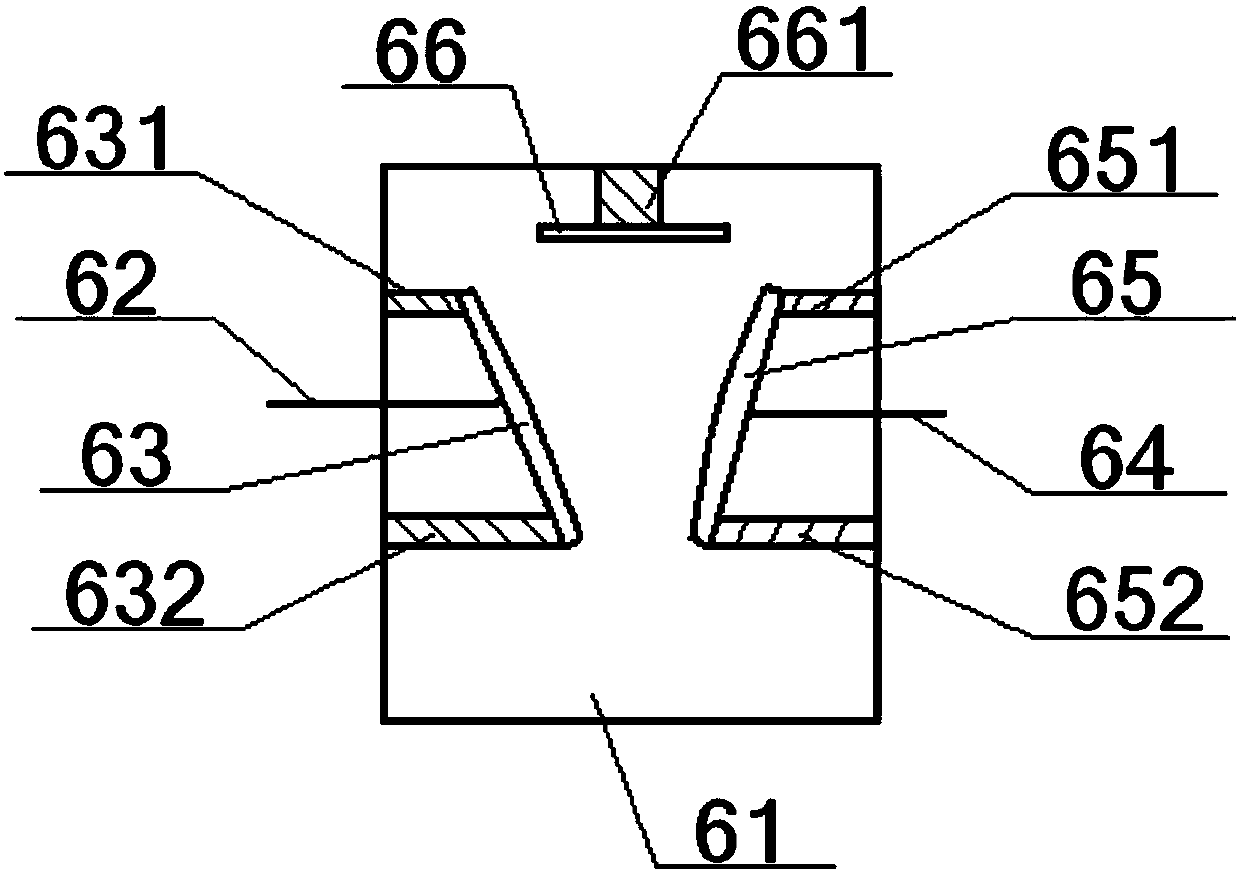

Electromagnetic stirring and flow control device technology for multi-mode bar plate continuous casting crystallizer

InactiveCN101549393AImprove metallurgical performanceAdded stirring functionElectromagnetic shieldingMolten steel

The invention relates to an electromagnetic stirring and flow control device technology for multi-mode bar plate continuous casting crystallizer, which includes respectively setting the inner arc induction apparatus and outer arc induction apparatus which are from electromagnetic stirring induction apparatus at two sides of the crystallizer copper plate, and molten steel passing through the induction apparatus and crystallizer copper plate. The inner arc induction apparatus and outer arc outer arc induction apparatus respectively set at least four magnetic field zone, and the magnetic field size and field direction of each magnetic field zone can be adjusted independently, and by changing the setup of magnetic field, single rotation stirring schema, electro-magnetism slowdown schema, electro-magnetism speedup schema, two zones rotation stirring schema and four zones rotation stirring schema can be combined into. The invention tentatively manufactures one set of multi-mode bar plate continuous casting crystallizer electromagnetic stirring and flow control device by employing slotless and magnetic shading technology, which well accounts for the difficulty of installation, greatly diminishes the alteration cost caused by increasing electromagnetic stirring, and also greatly increases the metallurgy effect of bar plate crystallizer electromagnetic stirring.

