Deep rotary cultivator capable of mixing of deep soil and surface soil

A hybrid, floating soil technology, which is applied in the direction of agricultural machinery and equipment, agricultural machinery and implements, shovels, etc., can solve the problem of plowing up deep soil that cannot be more nutritious, and the depth of the soil cutter on the rotating shaft is limited, which cannot fully meet the requirements. Problems such as crop growth, to achieve the effect of benefiting crop growth, reducing process machinery investment, and facilitating application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

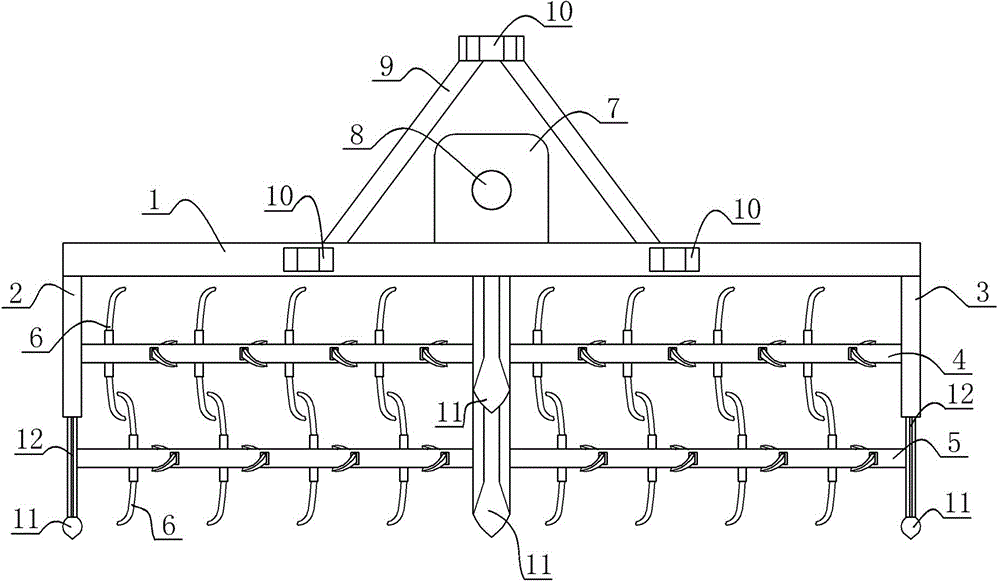

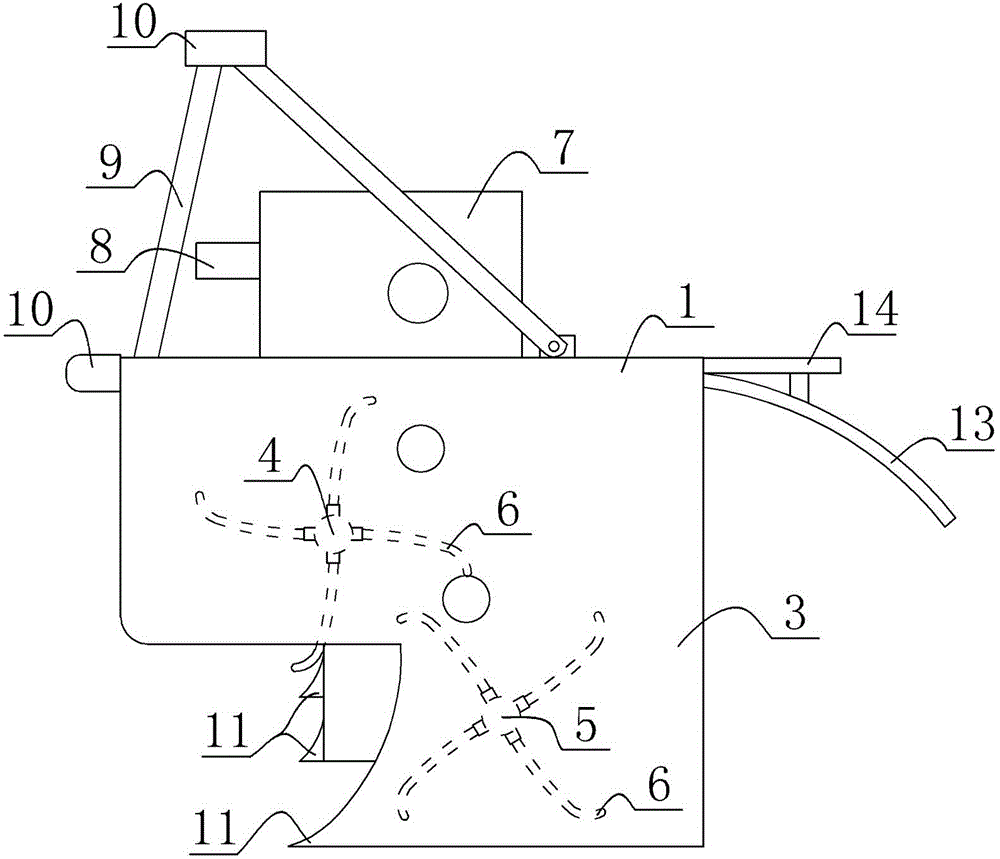

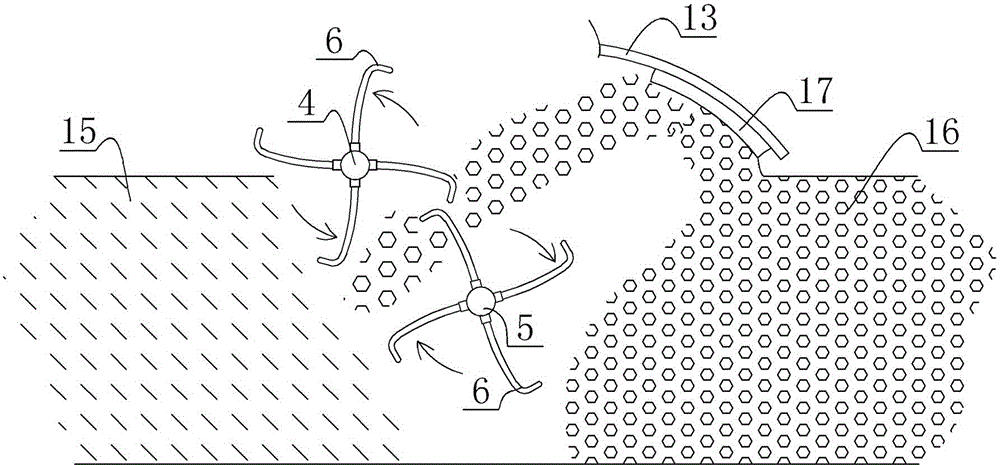

[0024] Such as figure 1 with figure 2 As shown, the front view and the right view of the deep soil and floating soil hybrid deep rotary tiller of the present invention are provided respectively, which include a frame 1, a left baffle 2, a right baffle 3, an upper rotating shaft 4, and a lower rotating shaft 5 , soil cutting knife 6, gearbox 7, connecting shaft 8, bracket 9, plow share loosening foot 11, arc baffle 13; the frame 1 shown plays a role of fixing and supporting, and the gearbox 7 is fixed on the frame 1 The middle part, and penetrates to the bottom of the frame 1, the upper end of the gearbox 7 is provided with a connecting shaft 8 connected with the power output shaft of the power machine. The left baffle 2 and the right baffle 3 are respectively fixed below the left and right ends of the frame 1, and the left and right ends of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com