Patents

Literature

189results about How to "Strong stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

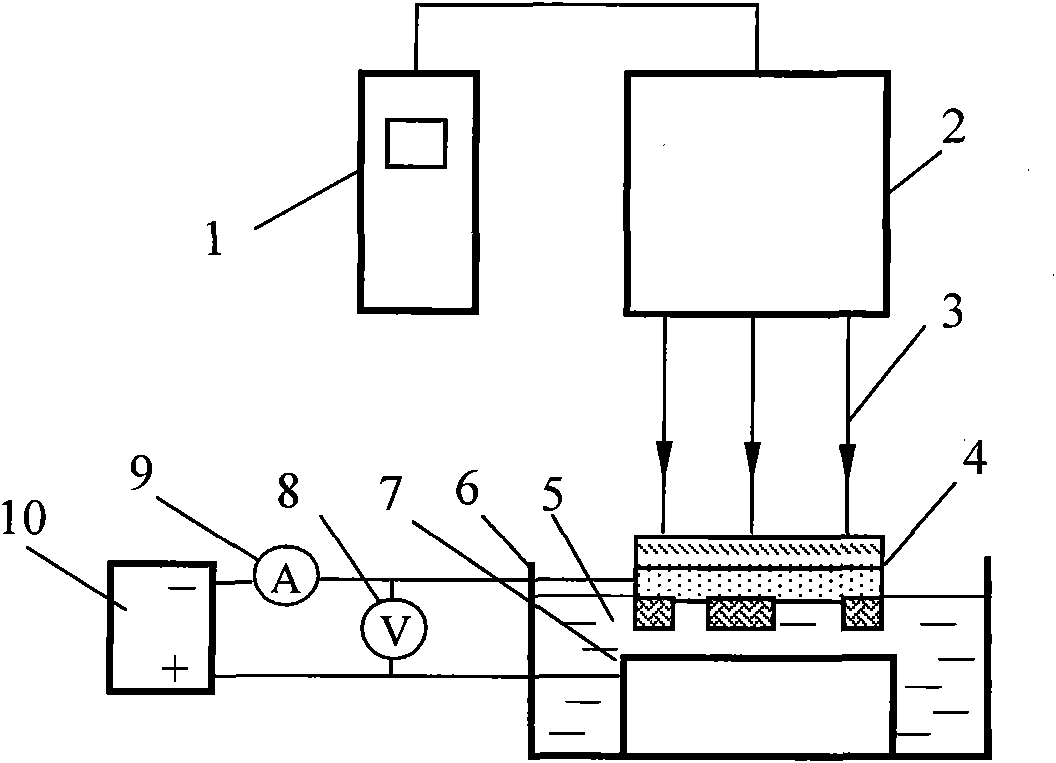

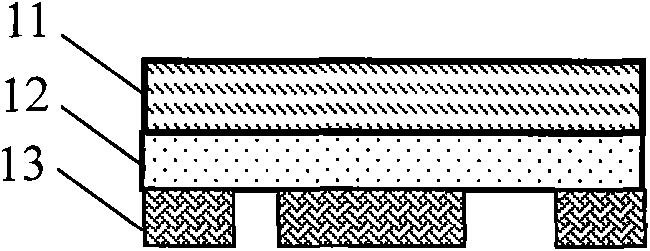

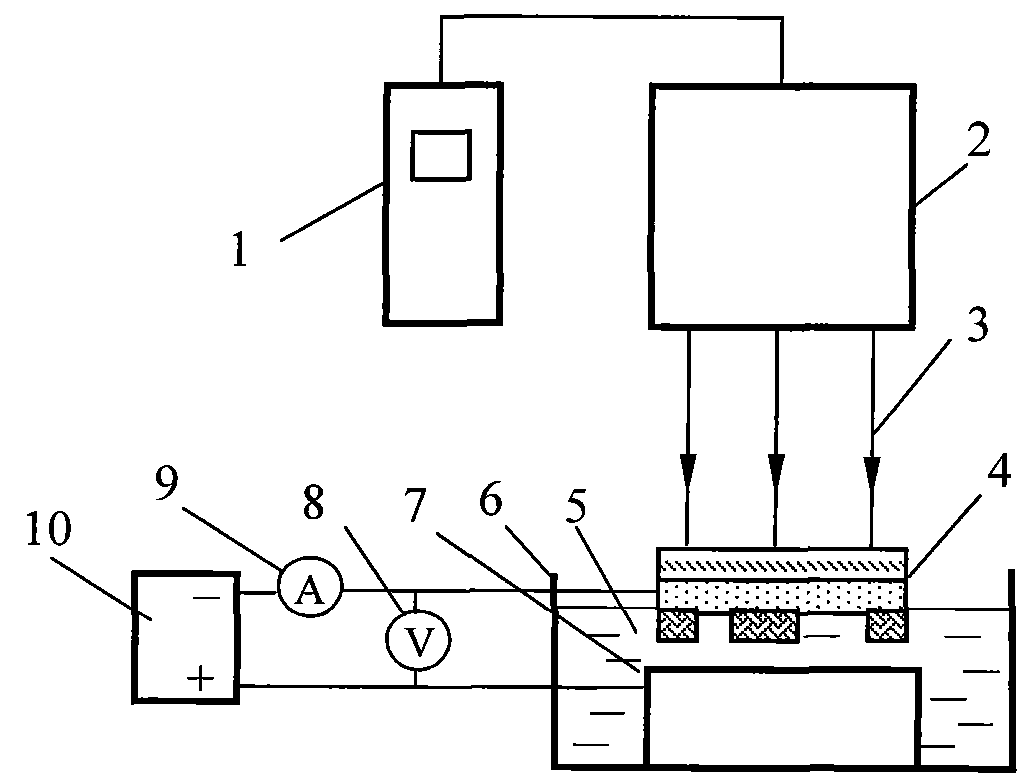

Method and device for realizing photoelectrochemical micro-etch processing of masked electrode

The invention provides a method and a device for realizing the photoelectrochemical micro-etch processing of a masked electrode, and relates to the micro processing field in the manufacturing technology. A masked electrode used by the invention comprises a glass substrate, an indium tin oxide (ITO) layer and a photoresist mask layer, wherein the conductive light-permeable ITO layer is used as a tool electrode for electrochemical processing and can be permeated by a laser beam, and the photoresist mask layer can limit the action zones of the laser beam and the electrochemical electrode to achieve the double effects of a beam mask and an electric field mask. When the laser beam permeates the masked electrode, a mask pattern is imaged on the surface of a workpiece, the force effect of a shock wave generated by the irradiation of the laser between the workpiece and the electrolyte enables the passivation layer to be removed by the generation of stress corrosion. Meanwhile, the workpiece material at the laser-irradiated part is removed by etching under the action of the photoelectrochemical reaction. The invention can effectively enhance the processing efficiency, the micro processing degree and the processing precision of the complex pattern, and is applicable to the micro processing of the conductive metal material.

Owner:JIANGSU UNIV

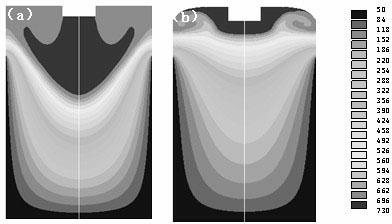

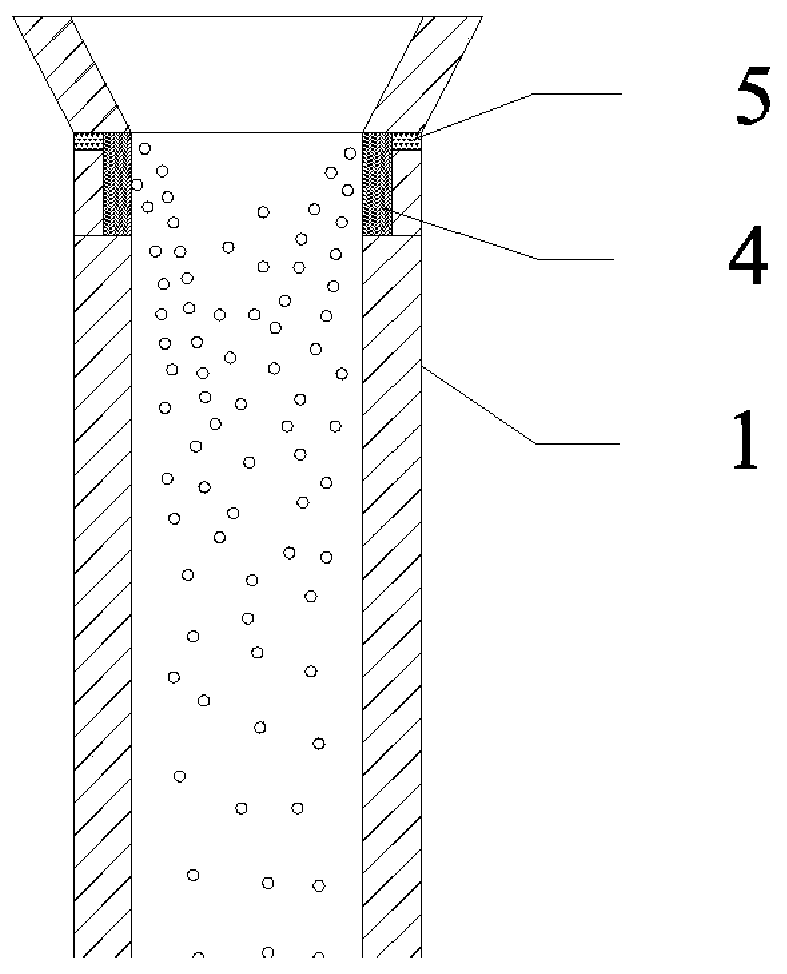

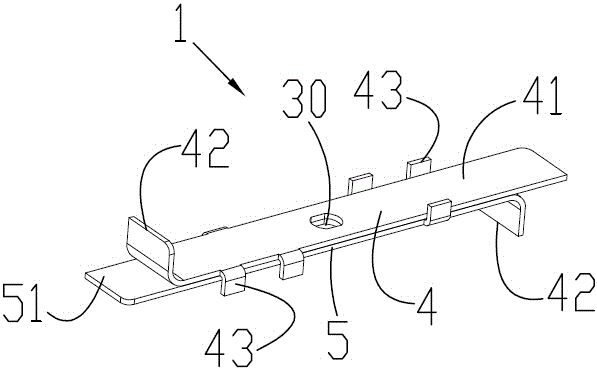

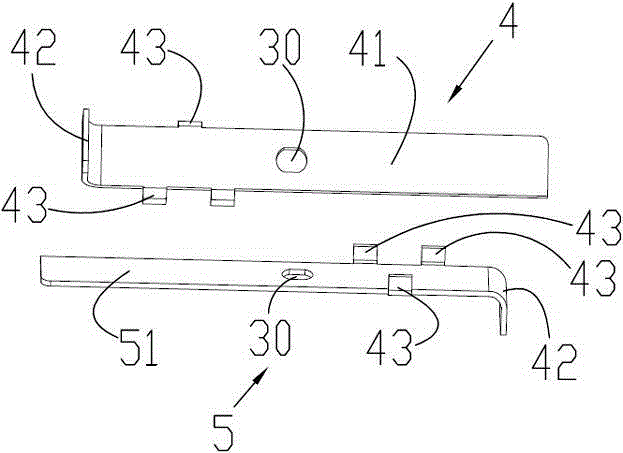

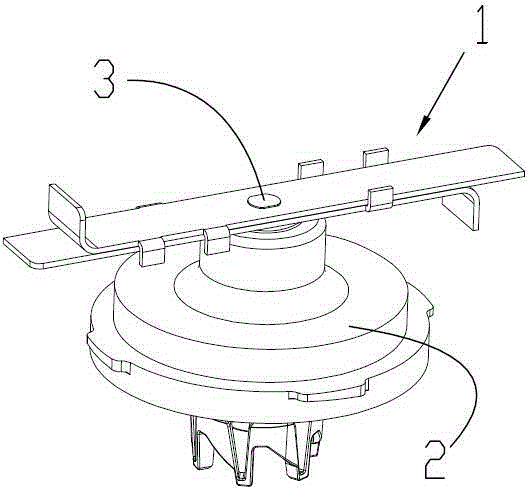

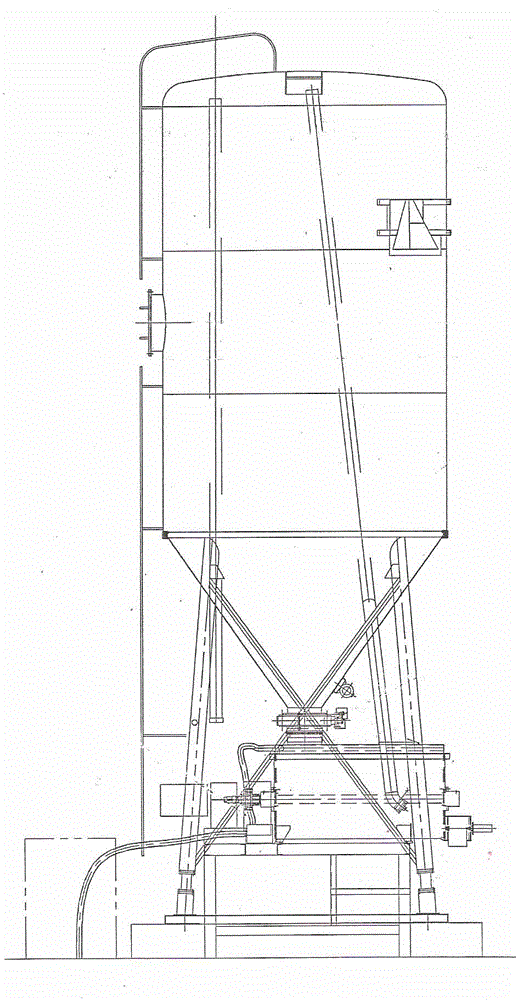

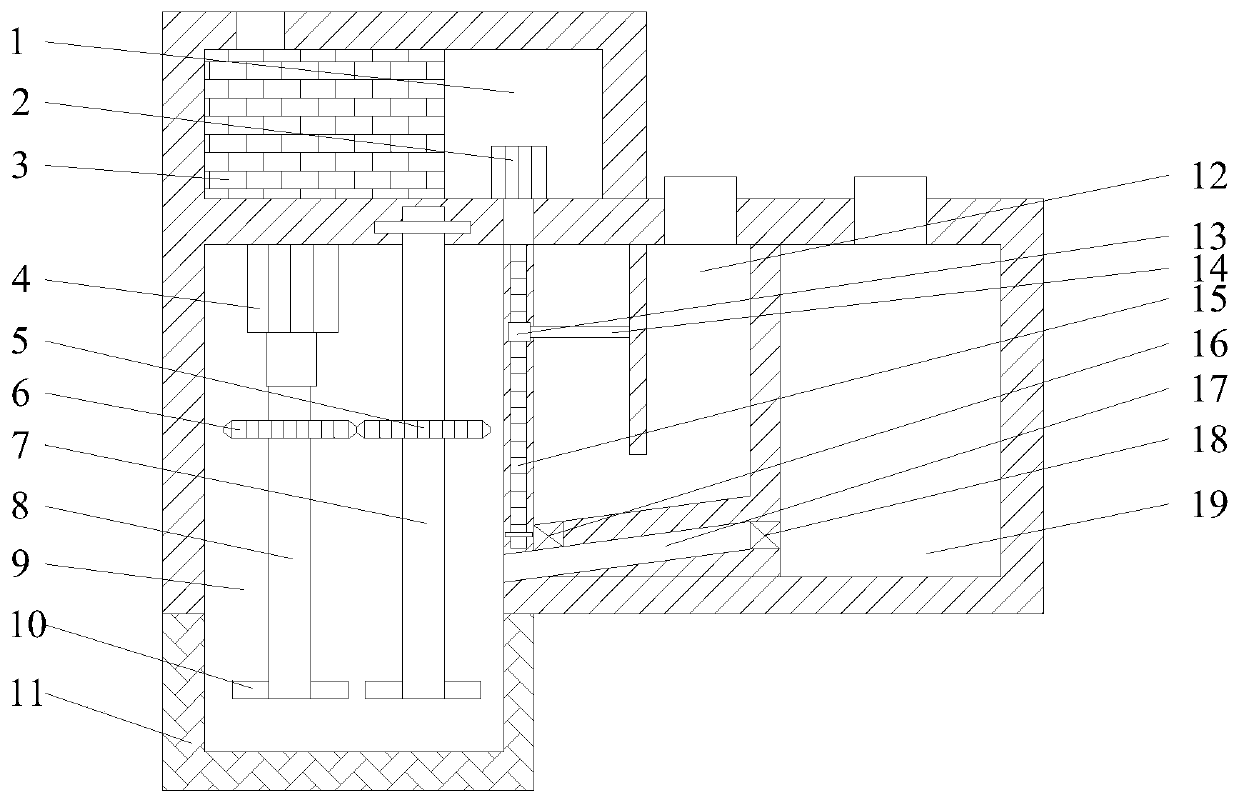

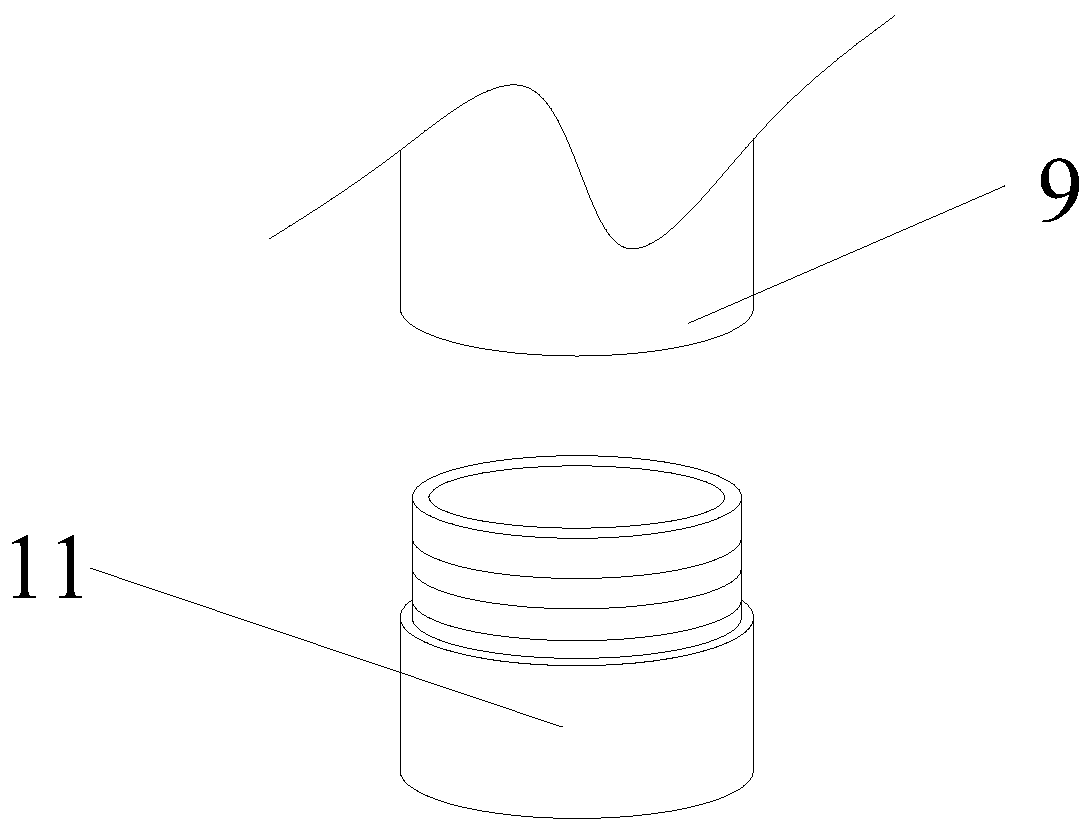

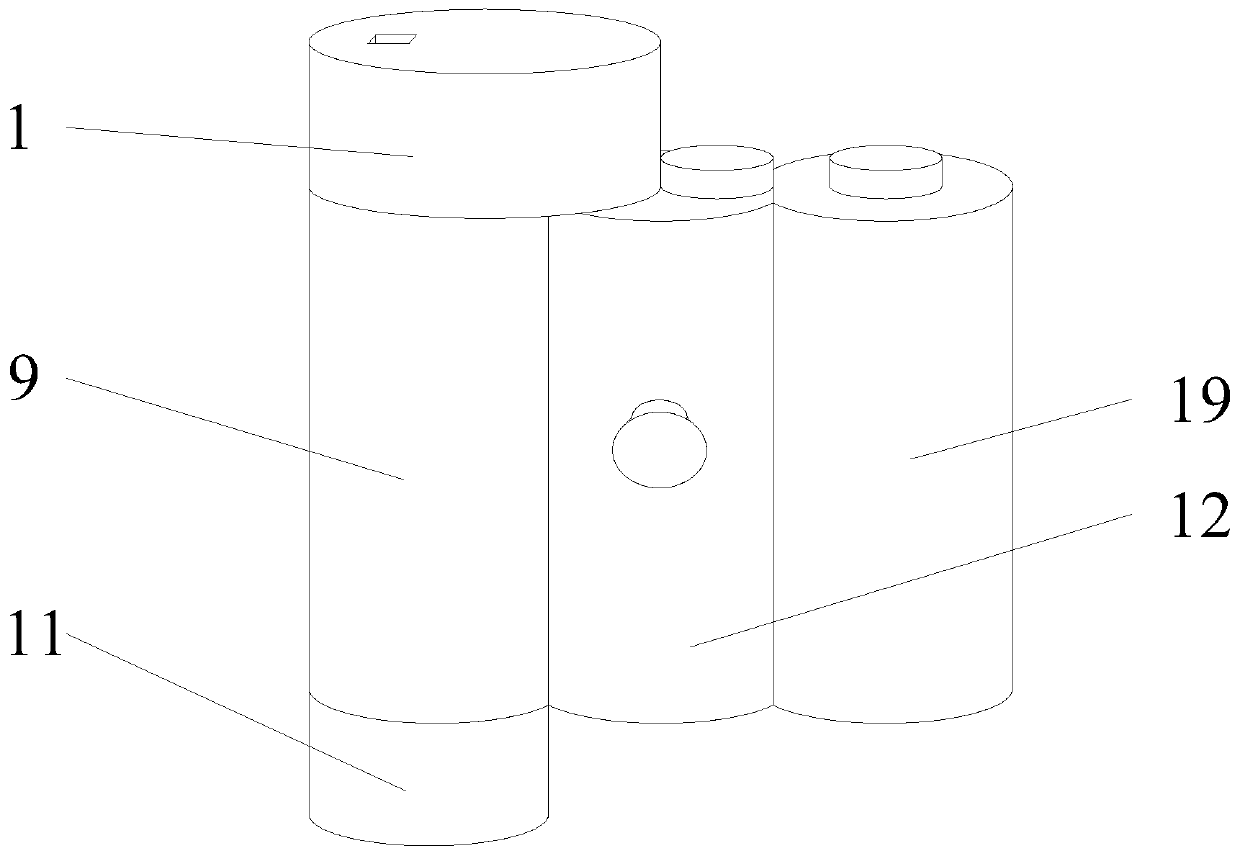

Method for preparing nanocystalline ingot casting by magnetic field and ultrasonic combined treatment of metal melt and dedicated apparatus therefor