Owner:HUNAN ZHONGKE ELECTRIC

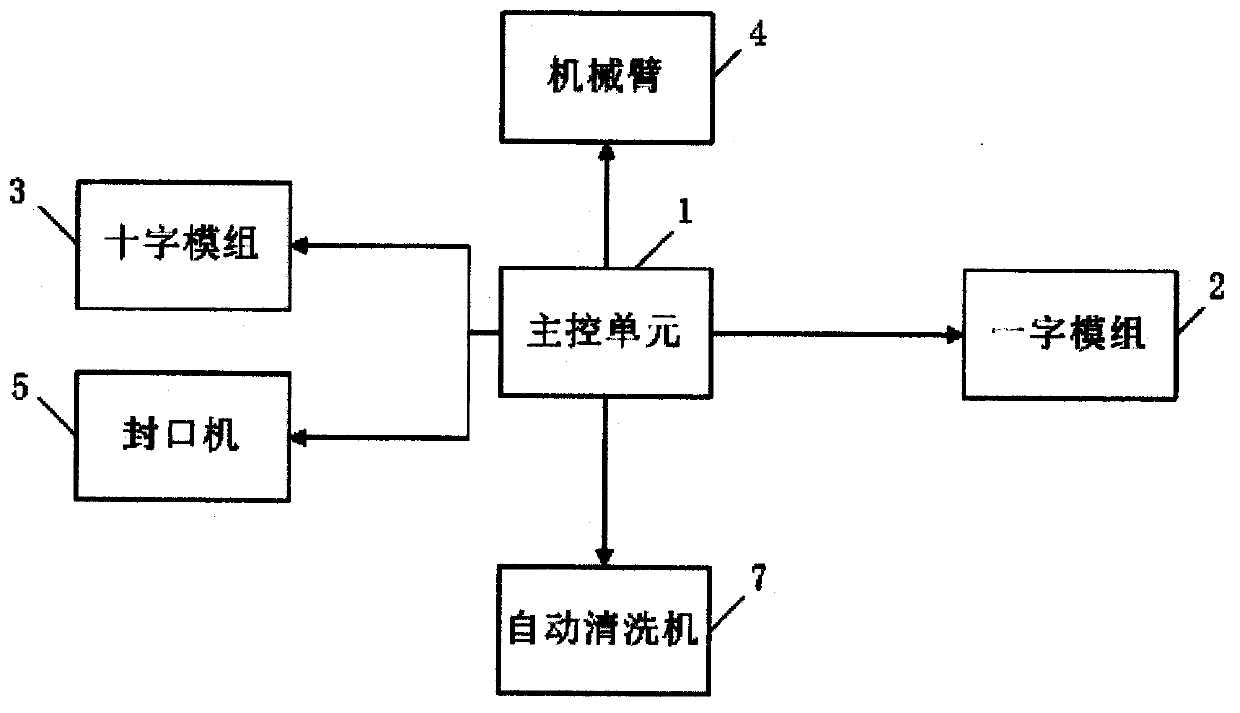

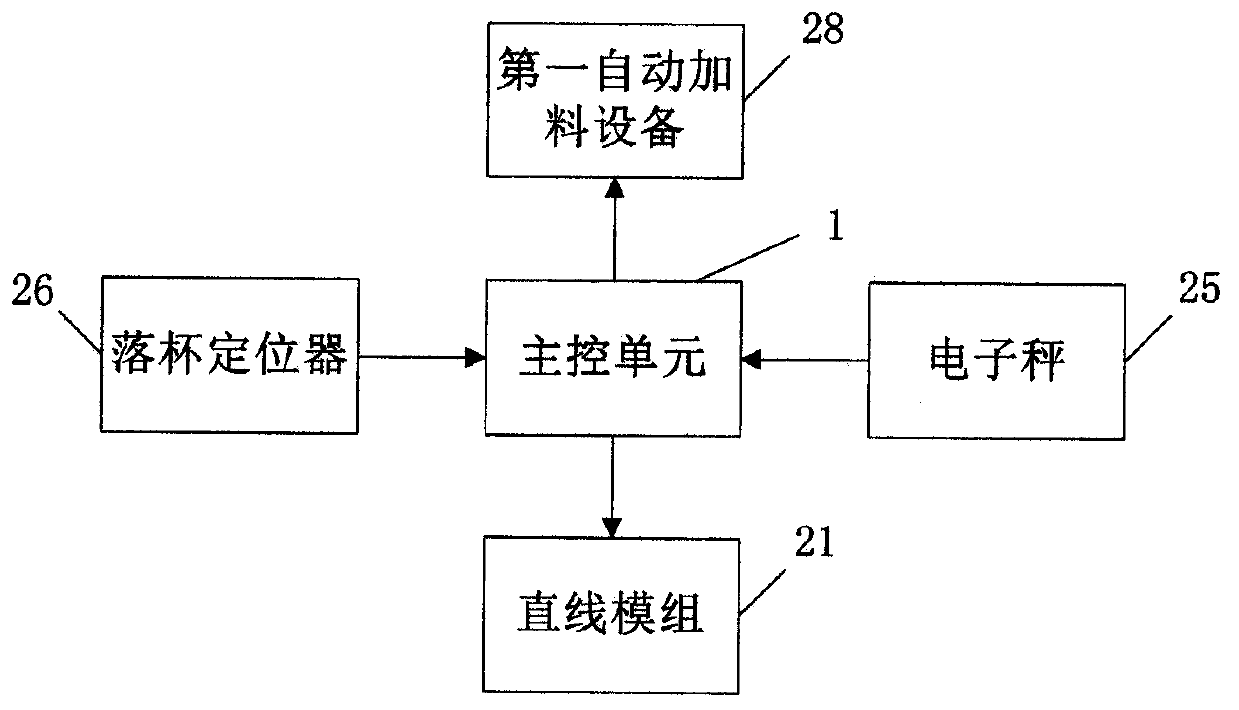

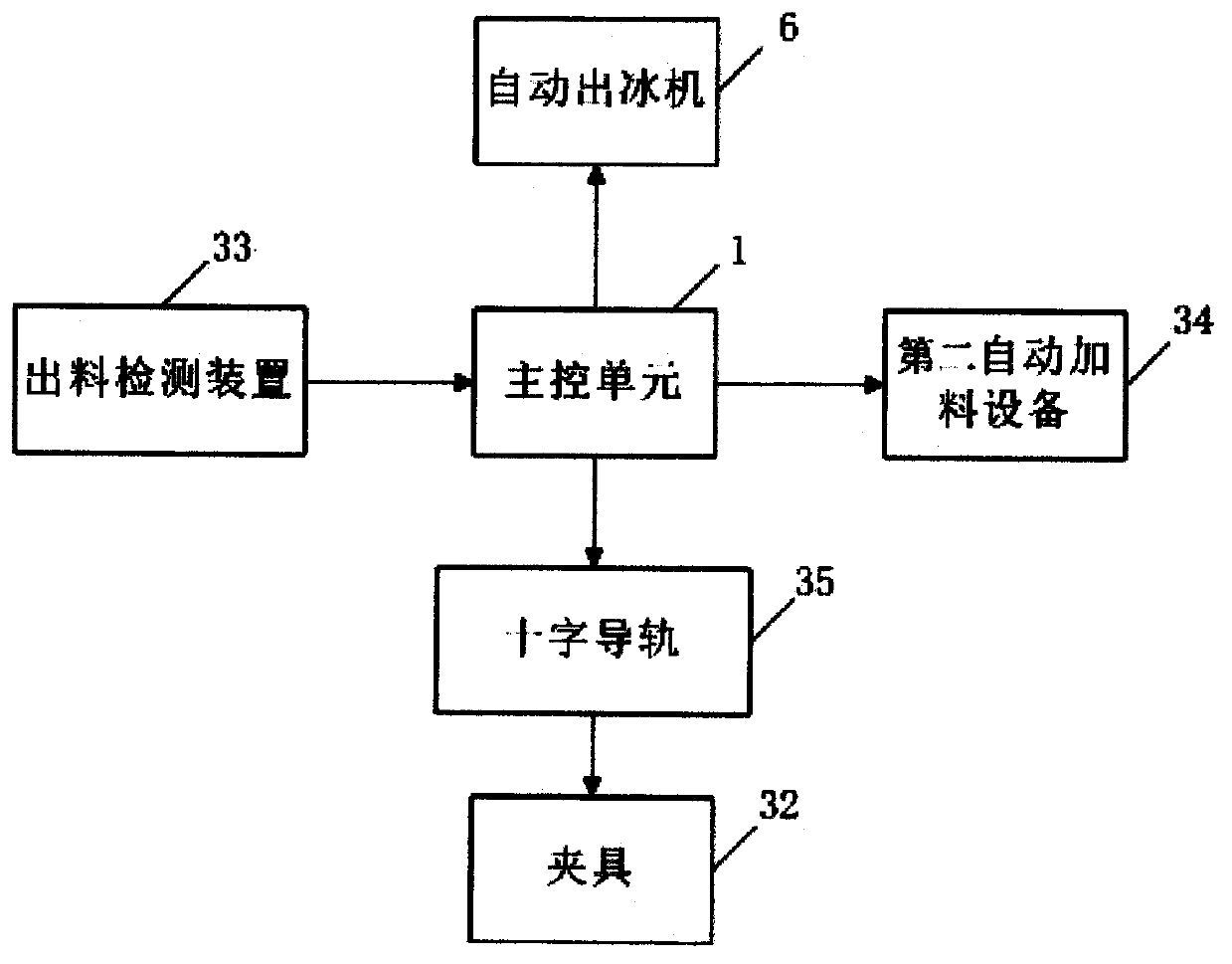

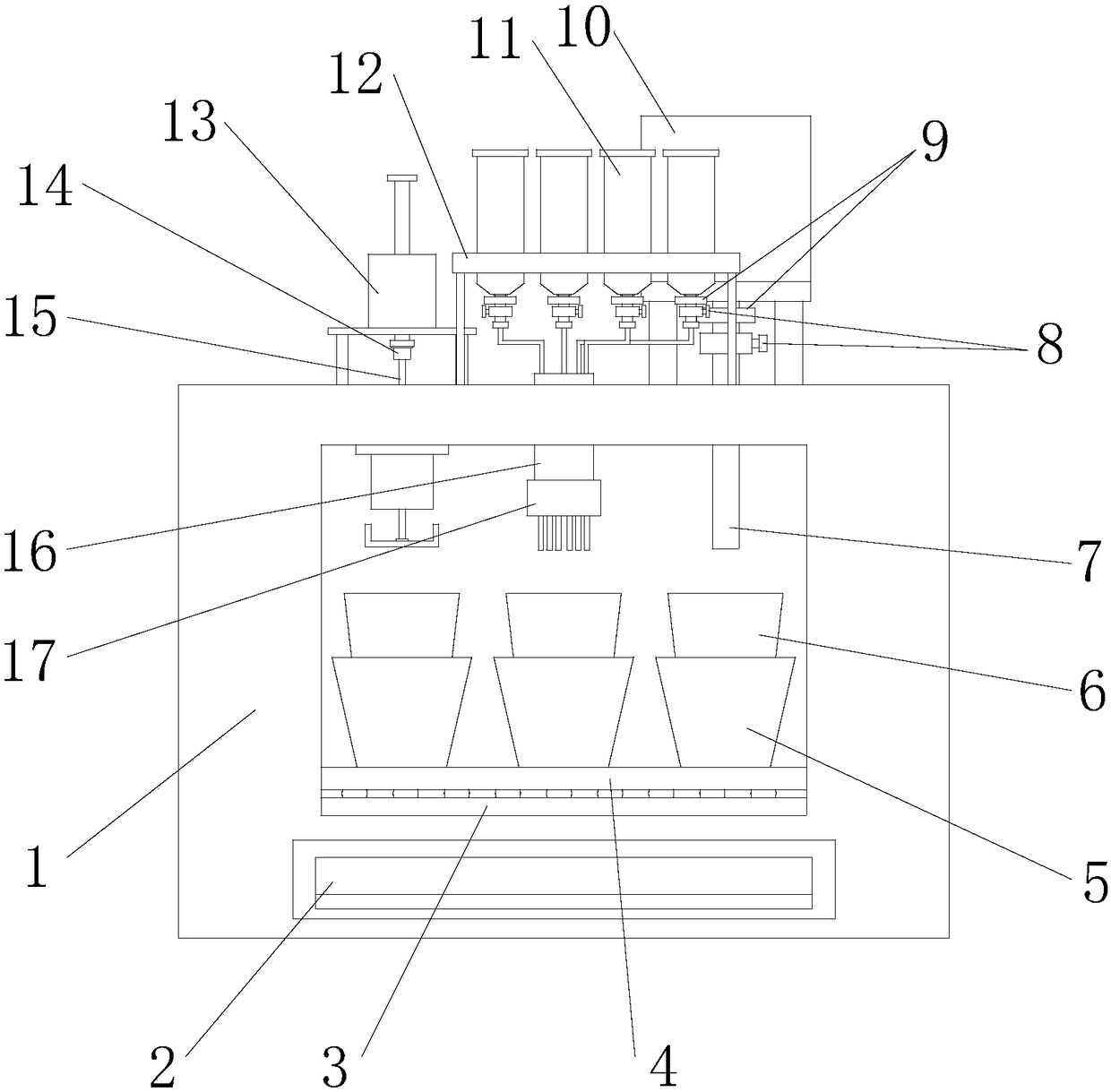

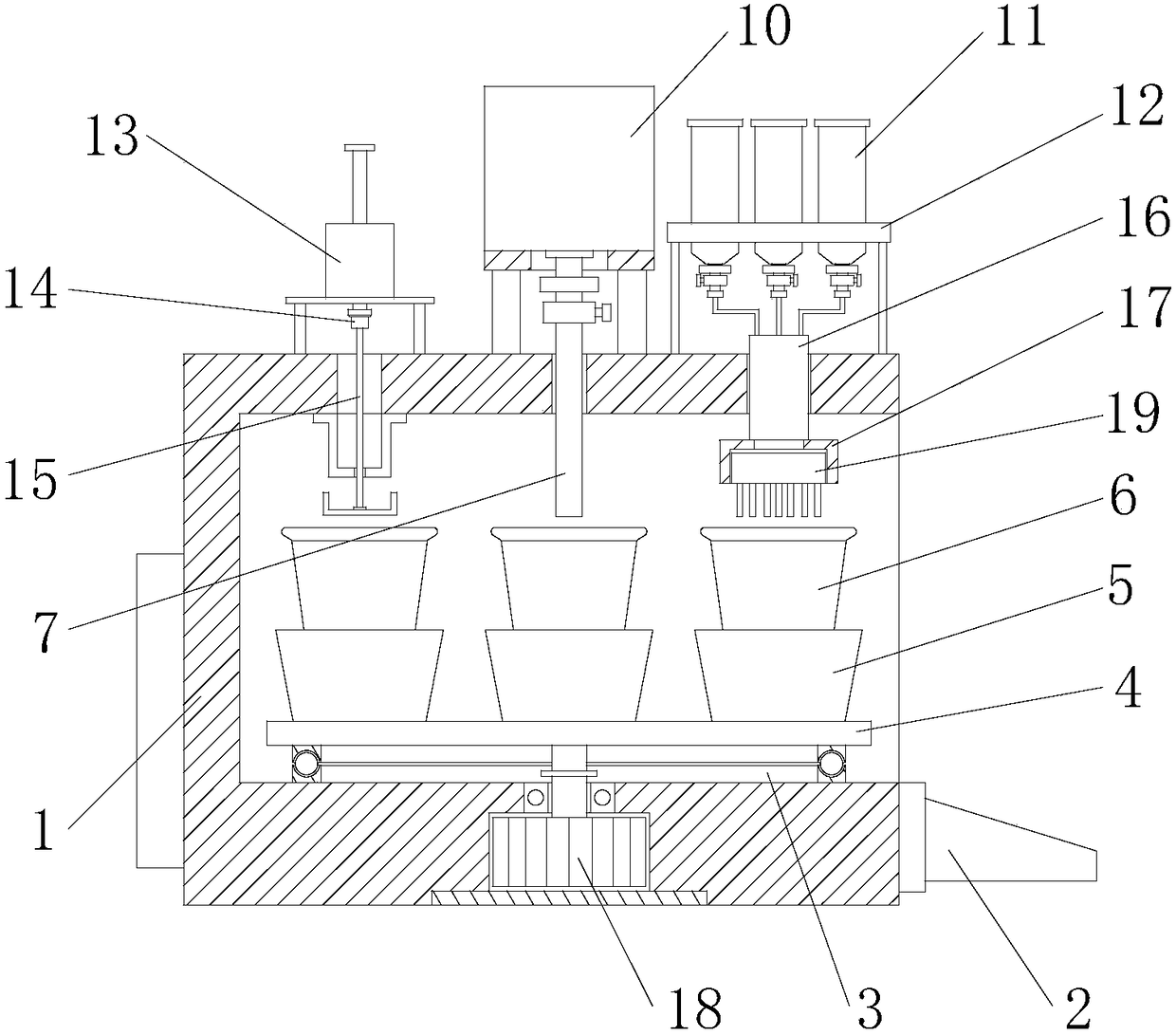

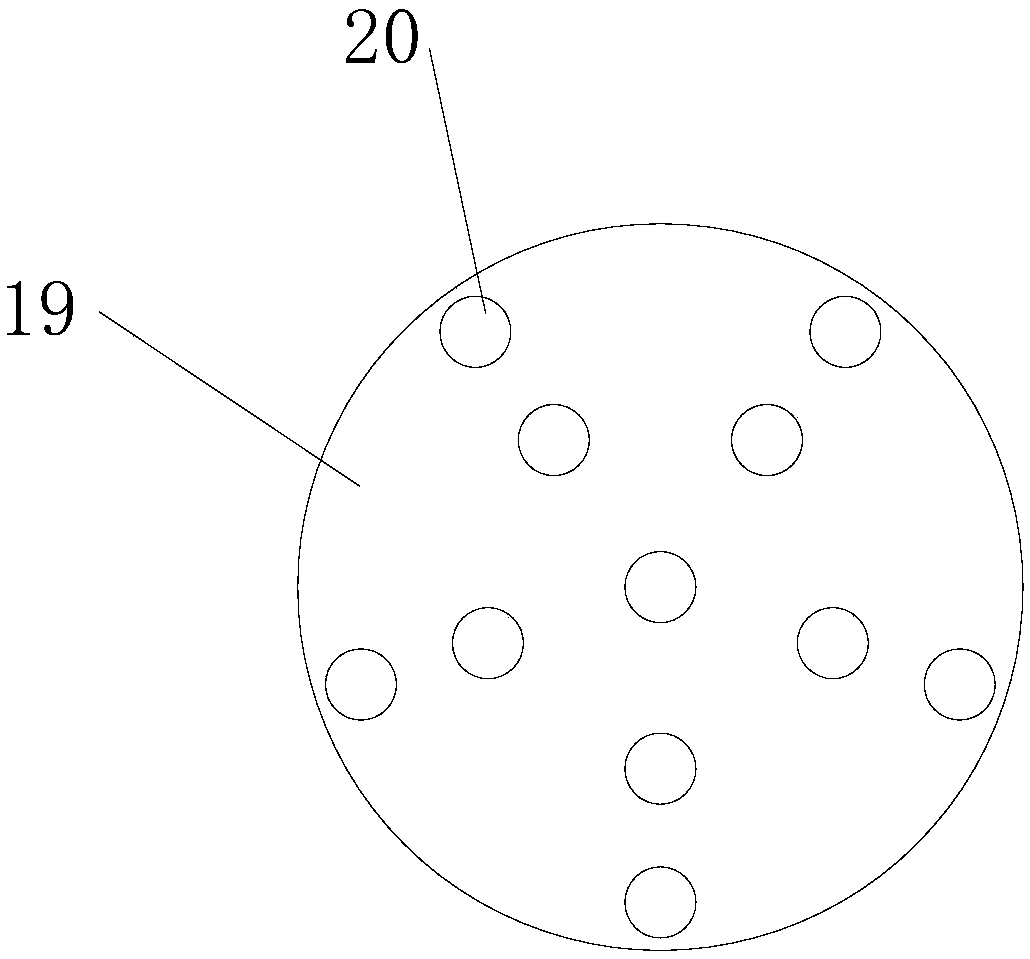

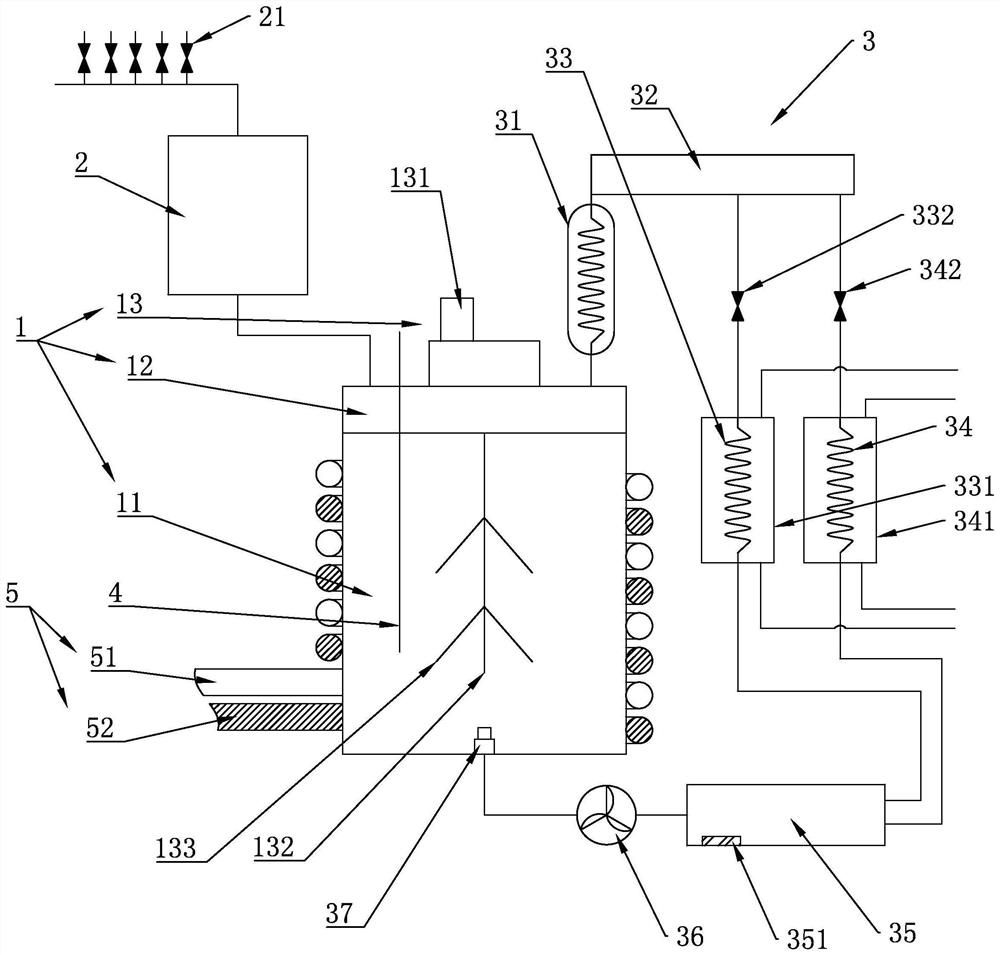

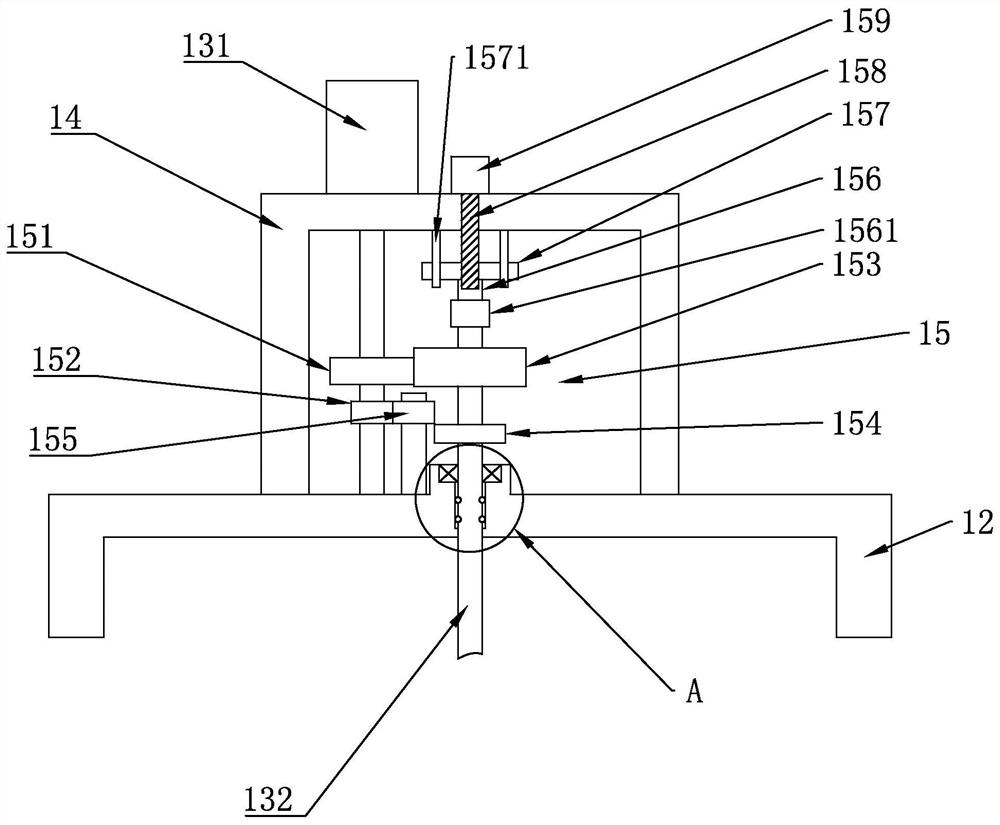

Fill-automatic milk tea production device and method

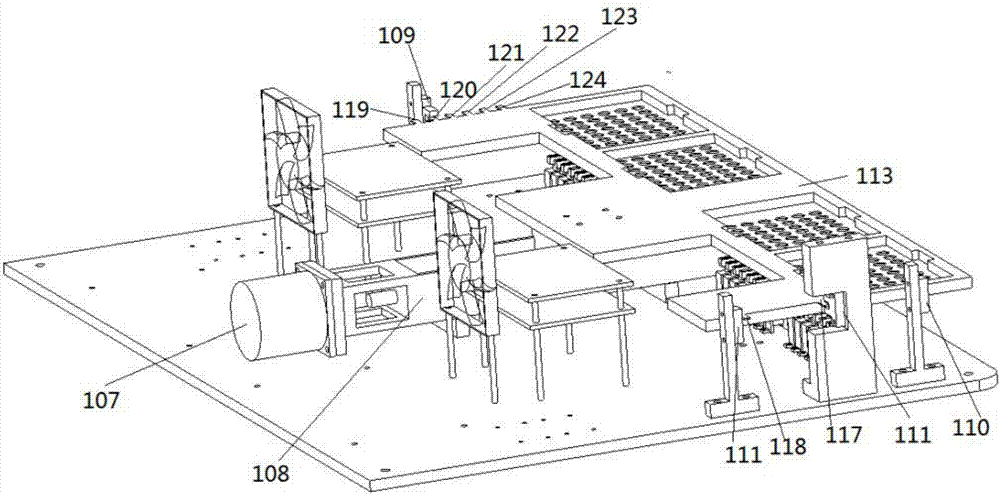

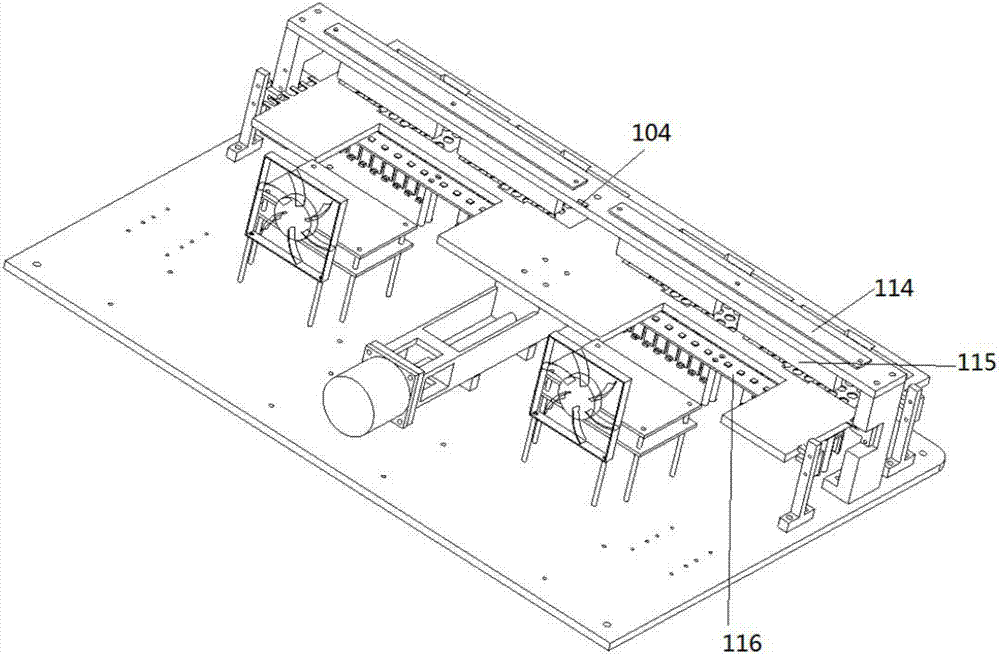

PendingCN110179337ACompact structureEasy to monitor injection volumeBeverage vesselsPackagingDissolutionEngineering

The invention provides a full-automatic milk tea production device and a method. The full-automatic milk tea production device comprises a main control unit, a straight-line-shaped module, a cross module, a mechanical arm and a sealing machine, wherein the straight-line-shaped module, the cross module, the mechanical arm and the sealing machine are controlled by the main control unit; the straight-line-shaped module is used for obtaining a finished product cup and quantificationally adding materials to the finished product cup; the cross module is used for obtaining a shaker and adding materials to the shaker; the mechanical arm is used for adding the mixture in the shaker to the finished product cup; and the sealing machine is used for sealing the finished product cup carrying the milk tea. The full-automatic milk tea production device is compact in structure, is convenient for monitoring the injection amount of materials in various milk tea production processes, solves the inconvenience of manually taking raw materials by spoons, increases a stirring function, and accelerates the dissolution and mixing of raw materials; the function of making multiple cups of milk tea one by oneis realized, the work efficiency is improved, and the number of employees is reduced.

Owner:刘伟利

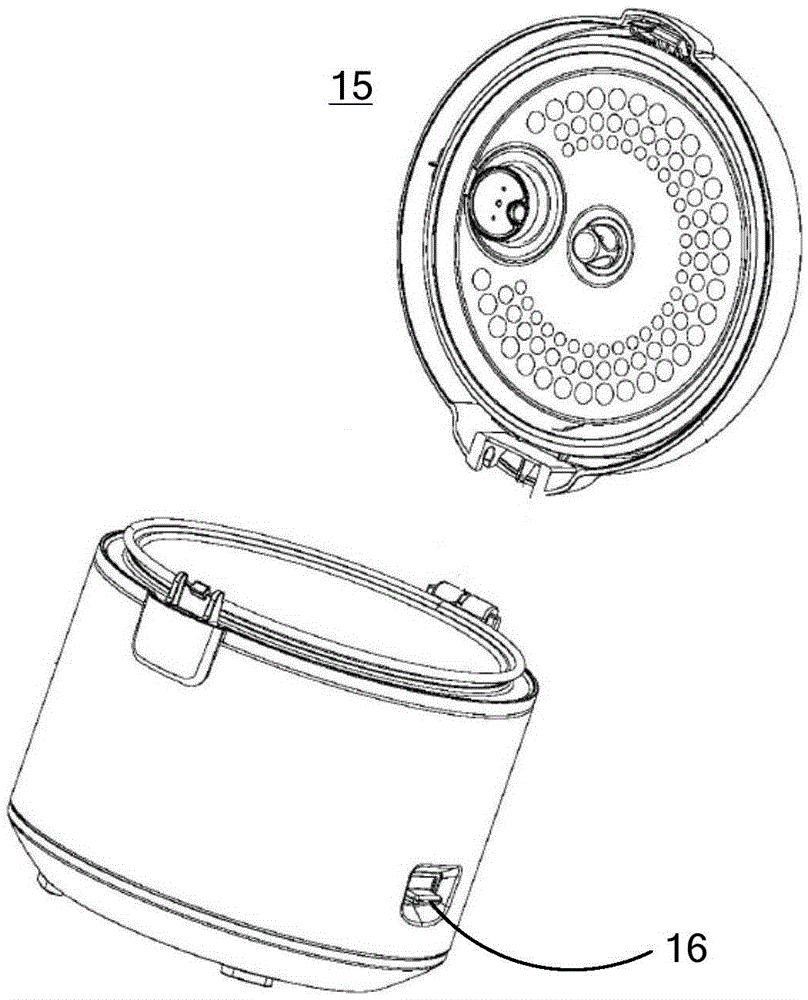

Food processer

The invention provides a food processer to solve the problem of existing food processors that a suitable menu is inconvenient to find. The food processor comprises a cooking pot and a processor body, wherein the cooking pot is used for accommodating food materials and processing the food materials, and the processor body is provided with a shell; the shell comprises a first shell body and a second shell body, a cooking pot installation part is arranged on the second shell in a defined mode, and the bottom of the cooking pot is placed in the cooking pot installation part. The food processor further comprises a touch screen type computer, wherein the touch screen type computer is arranged on the first side face of the first shell body and used for controlling the food processor through touch operation, the touch screen type computer further comprises a voice control system, and the voice control system is used for operating the touch screen type computer by receiving voice commands. Due to the fact that the touch screen type computer of the food processor comprises the voice control system, operation like looking for a menu can be executed conveniently through voice commands.

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

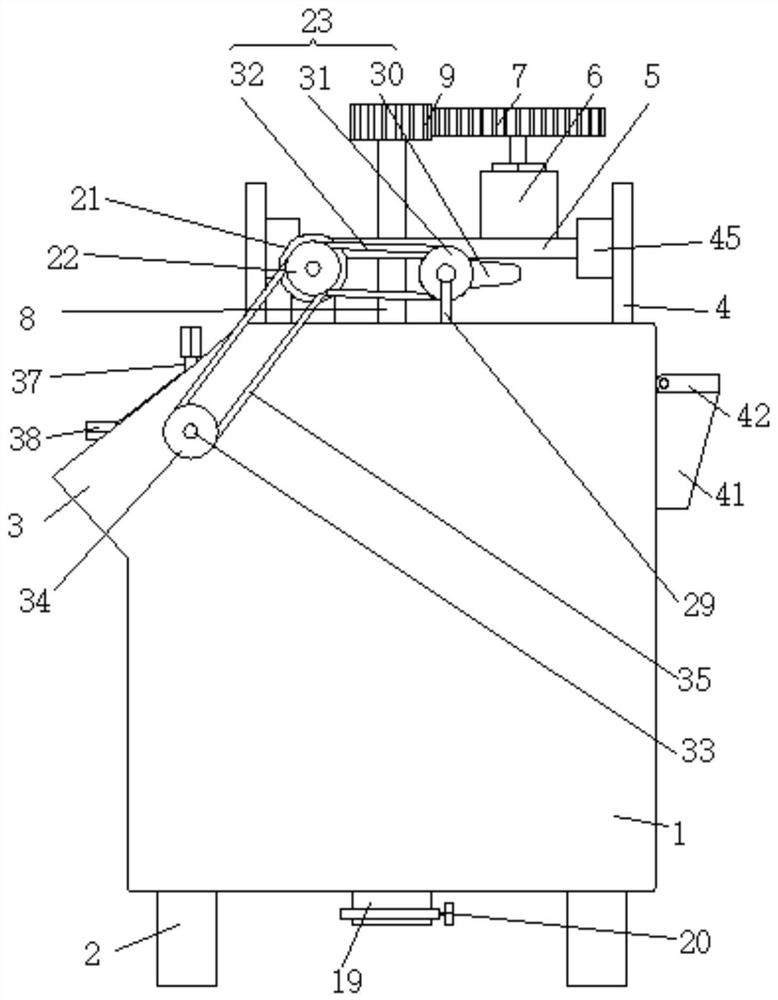

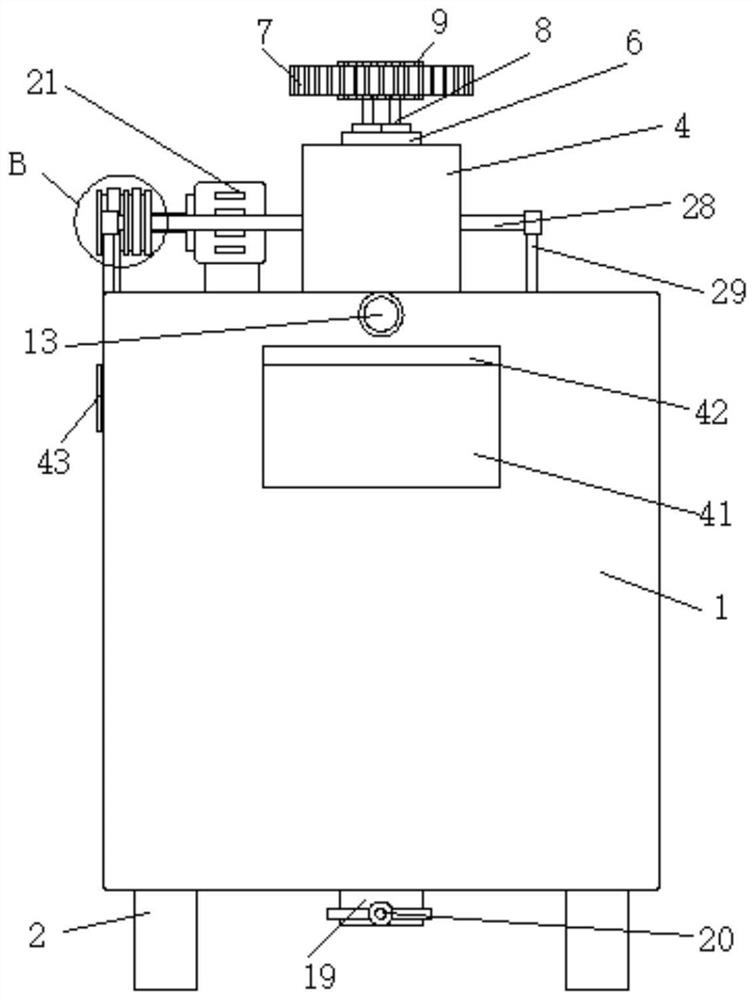

Environment-friendly refuse treatment tank

InactiveCN103193046AKeep moistEnough oxygenWaste collection and transferRefuse receptaclesTemperature controlSolar power

The invention relates to an environment-friendly refuse treatment tank which comprises a tank shell, a mixer, an insulation liner, and a fertilizer collection tank. The insulation liner above the fertilizer collection tank and the fertilizer collection tank are disposed in the tank shell. A double-layer filter plate is disposed at the bottom of the insulation liner. The mixer is disposed on the upper portion of the insulation liner. The side of the insulation liner and the side of the tank shell are provided with corresponding vent holes. The top of the tank shell is provided with a fertilizer entry. The sidewall of the fertilizer collection tank is provided with a fertilizer exit. Compared with the prior art, the environment-friendly refuse treatment tank has the advantages of reasonable design, simplicity in operation, convenience in demounting and carrying, attractive appearance and fine breathability, is well stable, and less susceptible to outdoor weather and environment changes. By temperature control by solar power and odor removal by ozone, novel techniques such as cutting function and mixing function are added, and the environment-friendly refuse treatment tank is more energy-saving and practical.

Owner:SHANGHAI JIAO TONG UNIV

Concrete slump detection device capable of regulating compaction plate

ActiveCN110231466AEvenly compactedPlay a self-locking effectMaterial testing goodsEngineeringExpansion joint

The invention discloses a concrete slump detection device capable of regulating a compaction plate. The device structurally comprises a bottom disk, a first guide rail, a movement frame, a slump cone,an importation hole, a rammer, an expansion link, a stay bar, a motor, a second guide rail and a measurement bar, wherein two sides of the bottom disk are independently vertically connected with thefirst guide rail and the second guide rail; the slump cone is arranged in the middle of the bottom disk; the top of the slump cone is provided with the importation hole; the slump cone and the movement frame are connected; the movement frame is installed on the first guide rail; the rammer is arranged above the slump cone and is connected with the stay bar through the expansion link; the stay baris installed on the second guide rail; the measurement bar is installed below the stay bar; and the motor is installed on the stay bar and is in transmission connection with the expansion link througha belt. The device has the beneficial effects that the connection position of the compaction plate and the expansion link is regulated to regulate a distance between the compaction plate and the inner wall of the slump cone, and therefore, concrete at different heights in the slump cone can be subjected to even compaction in an omnibearing way.

