Crystal growth device with melt stirring function

A technology of crystal growth and melt, applied in the direction of crystal growth, single crystal growth, self-solidification method, etc., can solve the problems of uneven distribution of doping ions, large radial temperature gradient, and gas is not easy to discharge, so as to improve uniformity. It has the effect of accelerating the escape of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

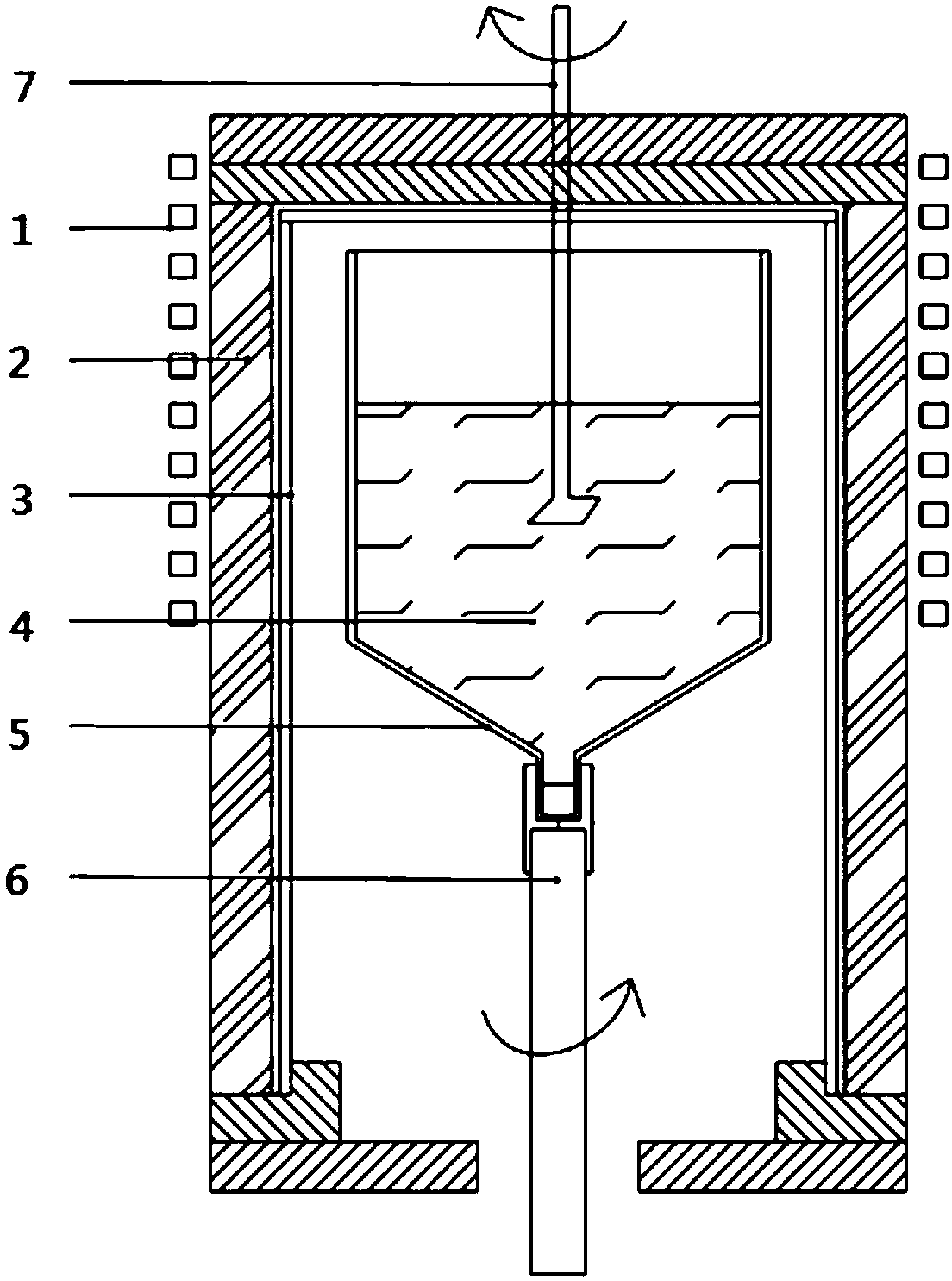

[0033] Taking induction heating to grow high melting point oxides such as sapphire Al2O3 and YAG as an example, such as figure 1 As shown, a crystal growth device with a melt stirring function includes an induction coil 1, an insulation layer 2, an induction heating element 3, a raw material 4, a crucible 5 and a crucible support 6, and the induction coil 1 is arranged on the insulation layer 2 outside, and 5-10mm away from the insulation layer. The induction heating element 3 is arranged on the inner wall of the insulation layer 2 to form a heat field with a cylindrical structure straight up and down. The thickness of the insulation layer 2 is 15mm-40mm. The crucible 5 is placed in the insulation layer 2 , and the crucible 5 is provided with a stirrer 7 for stirring the raw material 4 . The rotation rate of the agitator 7 is 2-10 rpm, and the stirring time is 30-60 minutes. The crucible 5 is arranged on the rotatable crucible support 6, and the rotation of the crucible sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com