Stainless steel silencing sheet

A stainless steel and muffler technology, applied in lighting and heating equipment, fluid heaters, etc., can solve the problems of insignificant turbulence effect, affecting the installation of R pipe, asymmetric force on R pipe, etc., to eliminate instantaneous vaporization, The effect of improving heat transfer rate and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

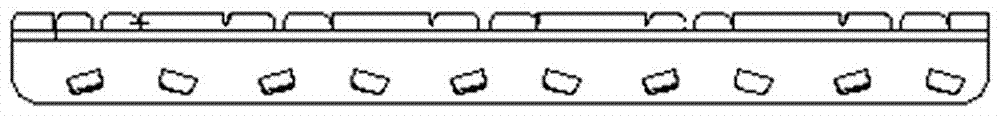

[0027] see Figure 1 ~ Figure 4 , The stainless steel sound-absorbing sheet of this embodiment includes a stainless steel main body 2 with an interference hole 1, and several sets of stainless steel interference fin groups 3 distributed equidistantly along the length direction of the stainless steel main body. Each group of stainless steel interference fins has two top stainless steel interference fins 4 and two bottom stainless steel interference fins 5 respectively mounted on the top and bottom of both sides in the width direction of the stainless steel body.

[0028] see figure 1 , figure 2 , Figure 4 , There are cutting fins 6 symmetrically installed on both sides of the stainless steel main body between adjacent interference holes on the stainless steel main body.

[0029] see figure 1 , the angle α between adjacent cutting fins in the middle of the stainless steel main body is 160°. The angle β between the cut fin in the middle and the length direction of the stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com