Roller type electromagnetic stirrer for block continuous-casting

An electromagnetic stirrer and slab continuous casting technology, which is applied in the field of metal smelting continuous casting, can solve the problems of high apparent power of the electromagnetic stirrer, limited inner space size, and small cross-section of the permeable core, so as to achieve low energy consumption and high efficiency. Increased efficiency and stirring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

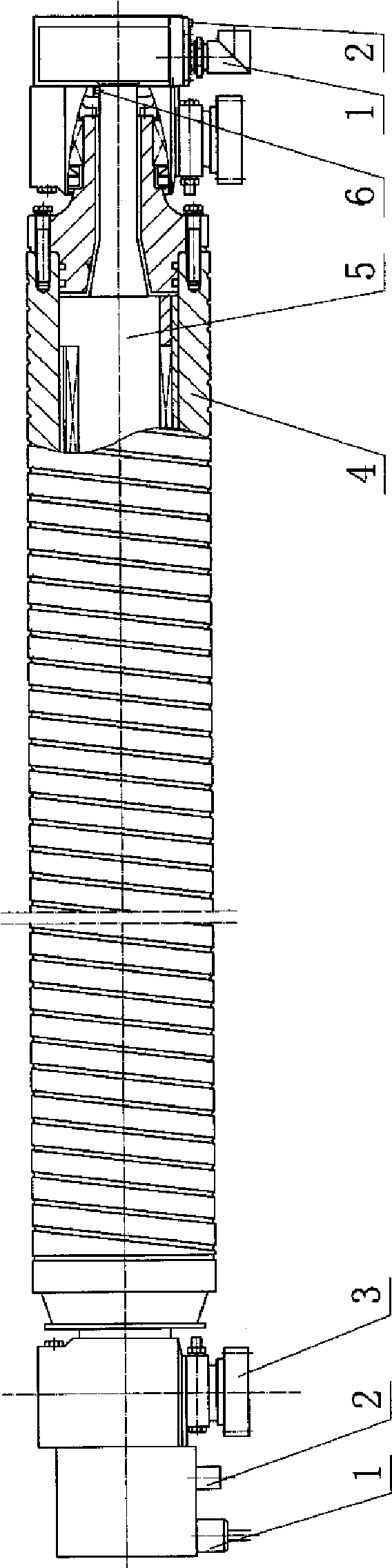

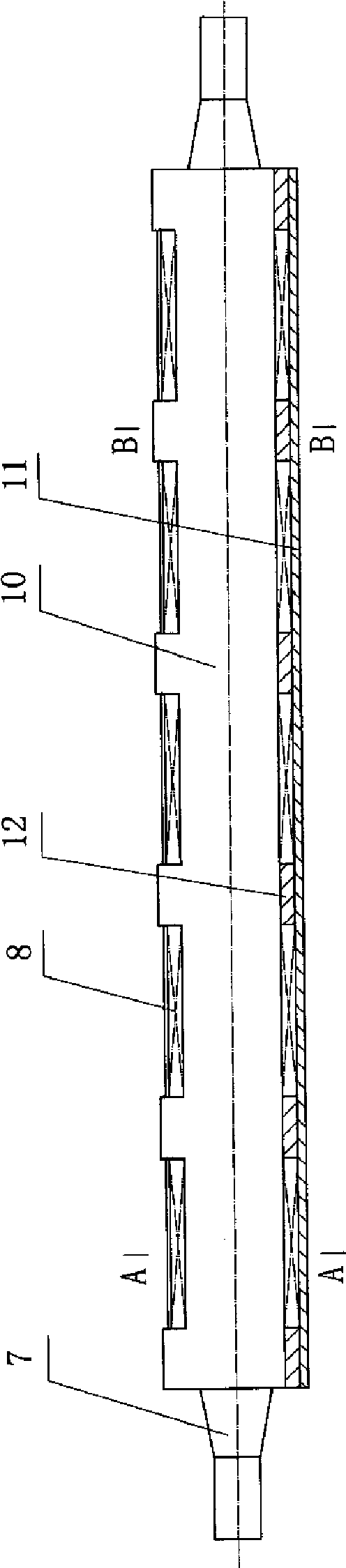

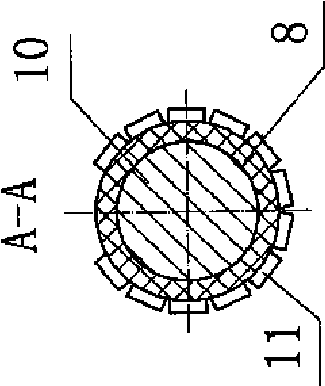

[0019] Depend on Figures 1 to 6 It can be seen that the present invention is composed of parts such as coil winding 8 and iron core 10, including:

[0020] The iron core 10 is set as a toothed cylindrical strip iron core 10, and the toothed part protruding from the cylinder is a magnetic pole 13;

[0021] The coil windings 8 are arranged at intervals between the magnetic poles 13 of the iron core 10;

[0022] The periphery of the iron core 10 and the coil winding 8 is provided with a squirrel cage member made of non-magnetic material; wherein:

[0023] The agitator body 5 composed of the iron core 10, the coil winding 8 and the squirrel cage member is a static structure;

[0024] The agitator body 5 is set in the fully enclosed rotating idler roller 4;

[0025] A cooling water channel for cooling the coil is provided between the agitator body 5 and the rotating idler roller 4 .

[0026] The squirrel cage component of the present invention comprises a C-shaped copper ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com