Cutting tool of blender

A technology for mixers and knives, applied in the field of mixer knives, can solve the problems of blade fracture, mixer knives wear, affecting mixing work, etc., and achieve the effects of increasing mixing intensity, increasing overall thickness, and improving material effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

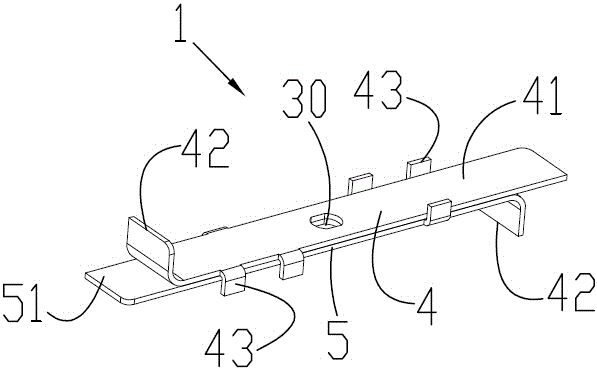

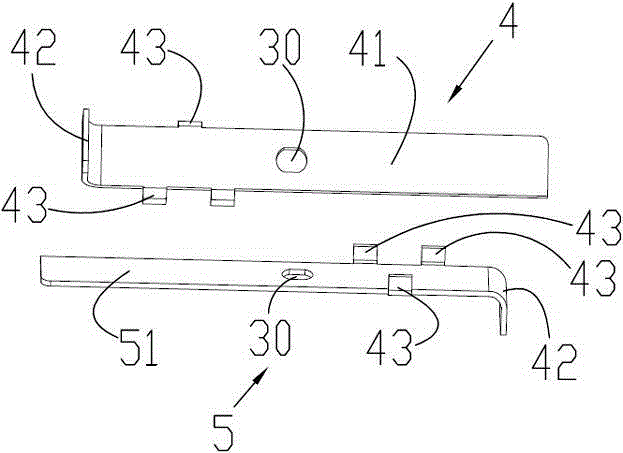

[0033] Such as Figure 1 to Figure 3 As shown, the blade 1 of the blender knife includes two sub-blades, namely a first sub-blade 4 and a second sub-blade 5 . The first sub-blade 4 includes a first cutter body 41 . The second sub-blade includes a second cutter body 51 . Both the first cutter body 41 and the second cutter body 51 are flat. Furthermore, both the first blade body 41 and the second blade body 51 are formed in a straight shape. Because the cutter bodies of the first sub-blade 4 and the second sub-blade 5 are flat, that is, the two cutter bodies are parallel to each other, and the two cutter bodies are parallel to the horizontal plane, there is no included angle, so the mixer cutter is in the working process It can effectively ensure the balance of the blade. Even if a hard object is stirred, the mixer knife is not easy to lose balance, so that the noise generated by the mixer knife during work can be effectively reduced.

[0034] The material is stirred and pu...

Embodiment 2

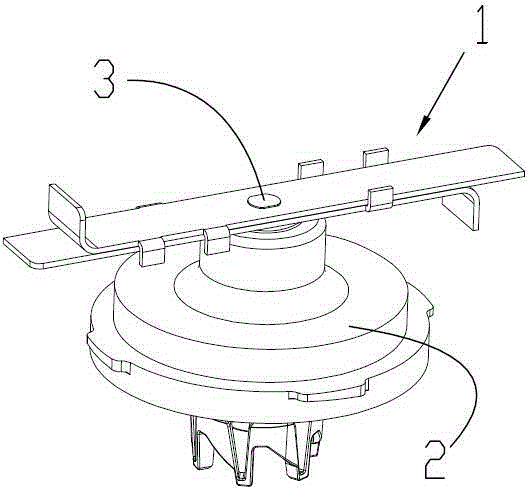

[0041] Such as Figure 4 As shown, the structure of the blender cutter in this embodiment is basically the same as that in Embodiment 1, the main difference between the two lies in the connection between the first sub-blade 4 and the second sub-blade 5 . In Embodiment 1, the first sub-blade 4 and the second sub-blade 5 are two independent blades respectively, and they are fixedly connected to the tool seat 2 through the connecting shaft 3 in the manner of stacking up and down. However, in Embodiment 2, the first sub-blade 4 and the second sub-blade 5 are integrally formed. The first sub-blade 4 and the second sub-blade 5 can be processed into an integrated blade by using precision casting technology, or sintering technology, or CNC machine tool processing technology, or 3D printing technology. The specific structure of the first sub-blade and the second sub-blade is the same as that of Embodiment 1, and will not be repeated here. Making the first sub-blade 4 and the second s...

Embodiment 3

[0044] Such as Figure 5 As shown, the structure of the blender cutter in this embodiment is basically the same as that in Embodiment 1, and the main difference between the two is that the two sub-blades are provided with blades. In Example 1, neither the first sub-blade nor the second sub-blade is provided with blades, and the material is stirred and pulverized mainly through the collision between the two sub-blades and multiple blades and the material. However, in Embodiment 3, both the first sub-blade 4 and the second sub-blade 5 are provided with cutting edges. In this embodiment, the first sub-blade 4 and the second sub-blade 5 are still centrally symmetrical about the center of the connecting hole, so as to ensure that the mixer blade can effectively maintain a balance during high-speed rotation. Therefore, only the specific structure of the first sub-blade is described here, and the structure of the second sub-blade is not described in detail.

[0045] At least one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com