It is a method for preparation and the special device of nanocrystalline ingotting from metallic fondant treated jointly by magnetic field and supersonic wave, solving the present technique problem of complex device, high cost, and difficulty to prepare large-scale nanometer material and so on. The invented method is as the following steps: melting and heating the matched raw material, deairing the metallic fuse-elements, pouring rapidly the deaired metallic fuse-elements into preheated crucible, heating upwards the liquidus curve, applying electromagnetic mixing and ultrasonic vibration, chilling until it freezes totally, then the block-shaped nanocrystalline ingotting being prepared; the special device that applied joint treatment of electromagnetic mixing and ultrasonic vibration having a holding furnace, which is equipped with a crucible, the special being characterized in that outboard of the holding furnace is equipped with magnetic field generator, over the crucible there is a ultrasonic transducer, and bottom of the crucible is equipped with a chiller.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

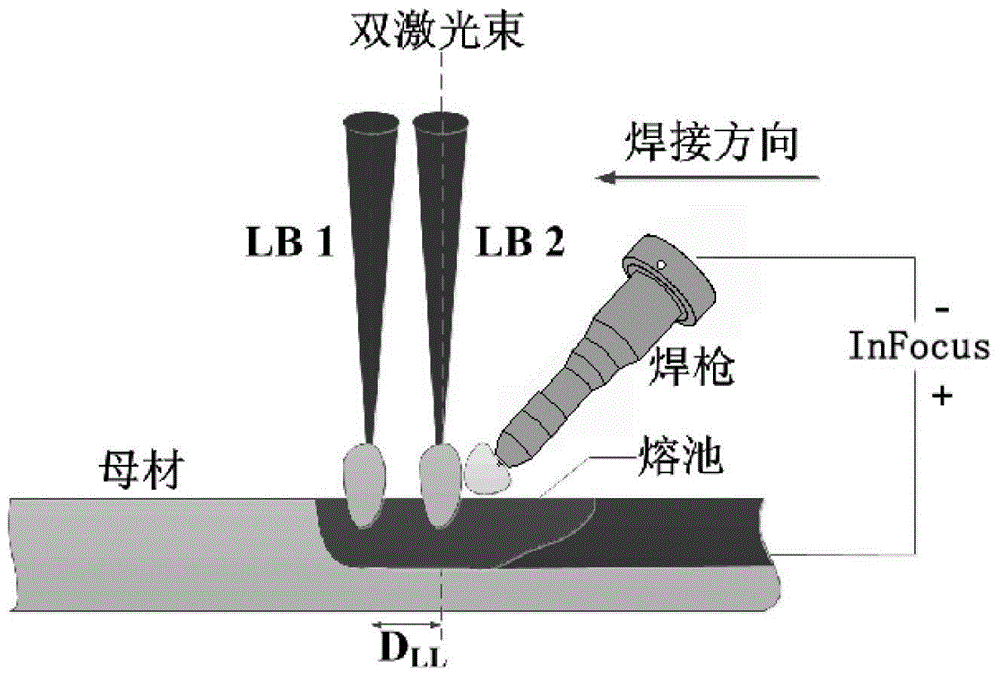

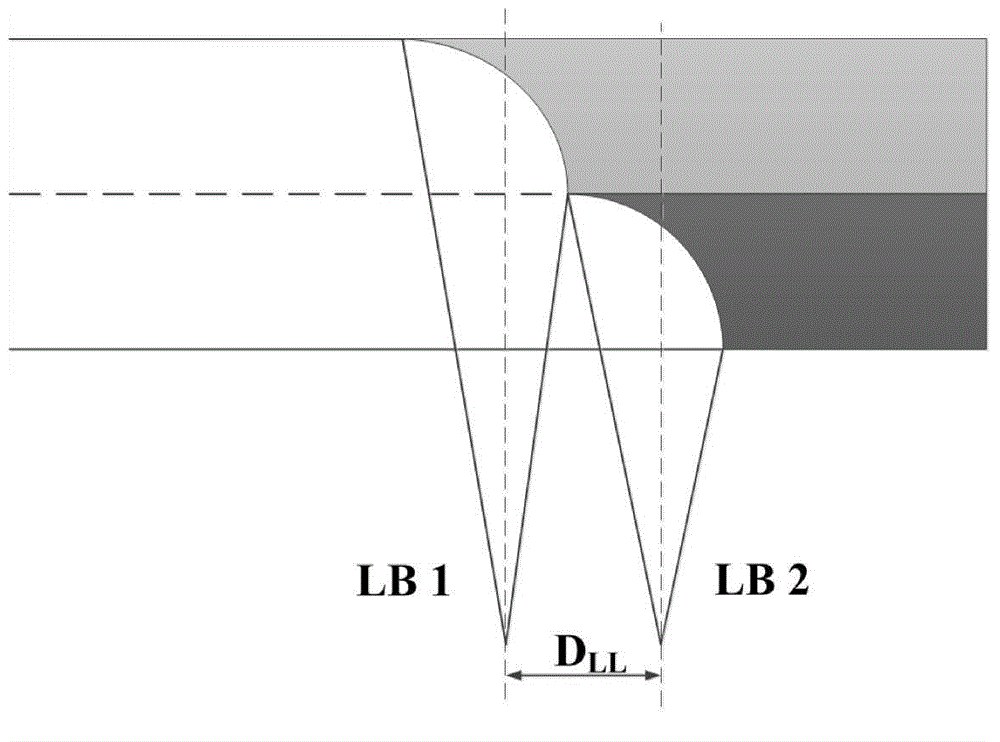

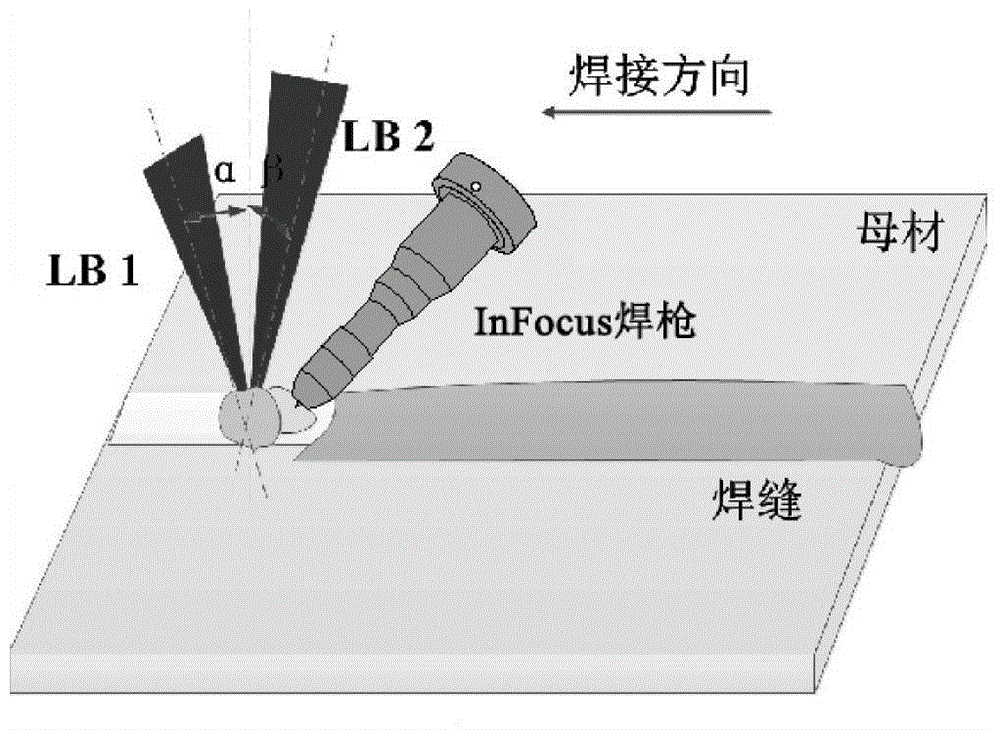

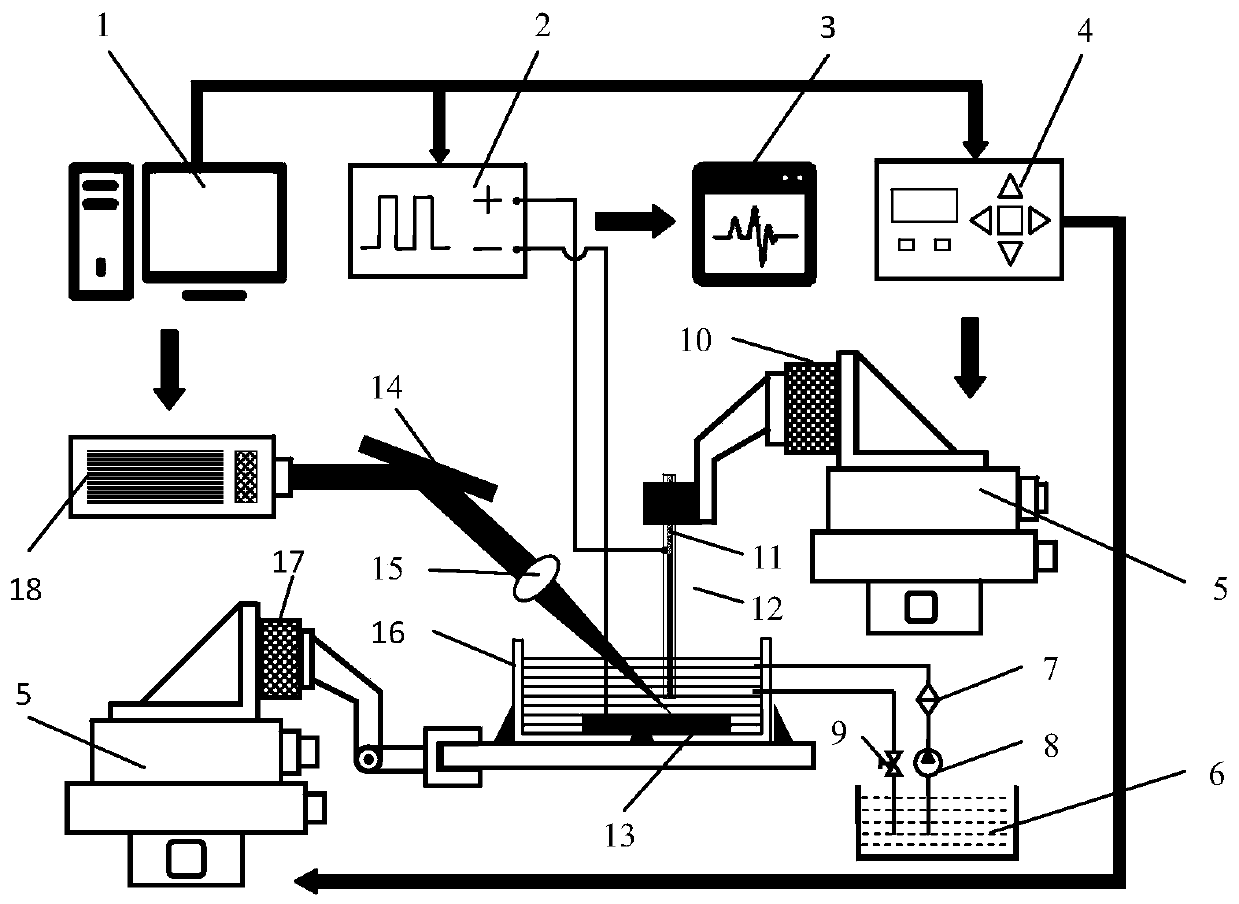

Bifocus laser and InFocus arc hybrid welding method

InactiveCN104985327AImprove energy utilizationIncrease weld penetrationLaser beam welding apparatusElectric arcEngineering

The invention discloses a bifocus laser and InFocus arc hybrid welding method, and relates to a welding method. The method includes the steps that (1) a to-be-welded workpiece is polished or washed; (2) the spot diameter is set to range from 0.1 mm to 0.5 mm, and the defocusing amount ranges from -3 mm to +3 mm; (3) welding parameters are set, wherein the arc current ranges from 50 A to 900 A, an included angle formed between a welding gun and the vertical direction ranges from 25 degrees to 55 degrees, the welding speed ranges from 100 mm / min to 1000 mm / min, the wire feeding speed ranges from 100 mm / min to 600 mm / min, the protection gas is inert gas, and the flow of the protection gas ranges from 15 L / min to 30 L / min; and (4) a switch is started, and laser-InFocus arc welding is carried out. According to bifocus lasers and InFocus, as the InFocus arc fusion depth is larger, and a key hole can be formed through welding, when a medium-thickness plate is welded, the lasers can directly act on the bottom of the key hole generated by the InFocus arc, and the fusion depth is continuously increased.

Owner:HARBIN INST OF TECH

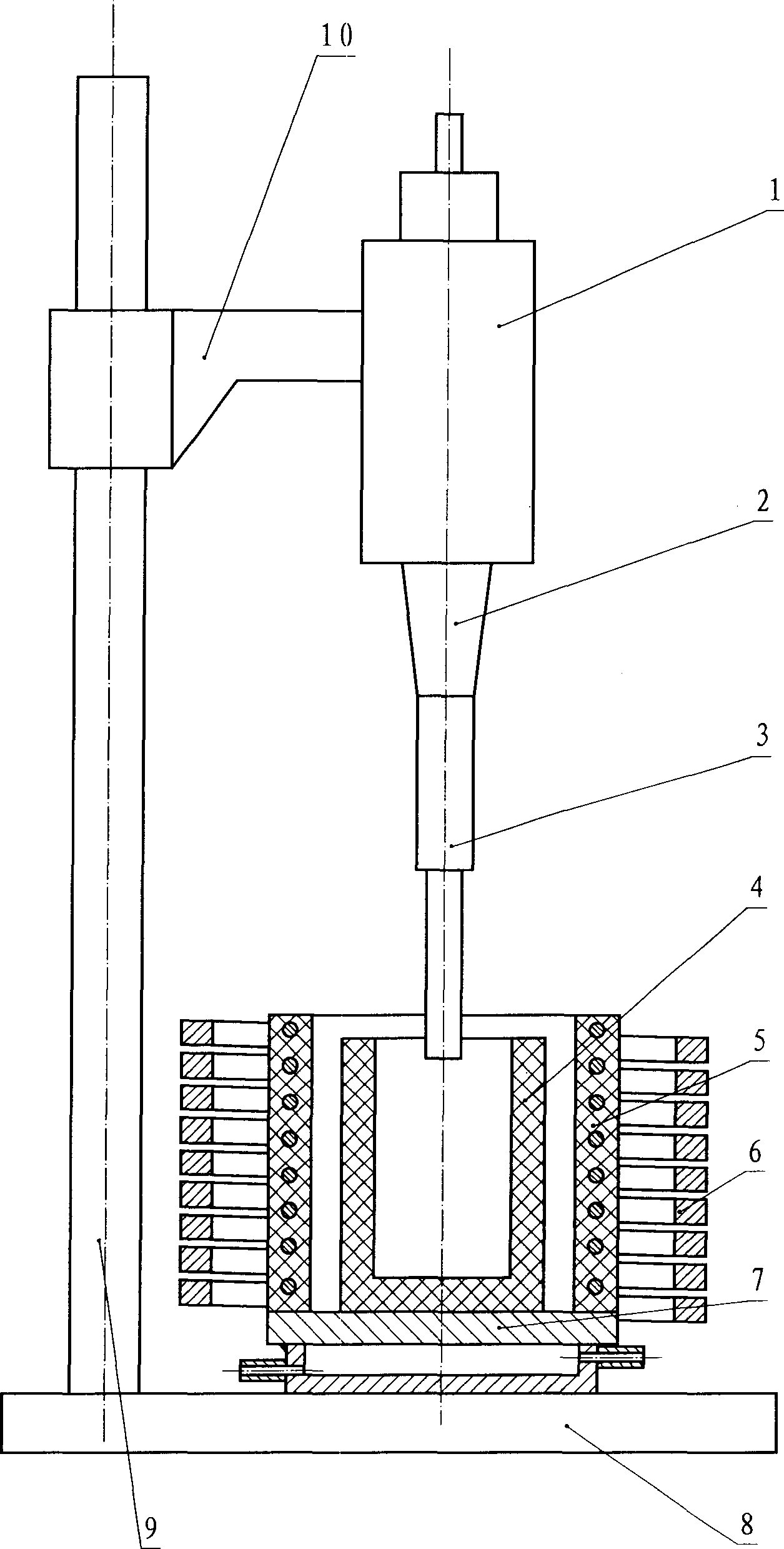

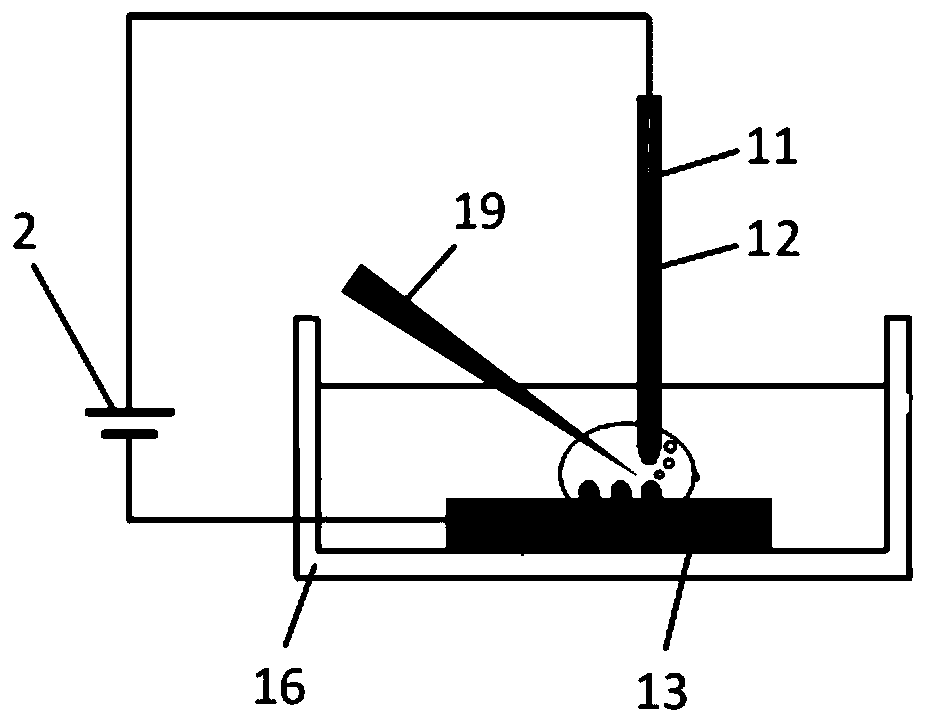

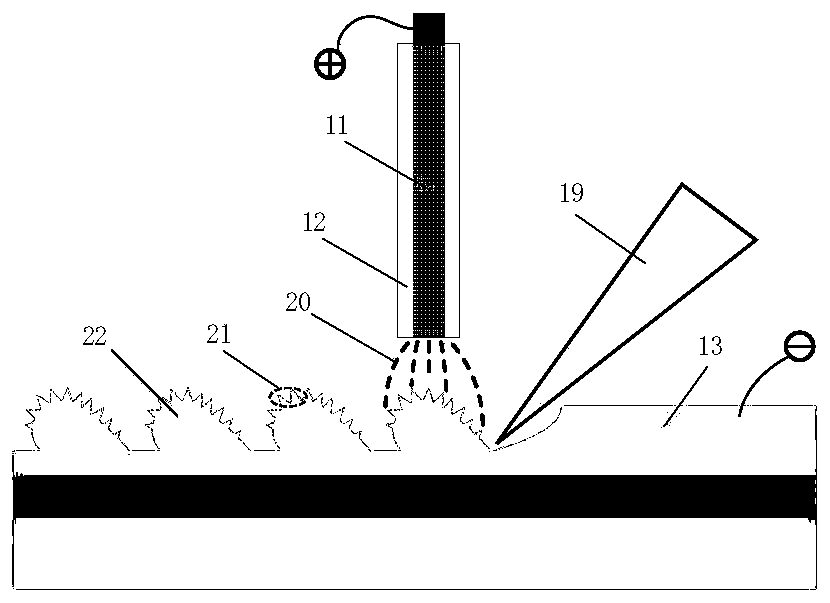

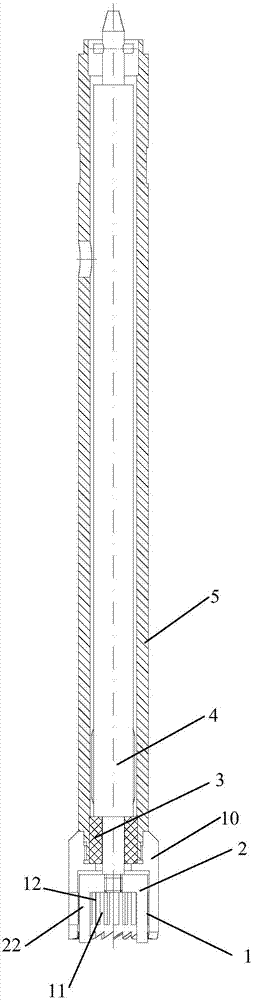

Machining method and device for preparing micro-nano two-dimensional structure on surface of workpiece

The invention discloses a machining method and device for preparing a micro-nano two-dimensional structure on the surface of a workpiece, and belongs to the field of special machining. In the machining process, a laser ablation and electrochemical deposition coupling method is adopted, a laser beam is focused on the surface of a workpiece substrate, the area and path of laser ablation are controlled through a numerical control system, and a micron-grade structure is machined on the surface of the workpiece substrate; and a tool anode keeps being aligned with the ablation area while laser ablation is conducted, and then a nano structure is deposited on the micron-grade structure in the area of the workpiece substrate. In order to restrain an anodic electric field in a top end area of an electrode to the maximum limit, the tool anode penetrates into an insulated glass pipe to achieve side wall insulating. In addition, the temperature of a solution in an irradiation area is increased through the thermal-mechanical effect of laser light, and meanwhile the strong stirring effect is generated to accelerate circular flow updating of deposition liquid and promote quick and efficient growthof the nano structure. The machining method and device are suitable for efficient machining and manufacturing of the micro-nano two-dimensional structure on the surface of a part.

Owner:JIANGSU UNIV

A Repairing Method of Hard Surface Gear

ActiveCN102294566AResolve fault thicknessQuick fixMetallic material coating processesChemical industryFertilizer plant

The invention relates to a technique for repairing a hardened gear, specifically disclosing a method for repairing a hardened gear, which can be applied to industries such as a cement plant, a steel mill, a missile unit, chemical industry, railway, petroleum, mine, a power plant, a sintering plant, a pelletizing plant, a steel rolling mill, a fertilizer plant and the like. The method is capable of solving repair of a fault thickness within a range of 1-300 mm in a cladding manner by employing different materials for a joint layer, a transition layer, a work layer and a processing layer in this order. Therefore, with the method, the hardened gear can be quickly repaired, so that the economic loss caused by the damage of the hardened gear is minimized.

