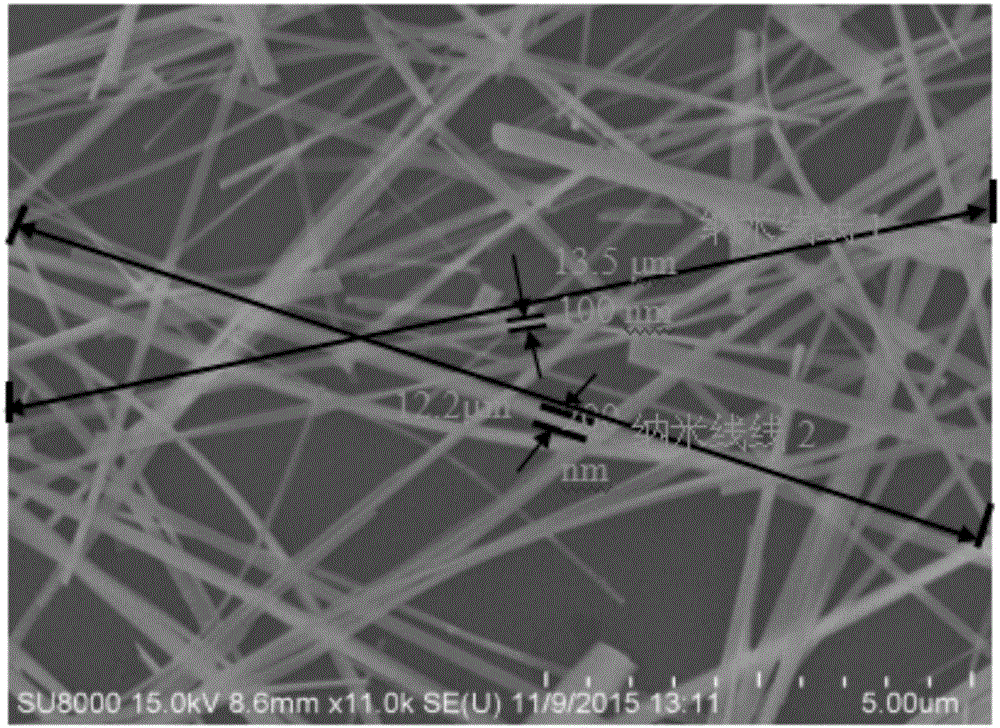

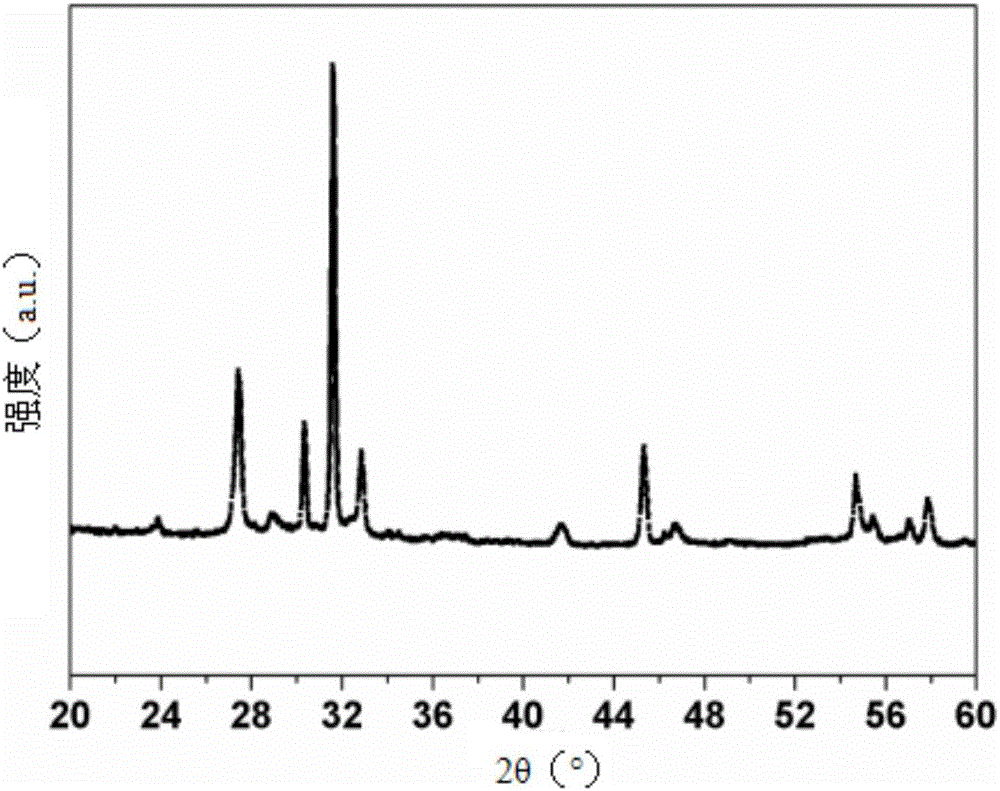

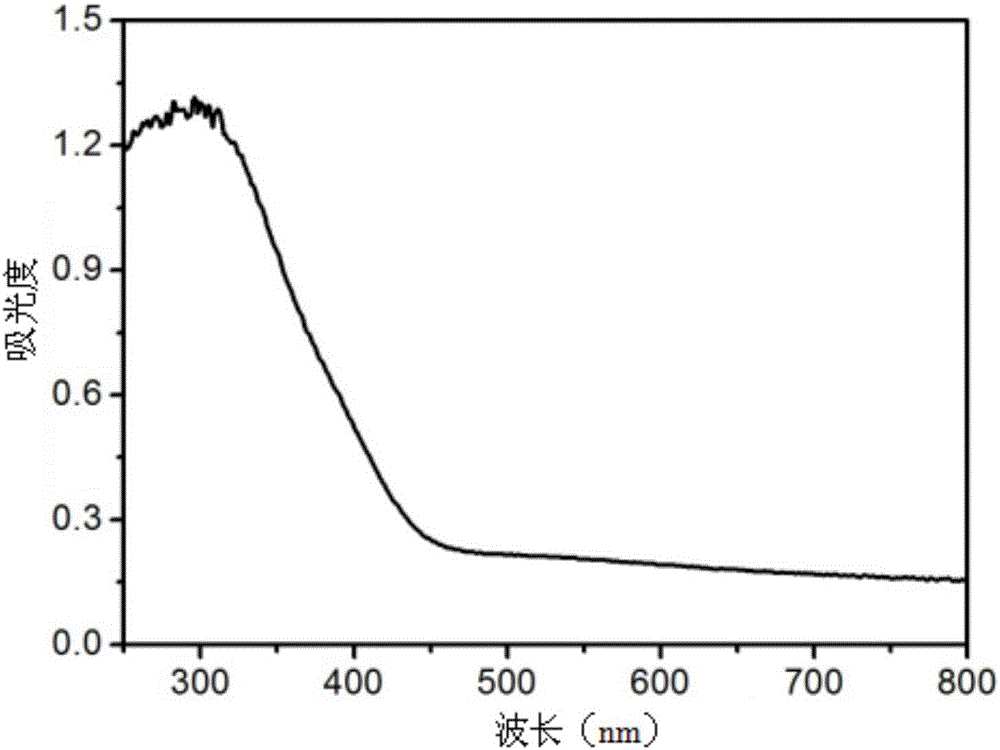

Silver tungstate nanowire and preparation method thereof

A technology of nanowires and silver tungstate, which is applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of difficult recovery of silver tungstate, achieve nanowires with excellent shape, perfect shape, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: select analytically pure sodium tungstate (Na 2 WO 4 ) and silver nitrate (AgNO 3 ) is the chemical raw material for synthesizing silver tungstate, after weighing the raw material according to the following stoichiometric ratio, it is prepared into solution respectively: Na 2 WO 4 +2AgNO 3 → Ag 2 WO 4 +2NaNO 3 . The preparation method of silver tungstate nanowires in the present embodiment is specifically completed through the following steps:

[0032] Step 1, while stirring, add 50ml of 0.01M silver nitrate solution dropwise to 50ml of 0.005M sodium tungstate solution (generally, the addition time is 15-20 minutes). The molar ratio of sodium tungstate to silver nitrate in the silver nitrate solution is 1:2, then dilute nitric acid (2% by mass) to adjust the pH to 2.5;

[0033] Step 2, then place the liner as a polytetrafluoroethylene (PTFE) reactor (the kettle material is chromium-nickel alloy (304II)), tighten the reactor with a bench...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com