Owner:武汉鸿诚工程咨询管理有限责任公司

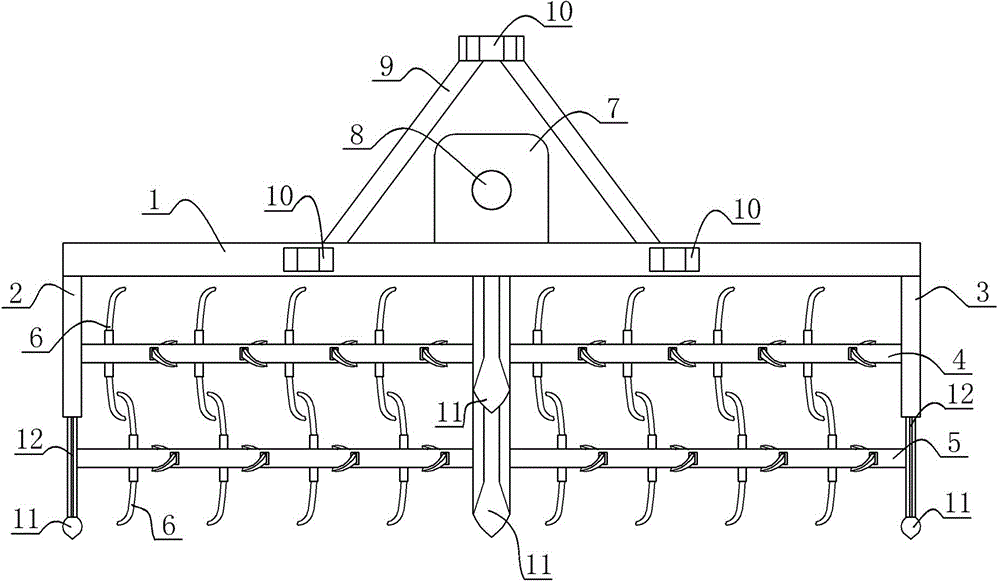

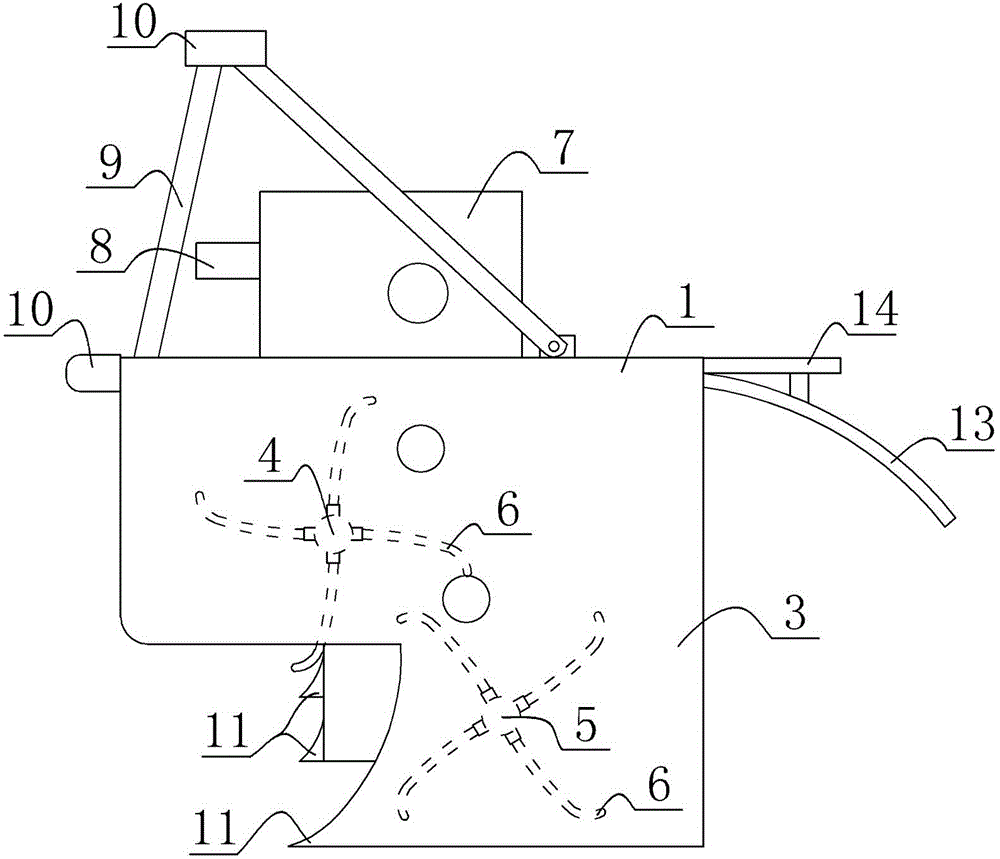

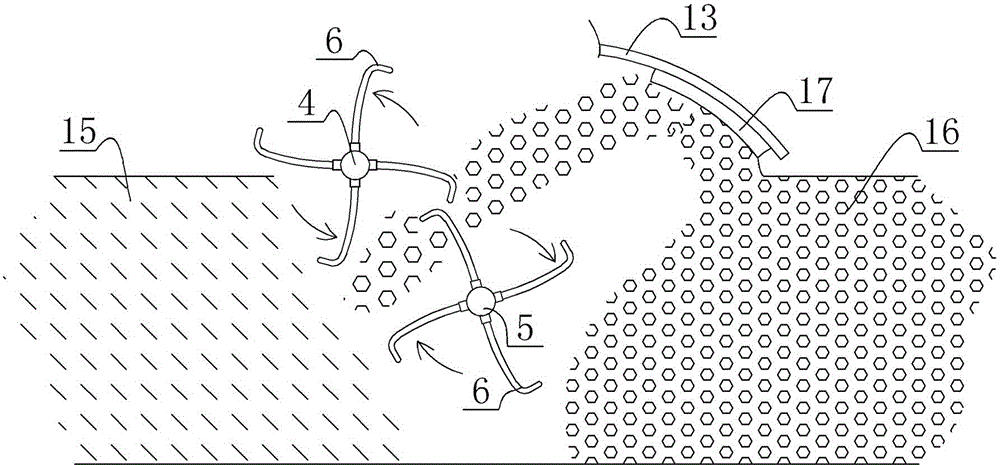

Deep rotary cultivator capable of mixing of deep soil and surface soil

The invention provides a deep rotary cultivator capable of mixing of deep soil and surface soil. The deep rotary cultivator comprises a frame, a transmission box, a left baffle and a right baffle, wherein at least three fixing buckles are arranged on the frame, and a connecting shaft is arranged on the transmission box. The deep rotary cultivator is characterized in that an upper rotating shaft and a lower rotating shaft are arranged on the left baffle and the right baffle; a plurality of soil cutters are fixed on the upper rotating shaft, and a plurality of soil cutters are fixed on the lower rotating shaft; a transmission mechanism is arranged in the transmission box, and is used for driving the upper rotating shaft to rotate forwards and the lower rotating shaft to rotate backwards; upper soil and the deep soil in a field are mixed through the soil cutters which are arranged on the upper rotating shaft and the lower rotating shaft and rotate in different directions, so that deep cultivation of the field is achieved. The deep rotary cultivator provided by the invention not only facilitates cultivation of the deep soil in the field, but also effectively achieves the mixing of the deep soil and the surface soil in the field, so that the cultivated soil is more fertile, and crop growth is better facilitated; the structure is simple and reasonable, and the benefits are remarkable, so that the deep rotary cultivator can be conveniently applied and promoted.

Owner:张正泉

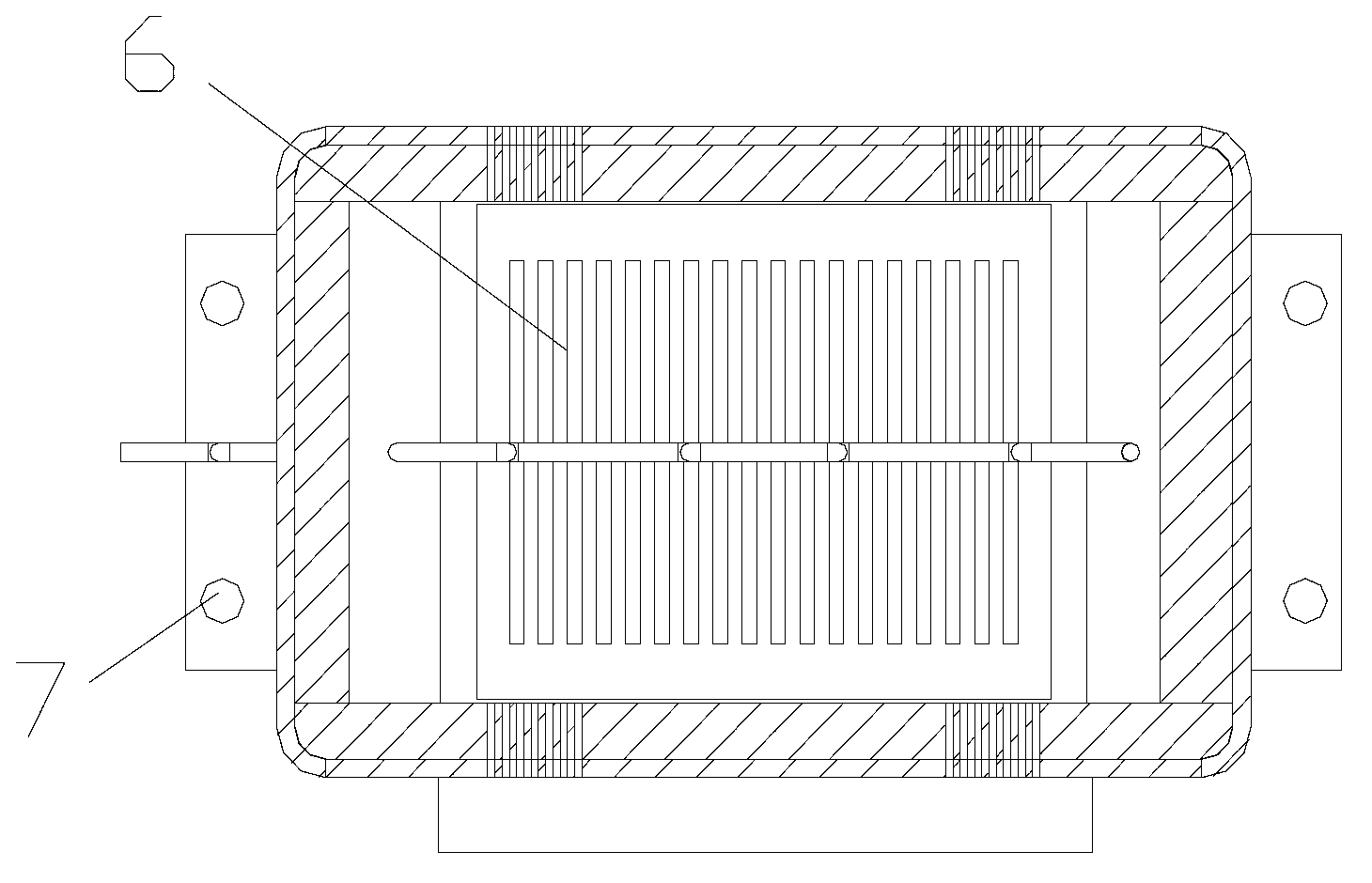

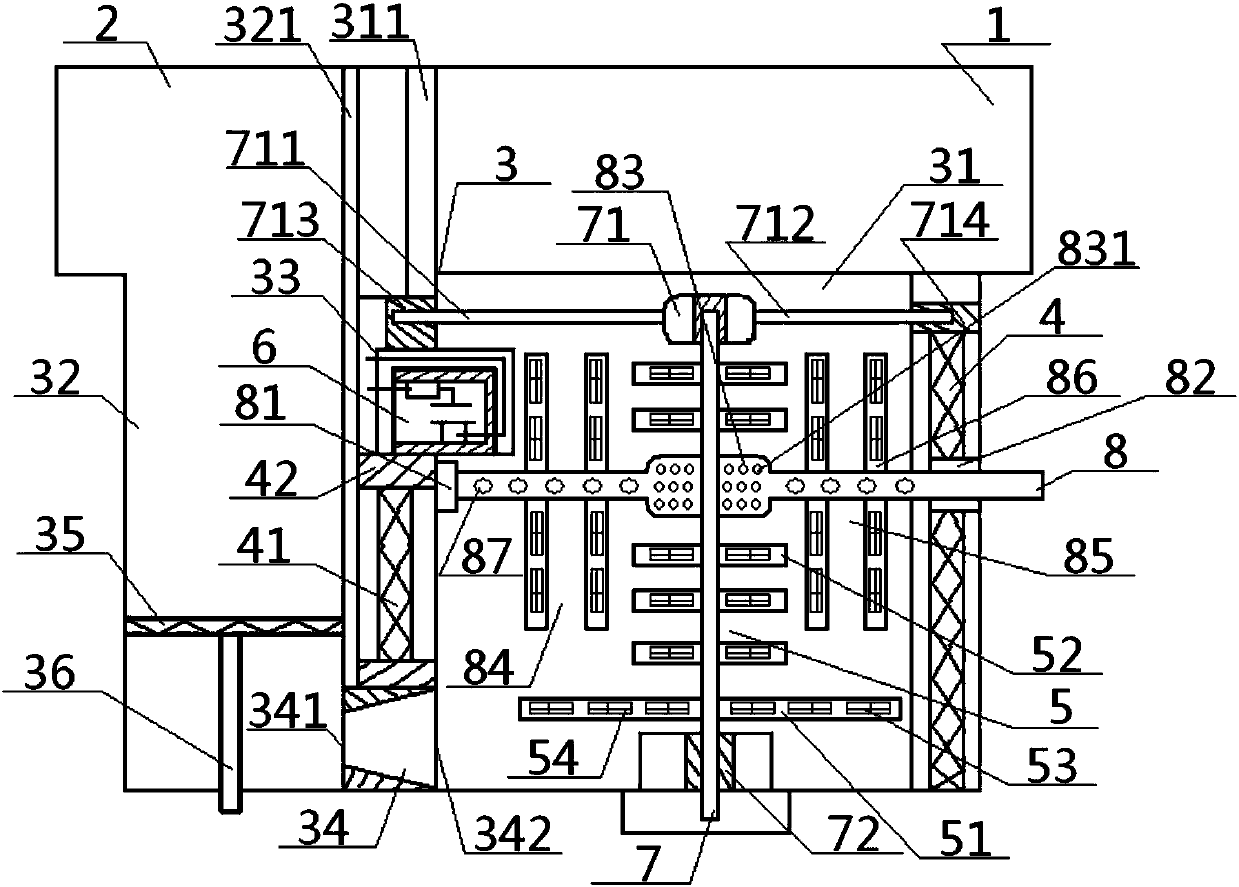

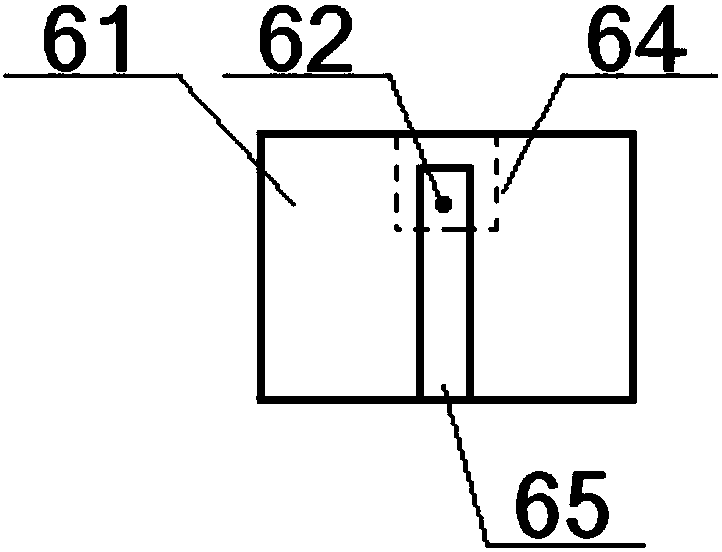

Magnetic shielding type multi-mode meniscus electromagnetic stirring system and method for continuous casting of square and round billets

ActiveCN105728679ARetain the electromagnetic stirring functionRealize the function of electromagnetic stirringControl systemEngineering

The invention provides a magnetic shielding type multi-mode meniscus electromagnetic stirring system and method for continuous casting of square and round billets. The system comprises a meniscus electromagnetic stirrer and a variable-frequency power source control system. The variable-frequency power source control system is connected with a tap of a coil of the meniscus electromagnetic stirrer to provide a variable-frequency power source for the meniscus electromagnetic stirrer. A meniscus electromagnetic stirring mode or a crystallizer stirring mode is realized by changing of a phase sequence and a phase angle of current in the coil. The meniscus electromagnetic stirring mode comprises two submodes enabling molten steel to form a first circulation area and a second circulation area respectively. The crystallizer stirring mode is selected for stirring steels high in internal quality requirement, and the meniscus electromagnetic stirring mode is selected for stirring steels high in superficial and under-skin quality requirement. The stirrer is free of limits of mounting space and mounting position, surface quality problems of cast billets are effectively solved, and excellent metallurgical effects of any cross sections and steels can be achieved.

Owner:HUNAN ZHONGKE ELECTRIC

Self-cleaning waste water pipe rack

InactiveCN107830304AAvoid cloggingIncrease intensityPipe heating/coolingPipe elementsFixed bearingWastewater

The invention discloses a self-cleaning waste water pipe rack. A stirring main shaft in the pipe rack drives a main stirring disc and secondary stirring discs to longitudinally stir sewage and waste water, such that pollutants are smashed and dispersed, meanwhile, a gas pipe rotates around a fixed bearing to drive and overturn a hollow body and vertical discs to transversely stir the sewage and the waste water, such that the smashing and dispersing effects of the pollutants are enhanced. In addition, overturning air pores and pipe air pores can outward spray gas during rotation to enhance a stirring capacity for the pollutants, water passing holes can reduce the resistance of the sewage during movement, and cross-shaped reinforcing ribs can avoid blockage of the water passing holes by thepollutants. The self-cleaning waste water pipe rack in such design not only can perform longitudinal and transverse stirring and has higher stirring and smashing functions, but also can realize dispersing by heating, is better in dispersing and uniformizing effects and is favorable for re-discharging the processed sewage and waste water.

Owner:李秀青

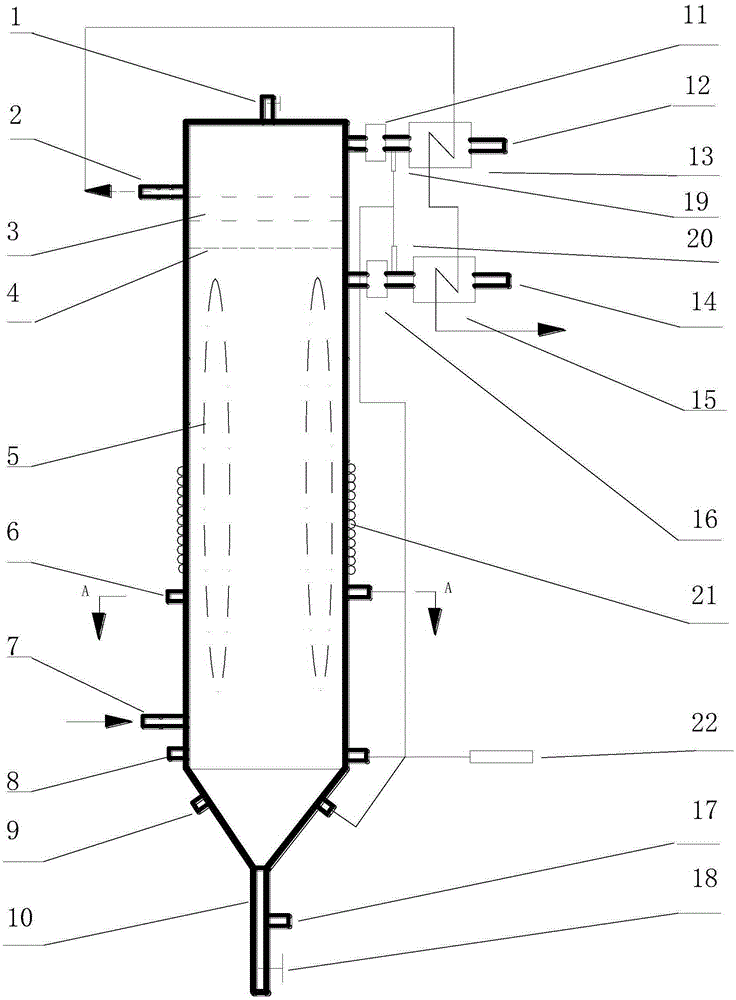

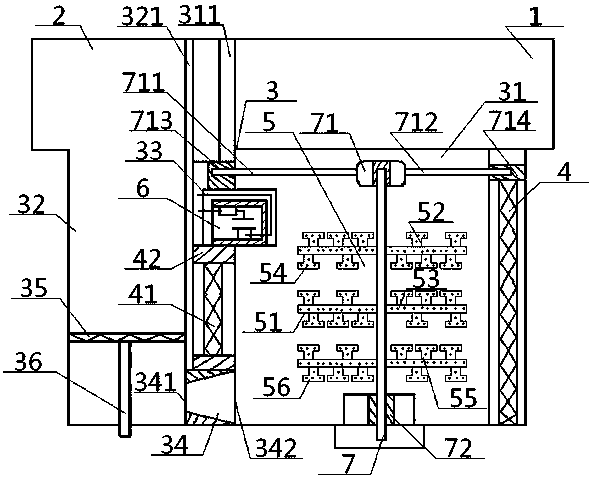

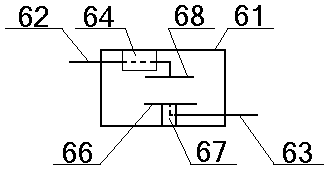

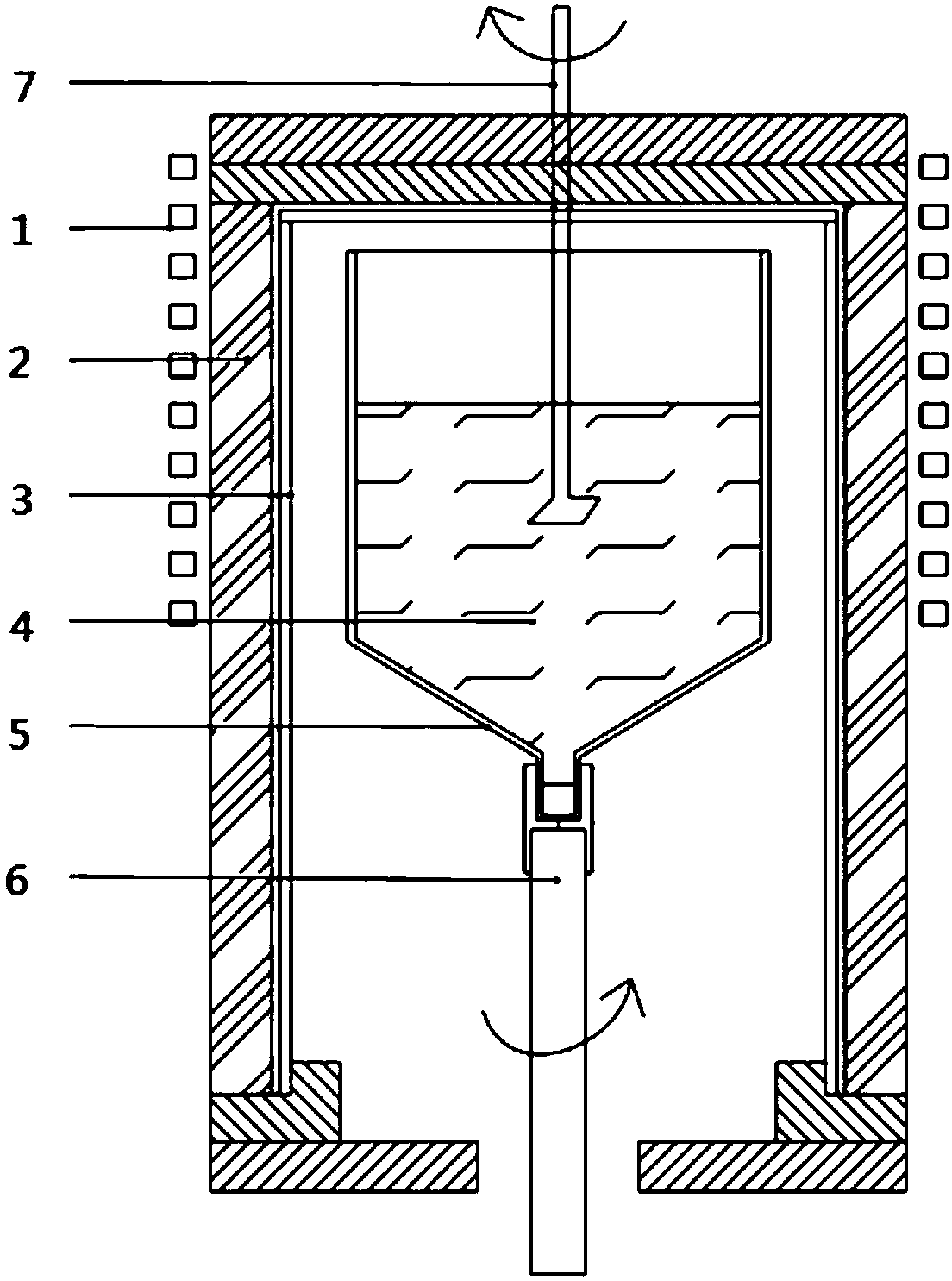

Efficient gas-liquid reactor

InactiveCN102580632AAdequate responseImprove responseChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesGas liquid reactionProcess engineering