Owner:WUHAN KAIMING HIGH TECH

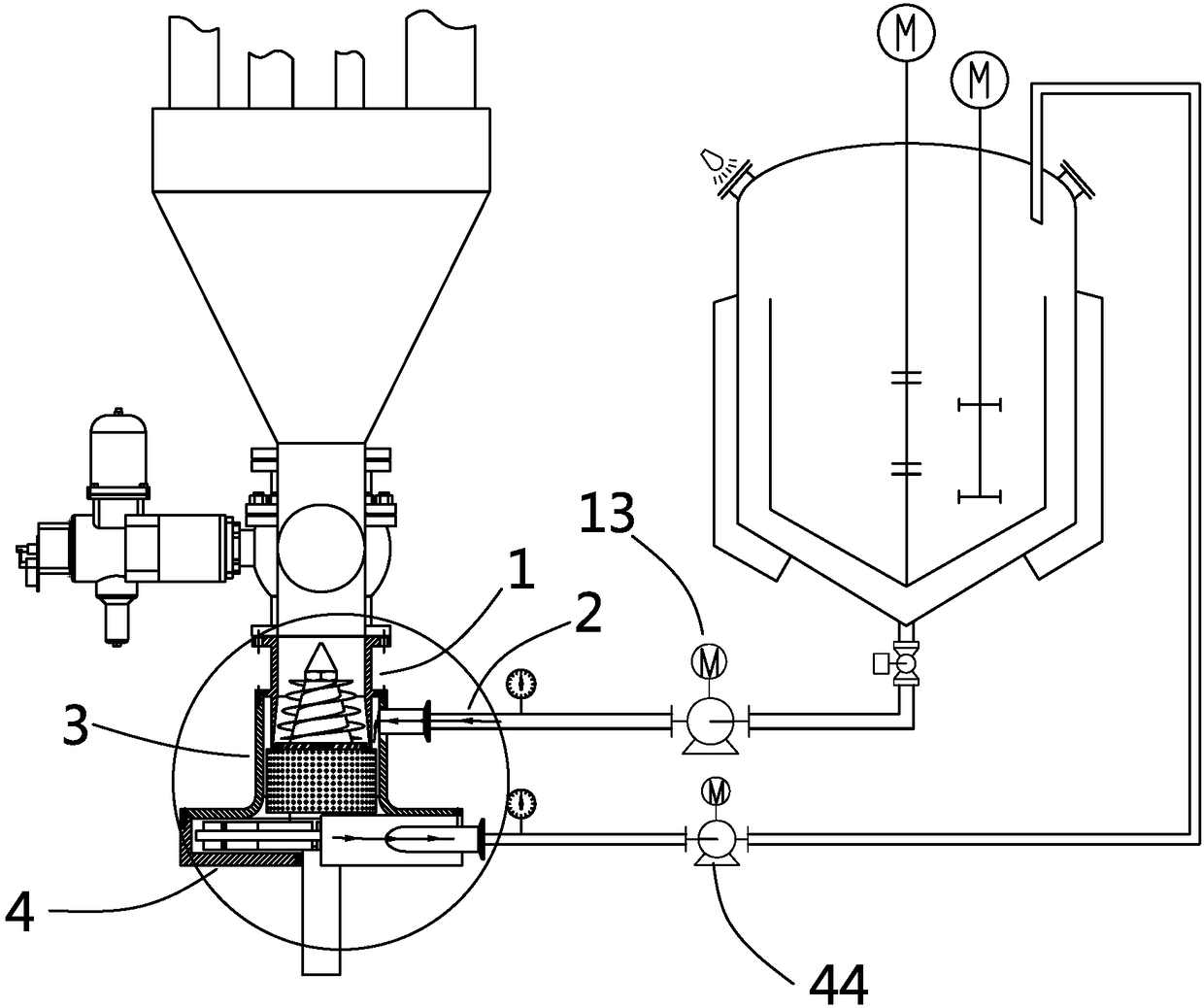

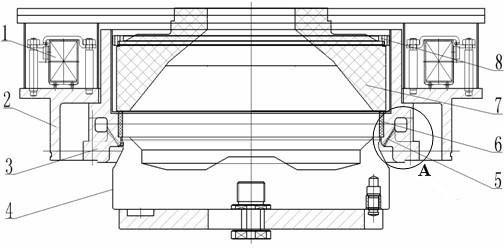

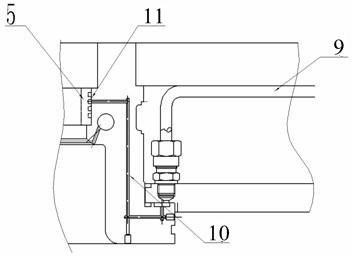

Solid-liquid mixing device and mixing method using the same

PendingCN108465388AIncrease moistureHigh viscosityRotary stirring mixersTransportation and packagingViscosityMaterials science

The invention provides a solid-liquid mixing device and a mixing method using the same. The solid-liquid mixing device comprises a liquid distributing module, a powder dispersing module, a solid-liquid mixing module and a discharging module. The liquid distributing module conveys to-be-mixed liquid to the mixing module. The powder dispersing module is used for dispersing and / or smashing to-be-mixed powder and making the powder enter the solid-liquid mixing module. The to-be-mixed liquid and the to-be-mixed powder are mixed and rapidly rotate in the solid-liquid mixing module and then discharged out of the discharging module. In the powder dispersing module, the to-be-mixed powder makes contact with the to-be-mixed liquid at a specific tilt angle for preliminary rapid moisturizing after being preliminarily dispersed, spiral feeding is adopted without the control of an independent valve, and the higher dispersing capacity is realized. In the mixing module, by means of a rapid rotating mixer, the moisturizing process of the powder and the liquid is accelerated; in the discharging module, slurry with high viscosity can be discharged, and meanwhile vacuum is generated.

Owner:SHENZHEN SHANGSHUI INTELLIGENT EQUIP CO LTD

Equipment and method for simultaneously preparing multiple round aluminum alloy ingots

The invention belongs to the field of aluminum alloy casting, and in particular relates to equipment and a method for simultaneously preparing multiple round aluminum alloy ingots. The equipment mainly comprises a crystallizer, a water tank, a magnet exciting coil, a magnet exciting power supply, a porous graphite ring, a lubricating oil supply system and a casting machine. The method comprises the following steps of: starting the lubricating oil supply system, introducing molten aluminum into a cavity which is formed by ingot butts, the porous graphite ring and a heat preservation cap, starting the casing machine for casting, starting the magnet exciting power supply, dynamically crystallizing aluminum melt under the stirring action of an induced magnetic field, and thus obtaining a fineand uniform metallurgical structure and the good surface quality of the ingots. By the equipment and the method, the semi-continuous casting of round aluminum alloy cast rods under the combined action of electromagnetic stirring and oil lubrication is realized, and the internal metallurgical quality and the surface quality of the ingots can be improved.

Owner:沈阳东铝特材科技有限公司

Smelting manufacturing method for high temperature ferric alloy

A technology for smelting the refractory Fe-base alloy includes such steps as primary smelting in ordinary electric arc furnace by return oxygen blowing method and smelting the qualified refractory Fe-base alloy in AOD furnace. Said second step includes blowing the mixture of argon gas and O2 in ratio of 4:1 for decarbonizing, heating, blowing the mixture of argon gas and O2 in ratio of 1:1 when C content is 0.1%, sampling and analyzing, regulating contents of its components, blowing argon gas when C content is 0.03%, adding prereducing slags, prereducing, sampling and analyzing, adding reducing slags, blowing argon for dissolving slags, blowing argon for 3 min, adding Ti in ladle, tapping, and casting rod electrodes.

Owner:宝钢特钢有限公司

Method for synthesizing gallic acid terpene alcohol ester with auxiliary supersonic wave

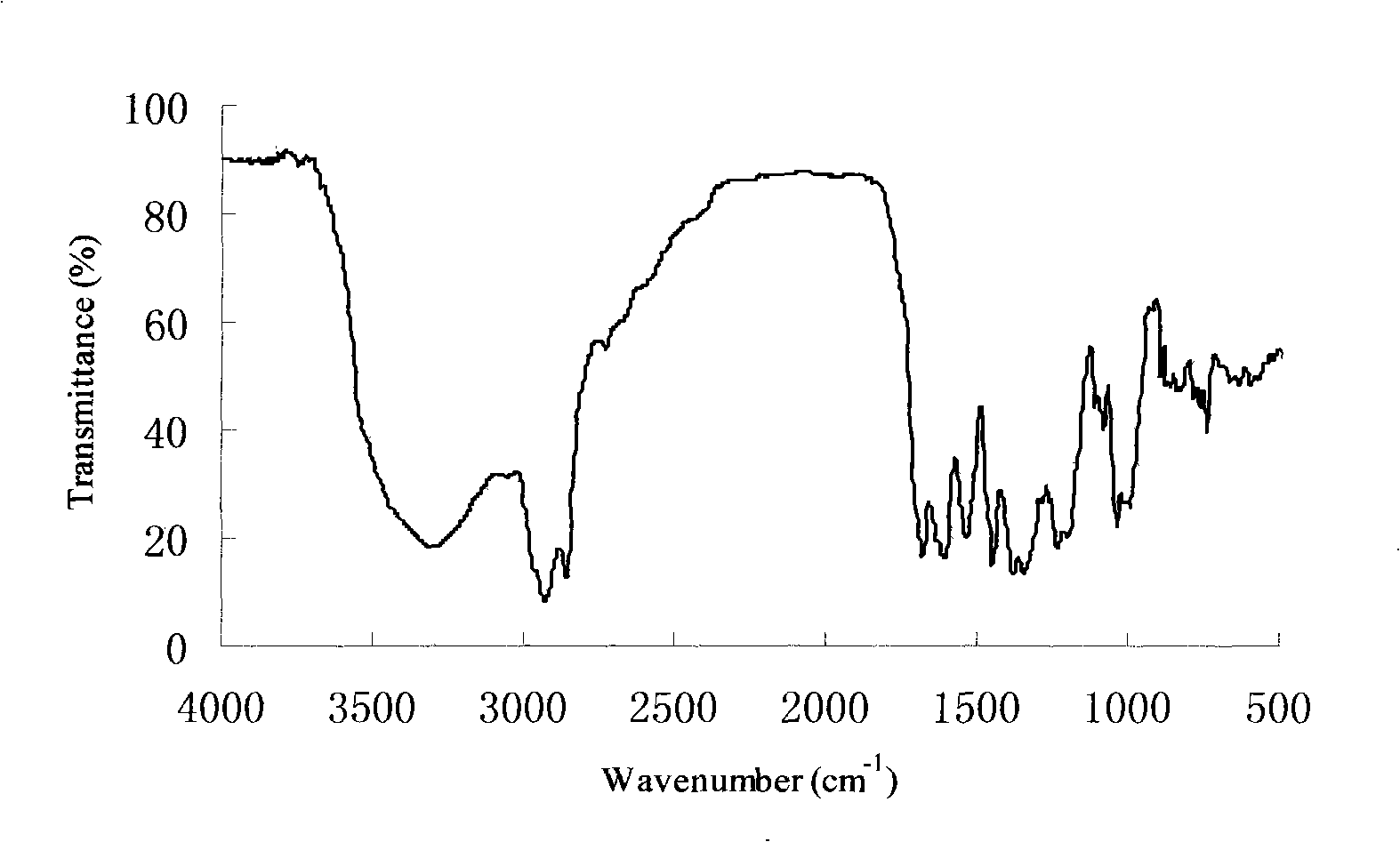

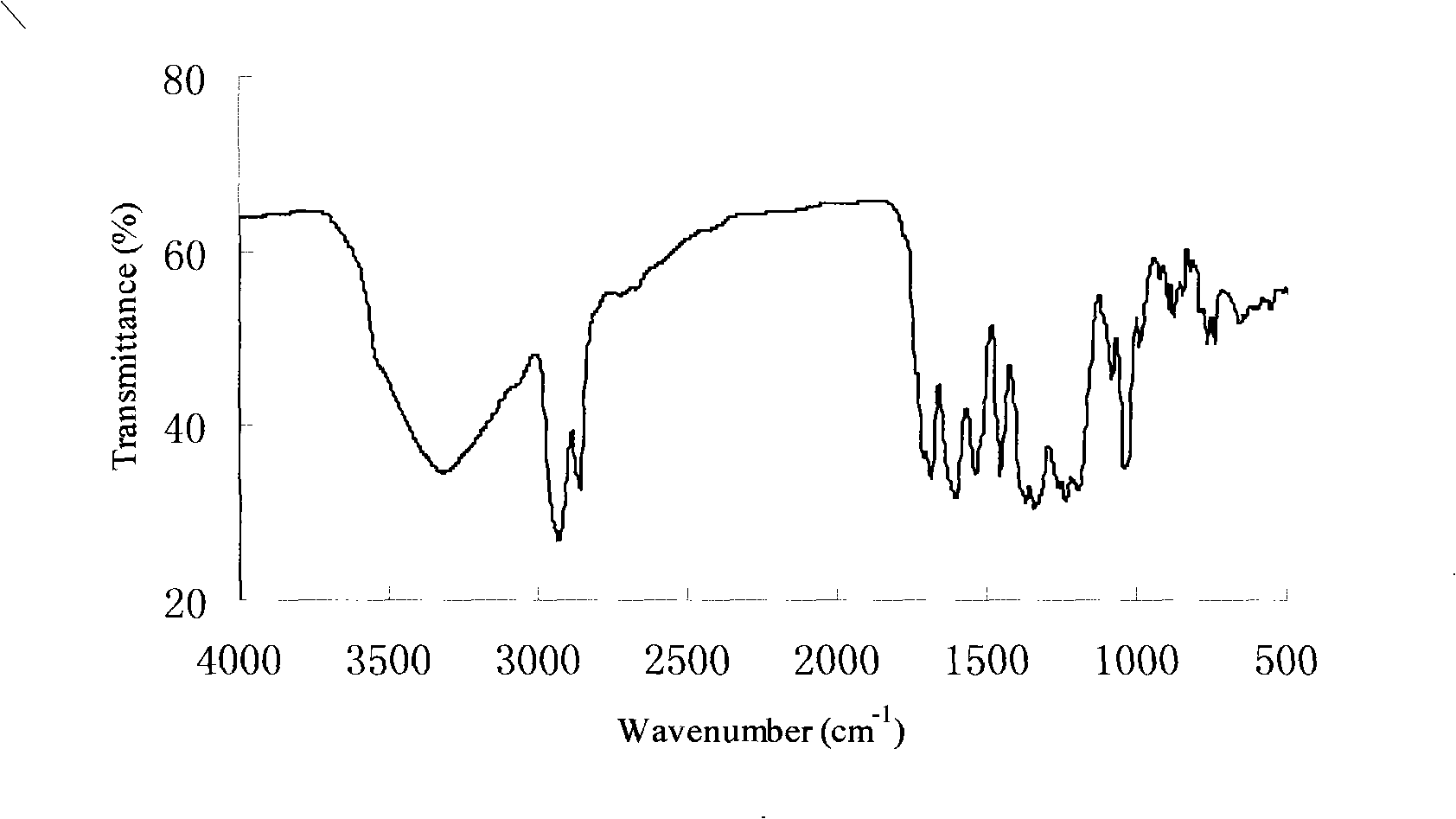

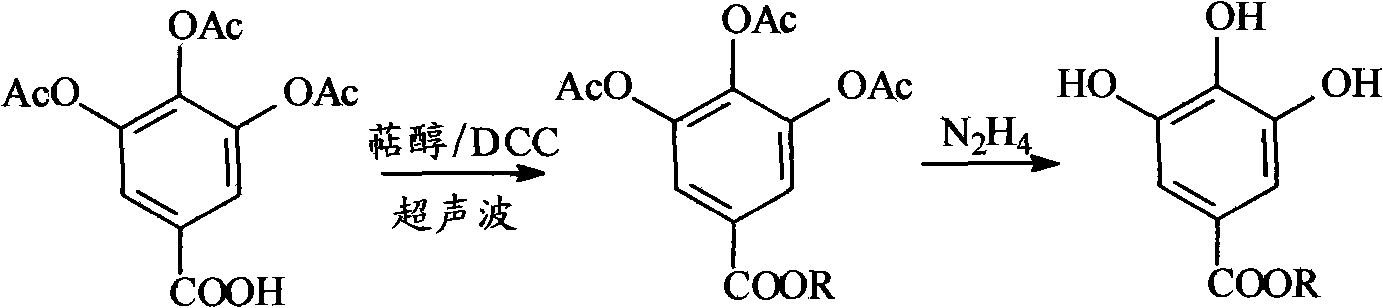

InactiveCN101318905AIncrease contactShort reaction timeOrganic compound preparationCarboxylic acid esters preparationGallic acid esterHydrazine compound

The invention discloses a method for ultrasound-assisted synthesis of gallic acid, terpene alcohol ester, comprising the following steps that compounds of a 3,4,5-triacetyl gallic acid and terpene alcohols are subjected to dehydration and esterification in acetonitrile through DCC(N,N'-dicyclohexylcarbodiimide) under conditions of ultrasound and room temperature to generate the 3,4,5-triacetyl gallic acid, terpene alcohol ester; and the 3,4,5-triacetyl gallic acid, terpene alcohol ester is subjected to deacetylation of hydrazine hydrate under the condition of room temperature to generate the gallic acid, terpene alcohol ester. The synthesis method has the advantages of low reaction temperature, short reaction time and easy separation of the product.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

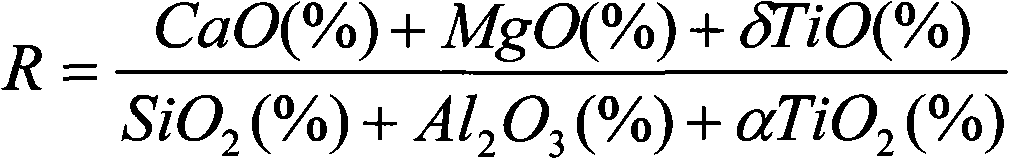

Method for melting, reducing and smelting high-titanium iron ore by oxygen-enriched top blowing

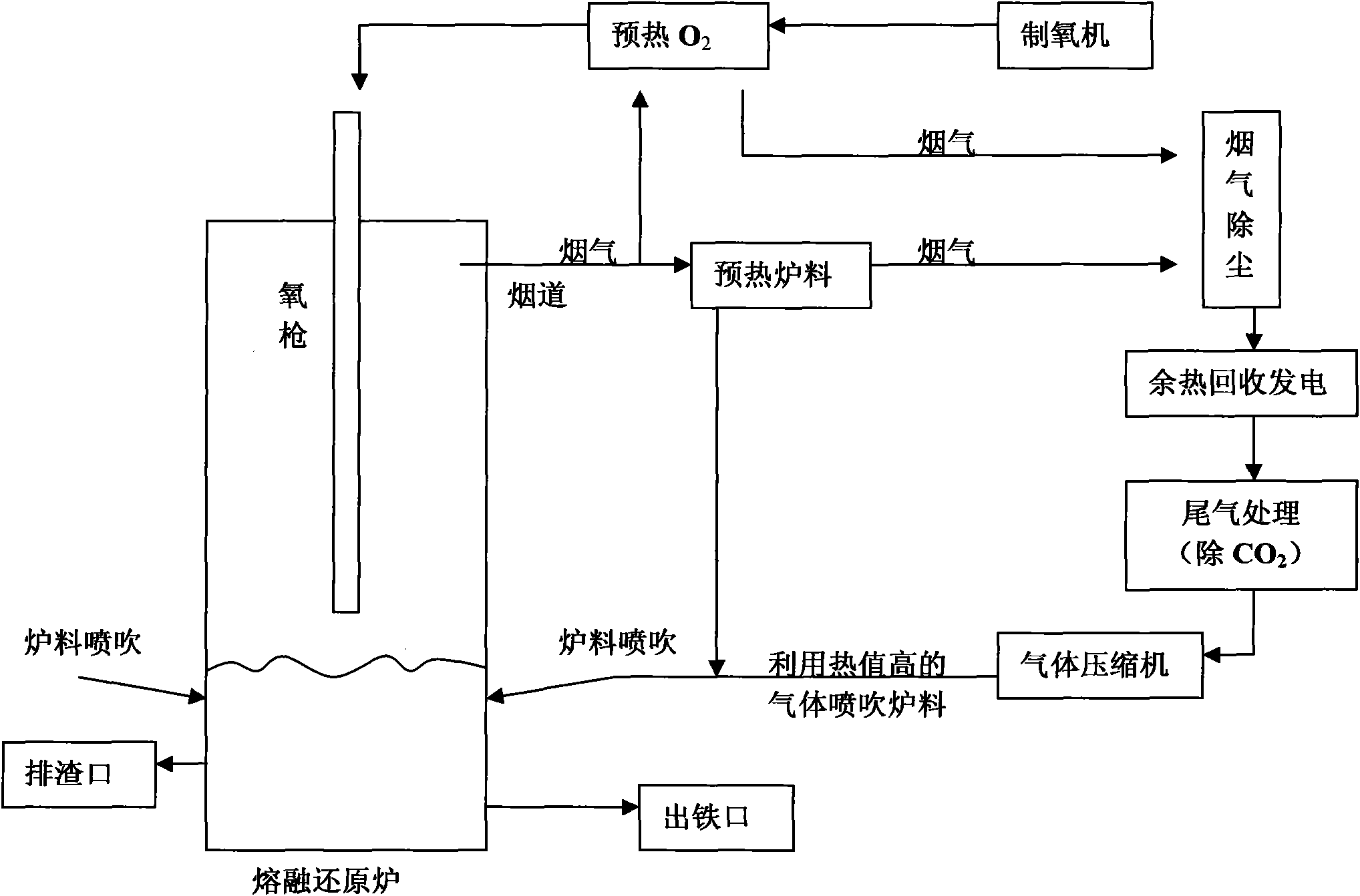

InactiveCN101857910ASolve problems that are difficult to smeltLow costGas emission reductionDolomiteCoal

The invention discloses a method using a high-titanium iron ore as a raw material, pulverized coal as a reducer and limestone and dolomite as a fusing agent to produce molten iron and high-titanium slag under the condition of oxygen-enriched top blowing, which belongs to the technical fields of energy resources and metallurgy. The method comprises the following technological steps of: crushing the high-titanium iron ore, the dolomite, the limestone and the pulverized coal, mixing evenly according to the mixture ratio of the technological parameters, preheating, then taking the treated gas with high heat value as carrier gas to blow a furnace charge from a furnace side to enter a melting and reducing furnace, smelting under the condition of the oxygen-enriched top blowing and discharging the products of the molten iron and the high-titanium slag of the method by a taphole and a deslagging port periodically and respectively. By means of the characteristics of strong oxidizing atmosphere and high titanyl affinity in the furnace, the invention treats the high-titanium iron ore which is difficult to smelt in a blast furnace. The process has simple requirement to the raw material and low construction cost, recycles high-temperature furnace gas, reaches the standard of zero discharge and has better effects of energy saving and discharge reduction. The process is beneficial to developing a large amount of ilmenite resources stored in China and also has a very large promotion function to the development of the titanium industry of China.

