Storage bin device of rotatable slurry spraying machine

A technology of shotcrete machine and silo, which is applied in the field of rotatable shotcrete machine silo device, which can solve the problems of difficult to meet the requirements of vibration blanking, clogging of shotcrete machine silo, and affecting normal production, etc., and achieves long service life , Reduce labor intensity, reduce the frequency of manual feeding and the effect of labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

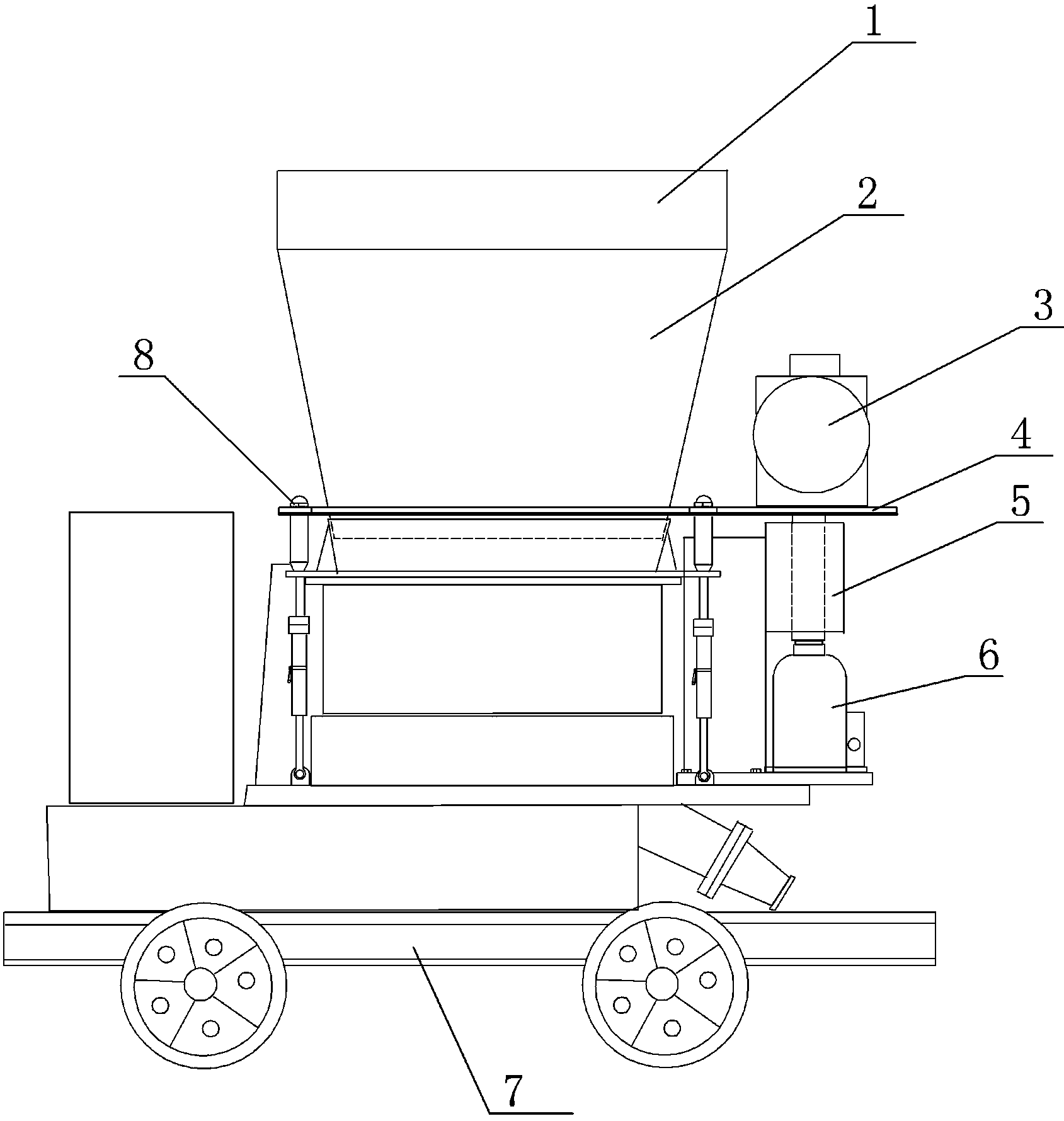

