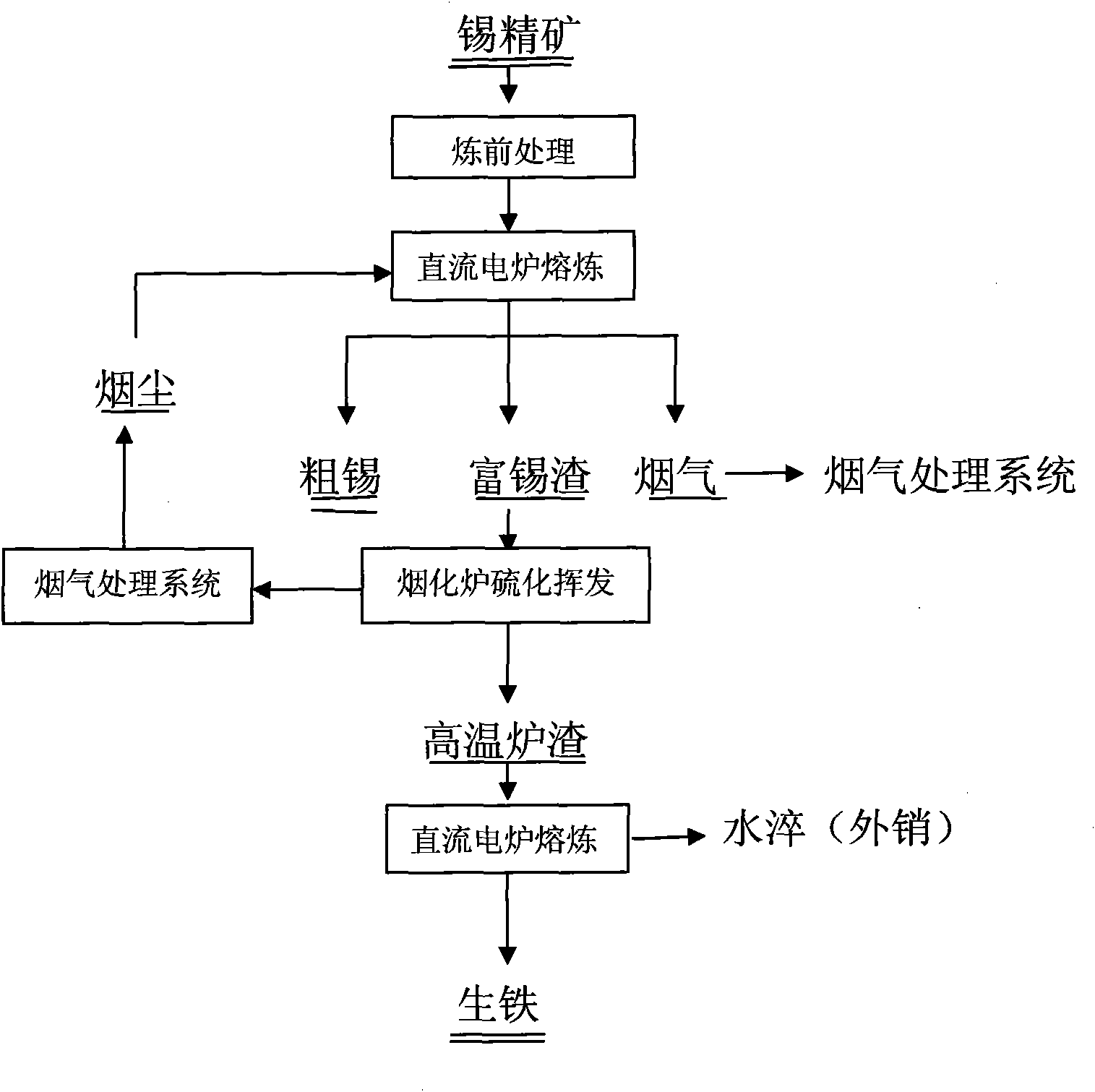

DC electric furnace-fuming furnace combined tin-smelting method

A technology of fuming furnace and electric furnace, which is applied in the field of tin smelting technology, can solve the problems of low production capacity and inability to process high-iron tin concentrate, and achieve the effects of low iron content, simple flue gas treatment facilities, and excellent technical and economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the steps are as follows:

[0019] A. The chemical composition of the tin concentrate used is as follows:

[0020] the element

sn

Fe

al 2 o 3

SiO 2

CaO

Content%

41

17

4

8

1

[0021] B. Use a 600KVA DC electric furnace for smelting. During the process, add diced coke accounting for 12% of the material weight and a particle size of 20-40mm. Control voltage 150-250V, current 2000-4000A, smelting time 4 hours, and produce crude tin containing Sn 97 %, Fe 0.2%, slag contains Sn 4%, FeO 42%, CaO 2%, SiO 2 22%, Al 2 o 3 6%, the degree of silicic acid is 1.2, the direct recovery rate of tin metal is 93%, and the power consumption is 900 degrees / ton ore.

[0022] C. Use 2m 2 The slag in the fuming furnace treatment step B is sprayed with pulverized coal to control the temperature at 1250°C, and then the theoretical amount of pyrite required for tin vulcanization is added...

Embodiment 2

[0024] Embodiment 2 The steps are as follows:

[0025] The first step is the same as step A of Example 1.

[0026] B. Use a 1250KVA DC electric furnace for smelting, adding 12% of the weight of the material, coke with a particle size of 20-40mm, controlling voltage 150-250V, current 5000-8000A, smelting time 5 hours, and producing crude tin containing Sn 96 %, Fe 0.4%, slag containing Sn 5%, FeO 38%, CaO 2%, SiO 2 28%, Al 2 o 3 6%, the degree of silicic acid is 1.6, the direct recovery rate of tin metal is 94%, and the power consumption is 1000 degrees / ton ore.

[0027] C. Use 2m 2 The slag in the fuming furnace treatment step B is sprayed with coal powder to control the temperature at 1300°C, and then the theoretical amount of pyrite required for tin vulcanization is added. The smelting time is 4 hours, and the output slag contains 0.2% of Sn, 45% of FeO, and 3% of CaO , SiO 2 32%, Al 2 o 3 6%, the volatilization rate of tin metal is 96%.

[0028] D. Use a 1250KVA...

Embodiment 3

[0029] Embodiment 3 steps are as follows:

[0030] A. The chemical composition of the tin concentrate used is as follows:

[0031] the element

sn

Fe

al 2 o 3

SiO 2

CaO

S

As

Content%

41

17

4

8

1

3.5

1.3

[0032] B. Use 2m 2 The fluidized furnace processes the material in step A. During the process, air is blown in, and coal powder accounting for 5% of the weight of the material is added. The temperature is controlled at 800-850°C and the weak oxidation atmosphere. The sulfur and arsenic in the material volatilize and enter the flue gas for recovery and treatment. The removal rates of sulfur and arsenic are 90% and 80% respectively, and the calcined sand produced will enter the next process.

[0033] C, step are identical with step B, C, D in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com