Owner:KUNMING UNIV OF SCI & TECH

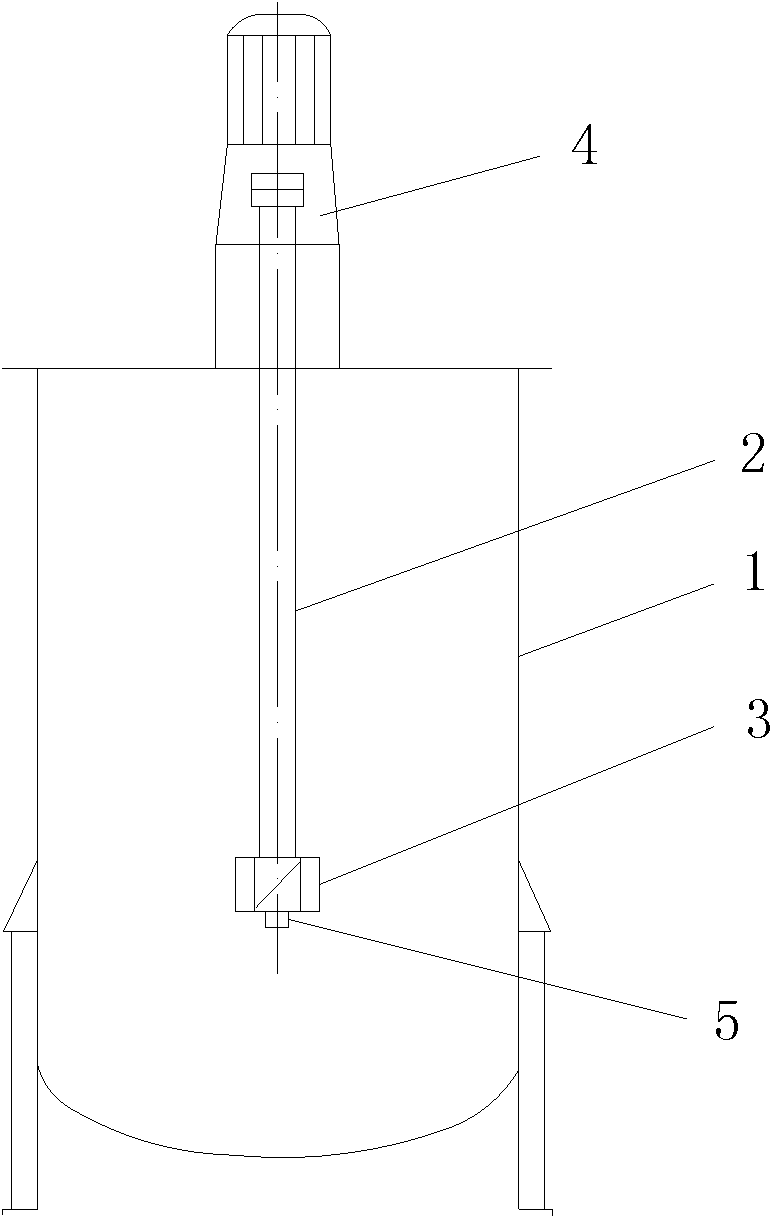

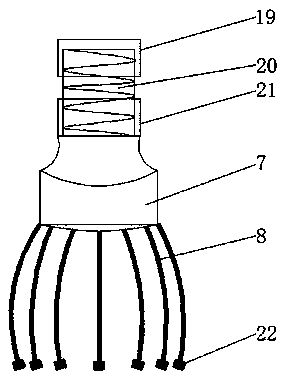

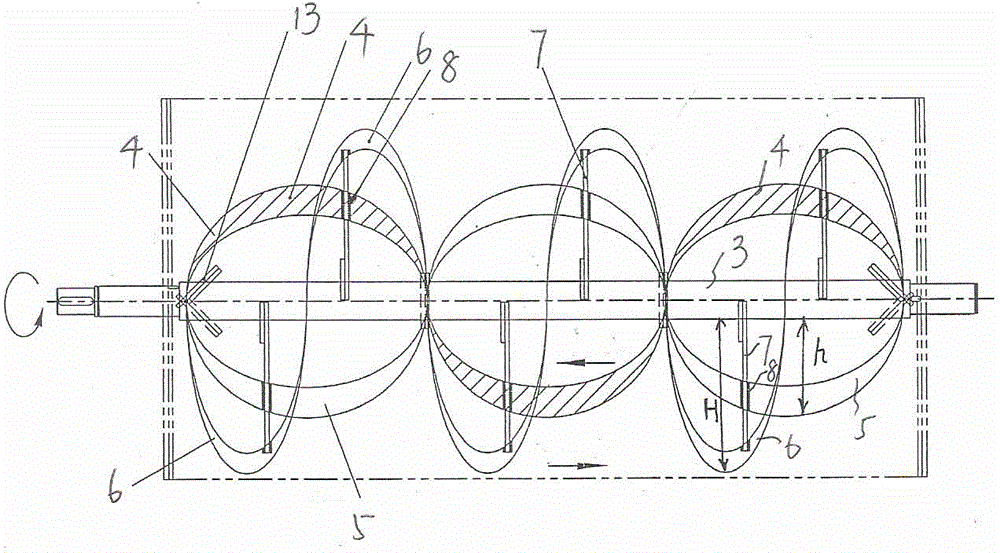

Single-shaft mortar and high-viscosity fluid stirrer for axial turbulent flow pattern multi-wire cutting machine

InactiveCN102059068AReasonable structural designEasy to manufacture and installRotary stirring mixersTransportation and packagingFlow diversionWire cutting

The invention discloses a single-shaft mortar and high-viscosity fluid stirrer for an axial turbulent flow pattern multi-wire cutting machine, comprising a stirring shaft, a stirring assembly and a driving mechanism, wherein the stirring assembly comprises impellers and short flow diversion tubes, the impellers are used for driving a material to move up or down in an axial and spiral mode along the inner wall of a pot body of a stirring pot, the short flow diversion tubes are used for restricting the material flow direction to an axial movement along the axis of the stirring shaft when the material moves up or down in the axial and spiral mode, the impellers and the short flow division tubes are assembled into the stirring assembly which drives the material needed to be mixed and stirred to do an axial turbulent flow motion during stirring, the impellers are coaxially installed at the bottom end of the stirring shaft, the short flow division tubes are coaxially and fixedly sleeved at the outer sides of the impellers, and the stirring speed of the stirring shaft is 600-1500rmp. The single-shaft mortar and high-viscosity fluid stirrer has the advantages of simplicity in structure, high stirring capacity, small shearing force, high dispersing power and high effect, and can be used for solving the problem that silicon carbide is broken due to the shearing force during the high-speed stirring of various traditional stirrers. Moreover, a stuck phenomenon is difficult to generate.

Owner:XIAN HUAJING ELECTRONICS TECH

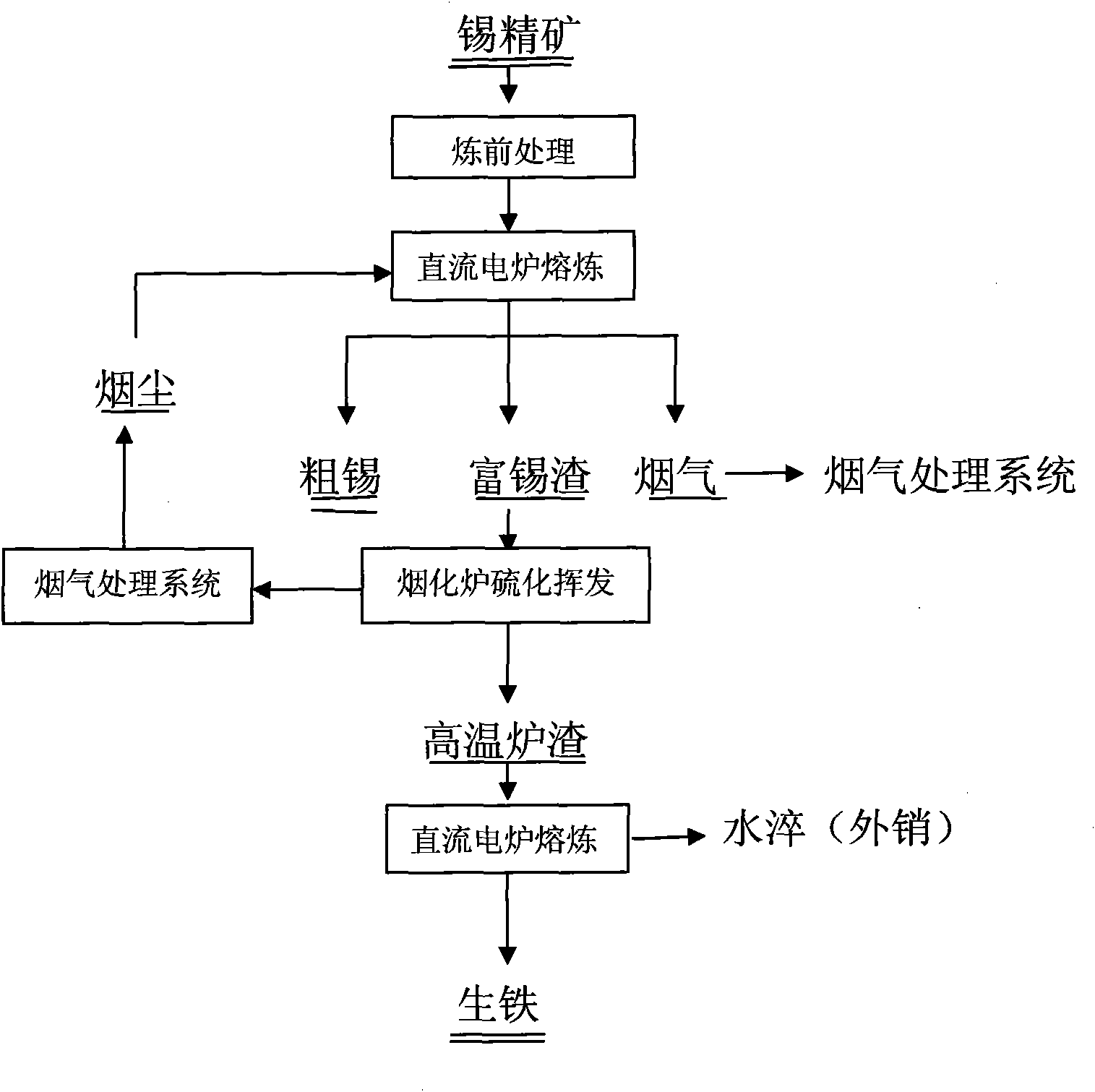

DC electric furnace-fuming furnace combined tin-smelting method

InactiveCN101787445AIncrease production capacityFast meltingProcess efficiency improvementElectric arc furnaceLiquid state

The invention relates to a tin-smelting process, in particular to a method for tin smelting by combining a DC electric furnace and a fuming furnace and for comprehensively recycling iron. The steps of the invention are as follows: reducing agent is added according to the components of tin concentrate, and then, the mixture is put in the DC electric furnace for reduction and smelting to generate metallic tin; and vulcanizing agent and slagging flux are added to liquid slag according to components of the liquid slag, and then, the mixture is put in the fuming furnace to be vulcanized to volatilize the tin in the slag; meanwhile, the mixture is recycled in the form of tin oxide fume; the fumed slag is put in the DC electric furnace in the liquid state, and then, the reducing agent and the flux are added to the fumed slag to be smelted to generate pig iron; meanwhile, the residual sulphur contained in the slag is utilized to continually volatilize the residual tin, and the water-quenched slag can be used as the raw material for building. The method is suitable for processing various tin-containing materials; compared with the traditional tin-smelting method, the tin-smelting method provided by the invention has the advantages of less investment and high tin recovery rate and can comprehensively recycle iron and other valuable metals.

Owner:YUNNAN TIN GROUP HLDG

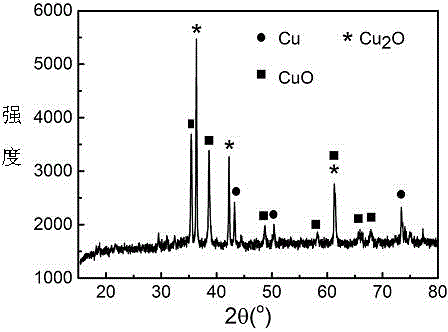

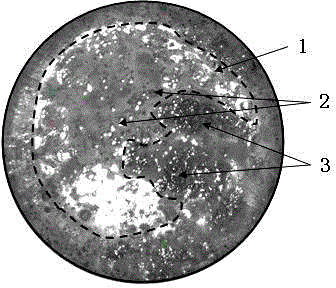

Method for separating amphoteric metal in waste circuit board powder

ActiveCN104946894AShort processImprove efficiencyProcess efficiency improvementSmelting processPhysical chemistry

The invention discloses a method for separating amphoteric metal in waste circuit board powder. The method comprises the following steps: 1) mixed-phase alkali fusion: the waste circuit board powder is uniformly mixed according to the mass ratio of 1: 1-7: 0-1 among the powder, an alkaline medium and an auxiliary oxidizing agent, and then is smelted under the condition of 400-900 DEG C; oxidation gas is fed into a melt in the smelting process; and a smelting product is obtained in 20-90 min of the smelting; and 2) rapid cooling infiltration: the smelting product is put in cold water for rapid cooling, and then is crushed; and water is added according to the liquid-solid mass ratio of 40-10: 1 between the water and the smelting product, is stirred and leached for 10-60 min at normal temperature, and is filtered to obtain washery slag enriched with copper and noble metal and alkaline rinse containing the amphoteric metal. The gas-liquid-solid phases of the reaction system coexist in the smelting process; and the oxidation gas is added to reduce the addition of expensive auxiliary oxidizing agent and to increase relative motion and collision among materials.

Owner:CENT SOUTH UNIV

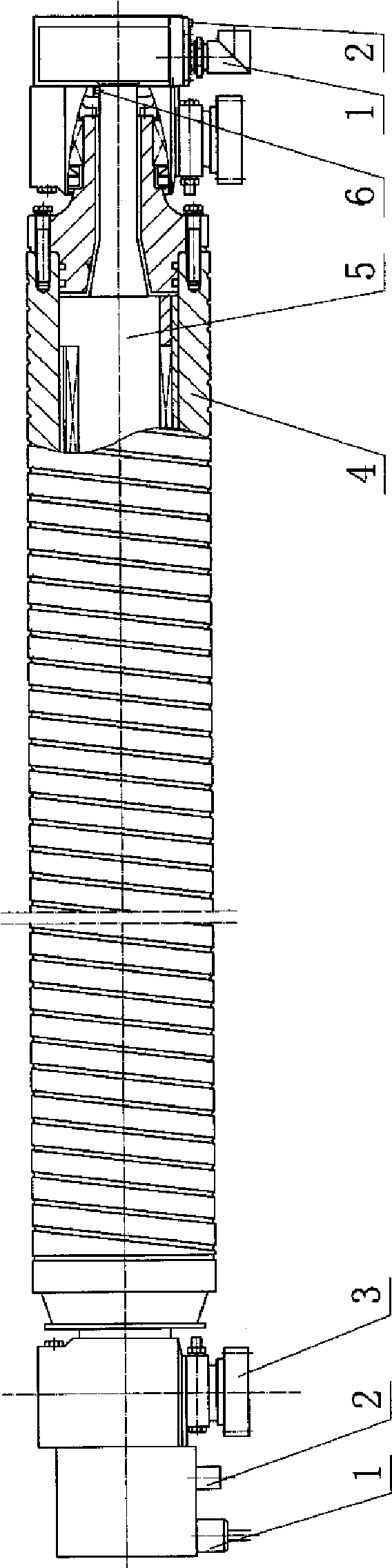

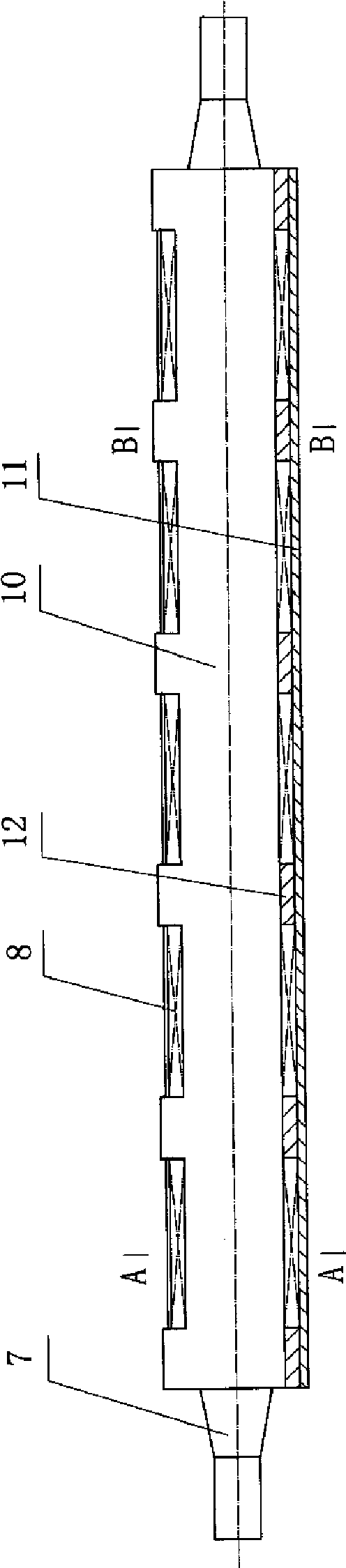

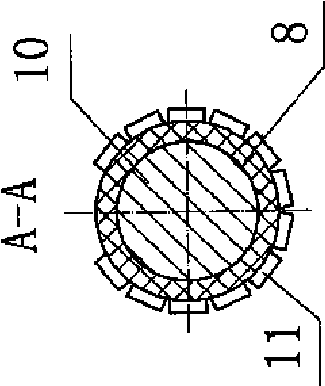

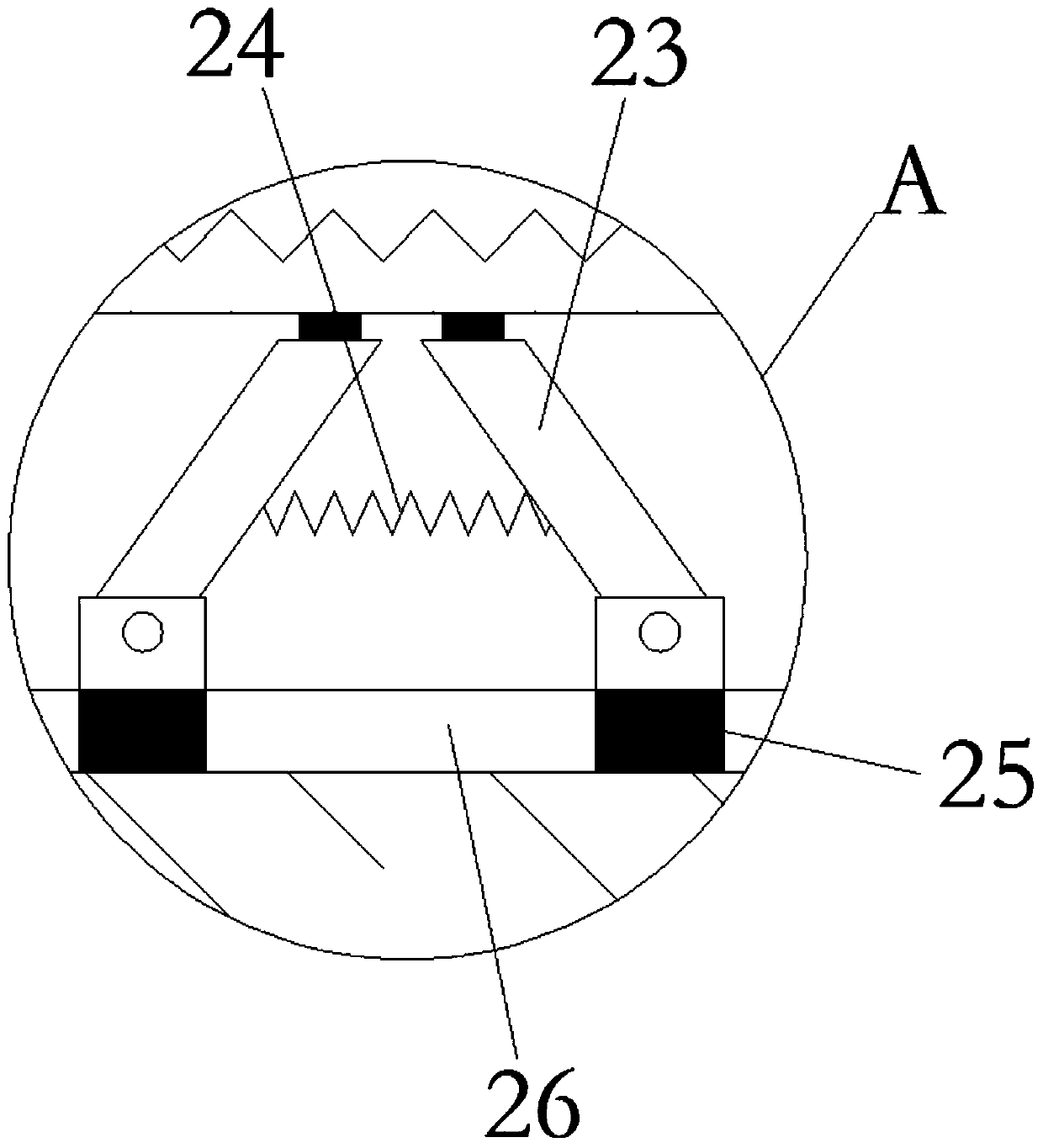

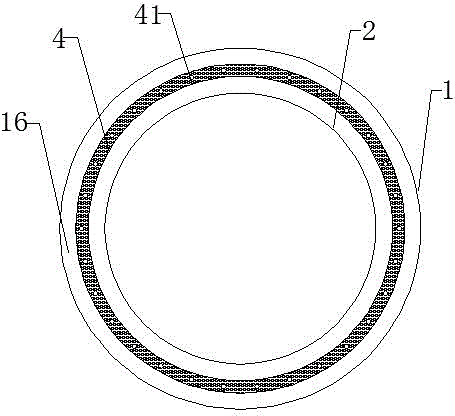

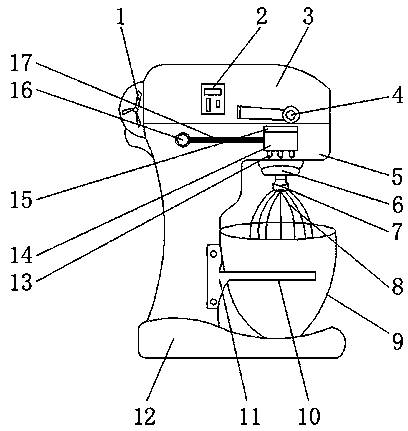

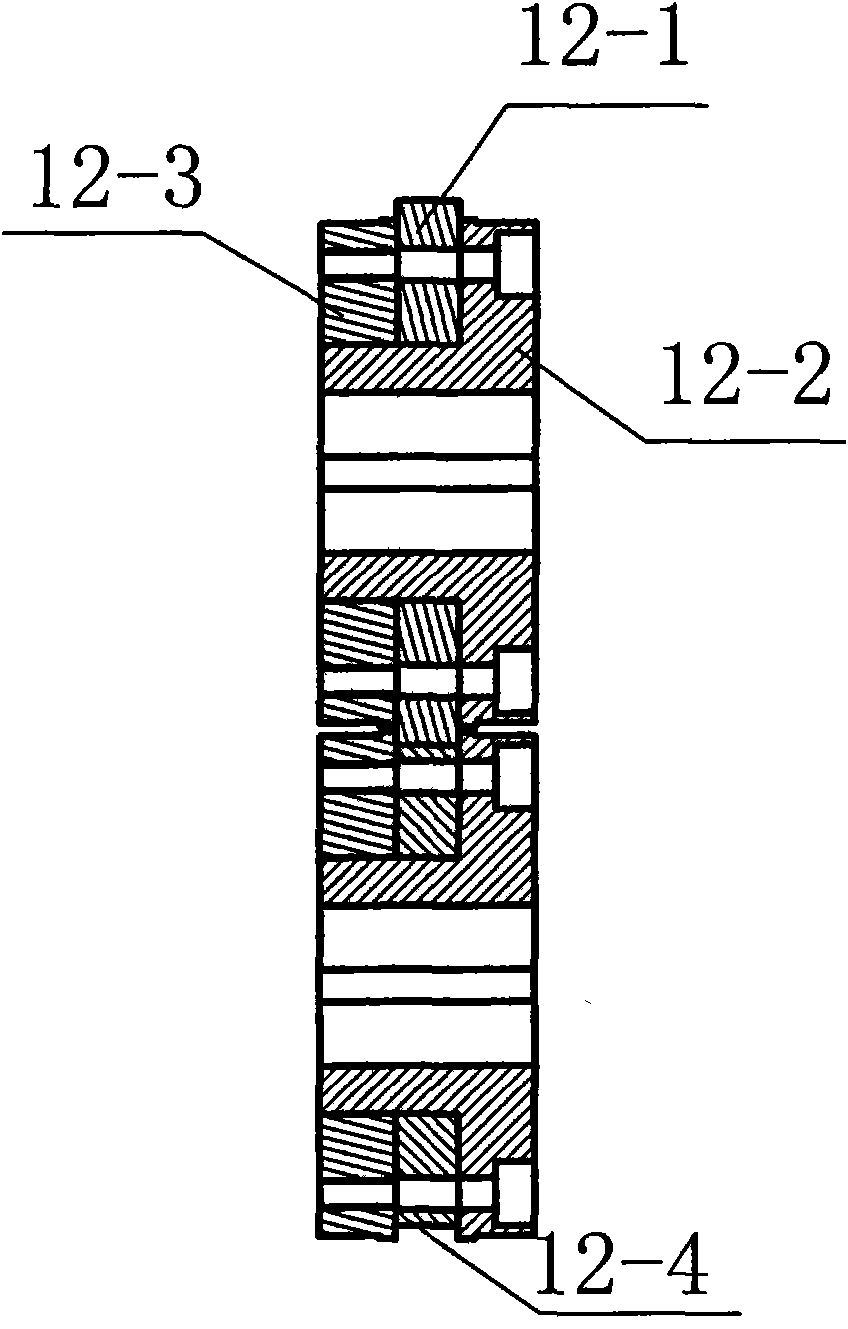

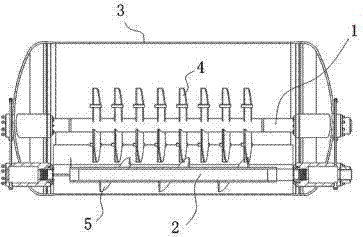

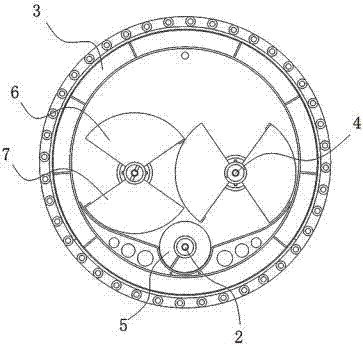

Roller type electromagnetic stirrer for block continuous-casting

The invention relates to a roll-type electromagnetic stirrer for continuously casting a plate blank, which comprises components such as coil windings, an iron core and the like, and is characterized in that the iron core is designed into a columnar elongated iron core with teeth, and tooth shaped parts protruded on a column are magnetic poles; the coil windings are arranged among the magnetic poles of the iron core at intervals; the peripheries of the iron core and the coil windings are provided with squirrel-cage components made of non-magnetic materials, wherein a stirrer body consisting of the iron core, the coil windings and the squirrel-cage components has a still structure; the stirrer body is arranged in a fully-closed rotating carrier roller; and a cooling water passage for cooling coils is arranged between the stirrer body and the rotating carrier roller. The rotating carrier roller is made of non-magnetic stainless steel with high temperature resistance and high strength, and a shell is provided with a spiral chute which is convenient for water flowing and heat dissipation. Because the formed copper squirrel-cage components cannot rotate, the current of the windings of the stirrer is increased under the same voltage; and relatively, the power for generating the same current is reduced, so the stirrer is easy to generate stronger stirring force.