The invention relates to an efficient gas-liquid reactor, which comprises a reactor body and a gas inlet pipe, wherein an agitation motor is arranged below the reactor body, a motor shaft of the agitation motor extends into the reactor body, a cover-shaped turntable which is positioned in the reactor body is installed at the upper end of the motor shaft, a group of air holes are produced in the cover body of the cover-shaped turntable, the gas inlet pipe is coaxially sleeved on the motor shaft, and the gas outlet of the gas inlet pipe is positioned in the cover-shaped turntable. The efficient gas-liquid reactor provided by the invention has a reasonable design and a simple structure, is easy to produce and has high practicability, the reactor is added with the cover-shaped turntable which has an agitation function, a plurality of air holes are arranged in the cover-shaped turntable and can produce a large quantity of small bubbles during the rotation process, so the gas-liquid contact surface area for unit gas quantity is greatly increased, the gas-liquid reaction speed is accelerated, and the reaction efficiency is improved.

Owner:TIANJIN UNIV OF SCI & TECH +1

Method for preparing oxygenous fuel by coal synthesis gas slurry bed

InactiveCN105289423AIncrease reaction spaceAdded stirring functionLiquid carbonaceous fuelsChemical/physical processesSlurryCoal

The invention relates to a method for preparing oxygenous fuel by a coal synthesis gas slurry bed. According to the method, a solid catalyst and inert liquid molten paraffin are placed in a slurry bed reactor from the bottom to the liquid level of the reactor, synthesis gas tangentially and swirlingly enter the slurry bed reactor and reacts in a bubble form to form a gas, liquid and solid fluidized form, then the obtained product is processed by a gas-liquid separator and a heat exchanger and the processed product is discharged from an outlet; cold water enters the reactor from the lower part, a natural convection recirculation zone is formed on the inner surface of a membrane water cooled wall, heat is absorbed by the membrane water cooled wall, and then the obtained product is discharged by the heat exchanger through a high-temperature hot water outlet of the reactor. The method adopts a plurality of spray nozzles to enable slurry to take the swirling motion so as to enable bubbles to spirally ascend, thereby reinforcing a stirring function and increasing contact time with slurry by 1.2 to 1.8 times; moreover, temperature difference of the slurry is between 4 DEG C and 8 DEG C, so that reaction efficiency of the reactor is greatly improved.

Owner:TAIYUAN UNIV OF TECH

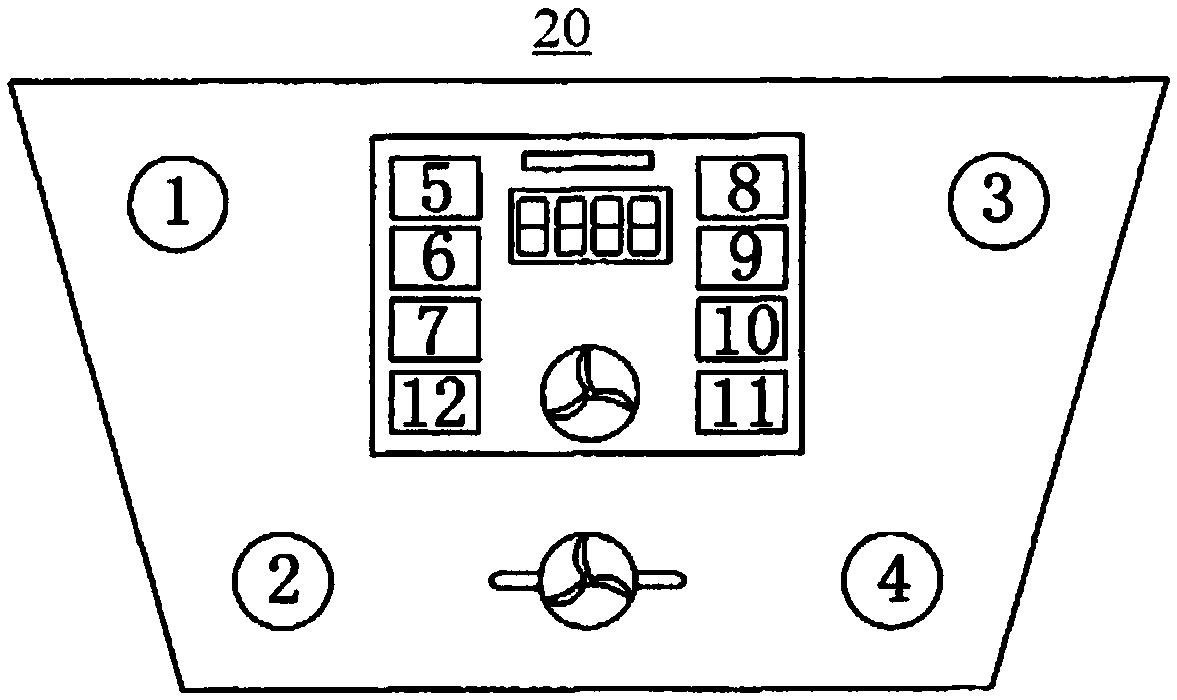

Milk tea manufacturing all-in-one machine

PendingCN108261082ACompact structureEasy to monitor usageBeverage vesselsCircular discOperation mode

The invention discloses a milk tea manufacturing all-in-one machine, which comprises a box body frame, a touch display screen, a slide groove circular ring, a placement circular disc, a fixing tube, apaper cup, a drainage pipe, a miniature electric regulating valve, a flow rate monitor, a heating water tank, a raw material containing tube, a placement plate frame, a linear motor, a motor, a slender rod, a round pipe, a connecting round frame, a driving motor, a round rubber plug and a plug hole. The structure is compact; the consumption of the milk tea powder raw materials and the injection quantity of boiling water can be conveniently monitored; the problem of manual spoon holding raw material taking inconvenience can be solved; the stirring function is added; the raw material dissolution is accelerated; the function of continuously manufacturing a plurality of cups of milk tea one cup by one cup is realized; the work efficiency is improved; the employed person number is reduced; a plurality of hole paper cups are sequentially put into the corresponding fixing tube; by using the operation mode, the function of continuously manufacturing a plurality of cups of milk tea one cup byone cup is realized; the work efficiency is improved; the employed person number is reduced.

Owner:黄毅

Sewage discharge pipeline

InactiveCN107724498AExpand strength and scopeGood dispersion and homogenization effectSewerage structuresSewer cleaningDecompositionThermal energy

A sewage pipeline, the stirring spindle drives the stirring unit to rotate to drive the horizontal plate and the stirring extension part to stir the sewage and waste water. The stirring extension part includes a vertical pipe and a horizontal pipe, and the medicine outlet hole of the plate and the medicine outlet hole of the part can be supplemented and decomposed online The medicine and heating device can provide heat energy to the mixing room. The connecting room and connecting port are conducive to the re-discharge of treated sewage and wastewater. The temperature sensor installed in the side wall of the mixing room can monitor the temperature in the mixing room. This design not only has a strong mixing and crushing function, can be heated and dispersed, and has a better dispersion and homogenization effect, but also can supplement and decompose drugs online, which is beneficial to the re-discharge of treated sewage and waste water.

Owner:陈征

Steam hot compress medical device

InactiveCN107789185AImprove uniformityImprove medical outcomesBathing devicesCartridge heaterPharmaceutical formulation

A steam hot compress medical device, in which the driving tube drives the top dispersing plate, the bottom baffle and a plurality of middle dispersing inclined tubes to rotate, so as to stir the liquid medicine and medicine vapor, and the top air hole and the middle air hole are in the rotating state The airflow injected from the bottom will form a vortex to enhance the stirring function. At the same time, the heater heats the drug solution in the blending chamber, and the temperature sensor monitors the temperature in the blending chamber. The design can not only improve the uniformity of the drug vapor concentration and have a better medical effect, but also have a better stirring effect and stronger adjustability.

Owner:李秀青

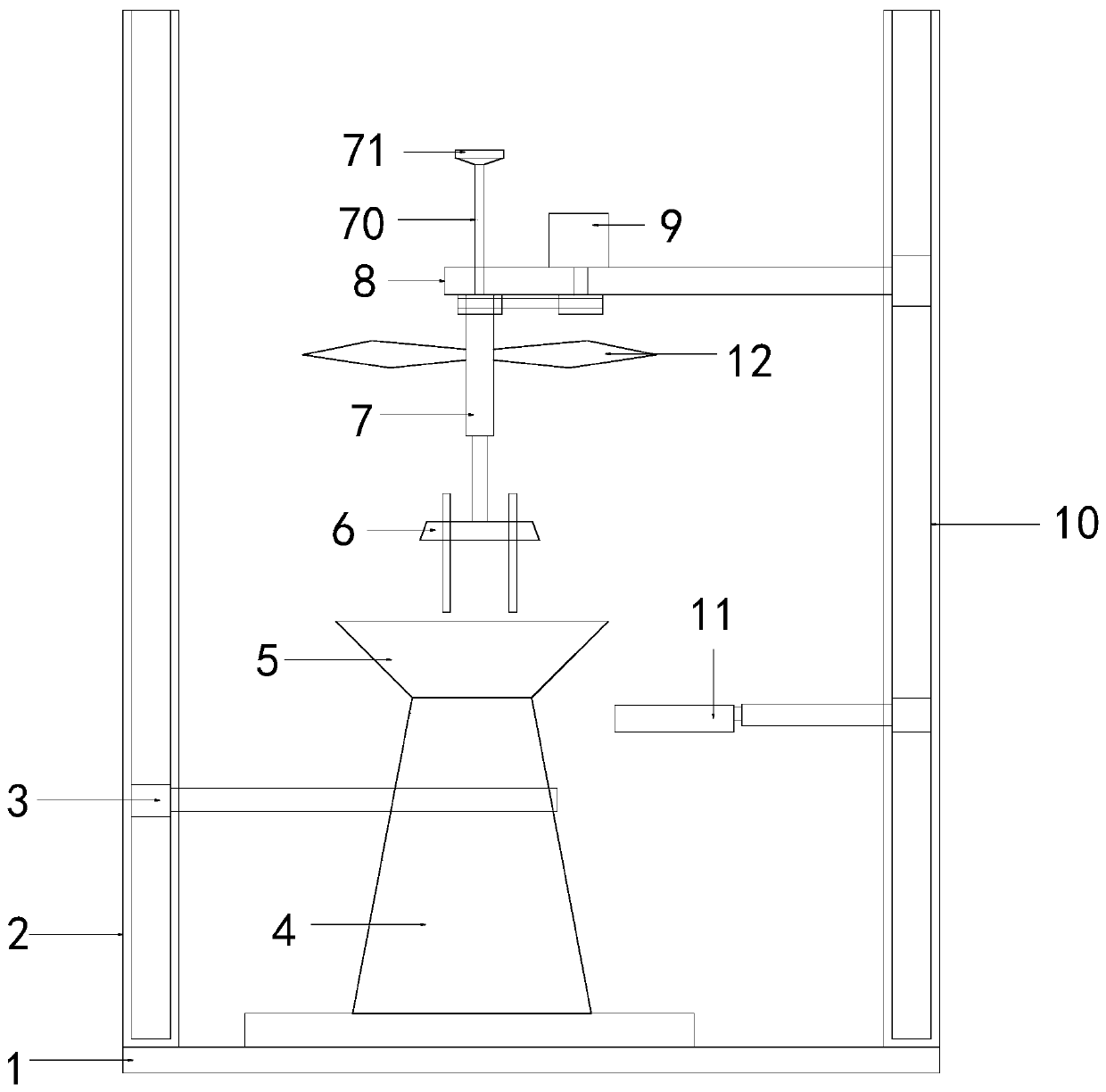

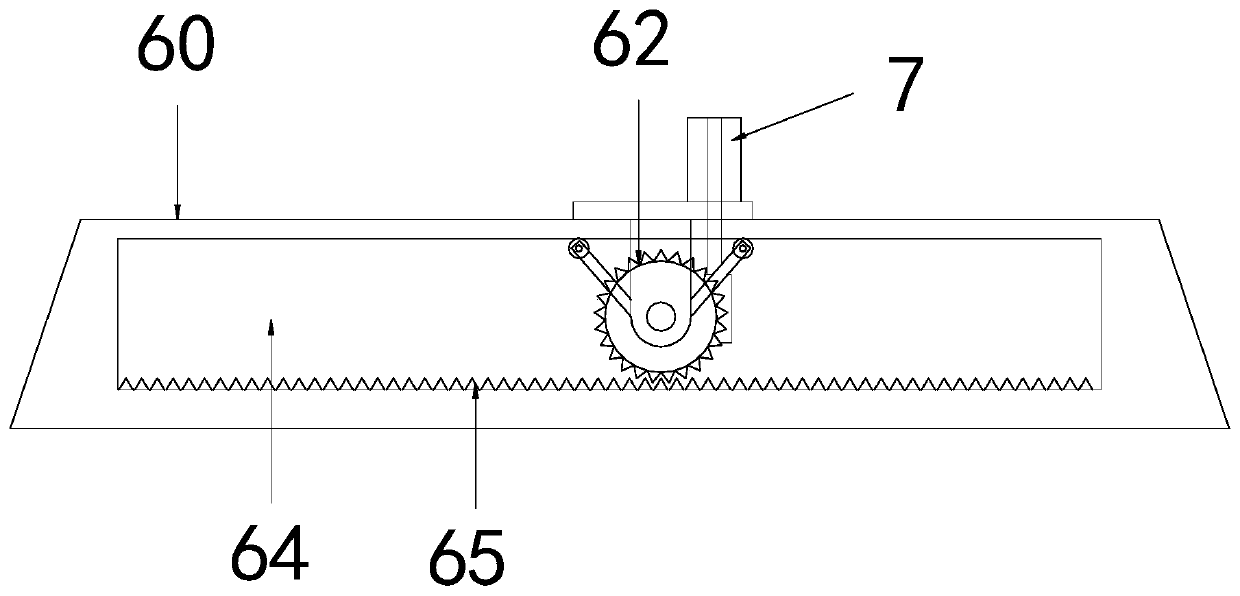

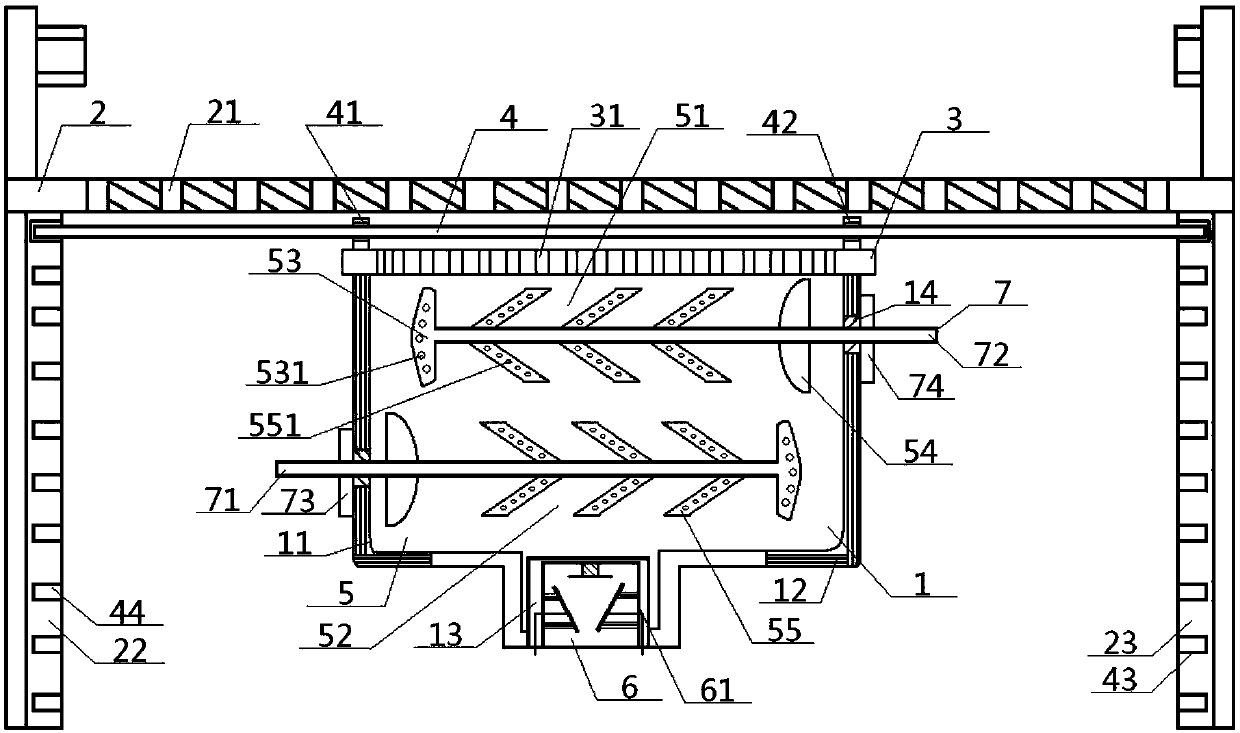

Lifting flotation machine for graphite production

InactiveCN112246447AFacilitate mixed reactionsPromote generationFlotationGear wheelElectric machinery

The lifting type flotation machine for graphite production comprises a tank body, the tank body is cylindrical, a plurality of vertically-arranged supporting columns are fixedly connected to the outerbottom face of the tank body, an opening is formed in the upper end of one side of the tank body, and two vertically-arranged supporting plates are fixedly connected to the upper surface of the upperwall of the tank body; a bottom plate is horizontally arranged between the two supporting plates; the bottom plate is slidably connected with the two supporting plates; a first motor is fixedly connected to the upper surface of the bottom plate; and a horizontally-arranged first gear is fixedly connected to a shaft of the first motor. a first connecting rod, a second connecting rod and a stirringrod are arranged, the mixing reaction of materials in the device is promoted; the stirring and mixing effect is enhanced through rotation and lifting motion, so that the reaction rate of the device is increased, foam generation is accelerated; meanwhile, bubbles attached to the inner wall of the tank body are removed through the stirring rod, and foam generation is promoted; the foam generation effect of the device is optimized, and the practicability of the device is higher.

