Multifunctional wiring-duct machining device and machining method thereof

A processing device and processing method technology, applied in metal processing equipment, punching tools, forming tools, etc., can solve the problems of poor shape uniformity, consistency, accuracy and other processing effects, difficult to ensure processing quality, and labor-intensive workers. and other problems, to achieve the effect of perfect appearance, saving man-hours, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

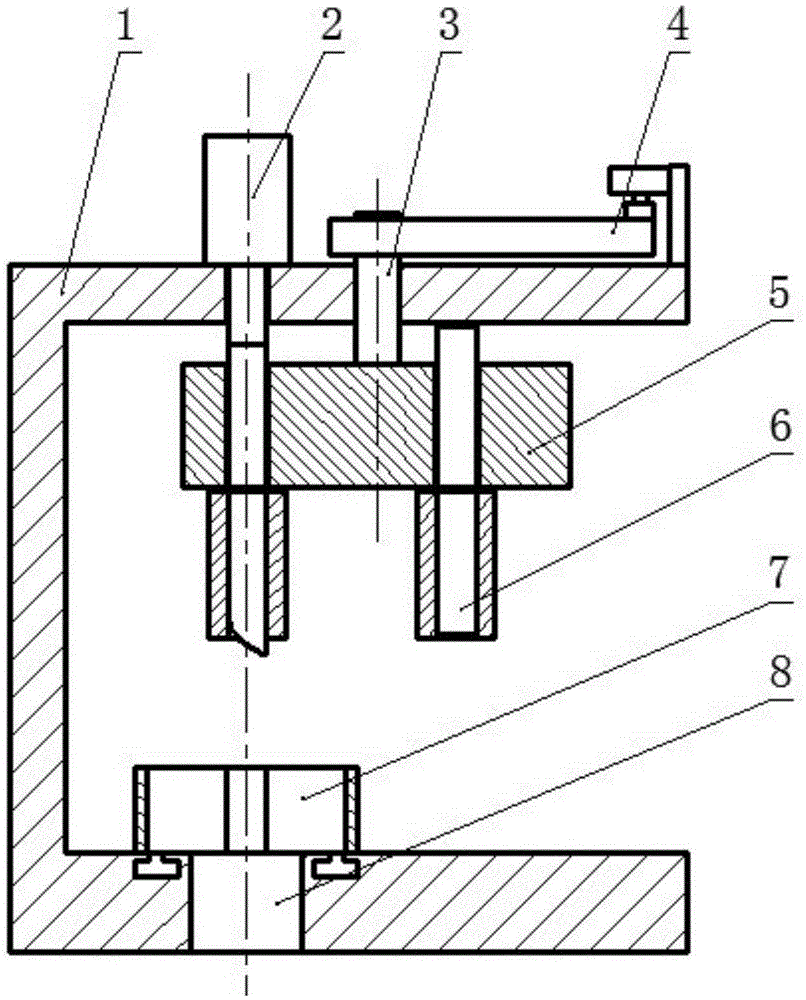

[0021] A multi-functional wire groove processing device, comprising a C-shaped base 1, an upper mold turntable 5, an upper mold 6, a lower pressing device 2 and a lower mold 7, as shown in the accompanying drawings, the inner upper end of the C-shaped base is rotatably installed with a Upper mold turntable, the upper mold turntable is hoisted on the C-shaped base through the rotation of the drive shaft 3, the upper end of the drive shaft is connected to the drive motor 4 through the transmission belt, and the drive motor controls the turntable to perform horizontal rotation and positioning. In this embodiment, a stepper motor is used. The rotation angle of the turntable is the same;

[0022] A plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com