Trichlorosilane reactor

A trichlorosilane and reactor technology, applied in the direction of halosilane and silicon halide compounds, can solve the problems of low production efficiency, easy burning loss, high cost, etc., so as to improve service life, avoid local burning loss, reduce The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

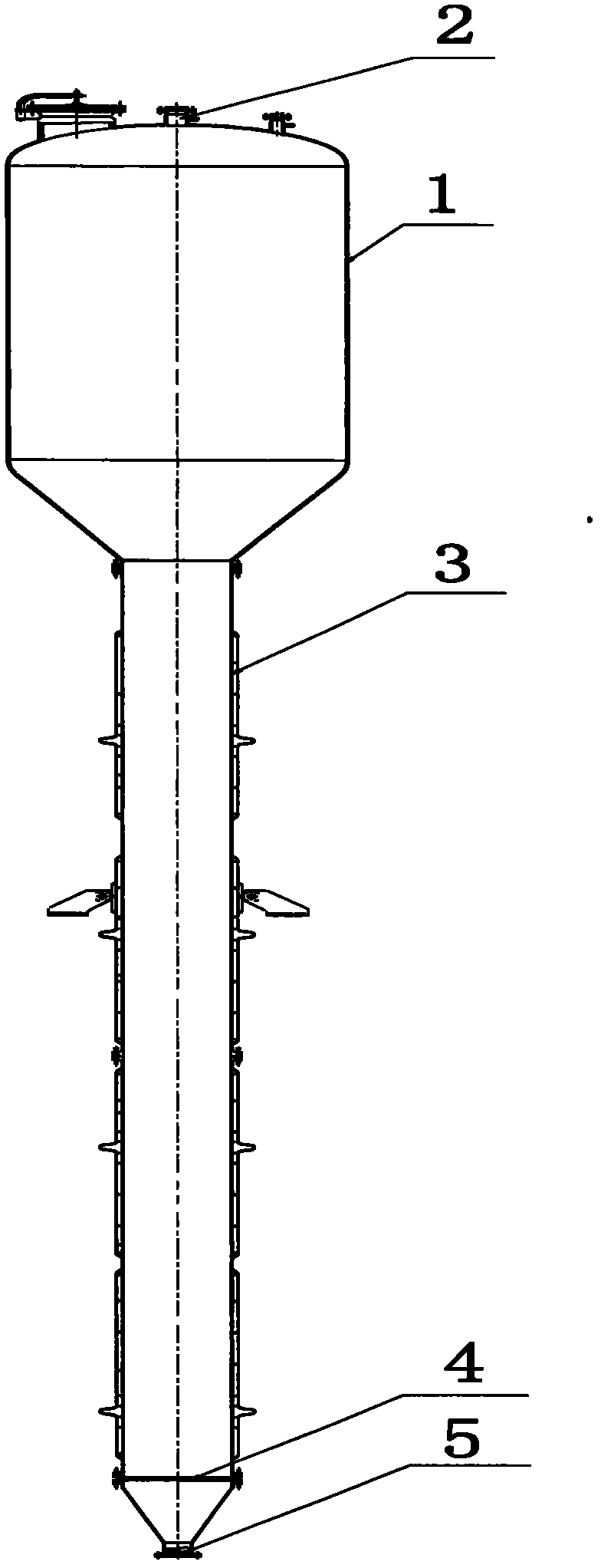

[0021] Now in conjunction with accompanying drawing, this trichlorosilane reactor is specifically described as follows:

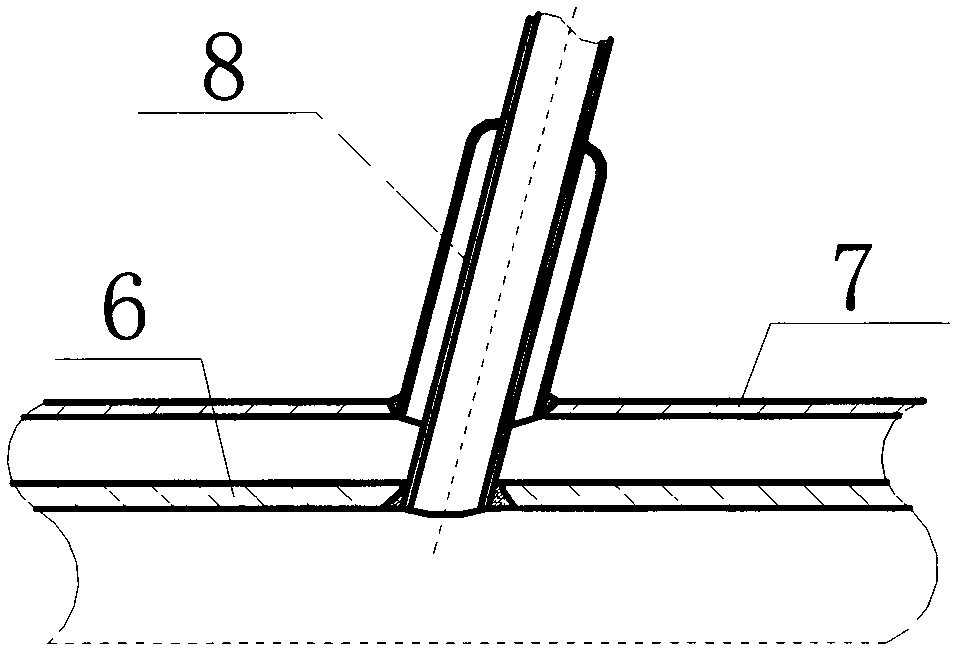

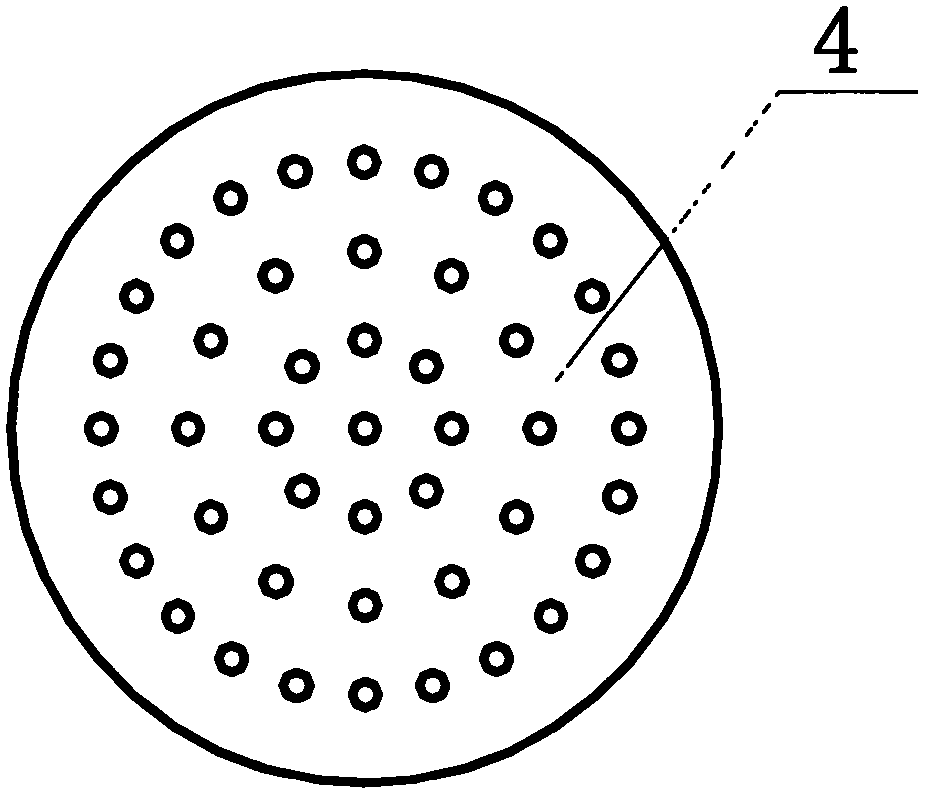

[0022] Reference attached figure 1 , through process calculation, design analysis, and cost comparison, the material of the main shell 1 of the equipment is changed from the original 0Cr18Ni10Ti to the more economical 15CrMoR material; the silicon powder feed port 2 is moved from the middle to the top; the water jacket 3 is added On the outer surface of the main shell 1; the gas distributor 4 is added above the air inlet 5; the water jacket 3 is formed by welding and sealing the jacket cylinder 7, the inner cylinder 6 and the connecting pipe 8.

[0023] During the operation of the equipment, the reaction gas is introduced from the mixed gas inlet 5, and then enters the equipment after being uniformly dispersed by the gas distributor 4; the silicon powder is added from the silicon powder feeding port 2, and the process of free falling realizes the dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com