Owner:岳阳鸿升电磁科技有限公司

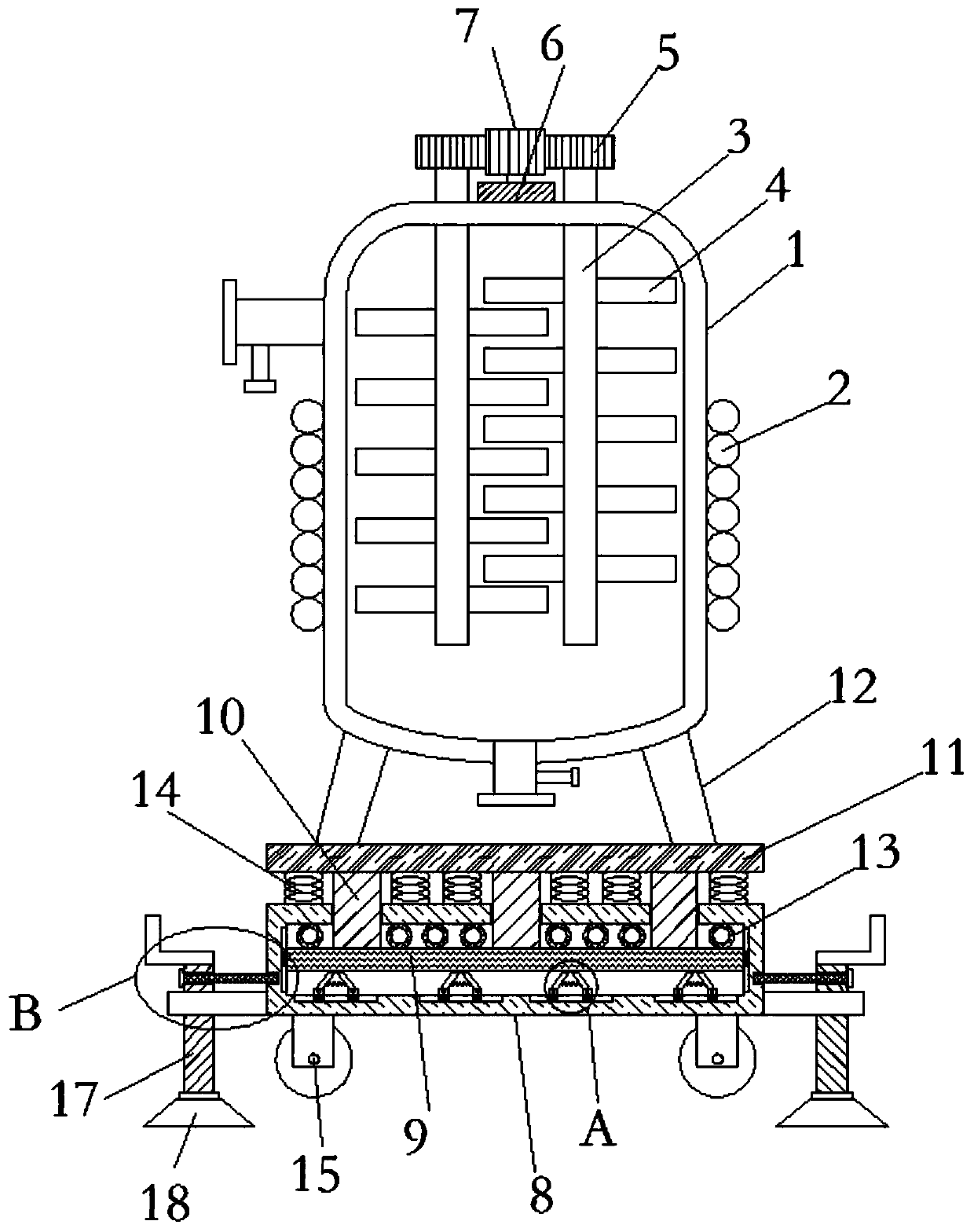

Easy cooling type reaction still for producing sodium hypochlorite

InactiveCN109908853AEasy cooling productionExpand the mixing rangeChemical/physical/physico-chemical stationary reactorsBall bearingCalcium hypochlorite

The invention relates to the technical field of reaction stills and discloses an easy cooling type reaction still for producing sodium hypochlorite. The easy cooling type reaction still comprises a still body, wherein water passing coiled pipes are fixedly arranged on the outer side of the still body; the upper end of the still body is symmetrically provided with two through holes; in addition, two stirring rods are rotationally connected to the inner parts of the through holes; a plurality of stirring blades are fixedly connected to the rod walls, positioned in the still body, of the stirringrods; the upper ends of the stirring rods extend out of the still body and are fixedly connected with driven gears; a motor is fixedly connected to the upper end of the still body; a driving gear meshed with the driven gears is fixedly connected to an output shaft at the upper end of the motor; a damping box is arranged below the still body. The easy cooling type reaction still disclosed by the invention improves the stirring efficiency and can perform multiple buffer damping on reaction degree.

Owner:TIANJIN YUFENG CHEM

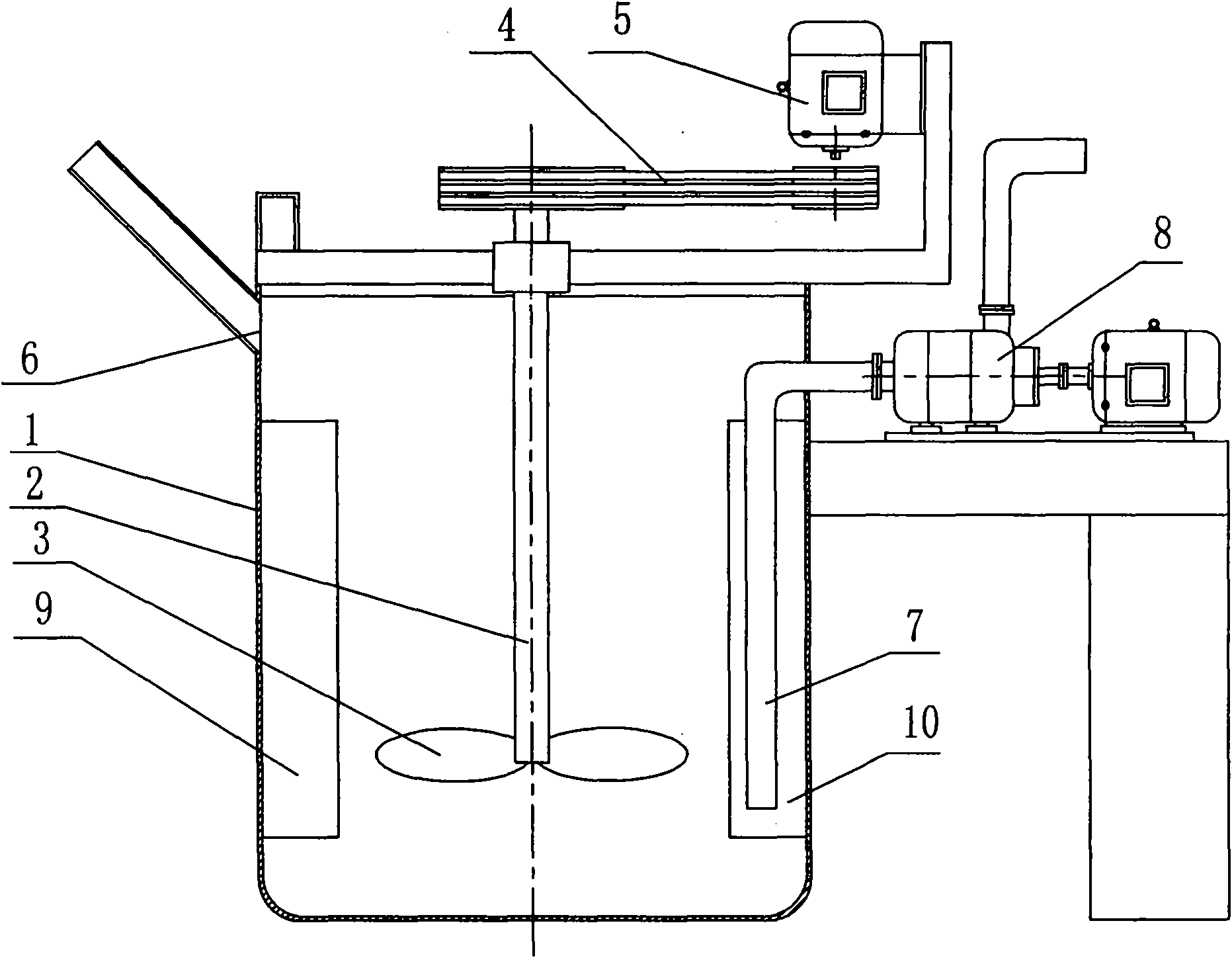

Efficient reactor for production and processing of epoxy soybean oil

ActiveCN104549105AStrong stirringWell mixedOrganic chemistryChemical/physical/physico-chemical stationary reactorsEpoxyBiochemical engineering

The invention discloses an efficient reactor for production and processing of epoxy soybean oil. The efficient reactor comprises a reaction tank and a stirring device, wherein the reaction tank comprises an outer barrel and an inner barrel which are sealed; a cover body is hermetically arranged at an upper end of the reaction tank; an inner cavity body is formed between the outer barrel and the inner barrel; a steam coil pipe is arranged in the inner cavity body in a manner of surrounding the inner barrel; inclined feeding grooves are formed in opposite side surfaces of the cover body; a flow diversion plate communicated with the inclined feeding grooves is arranged in the cover body; the stirring device comprises a main stirring shaft; a plurality of transverse stirring shafts are equidistantly arranged on two opposite sides of the main stirring shaft from top to bottom; a plurality of stirring blades are arranged on each of an upper end surface and a lower end surface of each transverse stirring shaft in parallel; a plurality of conical stirring teeth are fixedly connected to two opposite sides of each stirring blade. The reactor is simple in structure and easy to operate, and can realize uniform stirring, uniform feeding and uniform heating, so that the production quality and the production efficiency of the epoxy soybean oil is improved and the economic benefit is increased.

