Device for evaporating and removing residual solvent in eucommia ulmoides shell in spiral conveying manner

The technology of screw conveying and residual solvent is applied in the field of the device for evaporating residual solvent in eucommia nut husk by screw conveying, which can solve the problems of difficult evaporation of solvent, little mature experience and technology, and inability to desolubilize eucommia nut husk, etc. To achieve the effect of complete desolvation, low operating cost, simple and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

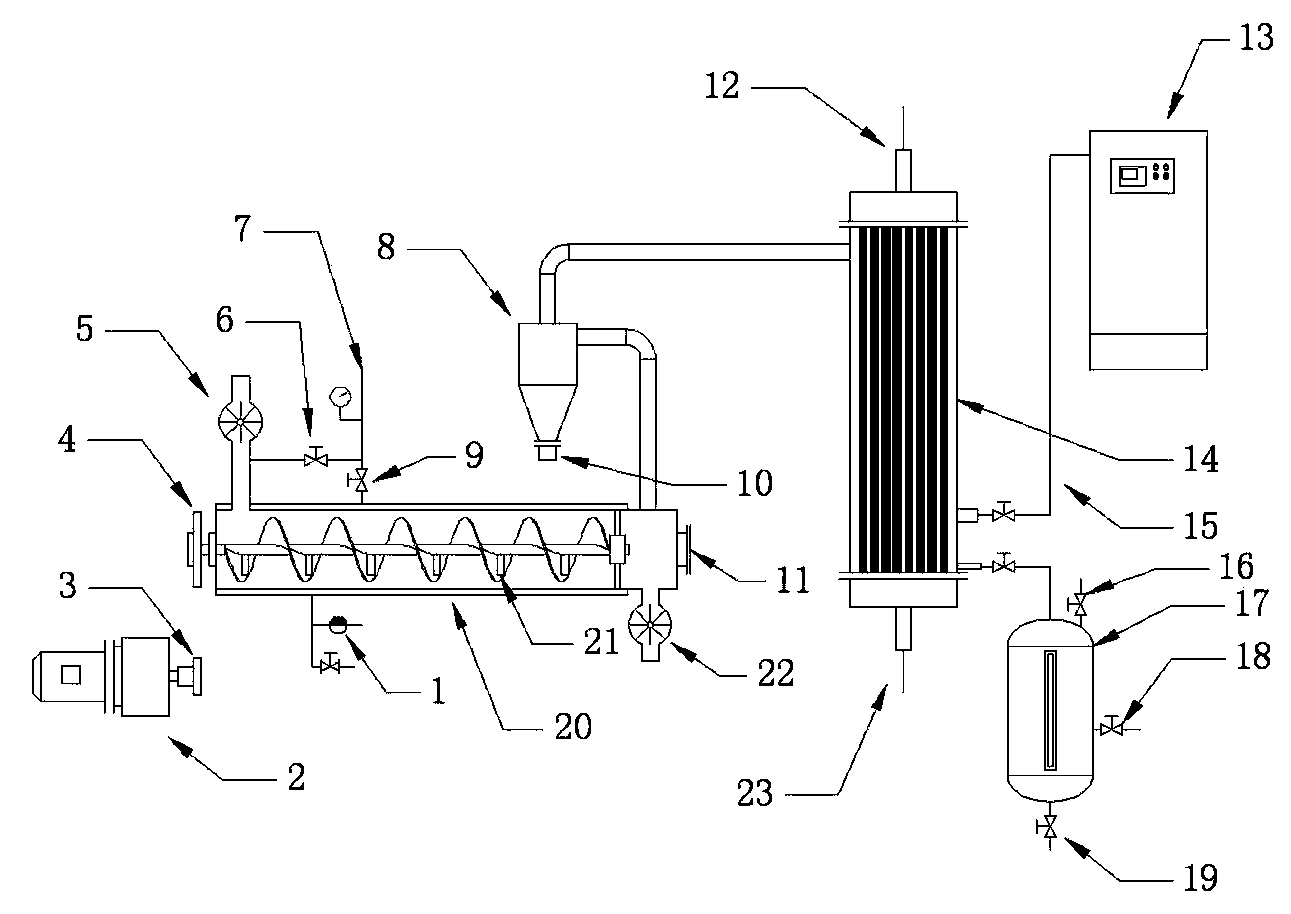

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0028] Such as figure 1 The device for steaming and removing the residual solvent in Eucommia ulmoides husk shown in the screw conveying type includes a screw conveyor 20 with a heating interlayer, and the screw conveyor is connected to the steam pipe 7 through the valve 6; the screw conveyor is provided with a feed valve 5 and a discharge valve. Valve 22; the screw conveyor is connected to the shell side of the tube heat exchanger 14 through the cyclone separator 8, and finally connected to the temporary storage tank 17; the temporary storage tank 17 is provided with a water diversion valve 19, a solvent return valve 18 and a vacuum breaking valve 16 ; The tube side of the tube heat exchanger 14 is connected to the cooling water inlet pipe 23 and the cooling water outlet pipe 12 .

[0029] The cyclone separator 8 is provided with a cleaning port 10 .

[0030] The she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com