Internal stirring structure of sludge hydrolysis tank

A hydrolysis tank and internal stirring technology, which is applied in the direction of mixer accessories, pyrolysis treatment sludge, mixer with rotating stirring device, etc., can solve the problems of small sludge flow, low hydrolysis efficiency, no gap, poor fluidity, etc. Achieve the effect of promoting sludge hydrolysis, high hydrolysis efficiency, and strong stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

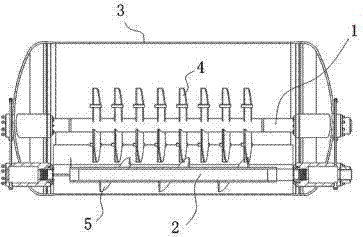

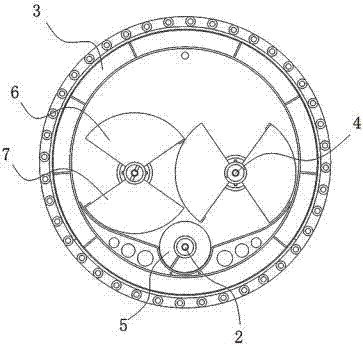

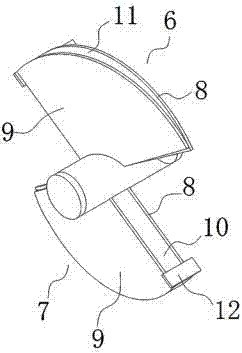

[0019] like Figure 1~Figure 3 As shown, the stirring structure in the sludge hydrolysis tank includes two main stirring shafts 1 and a spiral stirring and discharging shaft 2. The two main stirring shafts 1 and the spiral stirring and discharging shaft 2 are connected to corresponding motors respectively. The root main stirring shaft 1 is arranged in the middle part of the vertical direction of the hydrolysis tank 3, and the two main stirring shafts 1 are arranged side by side. The main stirring shaft 1 is provided with multiple groups of alternating stirring blades 4, and the stirring blades 4 play the role of stirring the sludge. function, so that the cell membrane or cell wall of sludge aggregated organic matter is broken, which is convenient for the anaerobic reaction of anaerobic bacteria, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com