Owner:DANYANG CITY AUX CHEM PLANT

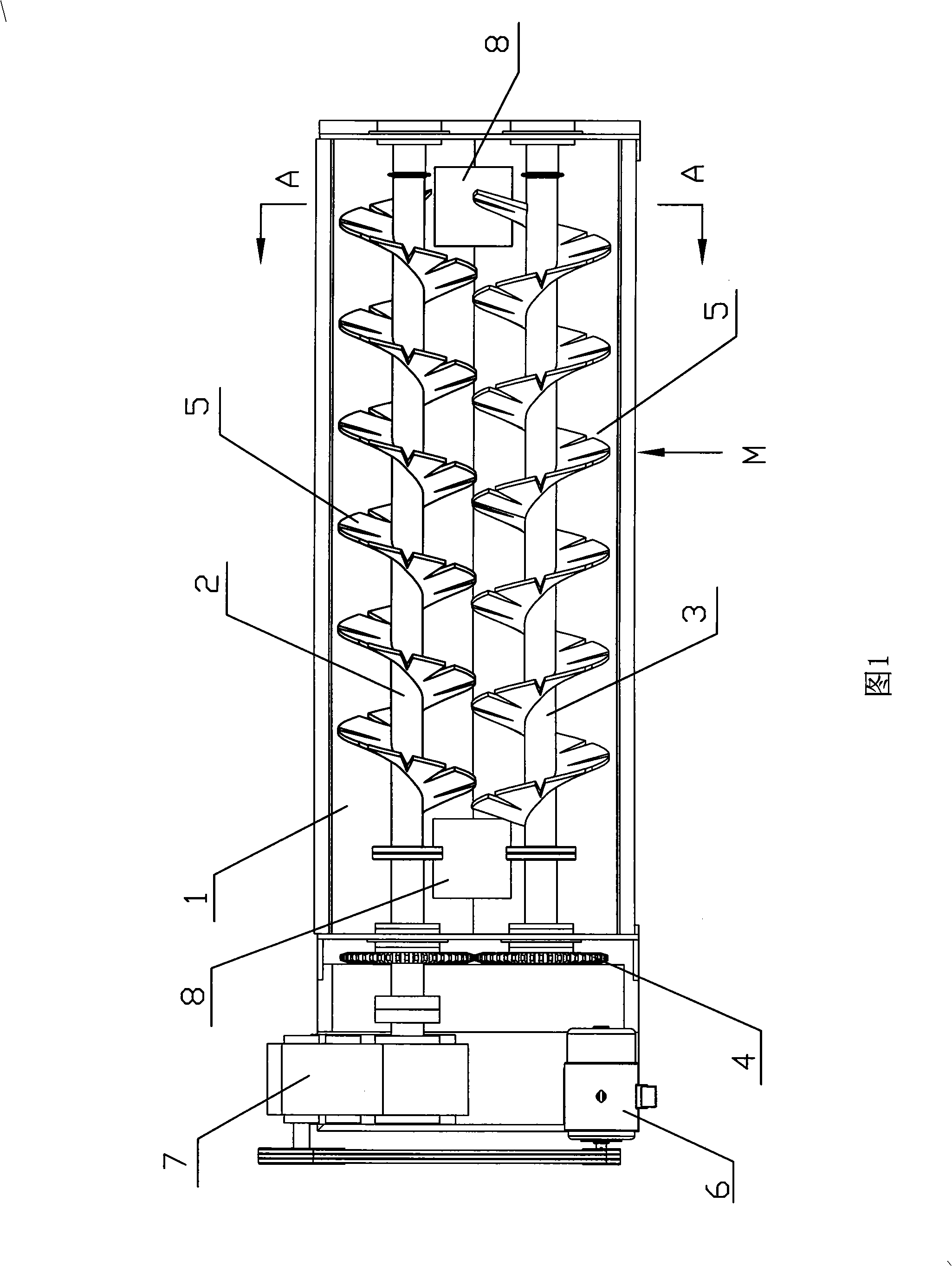

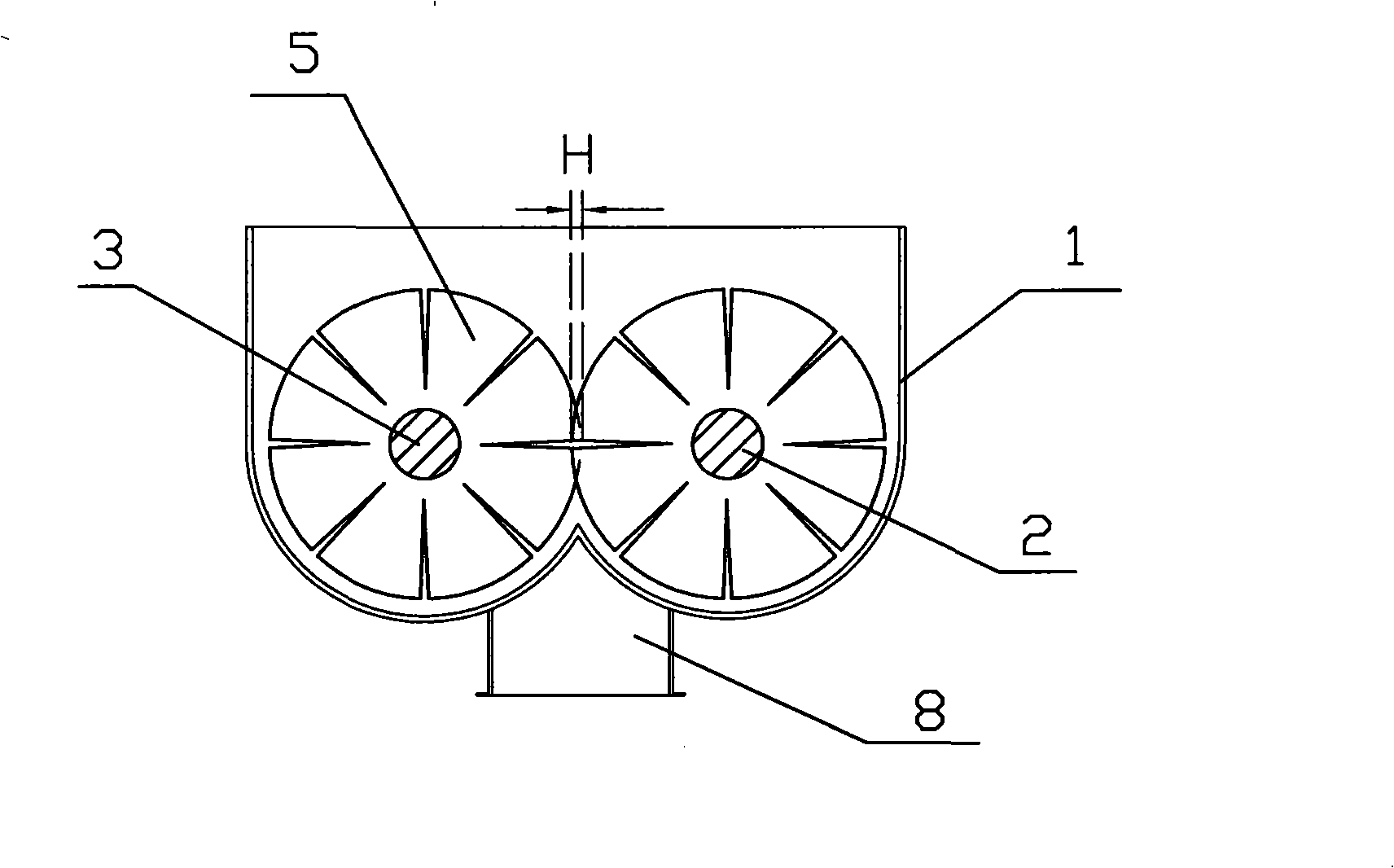

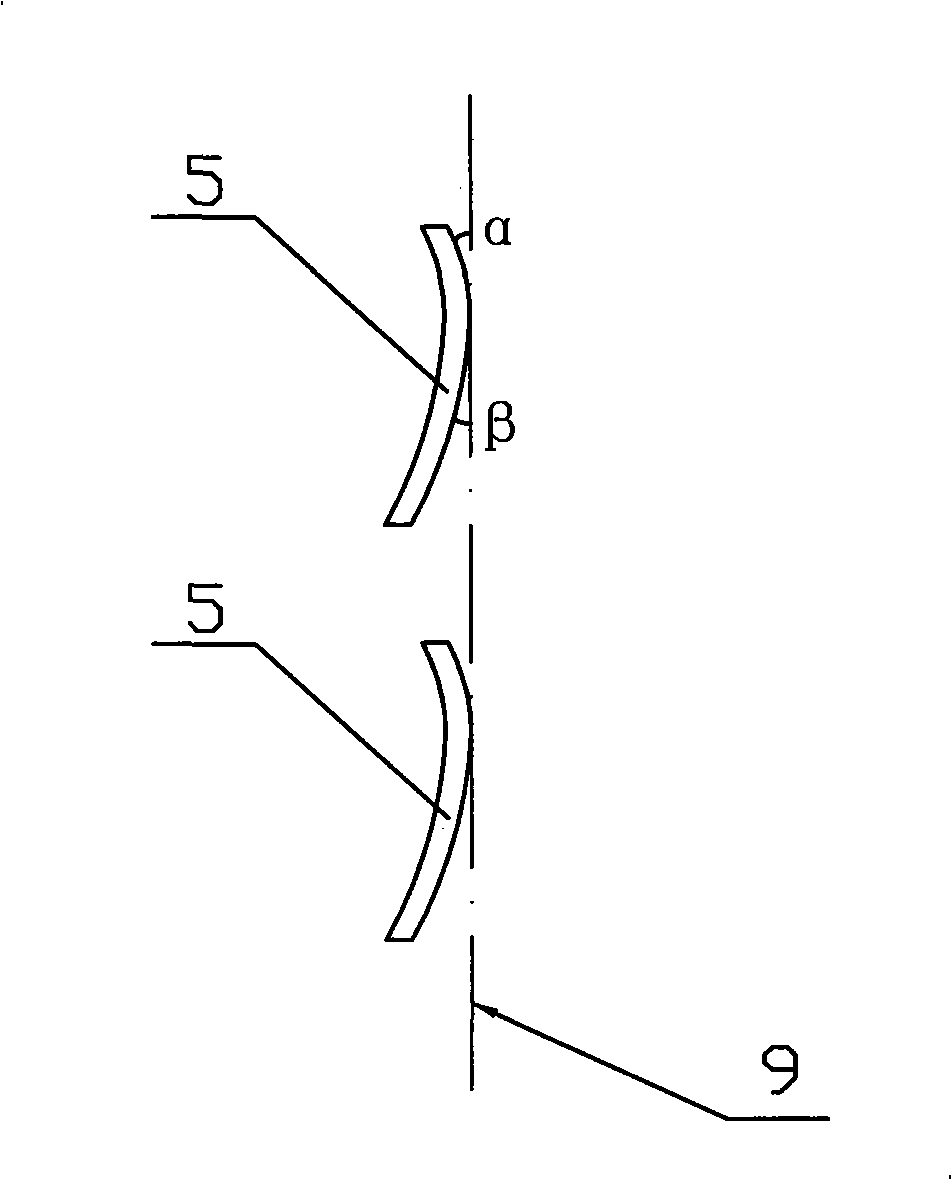

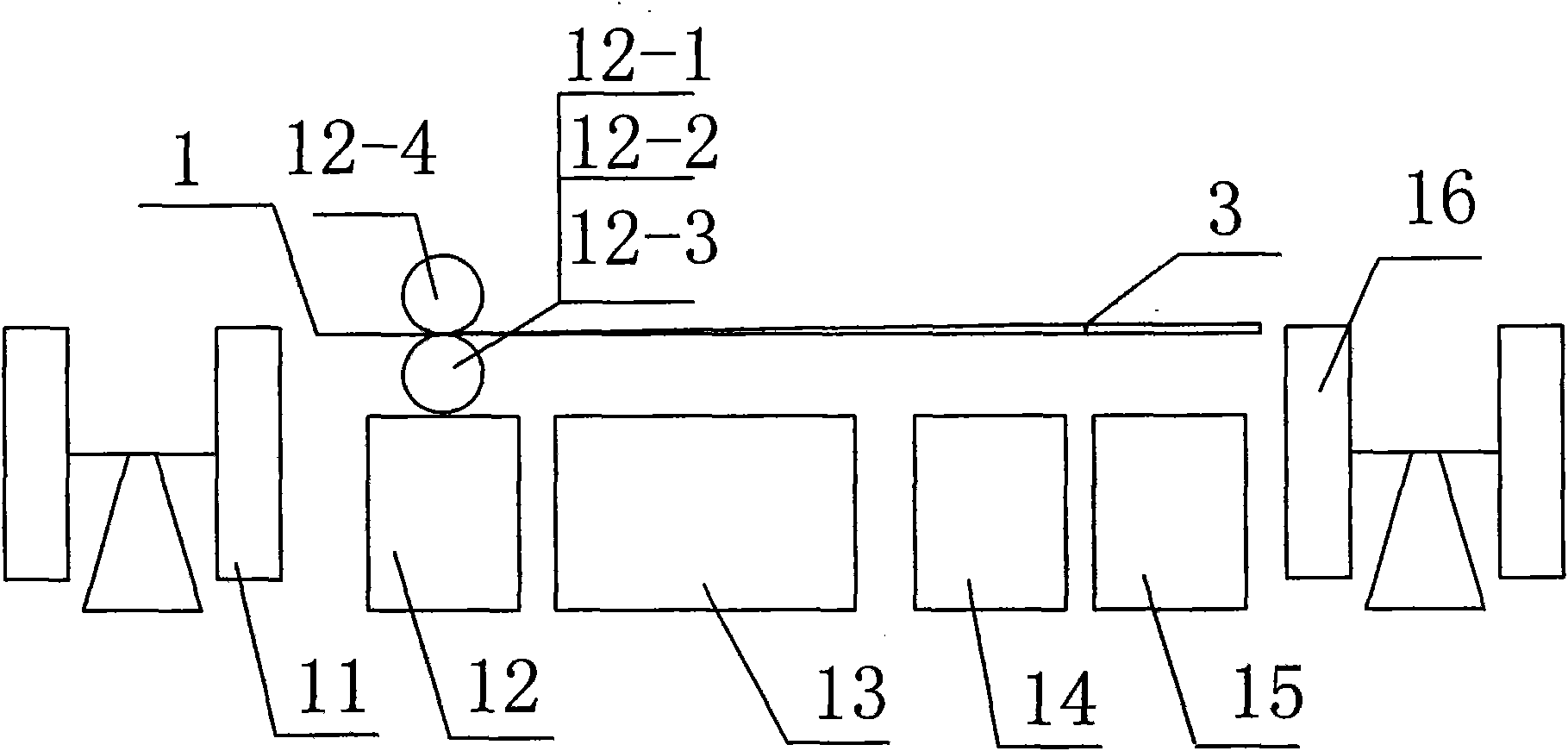

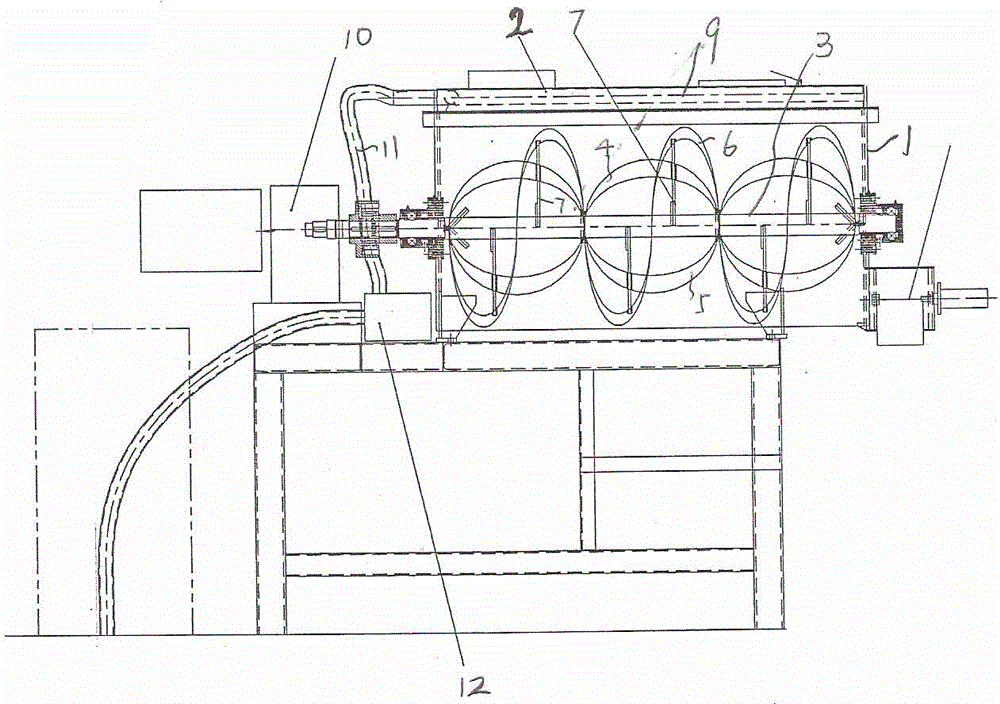

Coal-burning and coal-saving additive agent mixing/stirring conveyor

InactiveCN101259390AGuarantee normal productionWell mixedRotary stirring mixersLine shaftReduction drive

The invention relates to a mixing and stirring conveyor for bunker coal and a coal saving additive, including a housing provided with a supporting seat and a discharge opening arranged on the housing; the housing is a transversely arranged slot body; the cross section of the slot body is in a 'W' shape and the bottom part is a double-circle arc; a main shaft and a vice shaft which are mutually parallel are arranged in the slot body along the length direction of the slot body; the ends of the two shafts are connected with a gear; the two gears are engaged; a plurality of vanes are arranged on the main shaft and the vice shaft according to a spiral line; the twisting direction of the two spiral lines are opposite; the vanes on the main shaft and the outer edges of the vanes on the vice shaft have a coincidence part H along the coaxial direction; the main shaft is connected with a reducer which is arranged at one end of the slot body and connected with a motor; the discharge opening is arranged at the bottom part of the slot body and is close to the end location of the slot body. The conveyor can carry out stirring and conveying simultaneously and has a high stirring capacity. The coal mixed with the coal saving additive can be continuously conveyed without changing the original coal conveying flows of a large coal-using unit, thus not only improving coal saving performance, but also ensuring the normal production of the coal-using unit.

Owner:ZHEJIANG SHIJIA ENERGY SAVING MATERIALS

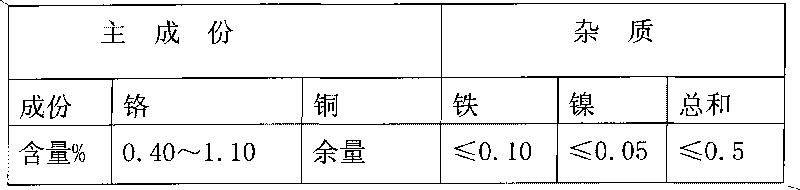

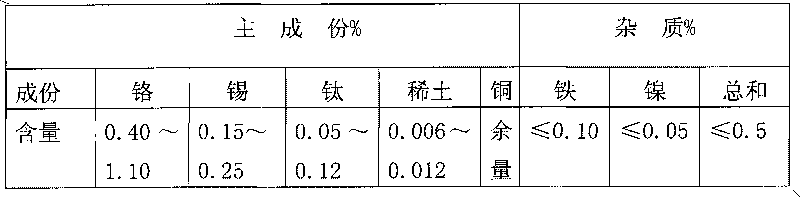

Chromium bronze alloy material and preparation method thereof

The invention discloses a chromium bronze alloy material and a preparation method thereof. The chromium bronze alloy material consists of chromium, tin, titanium, 0.006 to 0.012 percent of rare earth and 98.518 to 99.394 percent of copper. The preparation method for the chromium bronze alloy material comprises the manufacturing steps of batching, smelting, casting, extruding, stretching, straightening and finished product inspection and detection. Through the chromium bronze alloy material and the preparation method thereof, the prepared chromium bronze alloy material has good elastic recovery capability and smaller grain size; and because of the adoption of an advanced process method in the process, the quality of the chromium bronze alloy material is greatly improved, and meanwhile the service life of processing equipment is prolonged.

Owner:甘肃大鑫铜业有限责任公司

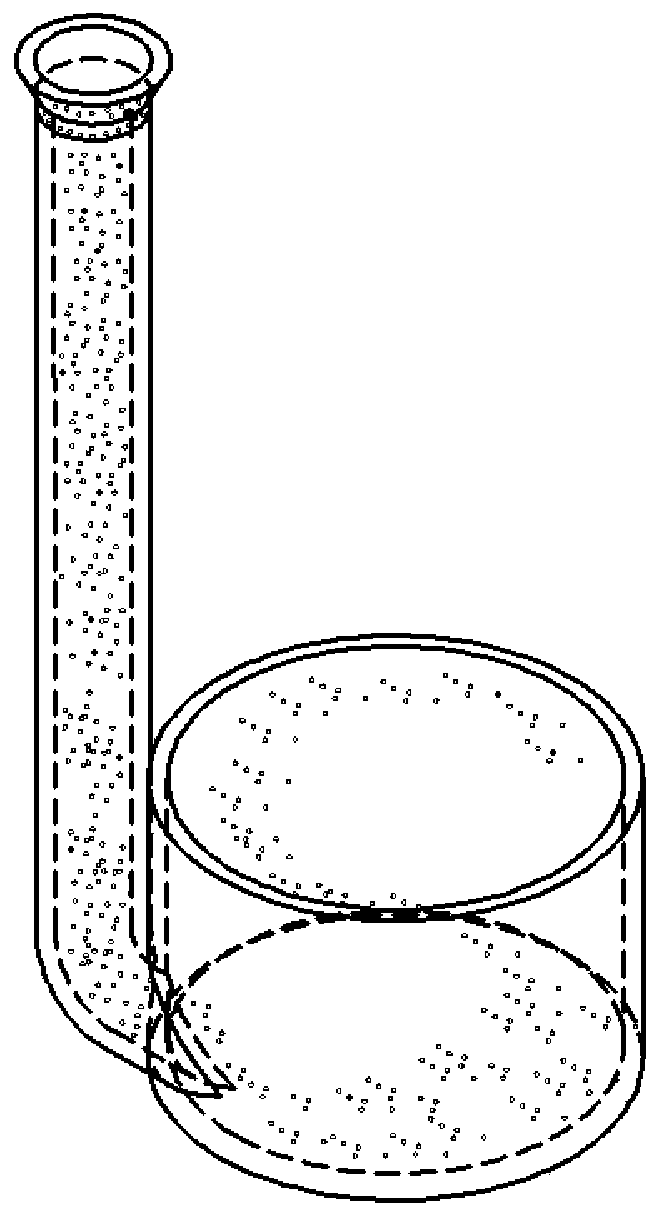

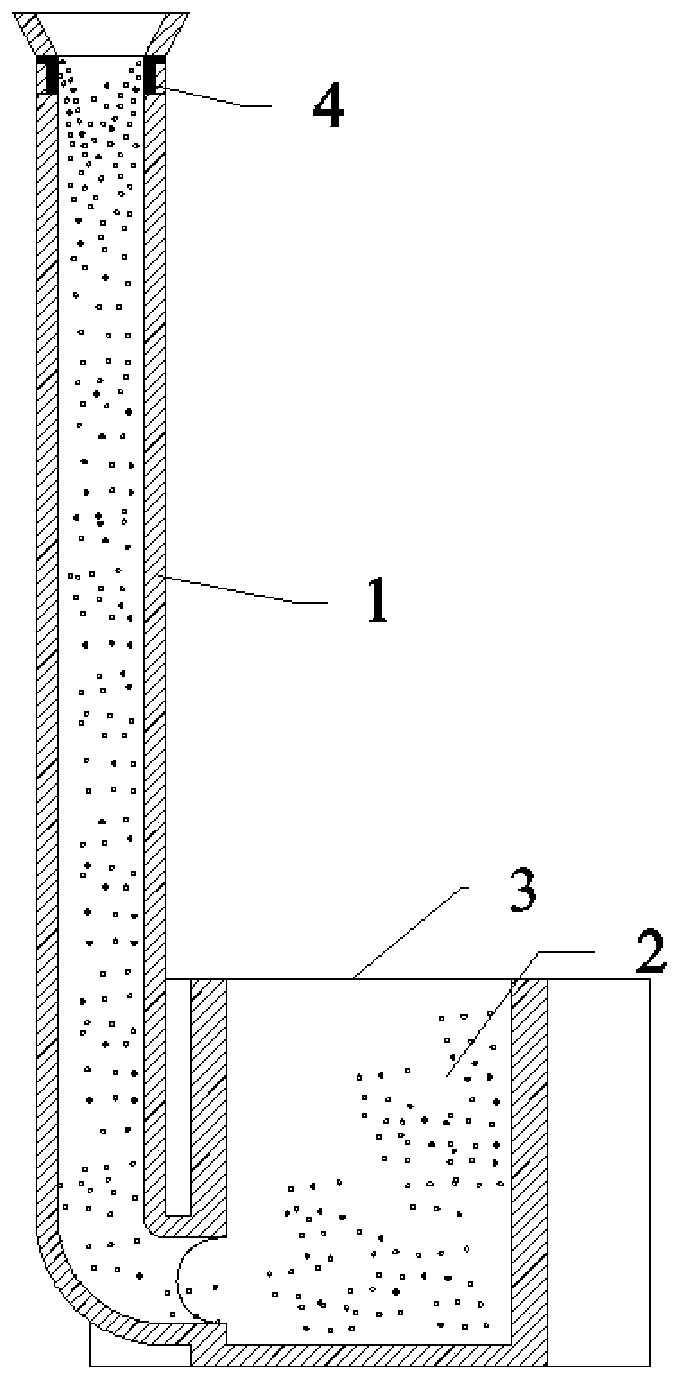

Long nozzle argon blowing refining device and method capable of effectively removing tundish inclusions

InactiveCN110394433AEasy to collide with adsorptionStrong stirringMelt-holding vesselsEngineeringHeat losses

The invention discloses a long nozzle argon blowing refining device capable of effectively removing tundish inclusions. The device is composed of a long nozzle, a swirling chamber and a swirling chamber outlet. An annular groove is reserved in the position, close to the top, of the inner wall of the long nozzle. An annular dispersion gas inlet chamber is arranged in the annular groove and connected with an argon conveying system through gas inlet holes formed in the wall of the long nozzle. The lower portion of the long nozzle is connected with the swirling chamber in the tangential direction.According to an argon blowing refining method adopting the device, the inclusions are removed by means of the adhering effect of dispersed phase argon bubbles, and the problems that a traditional argon blowing device is large in bubble size, the time of standing in molten steel is too short, the casting powder surface is prone to being broken, and consequentially, secondary oxidation and heat loss of the molten steel are caused are solved; and in addition, long nozzle argon blowing prevents scaffolding blockage of the long nozzle to a certain extent, meanwhile, gravitational potential energyof the molten steel in the swirling chamber is converted into rotational kinetic energy, the inclusions are promoted to collide, grow up and float upwards before being removed, and accordingly, the cleanliness of the molten steel is improved.

Owner:NORTHEASTERN UNIV

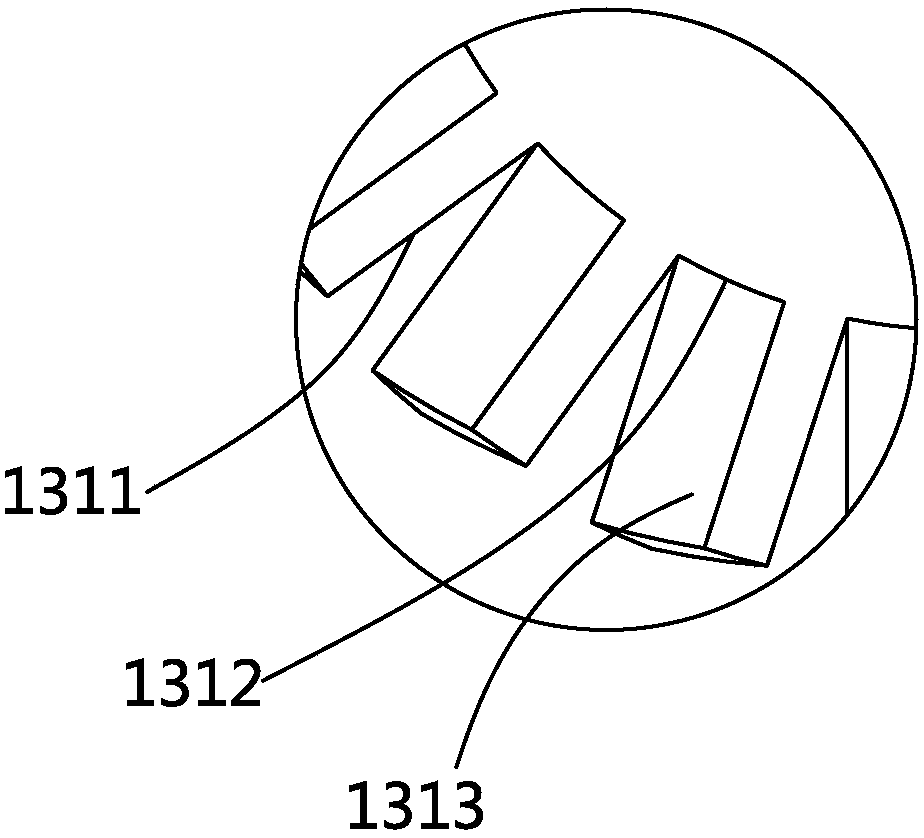

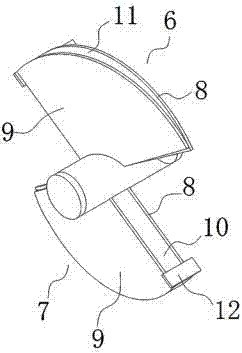

Cutting tool of blender

ActiveCN105167658AIncreasing the thicknessHigh impact strengthRotary stirring mixersTransportation and packagingEngineeringUltimate tensile strength

The invention relates to a cutting tool of a blender. The cutting tool comprises a blade, a tool holder and a connecting shaft. The blade is fixed onto the tool holder through the connecting shaft and comprises at least two auxiliary blades, each auxiliary blade comprises a flat blade body, and the auxiliary blades are in attached connection in a pairwise vertically coincided manner. The cutting tool of the blender has the advantages of ingenious structure, high stirring strength, low noise and high balance degree.