Owner:马丹丹

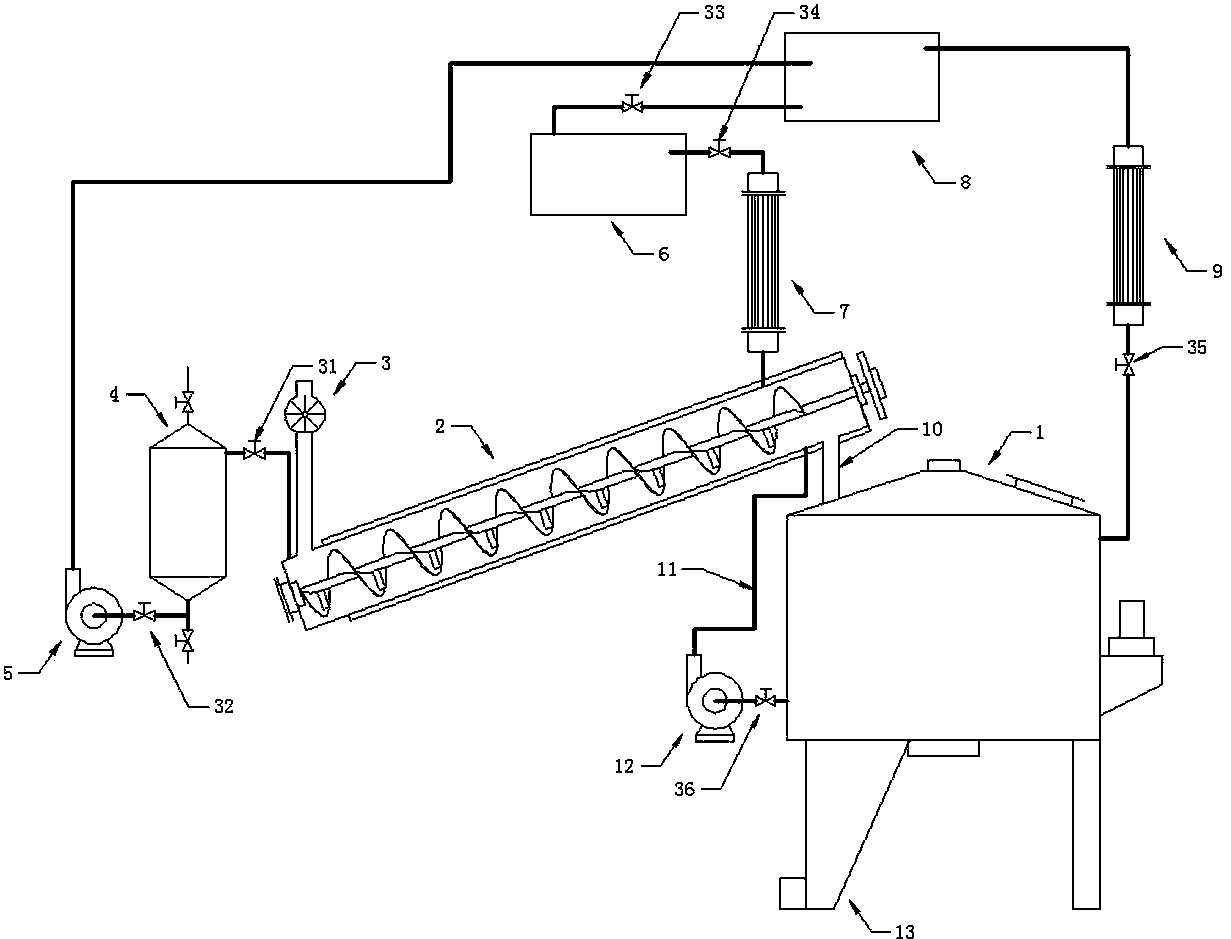

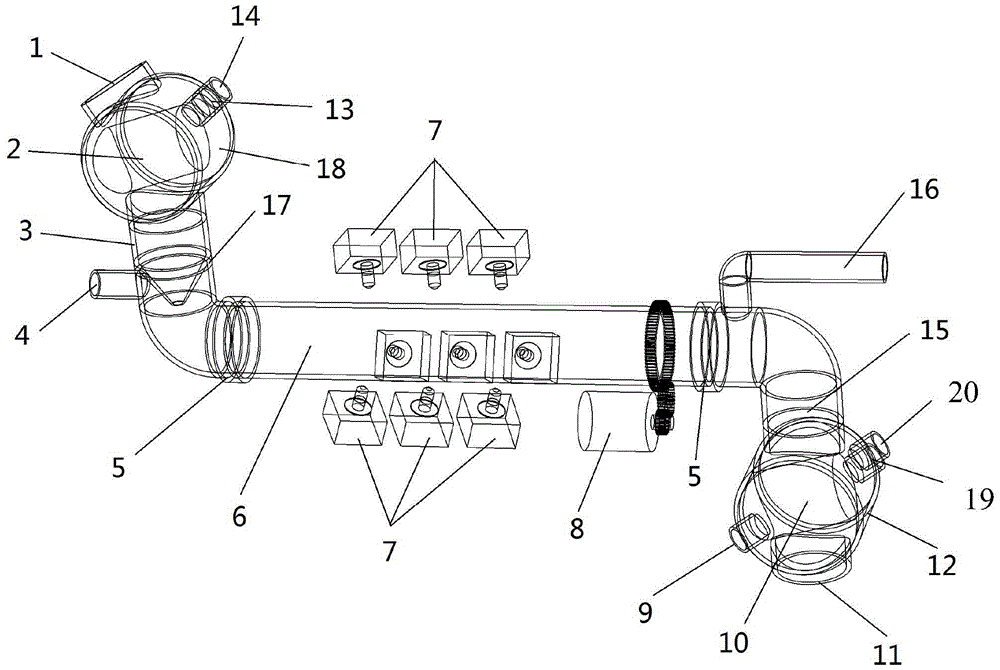

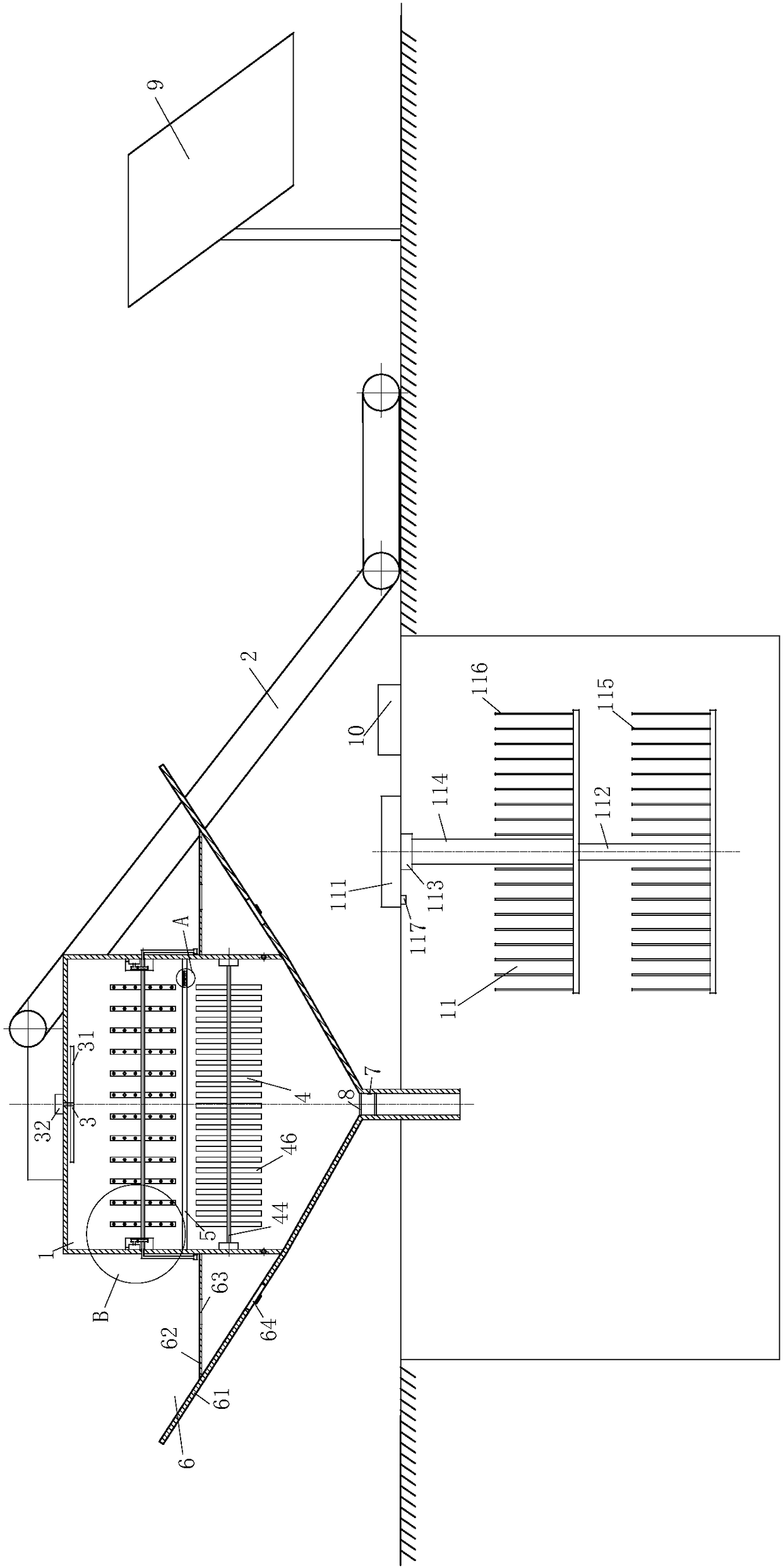

Spiral and horizontal rotating two-level tandem type gutta-percha leaching device

InactiveCN103977596APrevent overflowPrevent compactionChemical industrySolid solvent extractionGutta-perchaShell and tube heat exchanger

The invention discloses a spiral and horizontal rotating two-level tandem type gutta-percha leaching device. The spiral and horizontal rotating two-level tandem type gutta-percha leaching device comprises a spiral leaching device and a horizontal rotating leaching device, wherein the spiral leaching device is obliquely upwards positioned; a material pipe is connected between the two leaching devices and is connected with a solvent pump; a feeding valve is connected to the lower end of the spiral leaching device; a leaching slag outlet is formed in the horizontal rotating leaching device; the lower end of the spiral leaching device is connected with the solvent pump through an overflowing leaching liquid temporary storing tank and then is connected with a proportional evaporation concentrator; the proportional evaporation concentrator is connected with a tube pass of a shell-and-tube heat exchanger through a freeze-out separator and then is connected to the spiral leaching device, and the proportional evaporation concentrator is also connected with the horizontal rotating leaching device through the tube pass of another shell-and-tube heat exchanger. According to the spiral and horizontal rotating two-level tandem type gutta-percha leaching device, the spiral leaching device and the horizontal rotating leaching device are connected in series as a whole to perform two-level countercurrent leaching, the spiral leaching is applicable to materials that are difficult to be dissolved, difficult to penetrate and easily blocked, and the horizontal rotating leaching brings high output and achieves energy saving performance and high degree of automation, and therefore, the continuous leaching of gutta-percha is realized; the device has a wide application prospect.

Owner:JISHOU UNIVERSITY

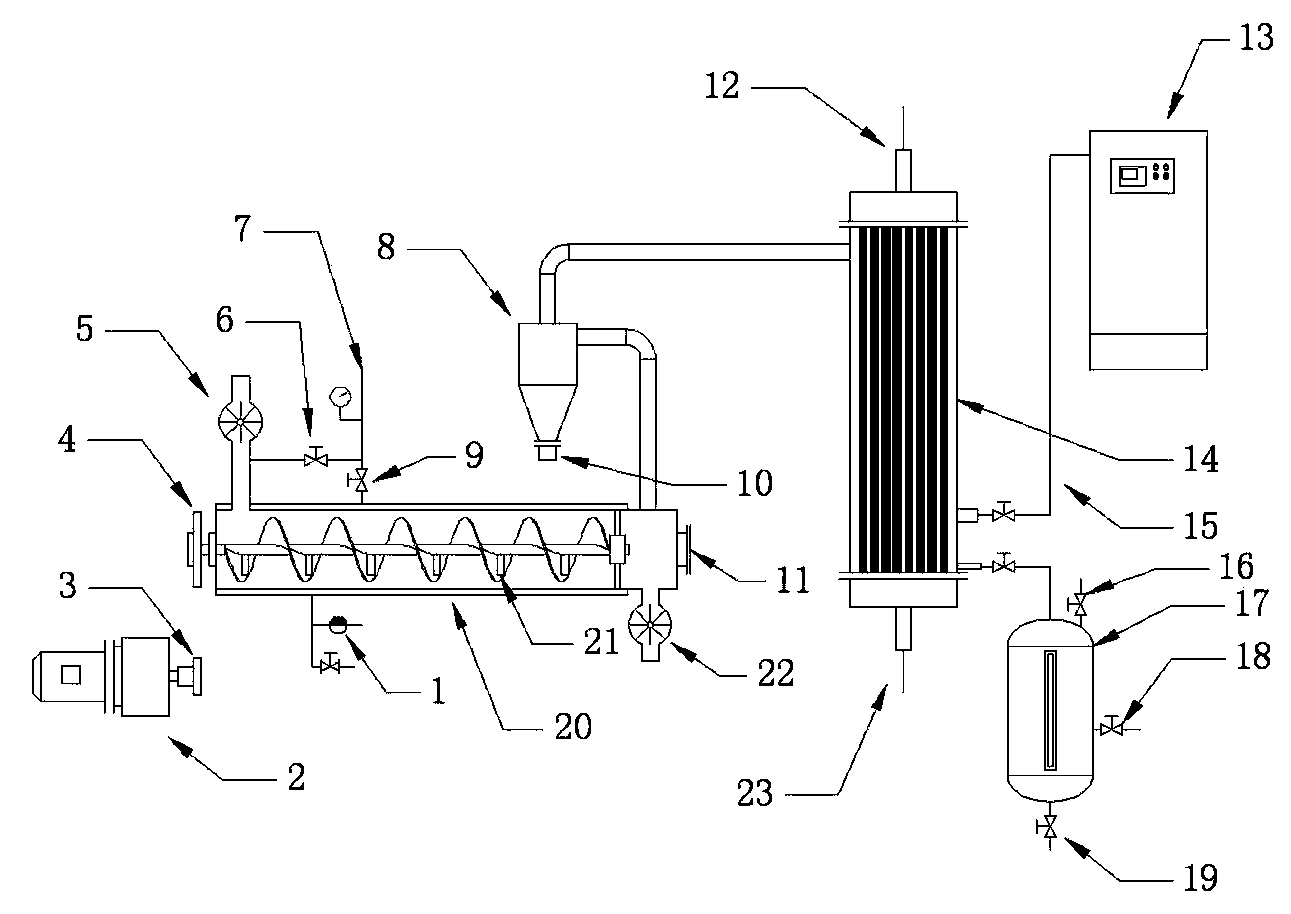

Device for evaporating and removing residual solvent in eucommia ulmoides shell in spiral conveying manner

InactiveCN103980532AEliminate vaporizationReduce consumptionShell and tube heat exchangerSpiral blade

The invention discloses a device for evaporating and removing residual solvent in a eucommia ulmoides shell in a spiral conveying manner. The device for evaporating and removing the residual solvent in the eucommia ulmoides shell in the spiral conveying manner comprises a spiral conveyer with a heating interlayer, the spiral conveyer is connected with a steam pipe by virtue of a valve; the spiral conveyer is provided with a feeding valve and a discharging valve, the spiral conveyer is connected with a shell side of a shell-and-tube heat exchanger by virtue of a cyclone separator and is finally connected with a temporary storage tank; a water dividing valve, a solvent return valve and a vacuum breaker valve are arranged on the temporary storage tank; the pipe side of the shell-and-tube heat exchanger is connected with a cooling water inlet pipe and a cooling water outlet pipe. The device for evaporating and removing the residual solvent in the eucommia ulmoides shell in the spiral conveying manner adopts totally-enclosed spiral conveying and direct steam and indirect steam combined heating desolvation drying, equipment is simple and reliable, operating cost is low, and desolvation is thorough, the technical problem that leaching solvent consumption of the eucommia ulmoides shell is high is solved, and the device for evaporating and removing the residual solvent in the eucommia ulmoides shell in the spiral conveying manner is applicable to small-scale continuous processing; stirring blades are arranged on a spiral blade of a spiral conveyer, a spiral conveying stirring function can be enhanced, materials are prevented from being hardened, and evaporation removal of the solvent is facilitated.

Owner:JISHOU UNIVERSITY

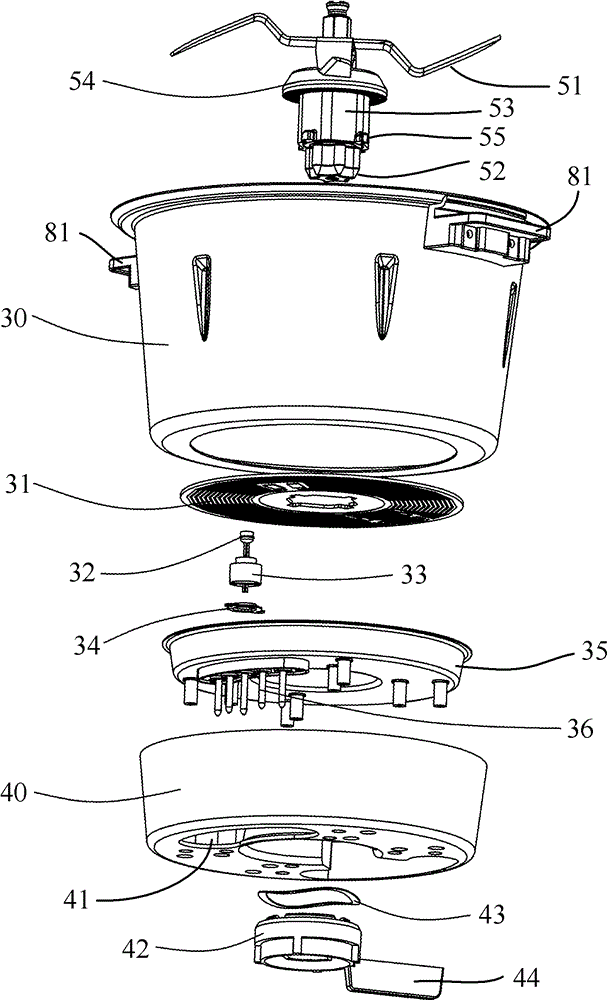

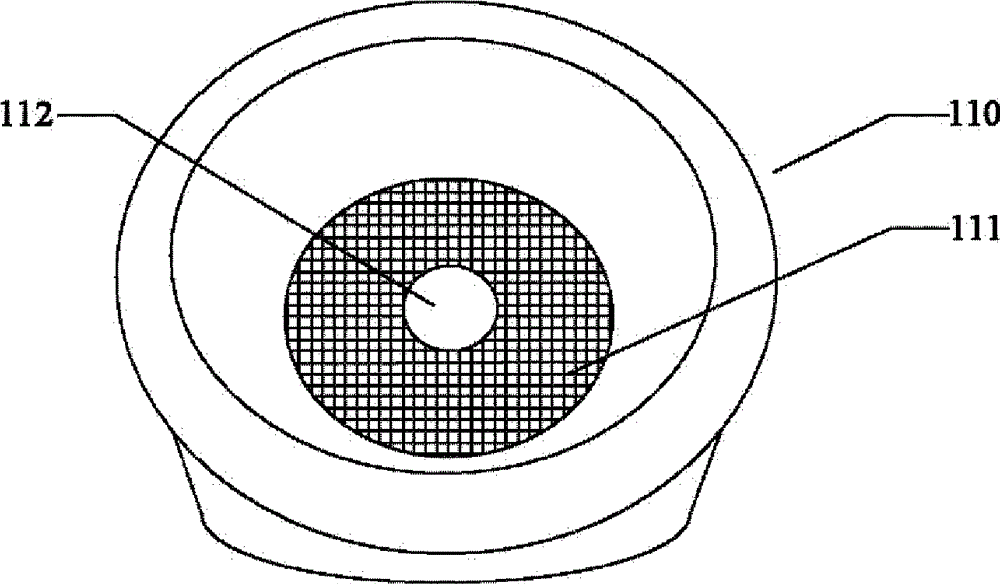

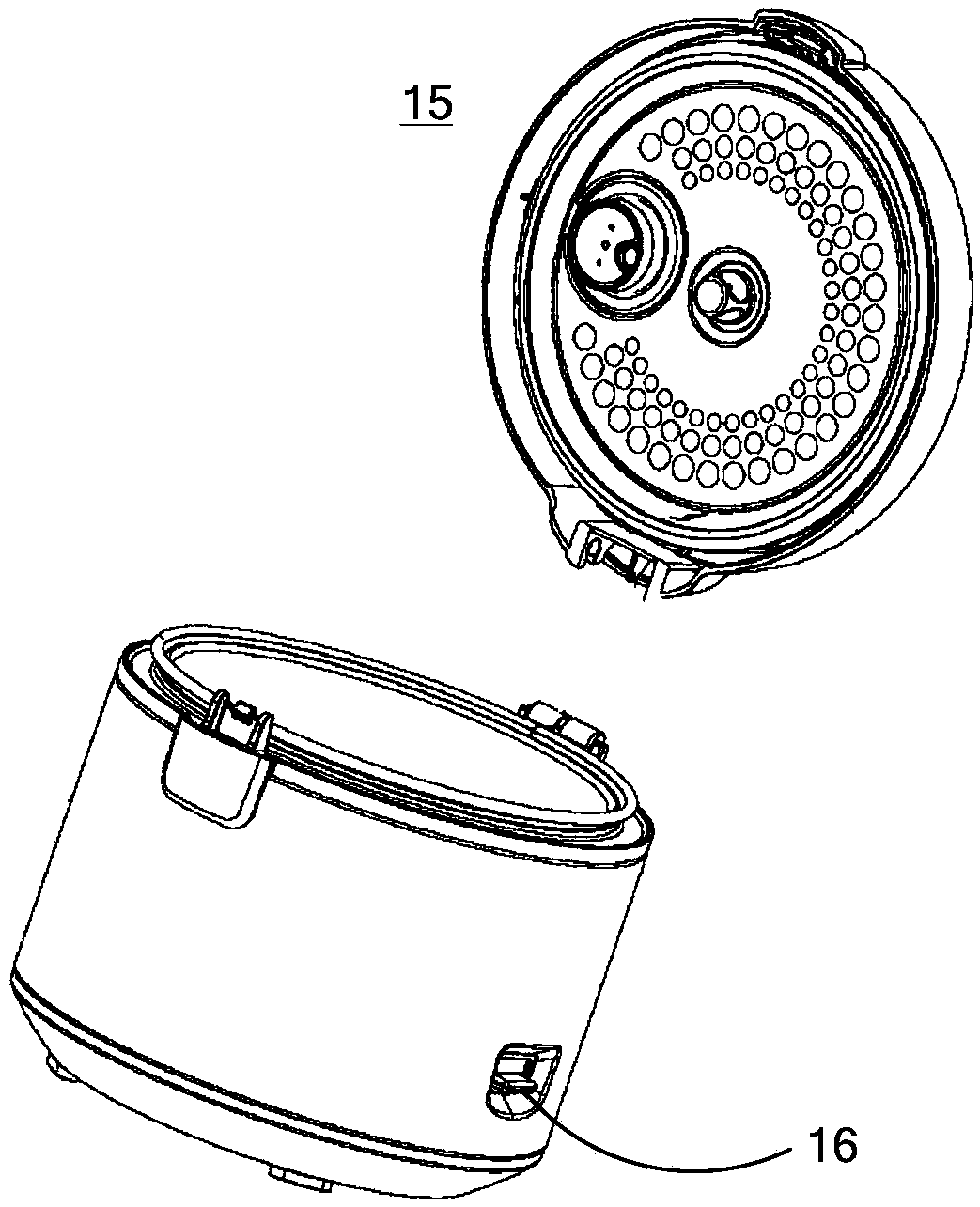

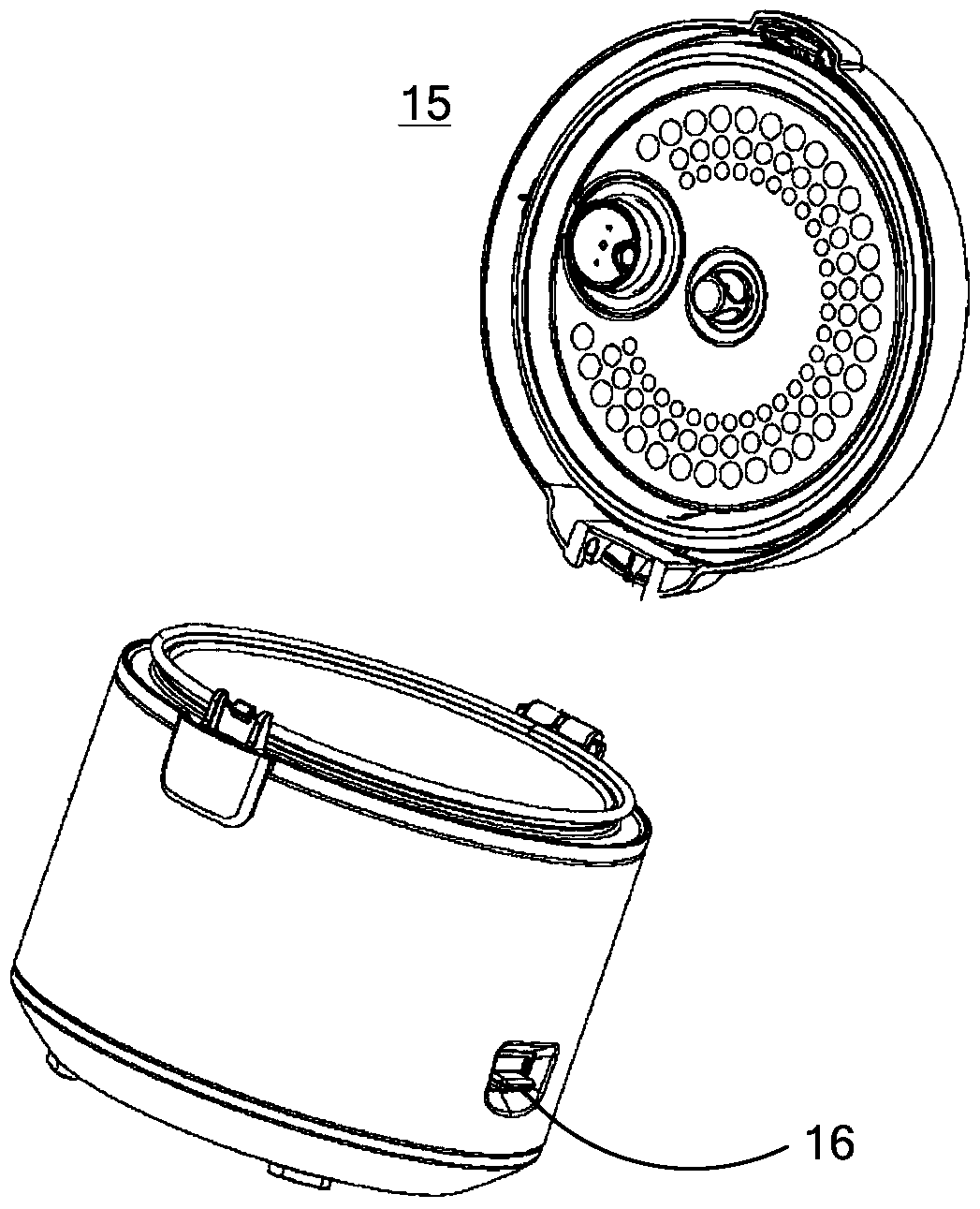

Food processor

ActiveCN105310458ATemperature controlIncrease temperatureWarming devicesUtilization rateEnergy analysis

The invention provides a food processor, which aims at solving the problems in the prior art that the heating efficiency of the food processor is not high. The food processor comprises a body, a cover, a liner and a thick membrane heating disc, wherein the body defines a containing space; the cover is connected to the body in a pivoting manner, so that the cover is closed by moving towards the body and opened by moving away from the body; the liner is arranged in the containing space of the body; the thick membrane heating disc is fixed on the bottom of the liner. By adopting the thick film heating disc, the heat can be rapidly and completely transferred to food in the liner, and the energy utilization rate is high.

