A wire rope decontamination device integrating revolution and rotation

A steel wire rope and gear shaft technology, which is applied in the field of wire rope decontamination devices, can solve the problems of unenvironmental protection, waste of time, and increase the labor intensity of staff, and achieve the effects of high degree of mechanization, improved work efficiency, and good decontamination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

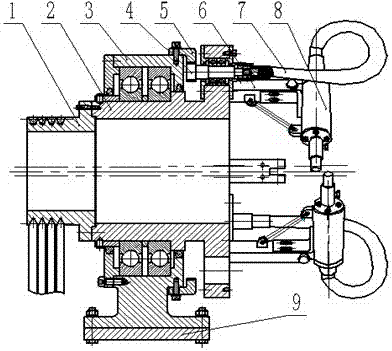

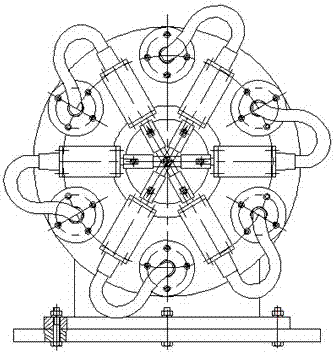

[0014] Such as figure 1 As shown, a wire rope decontamination device integrating revolution and rotation consists of a pulley 1, a brush seat 2, a base 3, a gear shaft 4, an internal gear 5, a connecting plate 6, a flexible shaft 7, a wire rope brush group 8, a bracket 9, etc. It consists of several parts. The base 3 is fixed on the bracket 9, the brush base 2 and the base 3 are supported by two deep groove ball bearings, the pulley 1 is fixed on the brush base 2 with screws, the internal gear 5 is fixed on the base 3 with screws, and the gear shaft 4 and the brush base 2 are supported by two deep groove ball bearings, the connecting plate 6 is fixed on the brush base 2 with screws, the wire rope brush group 8 is installed on the connecting plate 6 with pins, and the gear shaft 4 and the brush base 2 Between with flexible shaft 7 transmissions. Steel wire brushes are housed on the wire rope brush group 8, and the surface of steel wire rope is completely covered by six wire b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com