Method for preparing oxygenous fuel by coal synthesis gas slurry bed

A technology of oxygen-containing fuel and slurry bed, which is applied in the direction of liquid carbon-containing fuel, fuel, chemical instruments and methods, etc., and can solve problems affecting quality and heat transfer, unfavorable reaction speed, catalyst life, and enhanced fluid disturbance capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

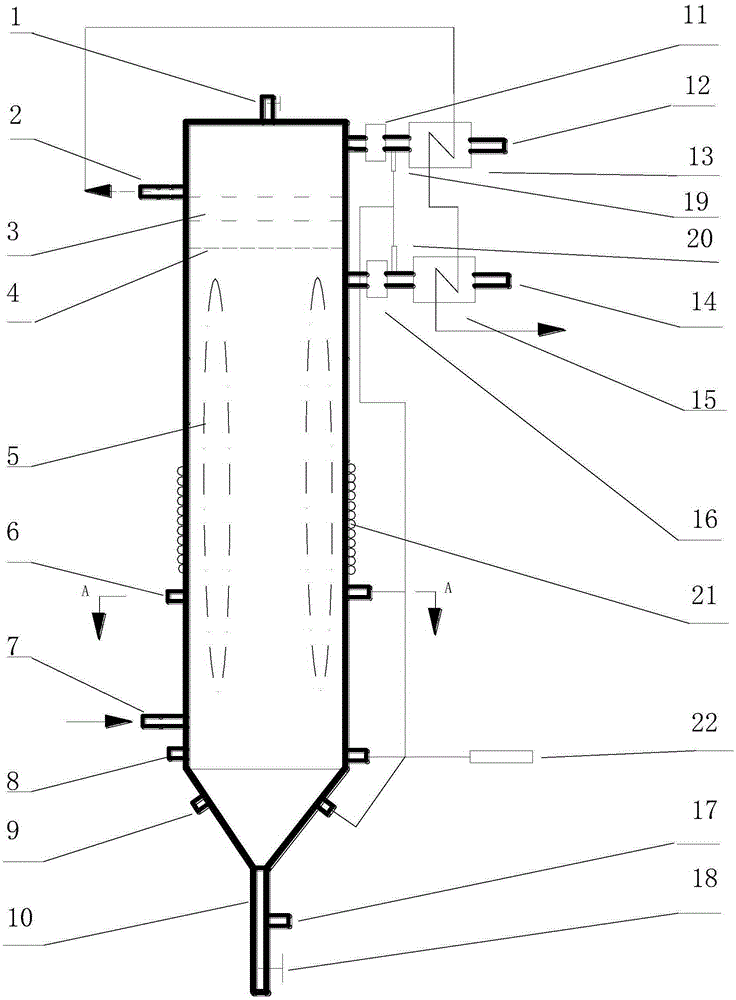

[0028] as attached figure 1 , using the attached figure 1 The technological process, implement a kind of coal synthesis gas external swirl type slurry bed system oxygenated fuel method of the present invention, this method is to carry out according to the following steps:

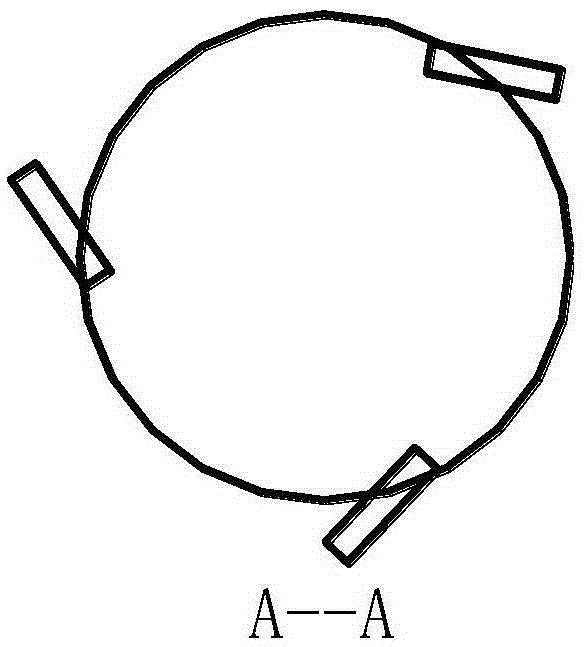

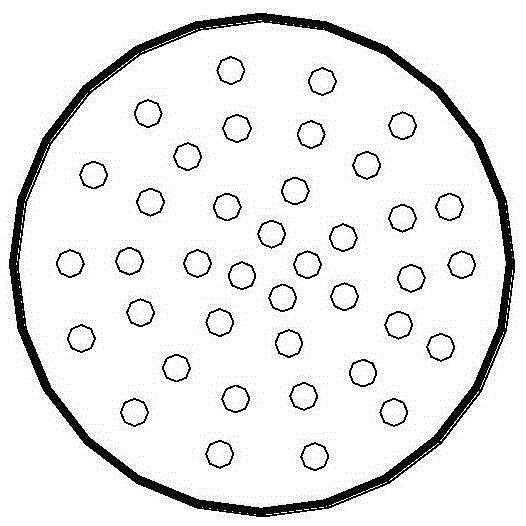

[0029] Step 1, the reactor is pre-loaded with solid catalyst particles and inert liquid molten paraffin to reach the reactor liquid level 4, and the synthesis gas (C0+H 2 ) from the upper layer reaction gas inlet 6, the middle layer reaction gas inlet 8, and the lower layer reaction gas inlet 9 swirl into the reactor, and enter the slurry bed reactor in the form of bubbles. After the unsteady process, the reactor forms gas, liquid, and gas phases. Fluidized form. The synthesis gas diffuses in the liquid paraffin and reacts on the surface of the catalyst particles. The heavy hydrocarbon liquid phase product generated in the reaction passes through the liquid phase product liquid-solid filter 16 and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com