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

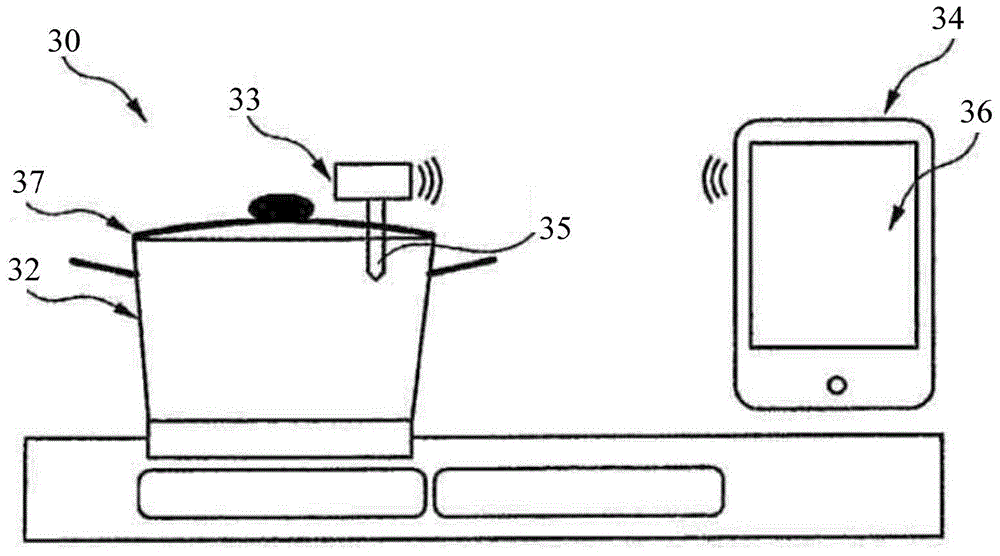

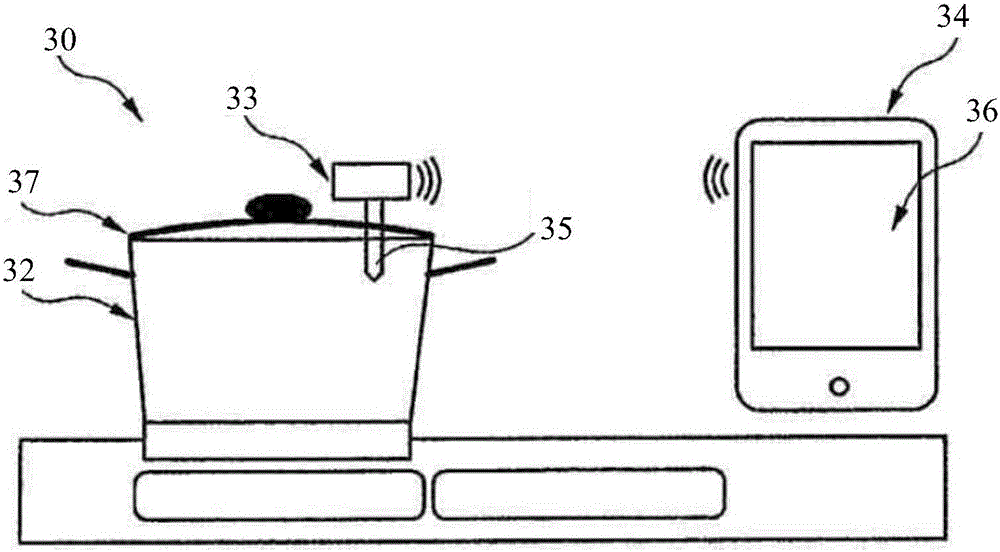

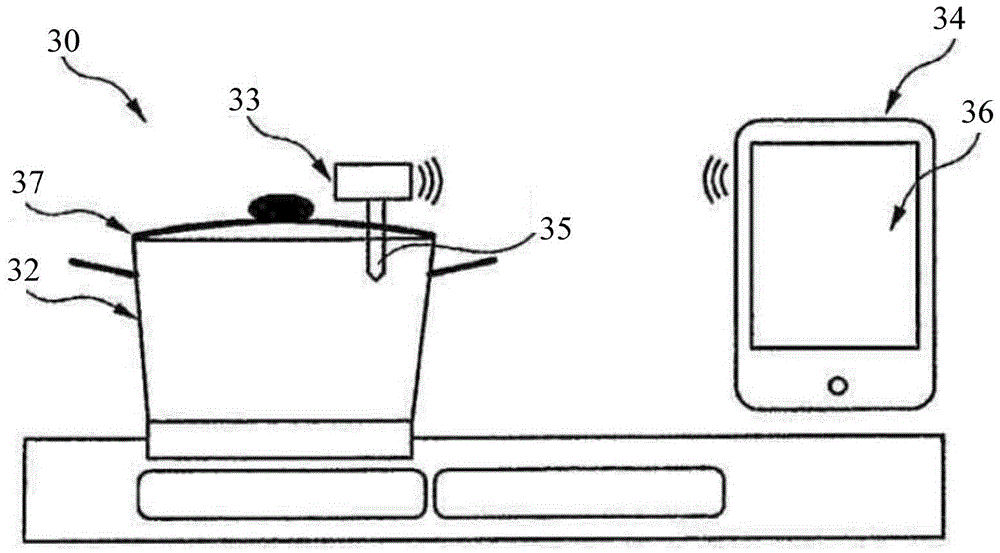

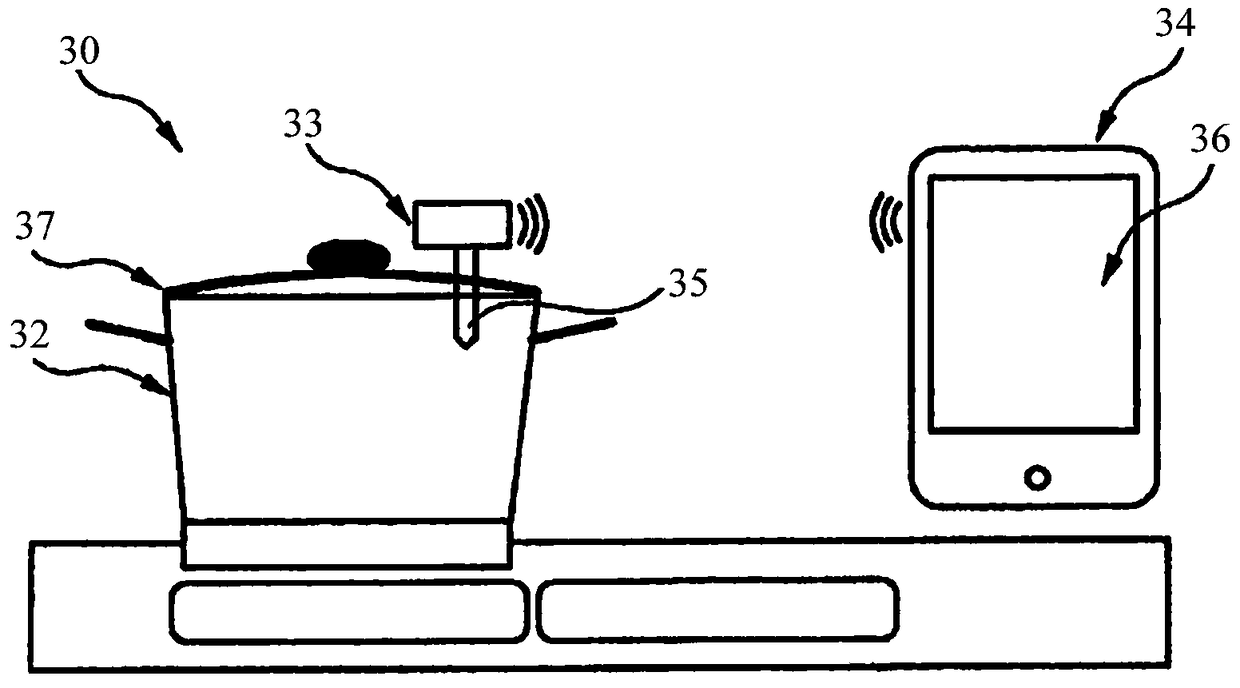

Food processor

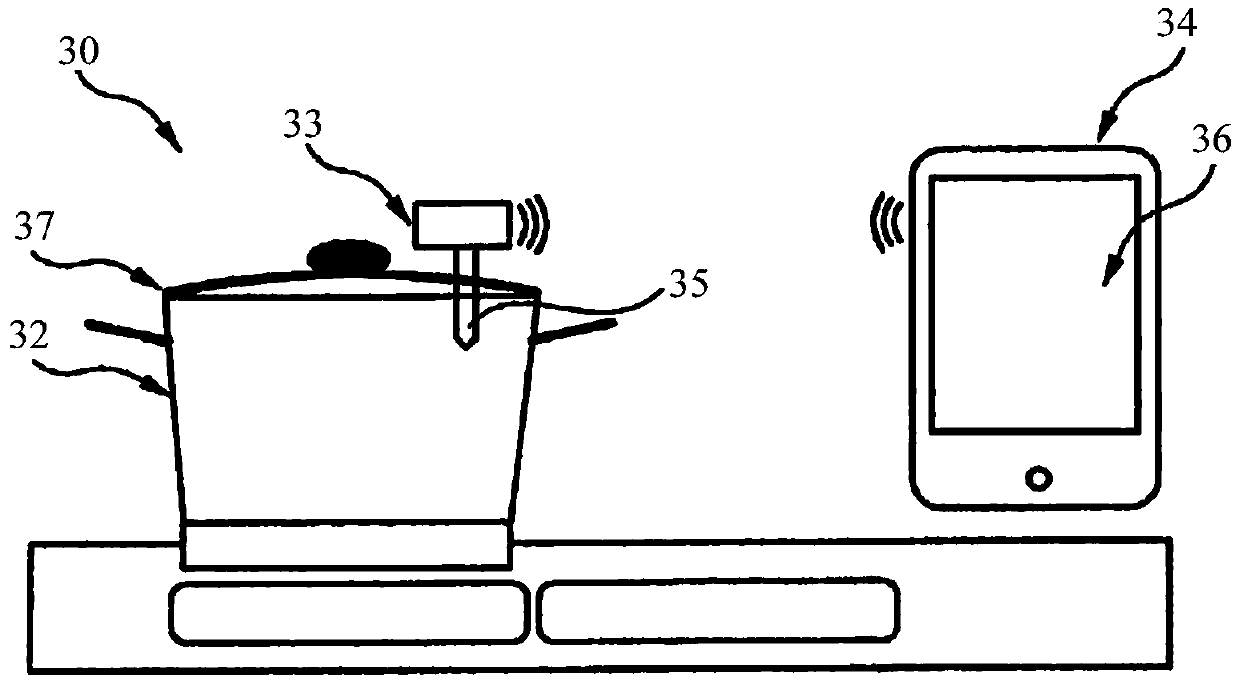

InactiveCN105411371AConvenient remote viewingFunction increaseCooking insertsVessels with intergral heatingVideo chatEngineering

The invention discloses a food processor, comprising a cooking pot and a machine body. The cooking pot is used to hole food materials and process the food materials. The machine body is provided with a housing. The housing is provided with a limited cooking pot installing portion. The bottom of the cooking pot is placed in the cooking pot installing portion. The food processor also comprises a camera device and a control panel. The camera device is detachably installed on the housing. A control panel is installed in the machine body. The control panel is connected with the camera device in a wired or wireless manner, and is used to control operation of the camera device. Since the food processor is provided with the camera device, functions of the food processor are increased. When the food processor is connected with a network, the camera device provides convenience for users to check actual operating conditions of the food processor in a remote manner. The camera device can be used as a tool for video chat, and can also be used as a security monitoring facility, so as to prevent inconvenience of additionally installing a camera.

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

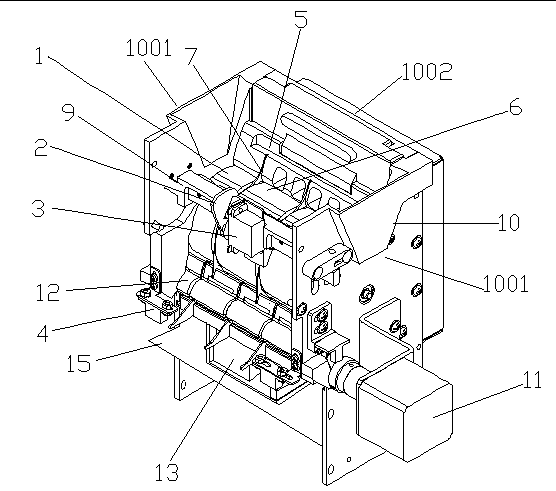

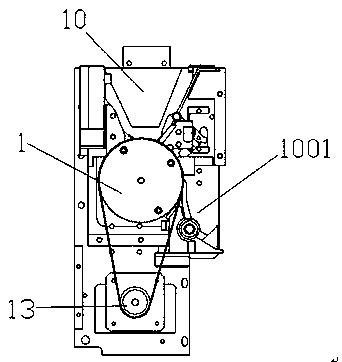

Strip screening mechanism for urine analyzer

The invention discloses a strip screening mechanism for a urine analyzer. The strip screening mechanism comprises a strip screening rolling shaft, a stirring piece, a stirring motor, strip dischargingdetection sensors, a drying frame, a test strip storage bin, a test strip push plate, a limiting body, a support piece, side plates, a strip screening roller motor, a test strip reversing roller, a reversing roller motor and a test strip falling plate; the strip discharging detection sensors are arranged above the test strip falling plate, a strip screening groove is formed in the strip screeningrolling shaft in the direction of a rolling shaft, and an inclined angle is formed at the portion, the height of which is larger than the thickness of test strips, of the rear side of the strip screening groove; a strip arranging groove is further formed in the strip screening rolling shaft, the limiting body is fixedly provided with the stirring piece and the stirring motor, the stirring piece is fixed to an extension shaft of the stirring motor, and an opening groove providing convenience for the rotation of the stirring piece is formed in the portion, corresponding to the stirring piece, of the limiting body. By means of the strip screening mechanism, the speed of screening the test strips is increased, the damage, misjudgment and sticking problems in the process of screening the teststrips are solved, and the screening efficiency is effectively improved.

Owner:SHANXI YASEN INDAL

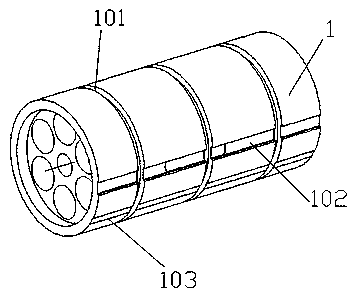

Powder microwave chemical vapor phase coating equipment capable of realizing continuous production

ActiveCN104878368APromote generationGenerate uniformChemical vapor deposition coatingMicrowaveStraight tube

The invention discloses powder microwave chemical vapor phase coating equipment capable of realizing continuous production. The microwave chemical vapor phase coating equipment comprises a feeding valve, a reaction chamber and a discharging valve which are sequentially connected, wherein the reaction chamber is a straight tube of which two ends are provided with elbows; a rotary driving device and a plurality of magnetrons are arranged on the straight tube; an air inlet I and a reaction chamber exhaust outlet are correspondingly formed in two ends of the reaction chamber; the feeding valve comprises a casing, a feeding valve rotor inside the casing as well as a feed opening, a feeding valve air inlet, a feeding valve exhaust outlet and a feeding speed-regulating valve which are arranged on the same plane together with the feeding valve rotor; the feeding valve rotor can freely rotate inside the casing and is tangent to the inner wall of the casing to form the sealing; the discharging valve is similar to the feeding valve in structure, and can also realize material transfer by the rotation of the rotor and keeps the sealing property of the reaction chamber; both the feeding valve rotor and a discharging valve rotor are of structures of which one ends are opened. According to the powder microwave chemical vapor phase coating equipment, the continuous production can be realized; in addition, prepared products are provided with uniform coating layers and are homogeneous and stable in property.

Owner:成都巴莫科技有限责任公司

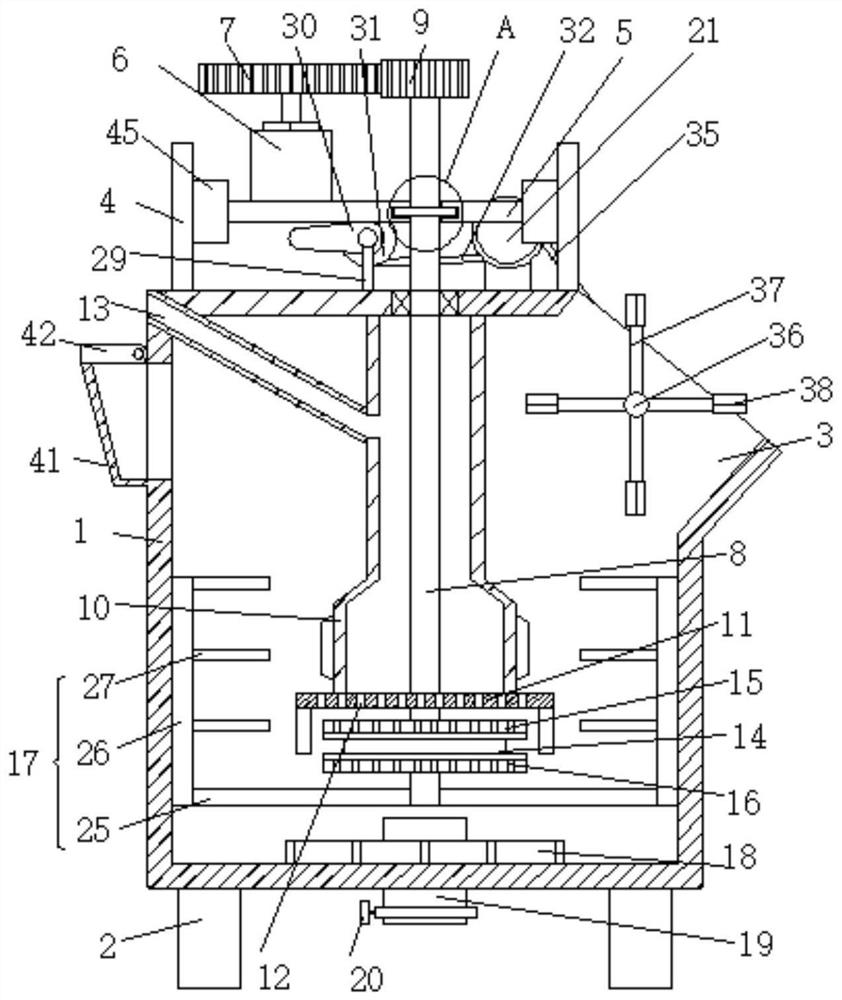

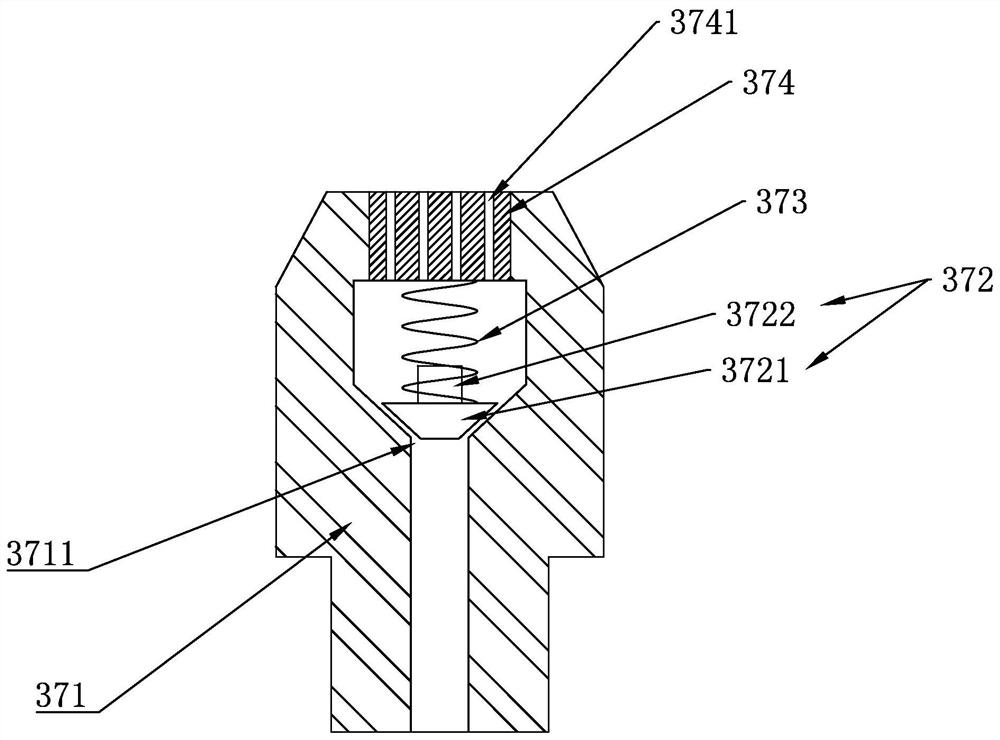

Flash type evaporator for pulping lignite through hydrothermal treatment and defoaming method

PendingCN107551578ASolve the hidden danger of blockageImprove the effect of defoamingEvaporator accessoriesGastric tube feedingEvaporator

The invention relates to a flash type evaporator for pulping lignite through hydrothermal treatment. The flash type evaporator comprises a tubular body, a secondary vapor discharging pipe arranged atthe top of the tubular body and a discharging pipe arranged at the bottom of the tubular body, wherein two charging pipes, which are of eccentric opposite distribution and are used for conveying a coal pulp material to the tubular body, are arranged at the middle part of the tubular body, a rotatable rotating shaft is vertically mounted in the center of the tubular body, a disc turbine which cannot rotate relative to the rotating shaft is mounted at the middle part of the rotating shaft corresponding to the charging pipes, thus, the coal pulp material impacts and rotates the disc turbine, a baffling demister is mounted on the rotating shaft in a manner of being incapable of rotating relative to the rotating shaft above the disc turbine, and a stirrer is mounted on the rotating shaft in a manner of being incapable of rotating relative to the rotating shaft below the disc turbine. According to the flash type evaporator for pulping the lignite through hydrothermal treatment and the defoaming method, by adopting middle opposite charging, the wear to the bottom of the tubular body is avoided; meanwhile, the rotating shaft is driven to rotate through the rotation of the disc turbine, thus, the stirrer at the lower part of the rotating shaft can rotate to play a role in preventing solid-liquid materials in the tubular body from settling blockage; and the baffling demister can rotate along with the rotating shaft to form a dynamic-uniform-distributed demister, thus, defoaming is more effective, and the integration of defoaming and stirring is achieved.