Owner:HUIYANG ALLAN PLASTIC & ELECTRIC INDS

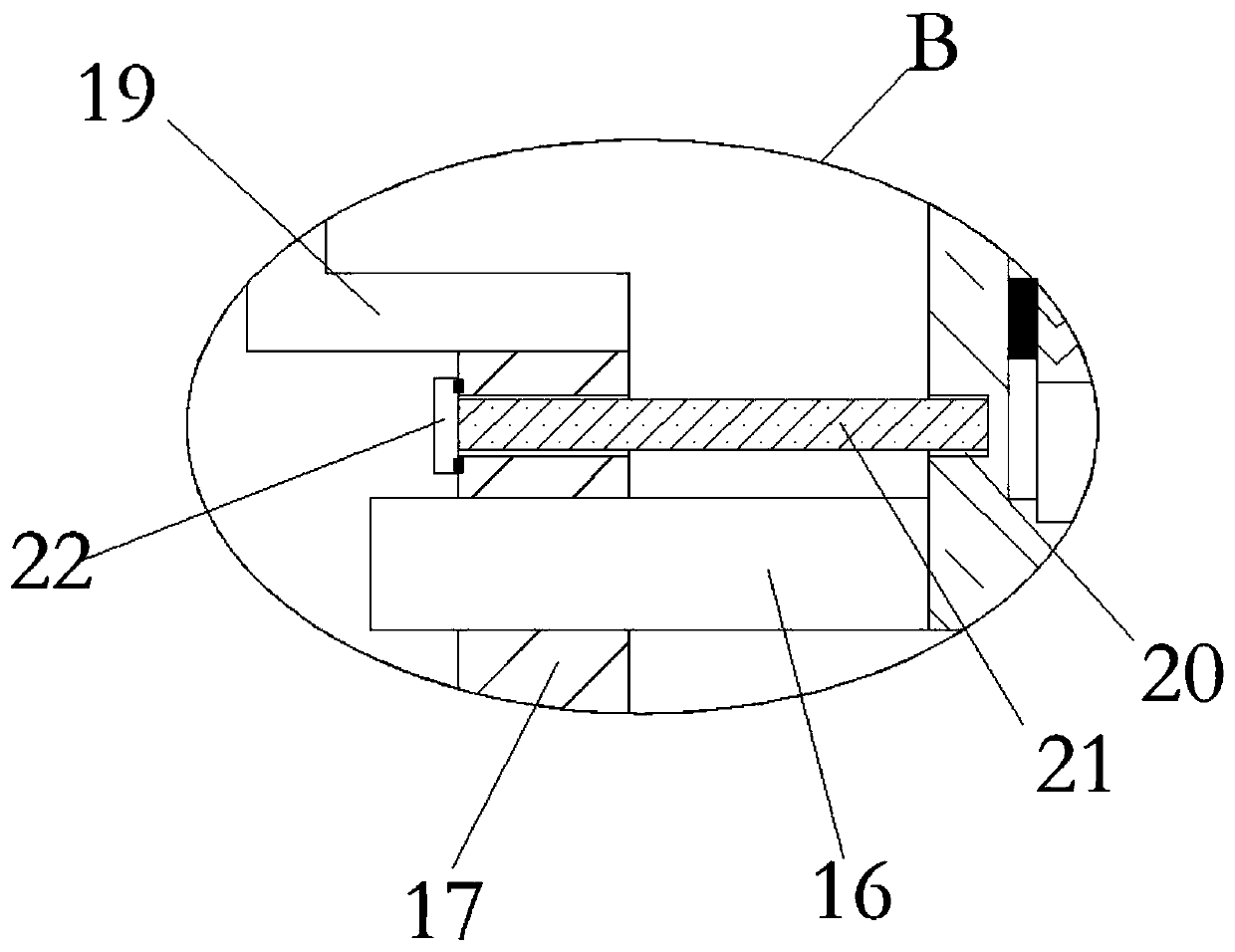

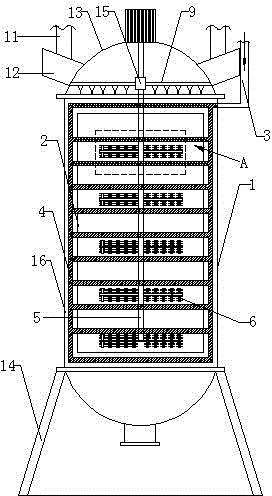

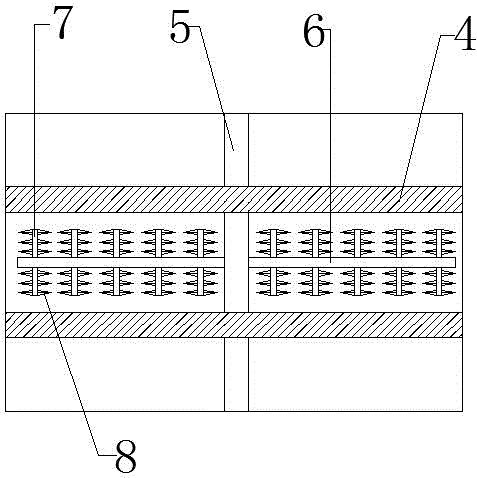

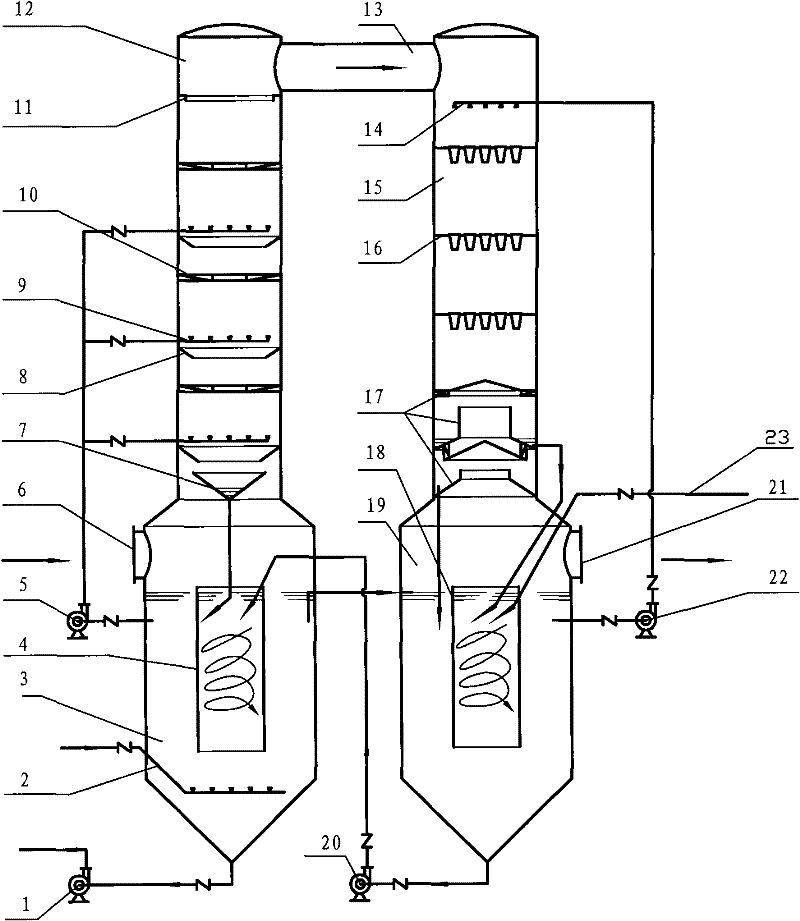

Twin exhaust gas purifying tower

The invention discloses a twin exhaust gas purifying tower, which comprises towers I and II and tower circulating pools I and II, wherein the towers I and II are paratactic and serially connected with each other; the circulating pools of the tower I and II are corresponding to the lower parts of the towers I and II; a liquid gathering hopper, a liquid-guiding ring, a nozzle, a spiral flow plate and a top liquid baffle ring are arranged in the tower I from bottom to top; an exhaust gas inlet and an air oxidation device are arranged on the tower I circulating pool; a tower II liquid distributing pipe, a conical cup atomizing layer and a multi-ring whirlwind demister are arranged on the tower II from top to bottom; a clean gas outlet is arranged on the tower II; spacing rings are arranged onthe circulating pools on the lower parts of the towers I and II; circulating pumps are arranged in the circulating pools of the tower I and II; lifting pumps and dewatering pumps are arranged at bottoms of the towers I and II; and a medium conveying pipe is arranged on the upper part of the tower II. By using the twin exhaust gas purifying tower, a gas / liquid mass transfer area is increased, a gas / liquid contact area is updated by repeatedly cutting, the purifying efficiency is high, the consumption of circulating kinetic energy is reduced, the flow speed of idle tower is increased, the reaction of absorbing medium is more complete, the utilization ratio is higher, solid content in cleaning solution in the towers is reduced, the abrasions of the circulating pumps and the nozzle are reduced, the service life is prolonged, and the maintenance is more convenient. The twin exhaust gas purifying tower is mainly used for cleaning, absorbing and purifying the exhaust gas.

Owner:永兴县皓天环保科技发展有限责任公司

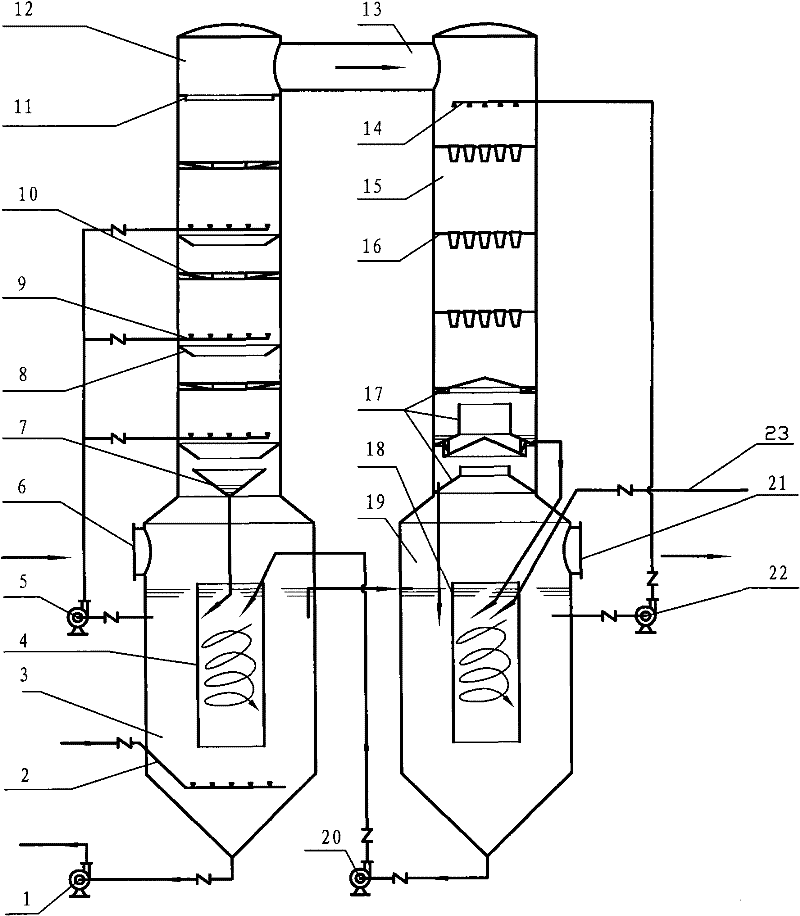

Household eggbeater with function of automatic cleaning

The invention discloses a household eggbeater with a function of automatic cleaning. The household eggbeater comprises an eggbeater body, the top of the eggbeater body is welded to an eggbeater head,the left side of the machine head is provided with a cooling fan, a gear-change lever is arranged on the right side of a first switch, a rotary shaft is installed on the lower portion of the right side of the machine head, and the bottom of a second connection head is welded to a fixing base. Protrusion blocks are welded to the bottoms of stirring rods, installation bases are fixedly arranged in the middles of the front surface and the rear surface of the machine body through bolts respectively, clamps are clamped to the right sides of springs, a base is welded to the bottom of the machine body, and a stirring barrel is arranged on the outer side bellow the stirring rods. The twelve stirring rods of the household eggbeater with the function of automatic cleaning are each set to be of an arc-shaped structure, the stirring rods and the protrusion blocks are all made of silica gel, the silica gel is soft so that the inner wall of the stirring barrel cannot be scratched, the protrusion blocks are each set to be of a cuboid structure with an arc-shaped corner, the stressed area is increased, the stirring strength is increased, and the stirring efficiency is improved.

Owner:赵春萍

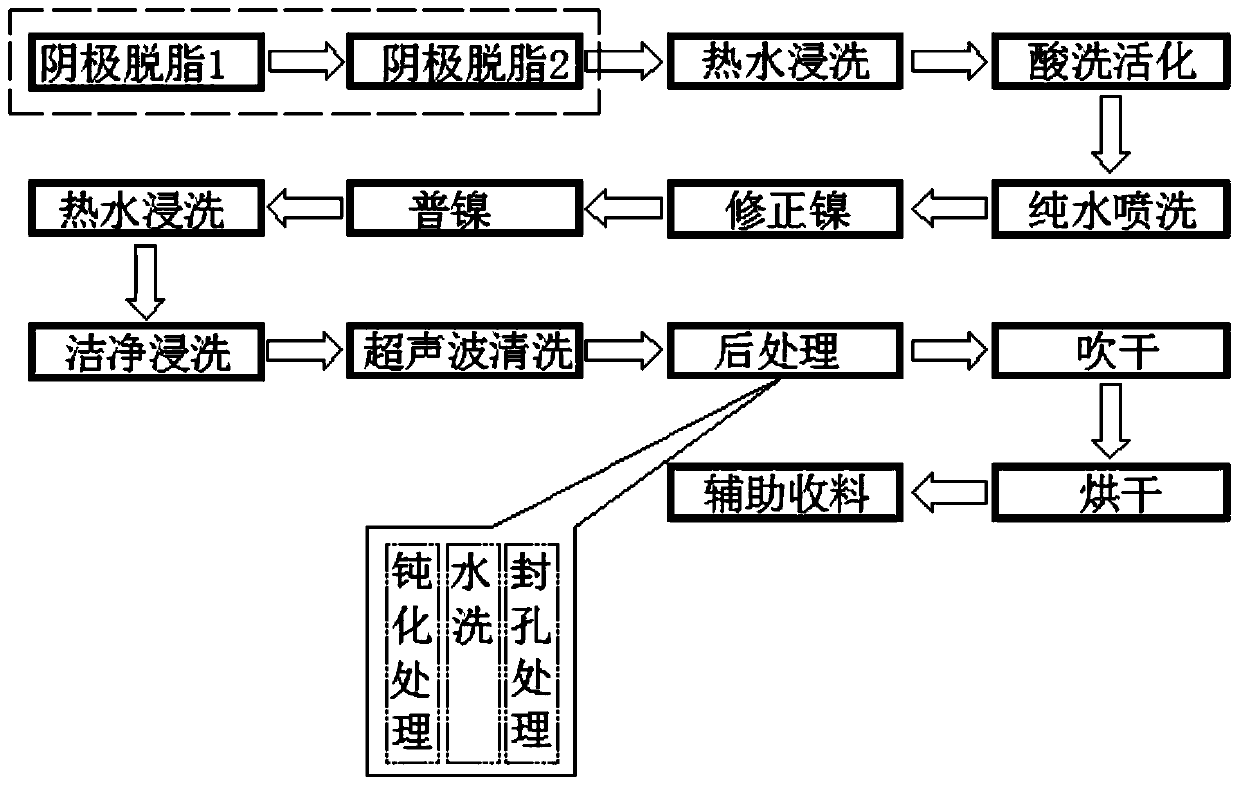

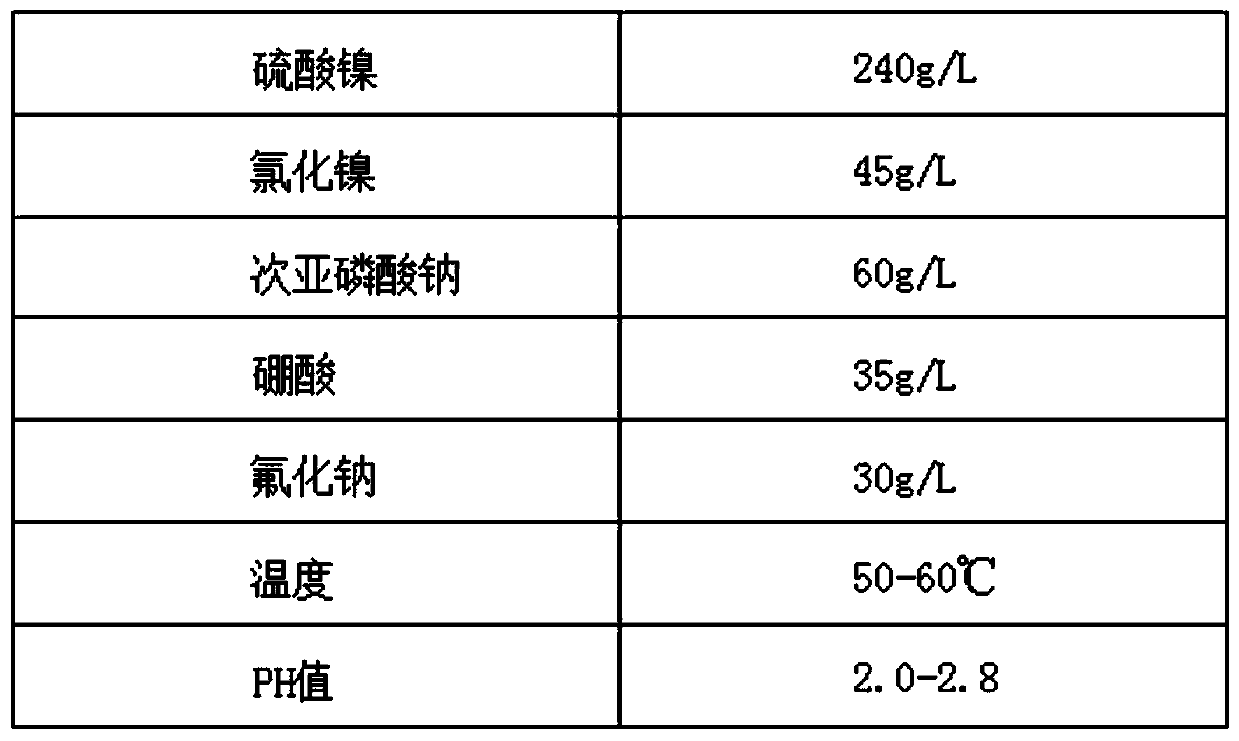

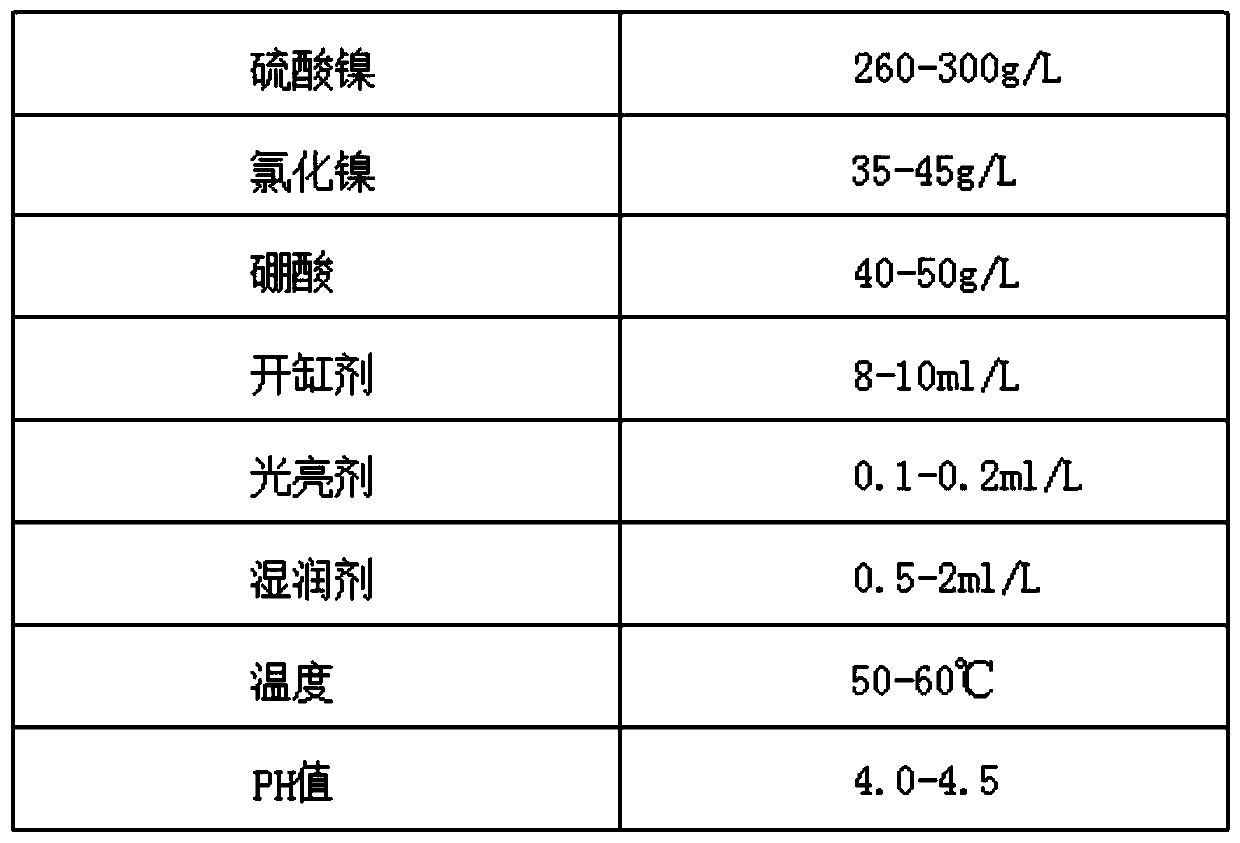

Copper alloy electroplating technology

ActiveCN109957822AImprove appearance cohesionReduce porosityMetallic material coating processesPorosityWater immersion

The invention discloses a copper alloy electroplating technology, and belongs to the technical field of electroplating. The copper alloy electroplating technology comprises the following steps of: step one. degreasing; step two. carrying out hot water immersion; step three. carrying out pickling activation; step four. carrying out spray rinsing by using pure water; step five. correcting nickel; step six. common nickel; step seven. carrying out hot water immersion; step eight. carrying out cleaning immersion; step nine. carrying out ultrasonic cleaning; step ten. carrying out post-processing; step eleven. drying; step twelve. drying; and step thirteen. carrying out auxiliary receiving. By extending and optimizing the pre-treatment process line, the copper alloy electroplating technology canprovide an electroplating plane of follow-up coating deposition and increases the appearance binding force of a coating. Crystal lattices of the nickel coating are significantly improved by using thecorrecting nickel for priming in the electroplating process, so that the structure is tight, the crystal lattices are refined, the porosity of the coating is reduced, thus, the uniformity and glossiness of the common nickel layer appearance are ensured; and a perfect cleaning process is developed and led to cooperate with passivation treatment and hole sealing treatment, so that the corrosion resistance of the coating is greatly enhanced.

