Method for separating amphoteric metal in waste circuit board powder

A technology for waste circuit boards and amphoteric metals, applied in the field of separation of amphoteric metals in waste circuit board powders, can solve the problems of low contact and collision probability, large media consumption, and no relative motion, etc., to increase relative motion and collision, time The effect of shrinking and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for separating amphoteric metals in waste circuit board powder of the present invention comprises the following steps:

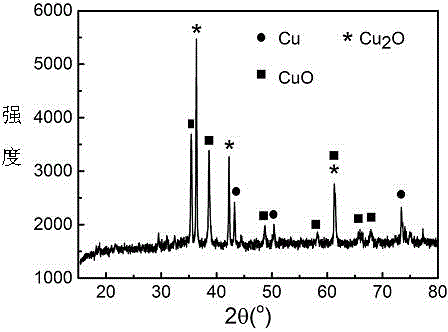

[0031] 1) Mixed-phase alkali fusion: Take 100g of waste circuit board powder and 200g of NaOH and mix them thoroughly, put them into a special crucible and place them in a well-type furnace, and blow oxygen into the crucible through 3 ventilators at the same time (the flow rate is 1L / min), the well-type furnace was heated to 450°C for constant temperature smelting for 60 minutes to obtain smelted products.

[0032] 2) Rapid cooling and leaching:

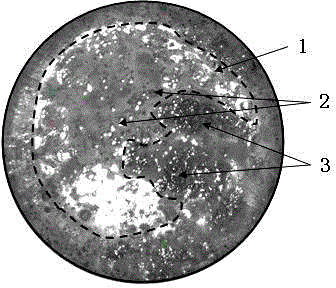

[0033] After the crucible is taken out of the pit furnace, it is quenched in cold water, and then the smelted product is taken out (photo as figure 1 As shown, melt 1, bubble 2 and solid slag 3 can be seen from the figure; melt 1 is amphoteric metal sodium salt and alkali medium; bubble 2 is wrapped in melt 1; solid slag 3 and melt 1), Crush until the particle size is 0.1~5mm; then add water accord...

Embodiment 2

[0038] A method for separating amphoteric metals in waste circuit board powder of the present invention comprises the following steps:

[0039] 1) Mixed-phase alkali fusion: take waste circuit board powder 100g, NaOH 250g, NaNO 3 After 20g is fully mixed, put it into a special crucible and place it in a well-type furnace. At the same time, air is blown into the crucible through 3 ventilation pipes (the flow rate is 2L / min), and the temperature of the well-type furnace is raised to 550°C for 40 minutes of constant temperature melting. , to obtain the smelted product.

[0040] 2) Rapid cooling and leaching:

[0041] Take the crucible out of the pit furnace, place it in cold water for rapid cooling, then take out the smelted product and crush it to a particle size of 0.1~5mm; then add water according to the liquid-solid mass ratio of water: smelted product of 30:1, stir and dissolve at room temperature Leach for 40min, filter to obtain washing residue and alkaline washing solut...

Embodiment 3

[0045] A method for separating amphoteric metals in waste circuit board powder of the present invention comprises the following steps:

[0046] 1) Miscible alkali fusion: Take 100g of waste circuit board powder, Na 2 CO 3 450g, NaNO 3 After 50g is fully mixed, put it into a special crucible and place it in a well-type furnace. At the same time, air is blown into the crucible through 3 ventilation pipes (the flow rate is 1L / min), and the temperature of the well-type furnace is raised to 800°C for 30 minutes of constant temperature melting. , to obtain the smelted product.

[0047] 2) Rapid cooling and leaching:

[0048] Take the crucible out of the well-type furnace, place it in cold water for rapid cooling, then take out the smelted product, and crush it to a particle size of 0.1~5mm; then add water according to the liquid-solid mass ratio of water: smelted product of 40:1, stir and dissolve at room temperature Leach out for 60 minutes, filter to obtain washing residue and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com