Owner:DATANG INT CHEM TECH RESINST

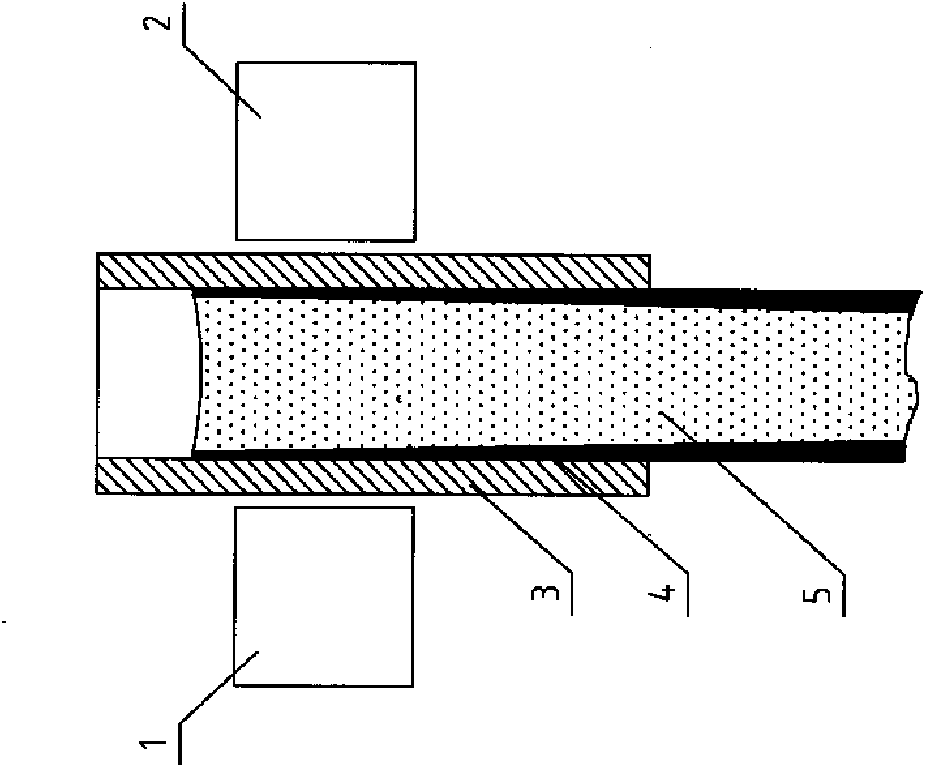

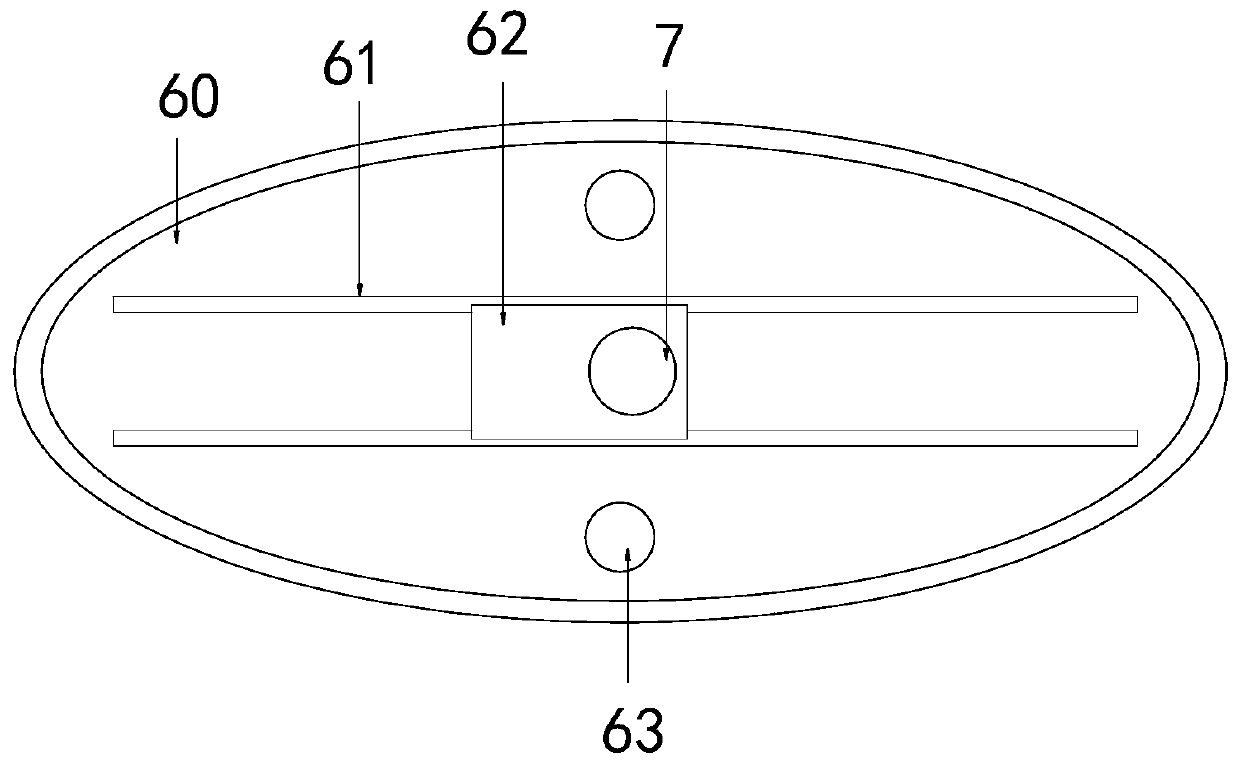

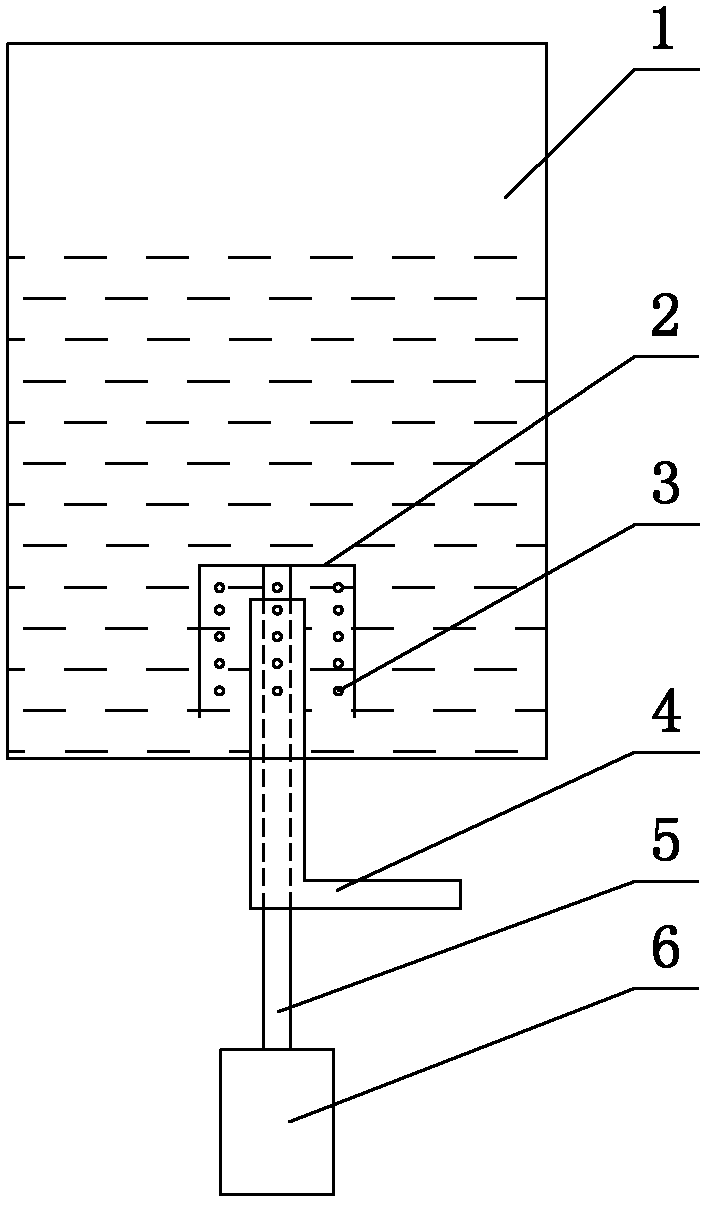

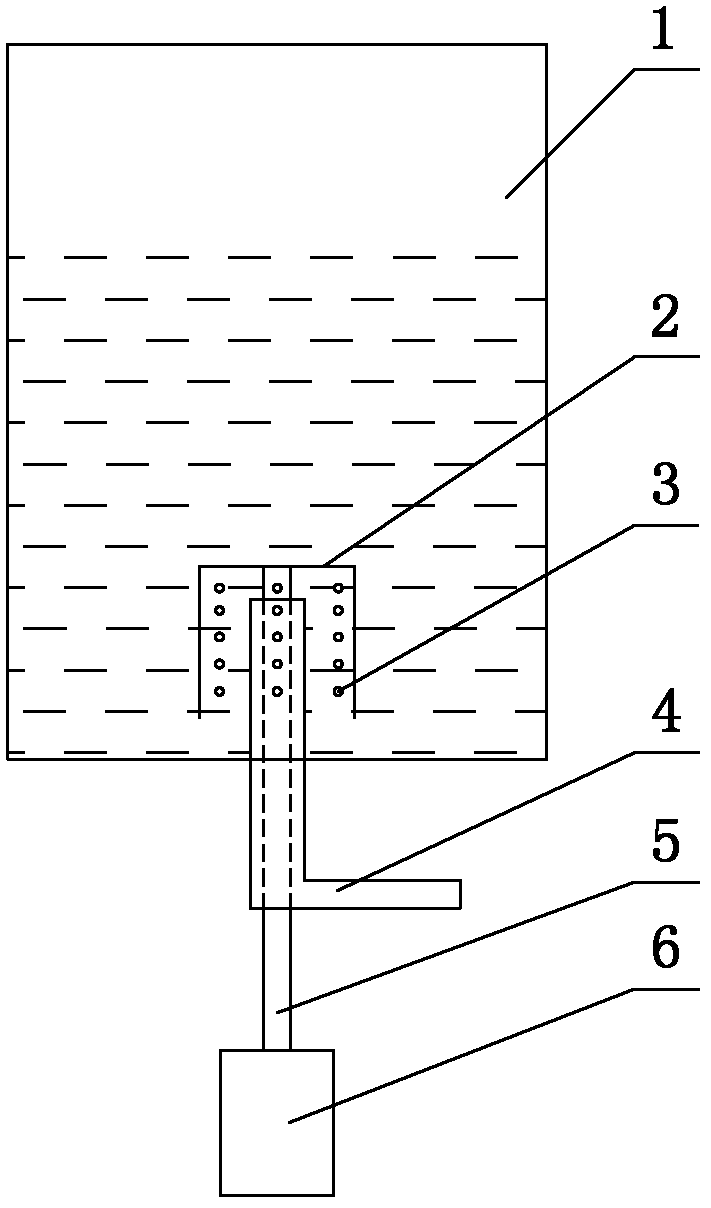

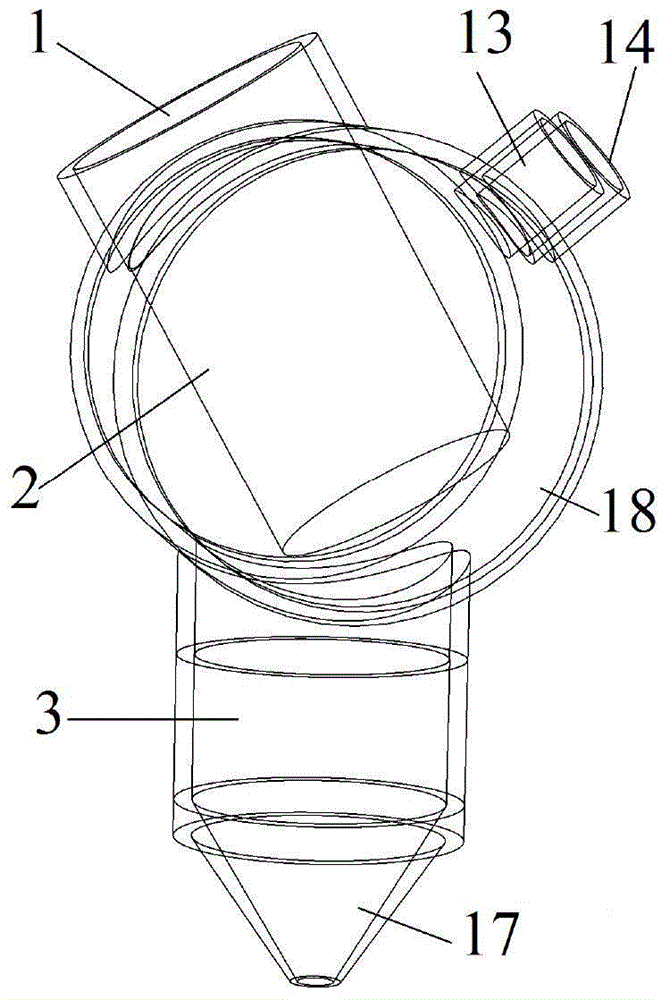

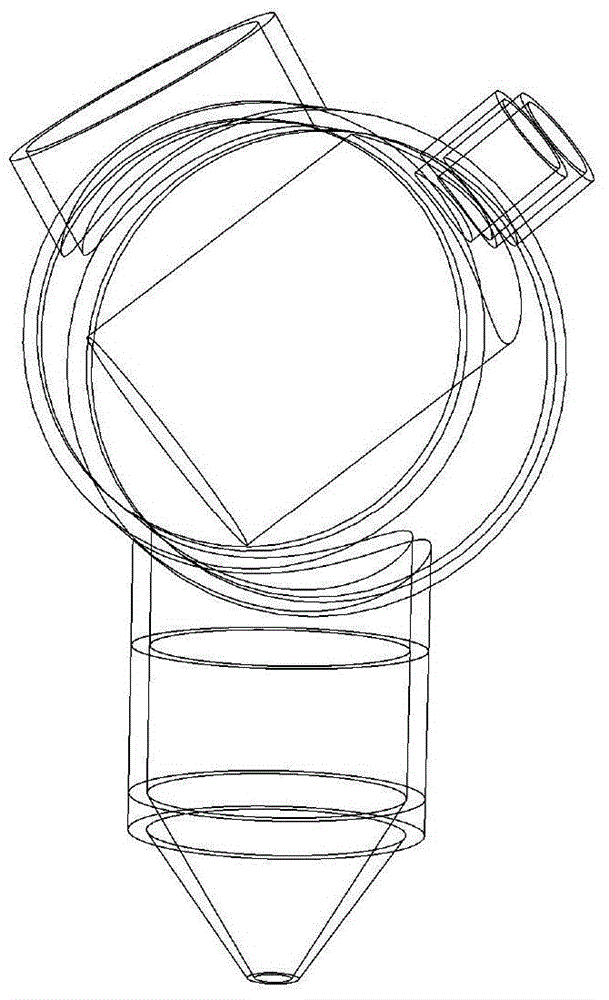

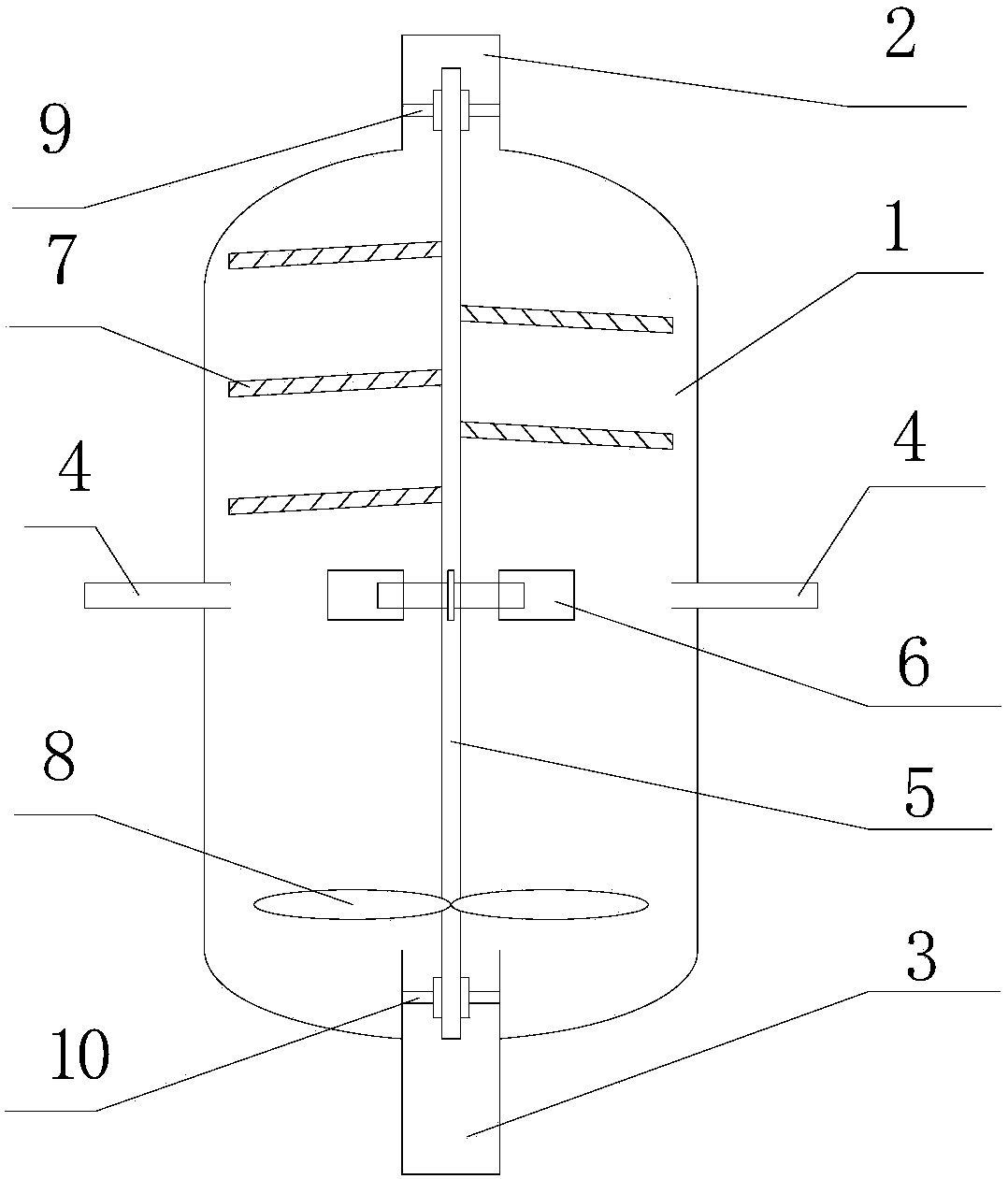

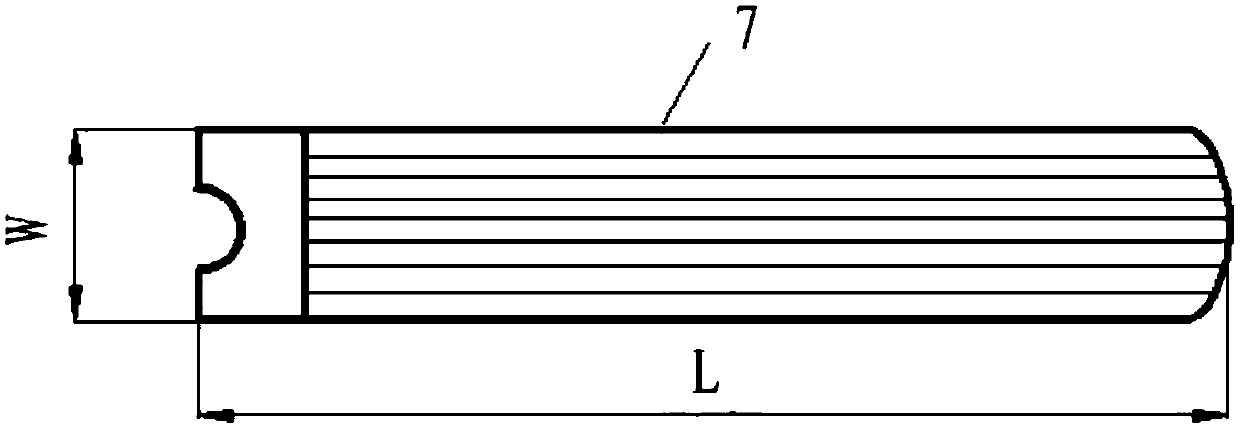

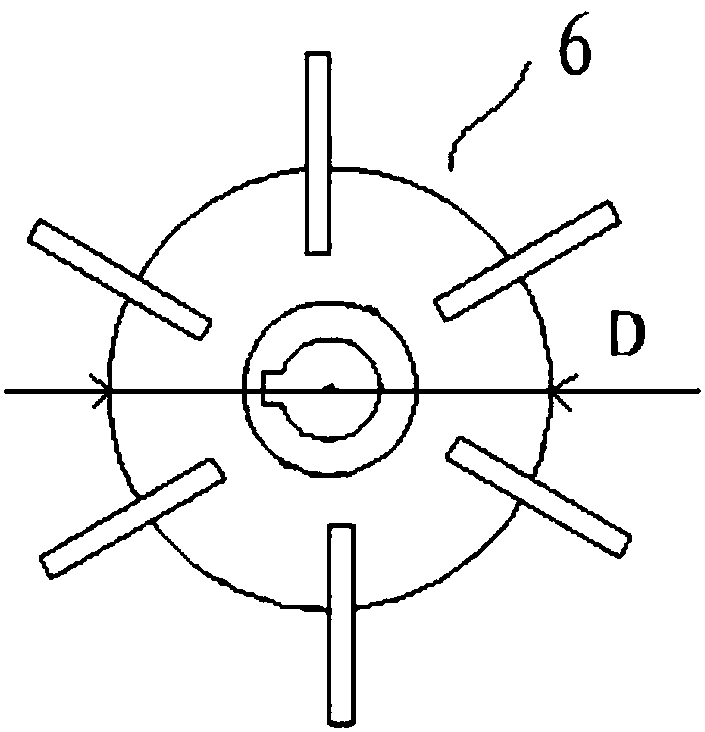

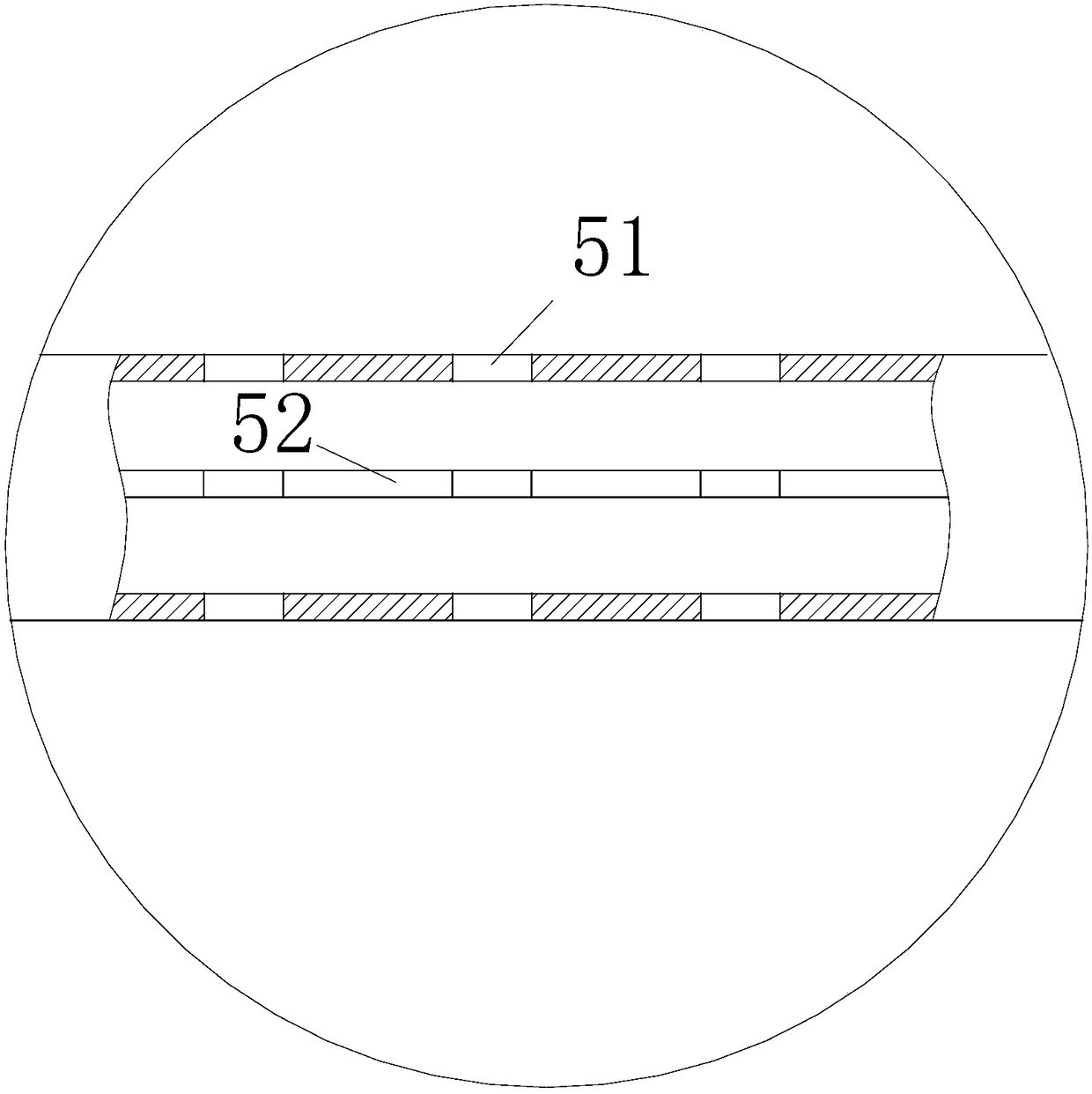

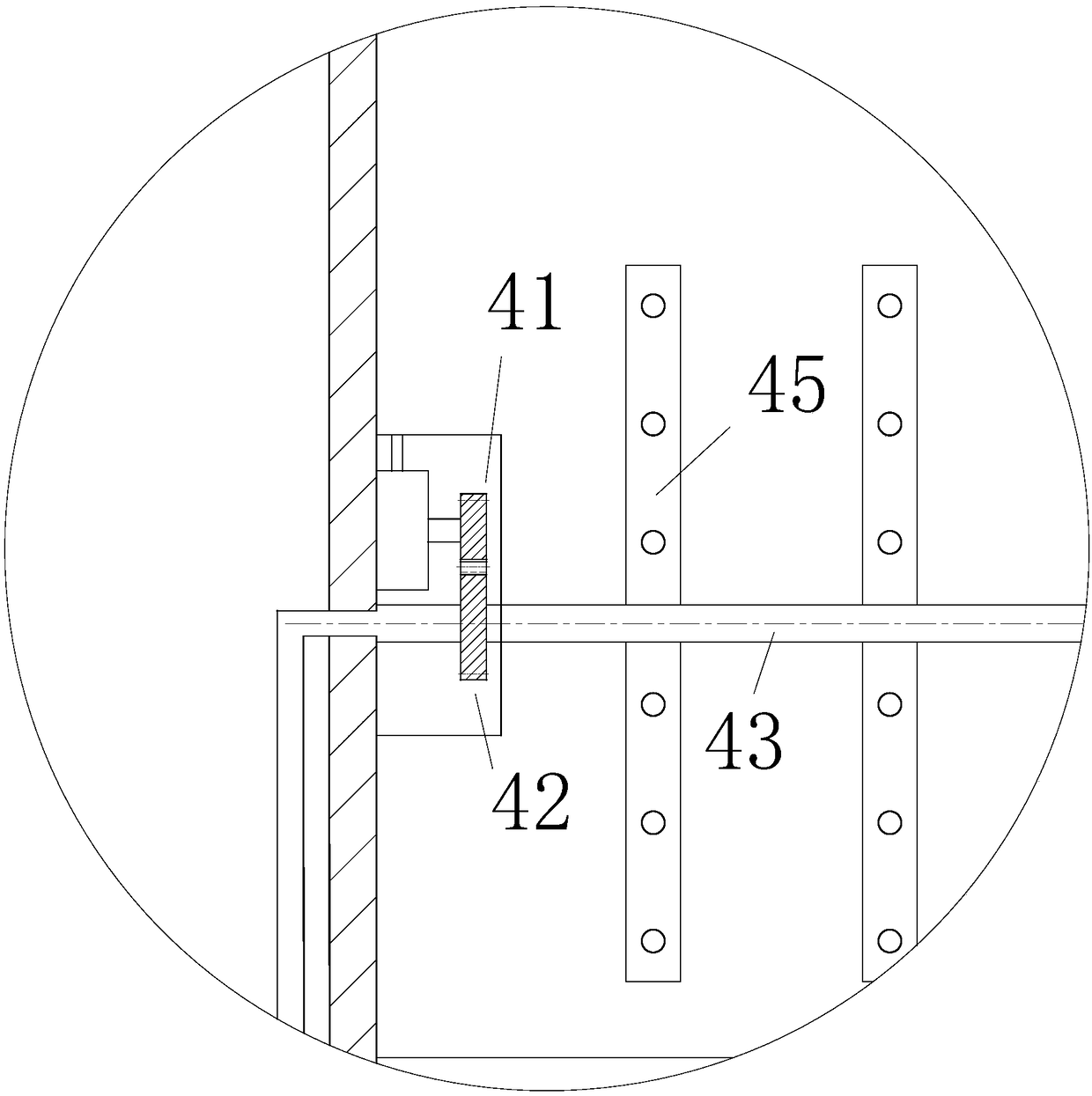

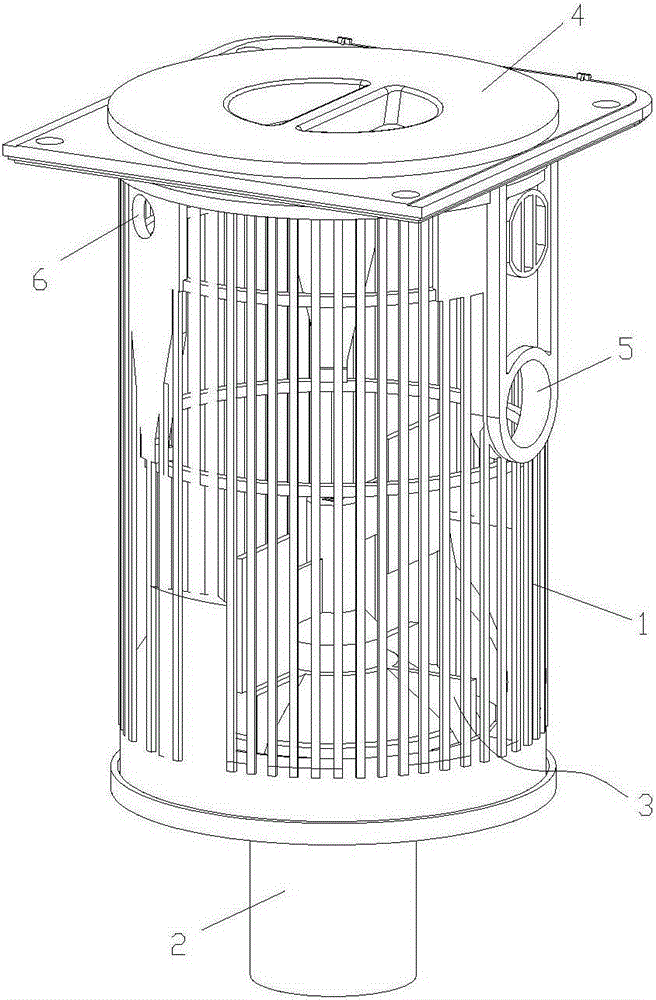

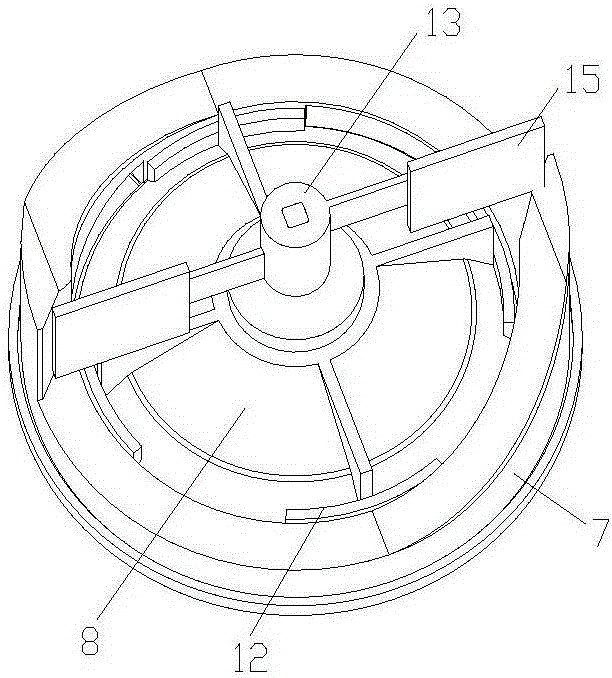

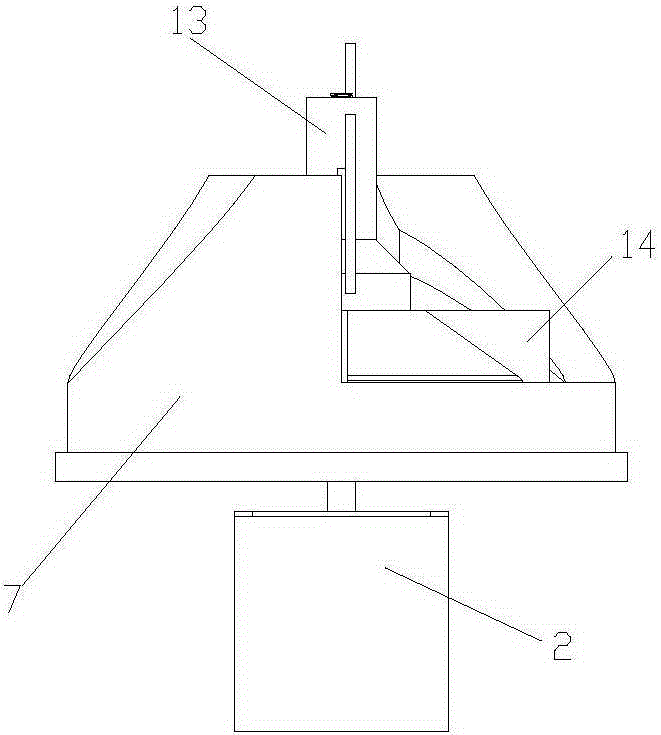

Crystal growth device with melt stirring function

InactiveCN108441937AAdd rotation functionPromotes relative motionFrom frozen solutionsRotation functionInsulation layer

The invention relates to a crystal growth device with a melt stirring function, crystal growth device comprises an induction coil (1), an insulation layer (2), an induction heating body (3), a raw material (4), a crucible (5) and a crucible pillar (6). The crucible (5) is provided with a stirrer (7) for stirring a raw material (4). Compared with the prior art, a crucible rotation function is addedon the conventional basis that the crucible and a melt are relatively static, the relative movement of the crucible and the melt is increased, bubbles in the melt can be more easily excluded, dopingelements in the raw material are more uniform in distribution, and the growth of high quality crystals is facilitated.

Owner:TONGJI UNIV

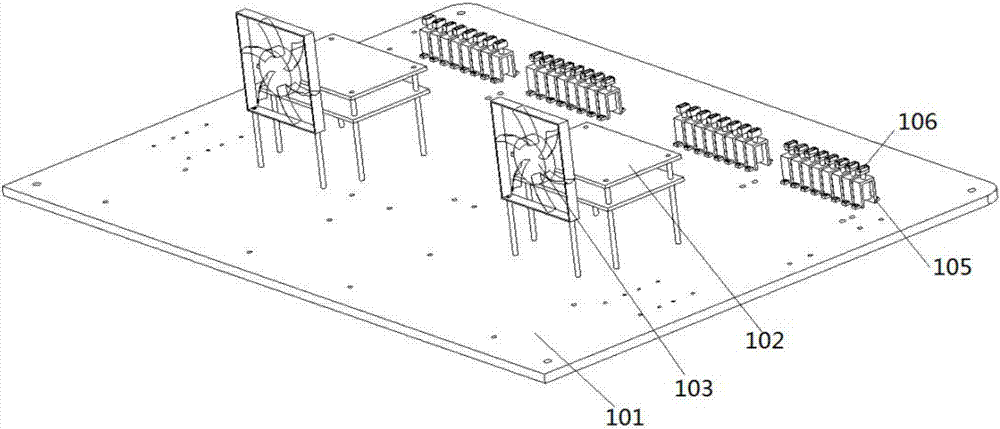

Feeding and stirring multi-step processing system used for bio-fuel tank

InactiveCN108587876AEvenly distributedPromote fragmentationBioreactor/fermenter combinationsBiological substance pretreatmentsFuel tankEngineering

The invention belongs to the technical field of biogas digesters, and particularly provides a feeding and stirring multi-step processing system used for a bio-fuel tank. The system includes a box body, a transport unit, a dispersion unit, a crushing unit, a heating and filter screen unit, a rainwater collection unit, a gas leakage detector, a seal valve, a solar power generation board, a storage battery and a stirring unit. The transport unit is used for transporting straw; the dispersion unit is used for uniformly dispersing the straw into the box body; the crushing unit is used for crushingthe straw; the heating and filter screen unit is used for heating and filtering the crushed straw; the rainwater collection unit is used for collecting rainwater; the gas leakage detector is used fordetecting biogas leakage; the seal valve is used for sealing a pipeline for avoiding the biogas leakage; the stirring unit is used for stirring residue liquid in the biogas digester. In the invention,the transport unit automatically sends the straw into the box body, then the straw is crushed in the crushing unit and is fed into the biogas digester. In addition, by enhancing crushing function onfloating residues and stirring function on biogas residues, microorganisms are more uniformly distributed.

Owner:汪通鲜

Magnetic stirring type drug sensitivity analysis apparatus and matched kit

PendingCN106916728AReproduce fastReduce reproduction rateBioreactor/fermenter combinationsBiological substance pretreatmentsGrowth curveMagnet

The relates to the technical field of drug sensitivity analysis, and in particular to a magnetic stirring type drug sensitivity analysis apparatus and a matched kit. The magnetic stirring type drug sensitivity analysis apparatus provided by the invention, which is used in a mode of being matched with a microcomputer, is simple to operate, short in drug-sensitivity time and high in result accuracy. Drug resistance of microorganisms can be judged by virtue of a final value method, and in addition, growth status of the microorganisms can be monitored in a culture process; and furthermore, by adding a stirring function in the culture process, a propagation speed of the drug-resistant microorganisms can be accelerated, the time of an entire drug-sensitivity process can be shortened and a step of manual operation can be omitted. In the microorganism culture process, a stirring motor rotates so as to drive a magnet to rotate and a stirrer, under the action of a rotating magnetic field, becomes rotating, so that drugs, microorganism liquid and air in drug-sensitivity stirring pores are fully mixed. The propagation speed of the drug-resistant microorganisms is accelerated and the drug-sensitivity process is shortened. After the culture process is implemented for a period of time, the kit, which is driven by a motion device, is moved to a detection device; and through repetitive culture and detection, a growth curve of the microorganisms is finally obtained.

Owner:朱红 +3

Food processor manufacturing method

ActiveCN105361630ARemove dependenciesFunction increaseCooking-vessel lids/coversWarming devicesLoudspeakerElectricity