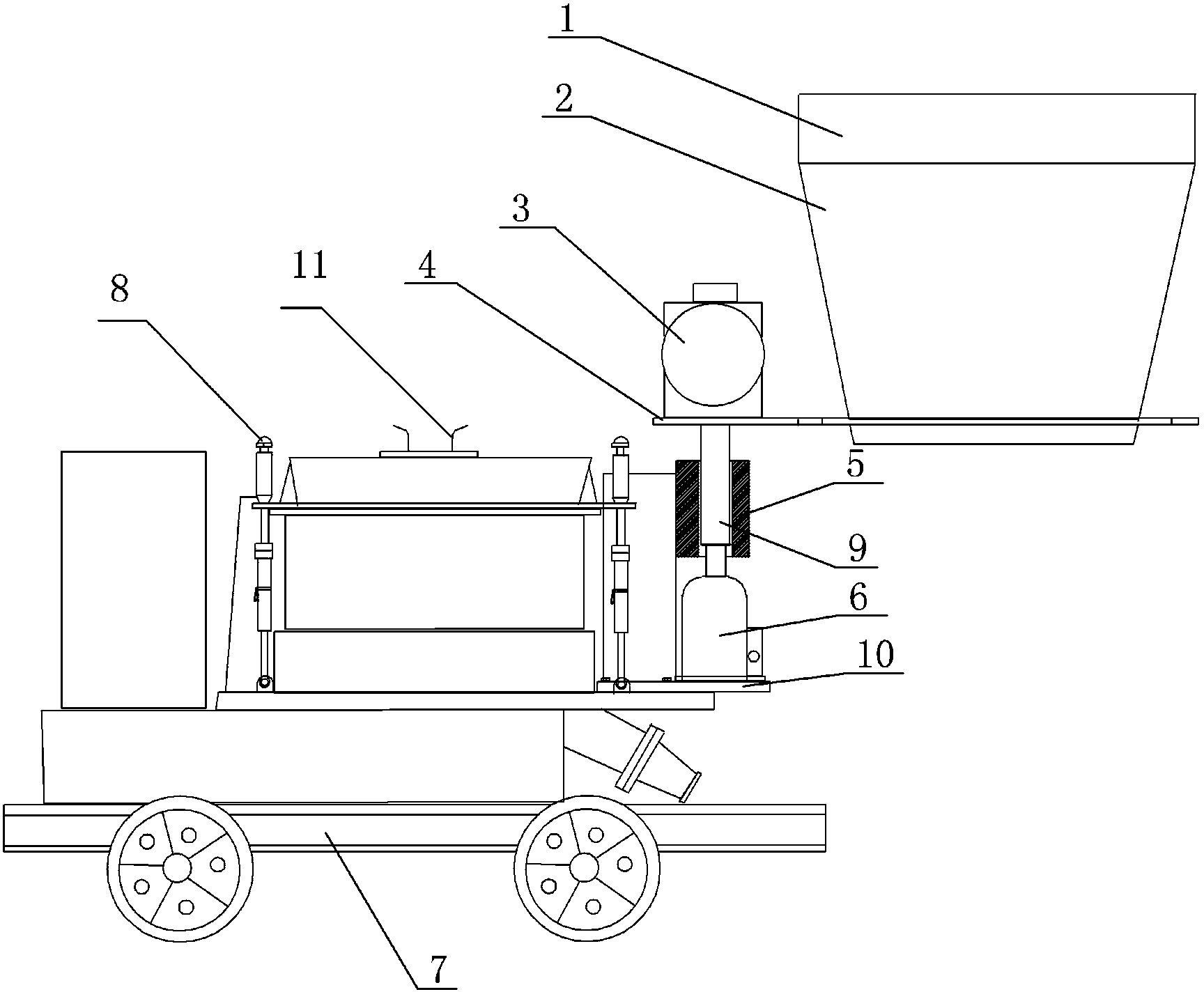

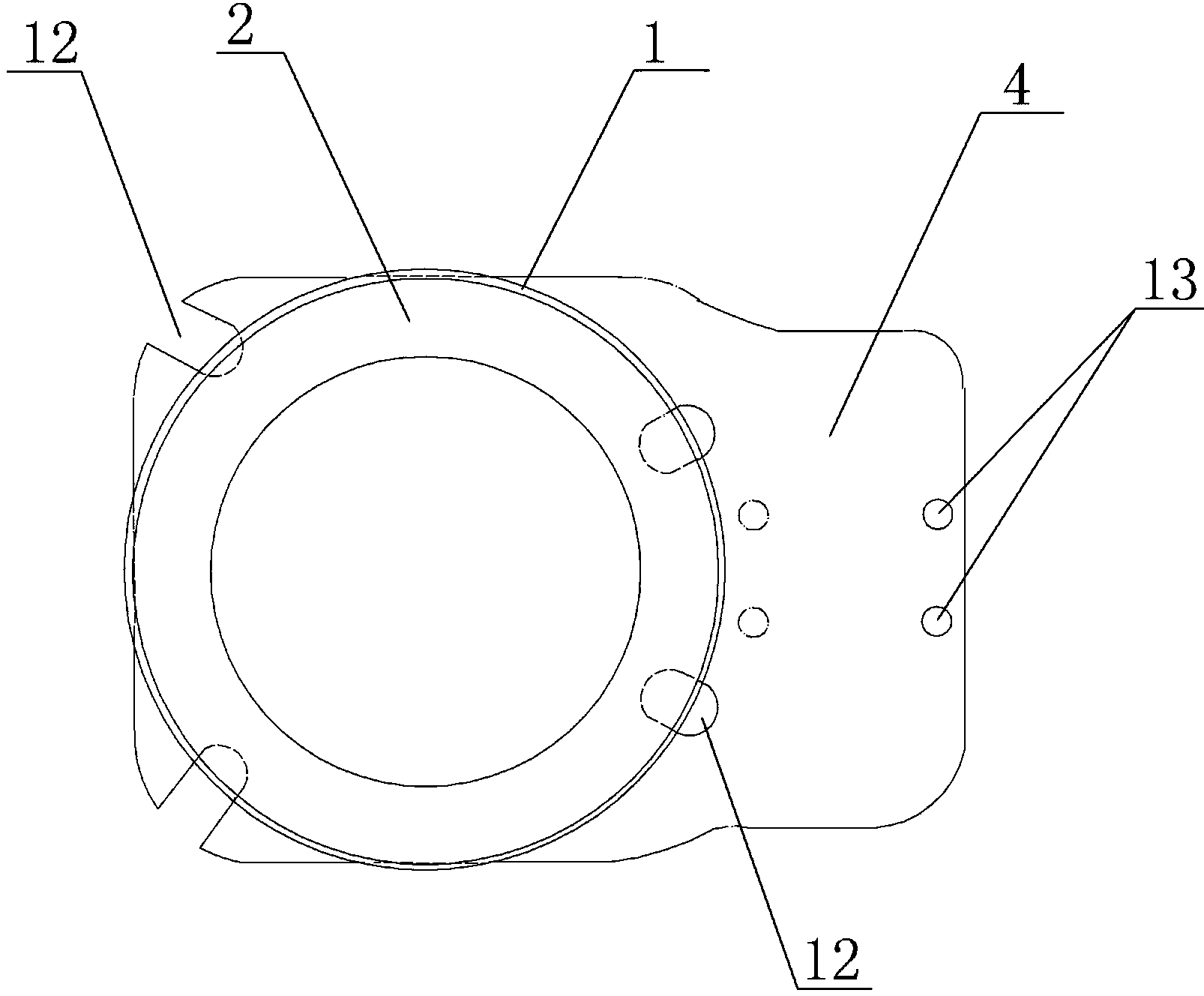

[0019] Embodiment one: see figure 1 , figure 2 and image 3 , in the figure, the number 1 is the upper silo, 2 is the lower silo, 3 is the vibration motor, 4 is the base of the silo, 5 is the shaft guide bushing, 6 is the hydraulic jack, 7 is the car body, and 8 is the compression bolt , 9 is a feed bin rotating shaft, 10 is a feed bin rotating support seat, 11 is a mixing tooth, and 12 is a fixed hole or a positioning hole. The rotatable shotcrete machine silo device is that a shotcrete machine and an electrical cabinet are installed on the car body 7, and the silo is a butt joint structure of the upper column silo 1 and the lower conical silo 2. Change the geometry of the silo. The original two-layer hopper is changed to a cylinder on the top and a cone-shaped integrated silo on the bottom, and the volume is increased by 50%. The lower end of the silo (that is, the lower end of the conical section) is horizontally fixed with a silo base 4, one side of the silo base 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com