Owner:东莞市康圣精密合金材料有限公司

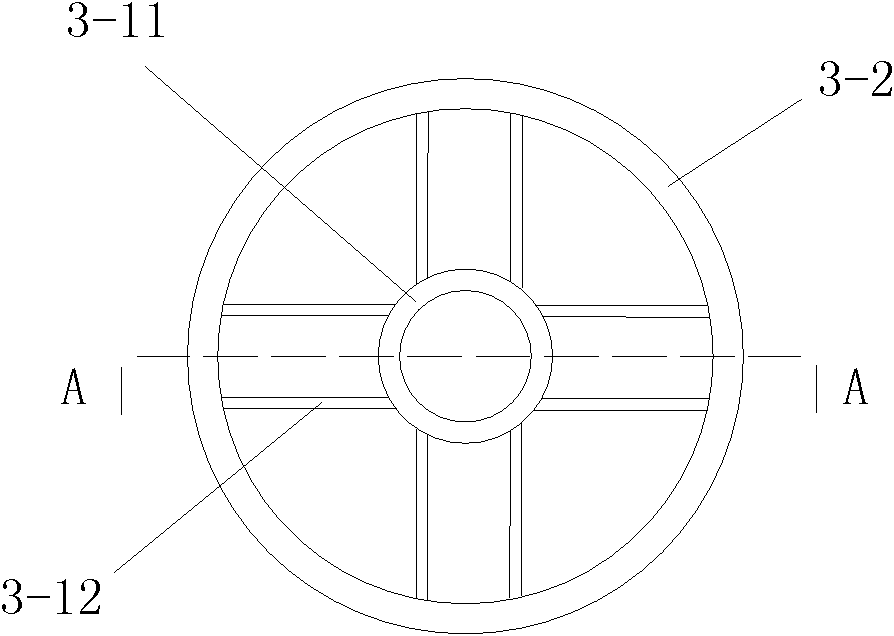

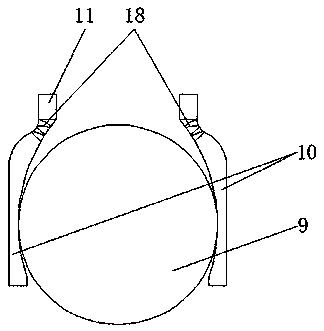

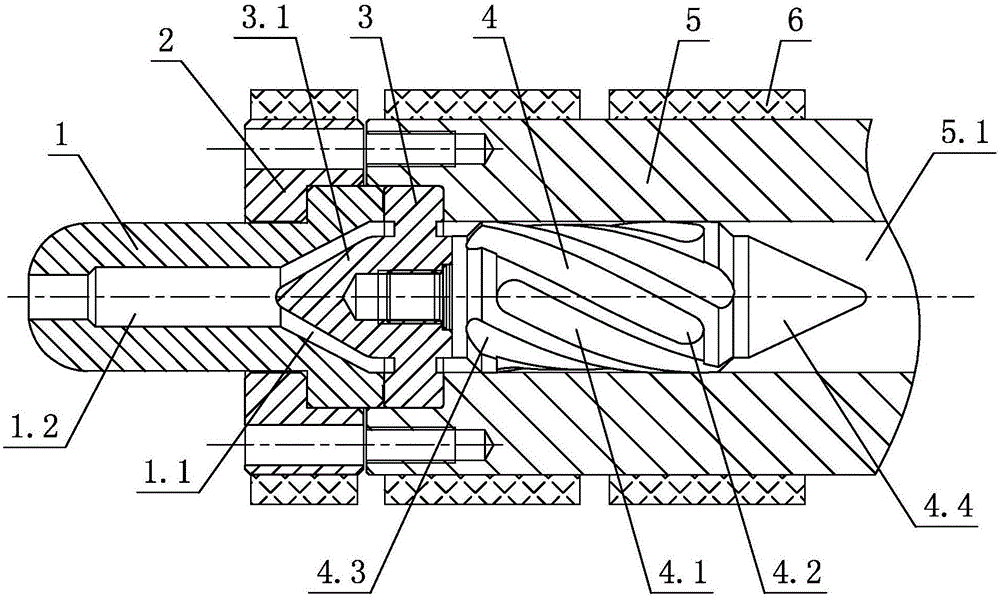

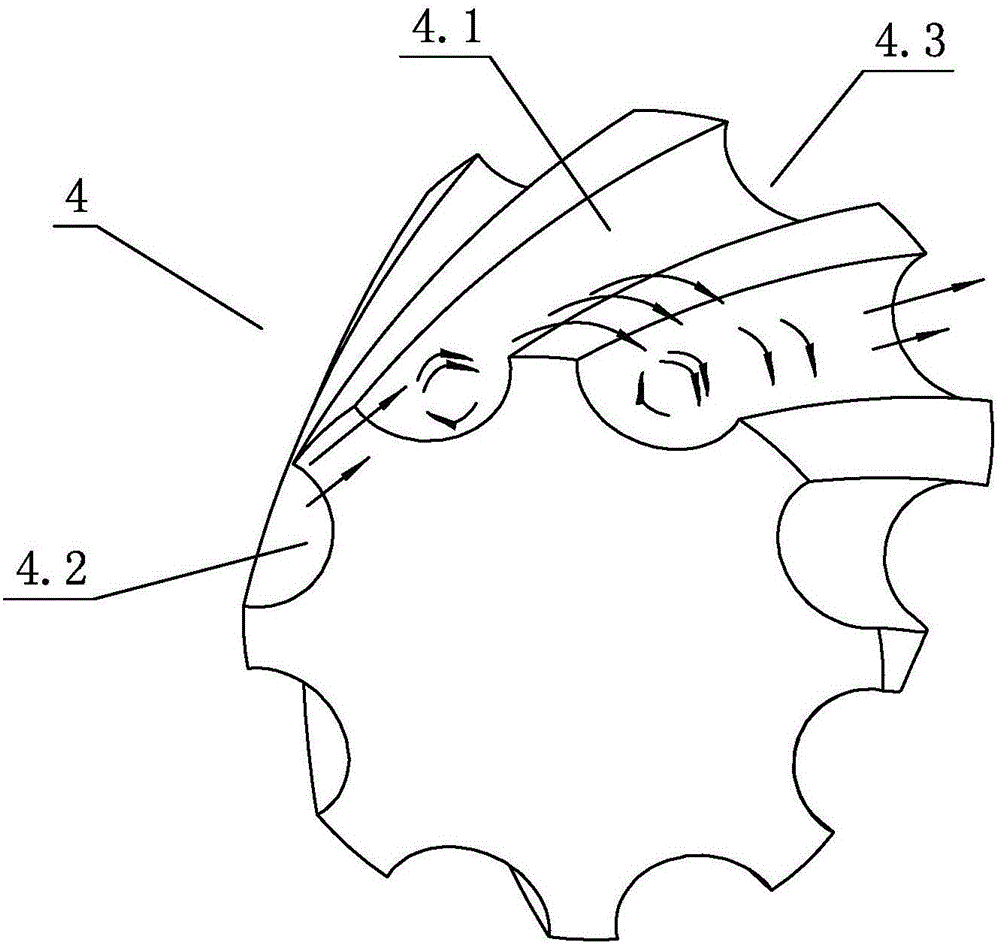

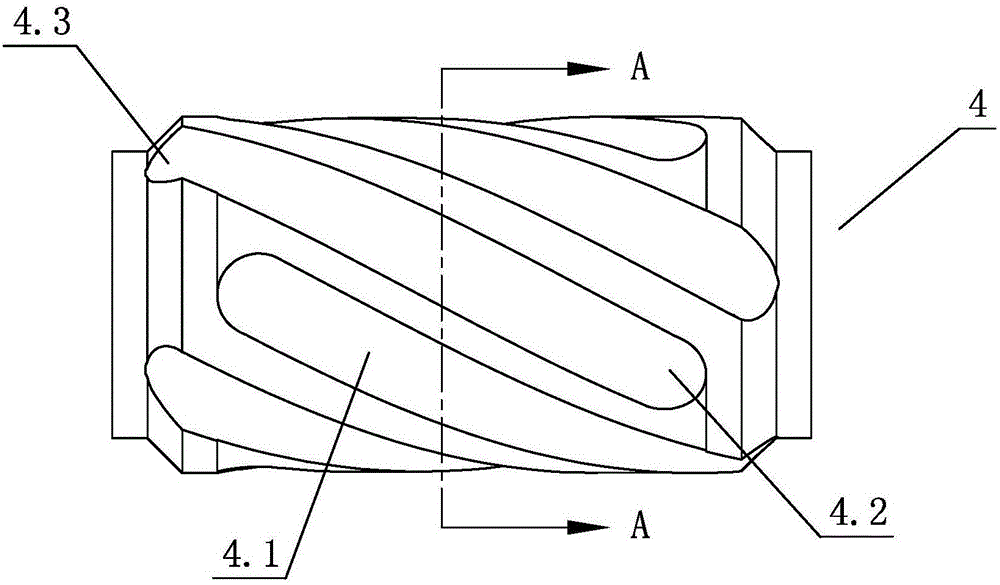

Static barrier mixing device for semi-solid-state alloy pulp-making

The invention discloses a static barrier mixing device for semi-solid-state alloy pulp-making. The static barrier mixing device comprises a barrier mixing head, a flow concentrating comb plate, a material barrel, a spray nozzle, a spray nozzle flange and a heater, wherein the barrier mixing head is statically arranged in a cavity; and a plurality of inclined slots are spirally formed in the outer wall of the barrier mixing head. Through the improvement on the structure, the plurality of inclined slots are spirally formed in the outer wall of the screen mixing head, metal melt is pushed to the barrier mixing head by utilizing pressure, and crystal nucleus of the metal melt is refined through the shearing action of the barrier mixing head and the material barrel, so that the semi-solid-state pulp preparation requirements are met. The static barrier mixing device has the characteristics of being simple and reasonable in structure, excellent in performance, quick to assemble, convenient to operate, low in manufacturing cost, easy to produce and realize, safe and reliable, and the like, and is high in practicability.

Owner:GUANGDONG YIZUMI PRECISION MACHINERY

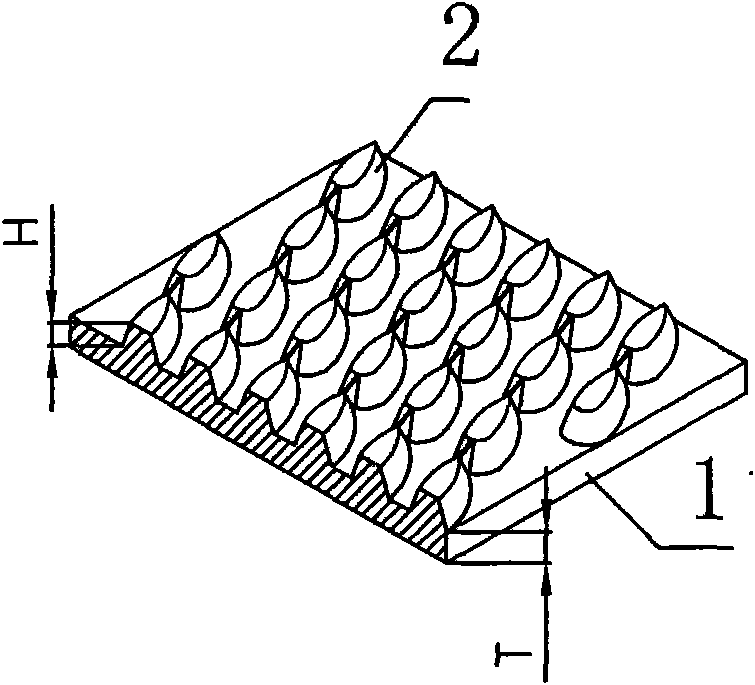

Welding metal heat exchange tube with outer surface provided with externally convex independent fins

InactiveCN101581554AStrong stirringImprove heat transfer performanceArc welding apparatusTubular elementsEngineeringDrop-shaped

The invention discloses a welding metal heat exchange tube with an outer surface provided with externally convex independent fins. The metal heat exchange tube of the shape and the structure can greatly increase the heat transfer and exchange area, reduce fluid resistance, and achieve the aim of efficiently exchanging heat. The welding metal heat exchange tube with the outer surface provided with the externally convex independent fins is distinguishably and technically characterized in that the outer surface of a metal tube body is fully distributed with groups of externally convex independent drop-shaped fins which are arranged along the longitudinal direction, and the heat exchange tube has an integrated molding and welding structure. The welding metal heat exchange tube can be widely applied to the heat transfer and exchange of industrial production.

Owner:杨元恒

Environment-friendly dry mortar mixer

ActiveCN104085047AReasonable structurePromote environmental protectionCement mixing apparatusLiquid ingredients supply apparatusAgricultural engineeringButterfly valve

The invention discloses an environment-friendly dry mortar mixer. A cover cap is installed on a shell, a feed opening is formed in the cover cap, a mixing shaft, which is driven by a driving mechanism, is arranged in the shell, two inner helical belts and one outer helical belt are installed on the mixing shaft, the height of the outer helical belt is greater than that of each inner helical belt, and the lowest end of the outer helical belt is positioned in a bottom area of the shell during operation; the inner helical belts are left helical belts, and the outer helical belt is a right helical belt; the inner helical belts and the outer helical belt are fixed on a mixing arm, and one end of the mixing arm is connected with the mixing shaft; a discharge door is arranged at the bottom of the shell. The environment-friendly dry mortar mixer has the advantages of reasonable structure and good environmental friendliness. Dry mortar enters a mixing tank from a flow tank through a butterfly valve to be matured and then is discharged by the discharge door, and the whole process is completed in a closed state without raising dust basically.

Owner:南通市方大机械厂

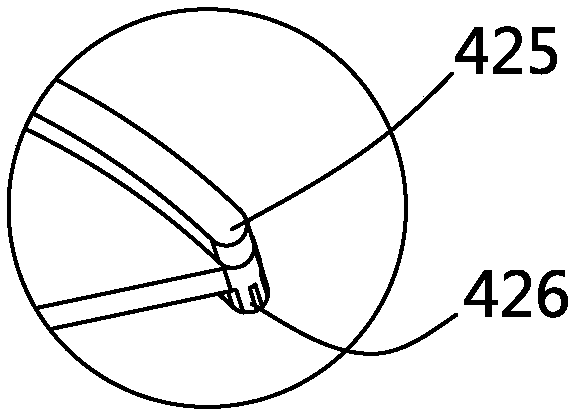

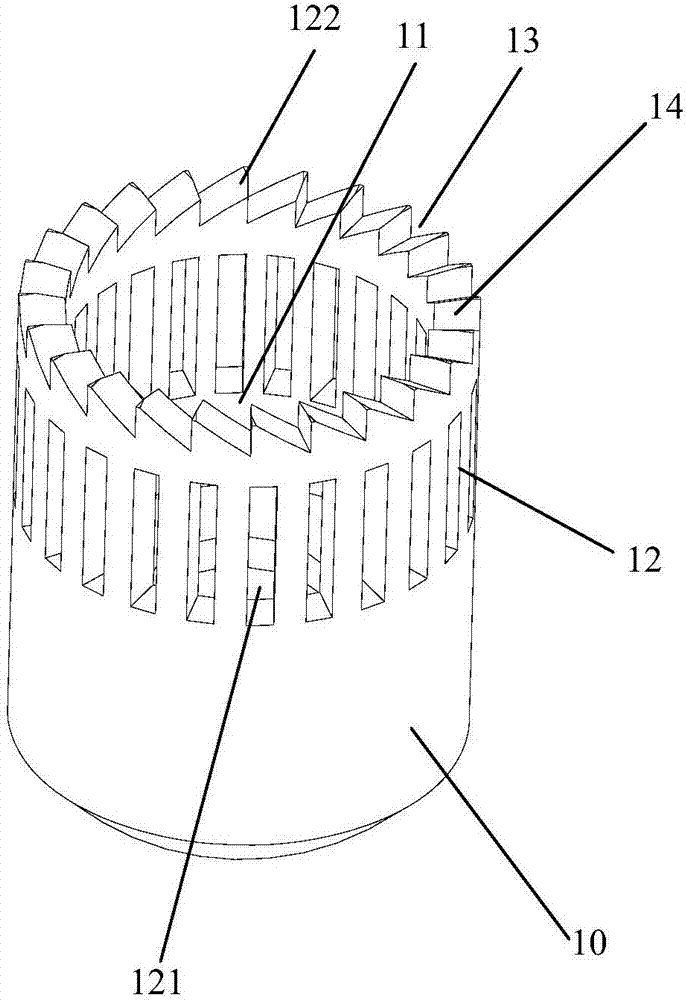

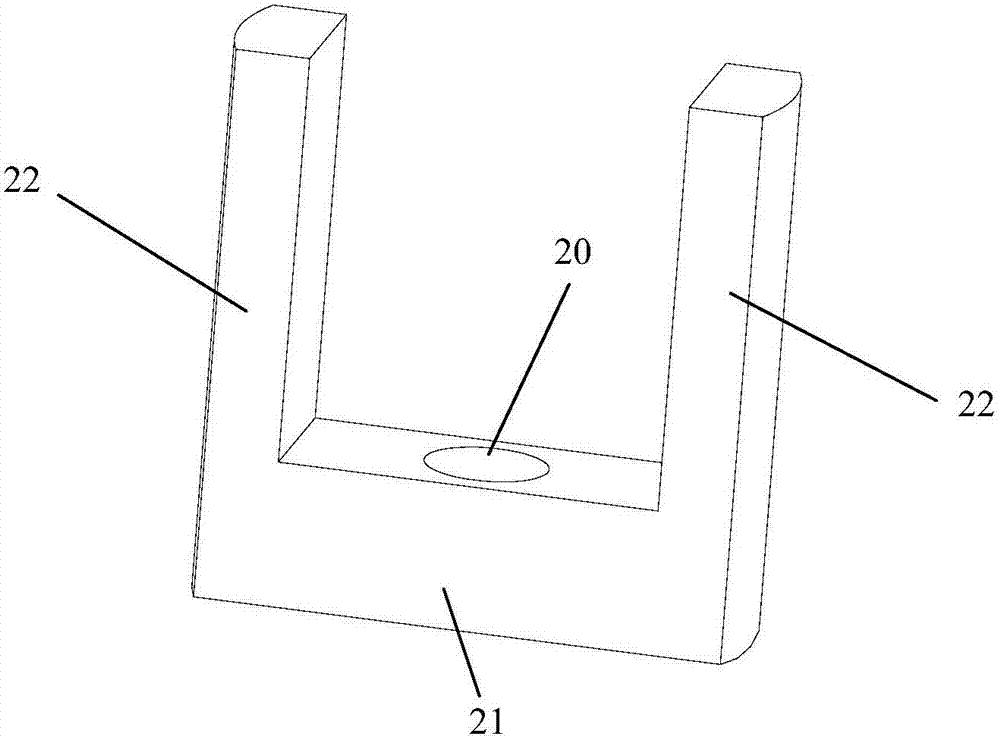

Animal and plant tissue homogenate dispersion machine and working head thereof

PendingCN107441975AQuick breakFast homogenizationRotary stirring mixersTransportation and packagingPlant tissueEmulsion

The invention discloses an animal and plant tissue homogenate dispersion machine and a working head thereof, and is applicable for animal and plant tissue homogenization and dispersion and preparation of a suspending agent and an emulsion. The working head of the animal and plant tissue homogenate dispersion machine comprises a rotor and a stator, wherein the rotor comprises a cross arm and stirring arms extending at two ends of the cross arm in parallel; the stator comprises a base part and a plurality of sawteeth annularly distributed from one side of the base part, the sawteeth are provided with inclined surfaces on two sides in circumferential direction, the sawteeth form a stator cavity, the rotor is arranged inside the stator cavity, and the stirring arms are positioned on the inner sides of the sawteeth.

Owner:SHANGHAI FLUKO TECH DEV

Facial cleanser foaming device

The invention discloses a facial cleanser foaming device. The device comprises a linkage chamber, a foaming chamber, a first storage chamber and a second storage chamber, and a second rotating motor is mounted on one side of the top in the linkage chamber; a driving shaft is arranged at the bottom end of an output shaft of the second rotating motor; a second gear is arranged in the middle of the driving shaft; a first gear is arranged on the side surface of the second gear; a driven shaft penetrates through the center of the first gear, stirring blades are arranged at the bottom end of the driving shaft and the bottom end of the driven shaft, a foaming chamber is arranged at the bottom of the linkage chamber, a first storage chamber is arranged on the side face of the linkage chamber, an equipment chamber is arranged at the top of the linkage chamber, and a first rotating motor is installed on one side of the interior of the equipment chamber. By means of powerful stirring, the foamingspeed of the facial cleanser is higher, foam is finer, smoother and denser, the cleaning effect is good, manual rubbing and foaming are not needed, and time and labor are saved; and the amount of thefacial cleanser and the amount of water can be accurately controlled, and the problems of excessive use amount, waste or insufficient use amount and poor cleaning effect are avoided.

Owner:上海梵木苒贸易有限公司

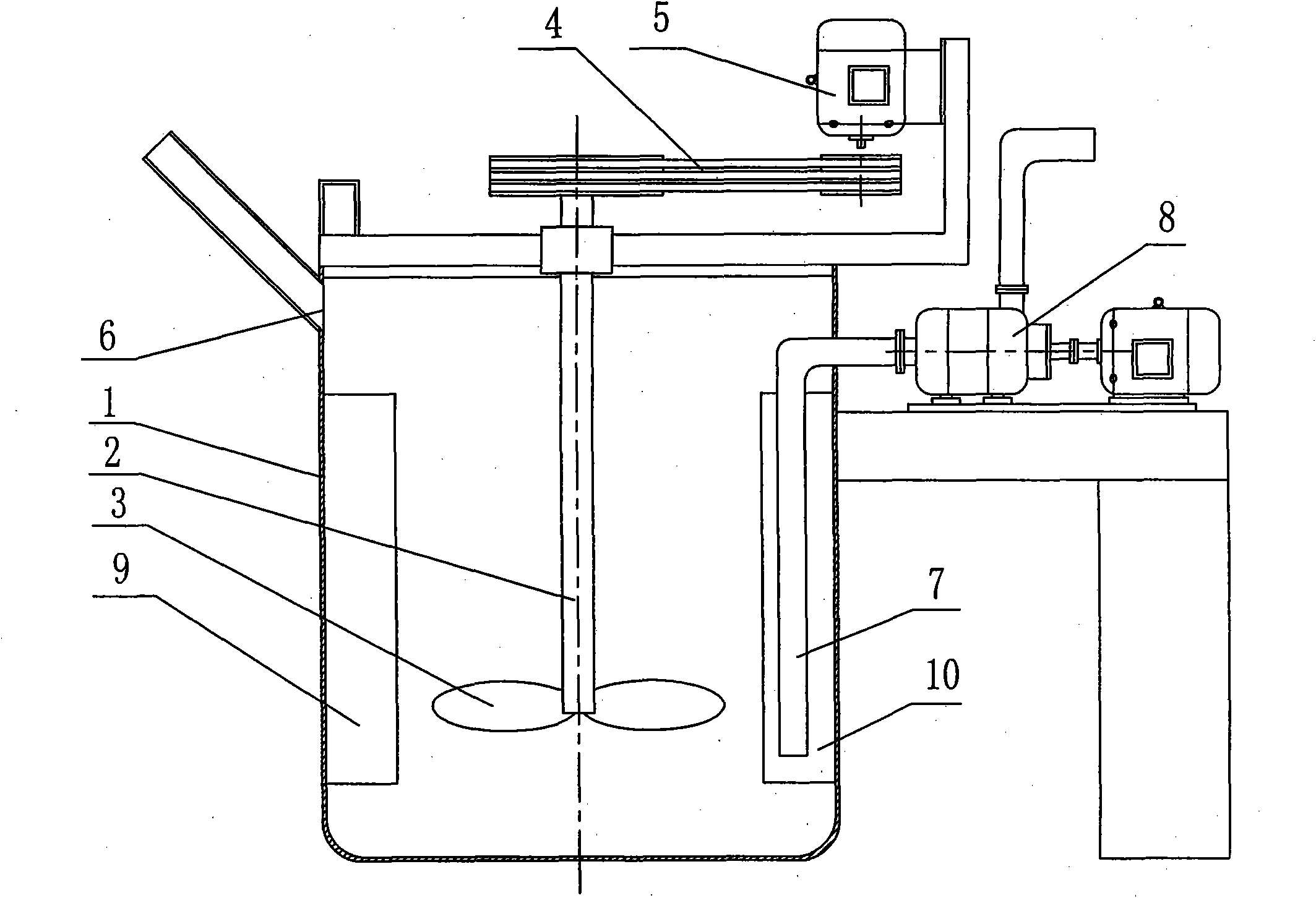

Mixing agitator for materials

InactiveCN101934206AEvenly dispersedReduce energy consumptionTransportation and packagingMixing methodsSlurryEngineering

The invention discloses a mixing agitator for materials and relates to the technical field of material mixers. A blade is connected at the lower end of an agitating shaft in a barrel; the agitating shaft is connected with a motor arranged outside the barrel body through a transmission speed-reducing mechanism; a feed port is formed at the upper end of the barrel body; a suction tube is arranged inside the barrel body; the upper end of the suction tube is connected with an inlet end of a water pump arranged outside the barrel body; two vertical guide plates are symmetrically and fixedly connected to an inner wall of the barrel body; the lower ends of the vertical guide plates are positioned below the horizontal plane of the blade; and an inlet end of the suction tube is arranged between the lower ends of the vertical guide plates and the horizontal plane of the blade. Slurry can generate omega-shaped and circumferential convective motion in the barrel body, fluid circumferentially shears convective circulation up and down, and the slurry is uniformly dispersed. The mixing agitator for materials has the characteristics of low energy consumption, uniform dispersion, strong agitation, long service life of an agitating wheel, no solid-phase settlement and the like, capacity of improving mixing uniformity of scale removing sand and water, and contribution to scale removal for steel pipes.

Owner:江苏诚德钢管股份有限公司

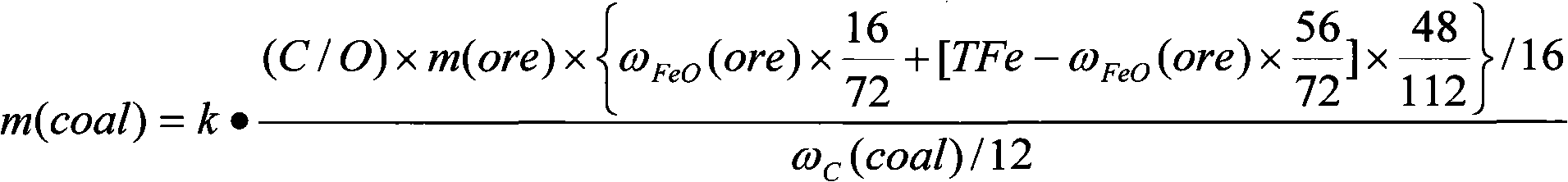

Internal stirring structure of sludge hydrolysis tank

PendingCN107056004AAchieve circular flowGuaranteed temperatureTransportation and packagingRotary stirring mixersPulp and paper industryHydrolysis

The invention discloses an internal stirring structure of a sludge hydrolysis tank. The internal stirring structure of the sludge hydrolysis tank comprises two main stirring shafts and a spiral stirring and discharging shaft, wherein the two main stirring shafts are arranged in the middle of a vertical direction of the hydrolysis tank side by side; a plurality of groups of stirring blades is arranged on each main stirring shaft; the spiral stirring and discharging shaft is arranged at the bottom of the hydrolysis tank; auger blades are arranged on the spiral stirring and discharging shaft, and the stirring direction of the auger blades is opposite to that of the stirring blades; the two main stirring shafts and the spiral stirring and discharging shaft are all hollow shafts; the stirring blades and the auger blades are all hollow blades, and the main stirring shaft is communicated with the stirring blades; the spiral stirring and discharging shaft is communicated with the auger blades. The internal stirring structure of the sludge hydrolysis tank has the beneficial effects of good stirring effect, sludge circulation flow and good sludge fluidity.

Owner:SICHUAN GAOBO ENVIRONMENTAL PROTECTION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com