The invention discloses a food processor manufacturing method which includes providing pots, bodies, touch computers and loudspeakers, electrically connecting the touch computers to the loudspeakers to control sounds of the loudspeakers, arranging the loudspeakers by closing to first casings so as to transmit sounds from holes formed in the first casings, and arranging bottoms of the pots in pot mounting portions of second casings so as to mount the pots to the bodies. The pots are used for containing and processing food; the bodies are provided with the first casings and the second casings, the first casings are connected with the second casings, and the pot mounting portions are defined by the second casings; the touch computers are fixedly mounted to first side surfaces of the first casings and used for operating and controlling the food processors by means of touch operations; and the loudspeakers are mounted in the first casings through loudspeaker holders. The problem about dependency on portable smart electric appliances is solved through application of the food processors manufactured by the method.

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

Garbage disposal mechanism

ActiveCN105234150AReasonable structurePromote decompositionSolid waste disposalImpellerLight sensing

The invention provides a garbage disposal mechanism which comprises a filter drum, a discharging assembly and a drive motor. One end of the filter drum is sealed through the discharging assembly. A wastewater inlet and a re-disposal inlet are formed in the filter drum. The discharging assembly comprises a sealing end cover, a rotary impeller and a light sensing head. The sealing end cover is installed at the end of the filter drum. The rotary impeller is fixed to the sealing end cover in the axial direction and driven by the drive motor to rotate. Multiple discharging holes are formed in the sealing end cover. Multiple blades are arranged on the rotary impeller, rotate along with the rotary impeller and intermittently cover the discharging holes. The light sensing head is further arranged on the rotary impeller and used for detecting the covering degree of the discharging holes by the blades. A stirring rod is further arranged in the axial direction of the rotary impeller and provided with a rubber strip. The largest rotation diameter of the rubber strip does not exceed the inner diameter of the filter drum.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

Preparation method and preparation device of silicone liquid glue

PendingCN113201298AEasy to adjust the direction of rotationAdded stirring functionProcess control/regulationEster polymer adhesivesDrive motorNitrogen gas

The invention discloses a preparation device of silicone liquid glue. According to the technical scheme, the preparation device comprises a reaction kettle, a measuring tank connected with the reaction kettle through a pipeline, a nitrogen circulating device and a temperature adjusting device; the measuring tank is connected with a plurality of adjusting valves for adjusting raw materials; the reaction kettle comprises a kettle body, a kettle cover hermetically connected with the kettle body and a stirring device arranged on the kettle cover; the stirring device comprises a stirring shaft, stirring blades arranged on the stirring shaft, a driving motor for driving the stirring shaft to rotate and a mounting shell for mounting the driving motor; and a reversing mechanism which is used for adjusting the rotating direction of the stirring shaft and is arranged in the mounting shell is arranged between the driving motor and the stirring shaft. The reaction efficiency of silicone liquid glue production is effectively improved, the reaction time is shortened, the temperature control during reaction is improved, and the heating is uniform.

Owner:QUZHOU DONGKAI GLUE IND CO LTD

How to operate a food processor

ActiveCN105167569BEasy to operateEliminate dependenciesTime-controlled ignitorsComputer scienceMobile phone

The invention discloses a manipulation method of a food processer. The food processor comprises a cooking pot with stirring and heating functions and a touch screen computer which is fixedly mounted on the food processor; the method comprises the following steps: searching the touch screen computer for corresponding menus according to types of food to be made; making food step by step according to the guidance of corresponding menus that are available; enabling entertainment and / or time killing functional software in the touch screen computer during the interval time after one making step is completed and before the next making step is started. According to the manipulation method of the food processer, provided by the invention, by manipulating the touch screen computer that is fixedly mounted on the shell of the machine body, a user can utilize the touch screen computer conveniently to manipulate the food processor, the dependence on mobile phones and other portable intelligence electric appliances can be eliminated, and the user can also utilize the touch screen computer for entertaining and / or killing time during the interval time of food making.

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com